Professional Documents

Culture Documents

Craig Conecoff Resume 2020

Uploaded by

api-3488320610 ratings0% found this document useful (0 votes)

56 views2 pagesOriginal Title

craig conecoff resume 2020

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

56 views2 pagesCraig Conecoff Resume 2020

Uploaded by

api-348832061Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

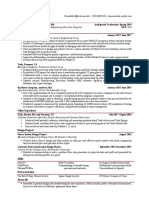

Craig Conecoff

719 Boylston Street Apt. 302, Boston, MA 02116

Craigjlconecoff.weebly.com / cconecjl@gmail.com

(914) 263-9175

❖ PROFESSIONAL EXPERIENCE

Diversified Technologies, Inc. Bedford, MA June 2018-Present

Mechanical Engineer

Managed Project Lifecycle

● Interfaced with customer to learn needs and determine requirements of system to ensure an effective product

● Planned and designed layout of high voltage modulator cabinet using Solidworks while employing high voltage safety

protocols

● Oversaw purchasing and budgeting of project, delegated tasks to optimize efficiency of work, and conducted factory

acceptance testing of system to ensure agreed expectations were met

● Assembled and mounted machined and purchased parts into larger part assemblies and used machining techniques to correct

improperly aligned features

● Oversaw overseas installation of system

● Collaborated with senior electrical engineers to further build out project requirements

● Researched concepts of pulse modulators and their circuit design in conjunction with RF tubes

NASA Jet Propulsion Laboratory Pasadena, CA July-December 2017

Testbed Engineer Co-op

Ensured high fidelity data to cognizant engineers through high attention to detail

● Used Siemens NX to design mechanical ground support equipment to adapt testbed to needs of the engineers

● Wrote command code in Python to control electromechanical components of test setup

● Created specific step by step testing procedures for use by technician operators

● Collaborated with many engineering teams across multiple disciplines to plan and perform 8 test campaigns for Mars 2020

Rover project

Upgraded testbed to meet standards dictated by project goals

● Designed and implemented new measurement systems for higher fidelity data collection and improved usability of testbed

● Updated complicated testbed CAD to reflect changes made on physical model

Keurig Green Mountain Burlington, MA July-December 2016

Research and Innovation Engineer Co-op

Established consistency of beverage testing conditions through creation of unique brewing system

● Created fully operational brewing system from scratch and implemented a LabVIEW program to provide the user with customizable

brewing functionality and an easy to use interface

● Chose electromechanical components such as water and air pumps, valves, and heaters to maximize accuracy and overall system efficiency

based on reverse engineering of current and legacy brewing systems

Conducted testing which produced findings to enable future business growth

● Won project presentation award for Largest Business Impact Amongst Peers

● Performed coffee extraction testing, providing numerical backing to proposed theories, resulting in a new direction for future

brewer design and technology

Johnson & Johnson Raynham, MA June-December 2015

Manufacturing Support Co-op

Identified and worked to eliminate issues with production efficiency

● Eliminated process inefficiencies with a projected cost savings of $30,000

● Gathered data by interviewing manufacturing floor staff in order to identify opportunities for process reengineering

● Filmed and documented processes and created time and cost analyses

❖ EDUCATION

Northeastern University Boston, MA May 2018

Bachelor of Science in Mechanical Engineering

GPA: 3.5

❖ PROJECTS

Infant Mouth Simulator Senior Capstone Spring 2018

Design and Integration Lead

● Collaborated with a team of 5 members to research, design, assemble, and test a mouth simulator that mimics the anatomy and physiology

of the infant mouth with cleft palate for the purpose of developing a pacifier to occlude cleft

● Conceptualized and designed simulator components with proper GD&T using SolidWorks for 3D print prototyping

● Speced electromechanical components based on force requirements determined through theoretical calculations

❖ TECHNICAL SKILLS

Applications: Siemens NX, SolidWorks, AutoCAD, Microsoft Office

Programming: LabVIEW, C++, Matlab, TeraTerm, Python

Manufacturing: Lean, Six Sigma, GD&T, 3D printing

Hands on Electrical: Wiring, soldering, crimping

❖ CLUBS & INTERESTS

NU Motorsports (Baja SAE), American Society of Mechanical Engineers (ASME), Alpha Epsilon Pi Fraternity

Listening to music\Fast cars and winding roads\Working with hands, building things\Symphonic, Jazz band\Soccer, basketball, football, golf

You might also like

- LongdoDocument1 pageLongdoapi-605137850No ratings yet

- miriam glickman -resume 2024Document2 pagesmiriam glickman -resume 2024api-483695163No ratings yet

- Resume - S M Abdur RobDocument1 pageResume - S M Abdur RobMuhtadin MushfiqNo ratings yet

- Stacey Rosenfeld Resume 2018Document1 pageStacey Rosenfeld Resume 2018api-333865833No ratings yet

- Straub ResumeDocument1 pageStraub Resumeapi-491772270No ratings yet

- Ian Dauphinais Resume 2019 12Document1 pageIan Dauphinais Resume 2019 12api-474123222No ratings yet

- Leedham Alison ResumeDocument1 pageLeedham Alison Resumeapi-252324780No ratings yet

- Project Coordinator AUG 2023Document3 pagesProject Coordinator AUG 2023ezechukwu tochukwu brightNo ratings yet

- Paul Lawson ResumeDocument1 pagePaul Lawson Resumeapi-338379665No ratings yet

- Engineering Director or Engineering Manager or Principle EngineeDocument4 pagesEngineering Director or Engineering Manager or Principle Engineeapi-78979258No ratings yet

- TC ResumeDocument2 pagesTC ResumeTaylor Lim CooperNo ratings yet

- Resume-M. AsadDocument1 pageResume-M. AsadAsad QureshiNo ratings yet

- Abhikul Kumar Singh: Mechanical EngineerDocument2 pagesAbhikul Kumar Singh: Mechanical EngineerBrent M GeorgeNo ratings yet

- Ethantangresume 2018 Springv 3Document1 pageEthantangresume 2018 Springv 3api-402915448No ratings yet

- Junior Mechanical Engineering Major Seeking Product Design InternshipDocument1 pageJunior Mechanical Engineering Major Seeking Product Design InternshipTONY KANYENo ratings yet

- Ample Esume: BjectiveDocument1 pageAmple Esume: BjectiveJoy JohnNo ratings yet

- Resume SampleDocument2 pagesResume Sample18TUEC119 Kiran SeshiNo ratings yet

- Resume Hudakandrew May-2020 HostedDocument1 pageResume Hudakandrew May-2020 Hostedapi-251739430No ratings yet

- Resume - Mechanical Engineer - Format1Document2 pagesResume - Mechanical Engineer - Format1prince SinghNo ratings yet

- Protected UploadDocument6 pagesProtected UploadRebecca SchroederNo ratings yet

- Jem Van Tyn - Resume 02-10-2024Document1 pageJem Van Tyn - Resume 02-10-2024api-566578740No ratings yet

- KristoferkurtinresumeDocument2 pagesKristoferkurtinresumeapi-280159290No ratings yet

- Koch Mechengineer ResumeDocument1 pageKoch Mechengineer Resumeapi-592258146No ratings yet

- Morteza MirzaeiDocument3 pagesMorteza MirzaeiUmitNo ratings yet

- Atley Brooks Eit OnlineDocument3 pagesAtley Brooks Eit Onlineapi-296552626No ratings yet

- Achieved 20% Greater Efficiency: Manage Facilitate Consult Organize Resolve Assist MotivateDocument12 pagesAchieved 20% Greater Efficiency: Manage Facilitate Consult Organize Resolve Assist MotivatestrganeshkumarNo ratings yet

- Resume MD Zeeshan AshrafDocument3 pagesResume MD Zeeshan Ashraferzeeshan92No ratings yet

- Cerier 090918Document1 pageCerier 090918api-332195824No ratings yet

- Resume Mohammad Abdul Wasay EjazDocument2 pagesResume Mohammad Abdul Wasay EjazRupinder JeetNo ratings yet

- Vignesh Eswaran: Skills Professional SummaryDocument2 pagesVignesh Eswaran: Skills Professional SummaryVignesh EswaranNo ratings yet

- Mechanical EngineerDocument1 pageMechanical EngineerAnjo PeterNo ratings yet

- Abigail Moadab Resume 2023Document1 pageAbigail Moadab Resume 2023api-538604468No ratings yet

- Abhishek Sumit ResumeDocument3 pagesAbhishek Sumit Resumehr.runrmobilityNo ratings yet

- Electrical Engineer Resume SummaryDocument5 pagesElectrical Engineer Resume Summarykiran2710No ratings yet

- Ali Ahmad CVDocument4 pagesAli Ahmad CVali ahmadNo ratings yet

- BESS Expert with 6+ Years ExperienceDocument3 pagesBESS Expert with 6+ Years ExperienceDebarchan MishraNo ratings yet

- Job Description File-1694141430481-567202283Document2 pagesJob Description File-1694141430481-567202283cu.16bme1259No ratings yet

- Resume 2023Document1 pageResume 2023api-549226414No ratings yet

- Education: Arissa IrelliDocument1 pageEducation: Arissa Irelliapi-651010738No ratings yet

- Development Project Leader - Phlip ShenoudaDocument3 pagesDevelopment Project Leader - Phlip ShenoudaPhelep MounirNo ratings yet

- Woodford Resume 2020Document1 pageWoodford Resume 2020Jeffrey WoodfordNo ratings yet

- Joseph Kochevar: Summary of Qualifications ExperienceDocument1 pageJoseph Kochevar: Summary of Qualifications ExperienceAnonymous d4JNXpDC7No ratings yet

- Senior Mechanical Design Engineer in Minneapolis ST Paul MN Resume Steven FischerDocument2 pagesSenior Mechanical Design Engineer in Minneapolis ST Paul MN Resume Steven FischerSteven FischerNo ratings yet

- Resume Muhammad AmmadDocument3 pagesResume Muhammad AmmadrizyasNo ratings yet

- Nathan Shull ResumeDocument2 pagesNathan Shull Resumeapi-438447056No ratings yet

- Akshay Pawar CV2Document3 pagesAkshay Pawar CV2Akshay pawarNo ratings yet

- Ken Weaver Mechanical Engineer ResumeDocument2 pagesKen Weaver Mechanical Engineer Resumeapi-308328805No ratings yet

- Megan Moyer Resume Spring 2021Document1 pageMegan Moyer Resume Spring 2021api-337794615No ratings yet

- Nicholas Robben - Mechanical EngineeringDocument1 pageNicholas Robben - Mechanical Engineeringapi-487597654No ratings yet

- JIGAR S DESAI MES ResumeDocument2 pagesJIGAR S DESAI MES ResumeJigar DesaiNo ratings yet

- Slawson Generic ResumeDocument1 pageSlawson Generic Resumeapi-294846886No ratings yet

- Venkadachalapathy Thangavel: LinkedinDocument4 pagesVenkadachalapathy Thangavel: Linkedinvenkatachalapathy.thNo ratings yet

- Chaitanya+CV +23+Document4 pagesChaitanya+CV +23+Merin JacobNo ratings yet

- Resume Miranda Taylor 2017 - FinalDocument1 pageResume Miranda Taylor 2017 - Finalapi-349694245No ratings yet

- Hayden Morgan Resume PersinforedacDocument1 pageHayden Morgan Resume Persinforedacapi-392605227No ratings yet

- SamschmidtresumeDocument2 pagesSamschmidtresumeapi-352344484No ratings yet

- Trester Resume 2020Document1 pageTrester Resume 2020api-482596257No ratings yet

- Purdue MSME Seeks Product Engineering RolesDocument1 pagePurdue MSME Seeks Product Engineering RolesvrushalmaniyarNo ratings yet

- Skills: Industrial/Mechanical EngineerDocument4 pagesSkills: Industrial/Mechanical EngineerBivek SapkotaNo ratings yet

- 8085 PRJ Schematic 1Document44 pages8085 PRJ Schematic 1Jani ServiniNo ratings yet

- BC8002+ Operating ManualDocument44 pagesBC8002+ Operating Manualarmand isakhNo ratings yet

- EASE Scheme of Image Zooming DocumentationDocument50 pagesEASE Scheme of Image Zooming DocumentationSrikrishna Acharya BailoreNo ratings yet

- Pagine Da Auriga UPS - Service ManualDocument9 pagesPagine Da Auriga UPS - Service ManualcaohuynhtaiNo ratings yet

- Unit 3Document42 pagesUnit 3Diksha SinghalNo ratings yet

- Owner's Manual: System PilotDocument8 pagesOwner's Manual: System Pilotlecau50cdlNo ratings yet

- ConsultanciesDocument8 pagesConsultanciesSaranya PugazhenthiNo ratings yet

- Spectralwave™ Dw4200: Equipment ManualDocument10 pagesSpectralwave™ Dw4200: Equipment ManualGraciela A JuárezNo ratings yet

- PGF Pie ManualDocument5 pagesPGF Pie ManualViral ThakarNo ratings yet

- Integrated BTech MBA Gaurav ResumeDocument2 pagesIntegrated BTech MBA Gaurav ResumeAbhinav SinghNo ratings yet

- MSP 34x0G Multistandard Sound Processor Family: MicronasDocument106 pagesMSP 34x0G Multistandard Sound Processor Family: MicronasasistekNo ratings yet

- String FunctionsDocument2 pagesString FunctionsvenuNo ratings yet

- Experion PKS R430 3 SCNDocument52 pagesExperion PKS R430 3 SCNjosh3340% (1)

- ISE SchemeDocument11 pagesISE SchemearjuninformationNo ratings yet

- IUR Benefits License Table April-2021Document21 pagesIUR Benefits License Table April-2021maukpNo ratings yet

- RE - 17328 RexrothDocument32 pagesRE - 17328 RexrothLeo VanNo ratings yet

- Basic Computer ConceptsDocument9 pagesBasic Computer ConceptsSadiq Merchant100% (12)

- SD Creation Guide For Kess V2Document8 pagesSD Creation Guide For Kess V2halil ibrahim soysalNo ratings yet

- Siemens Siremobil 2000 PDFDocument247 pagesSiemens Siremobil 2000 PDFTeresa Rosas Guzmán100% (5)

- Automation 360 Migration FAQ: Question Quick LinksDocument13 pagesAutomation 360 Migration FAQ: Question Quick LinksSVM SrgmNo ratings yet

- GMI PressSIGN ManualDocument220 pagesGMI PressSIGN ManualAllanNo ratings yet

- Information Systems: Research, Development, Applications, EducationDocument167 pagesInformation Systems: Research, Development, Applications, EducationJhonGarciaNo ratings yet

- Propeller Led Display For ImagesDocument7 pagesPropeller Led Display For ImagesMuhamad SaipudinNo ratings yet

- Rareswans High Quality Dorks TutorialDocument13 pagesRareswans High Quality Dorks TutorialshubhamNo ratings yet

- CST8288 ReviewDocument84 pagesCST8288 Reviewsaika sairaiNo ratings yet

- Appfuse-Documentation-2 1 0 PDFDocument206 pagesAppfuse-Documentation-2 1 0 PDFramsharma4No ratings yet

- Josh Wright Scrum The Complete Guide To The Agile Project ManagementDocument102 pagesJosh Wright Scrum The Complete Guide To The Agile Project ManagementJUANnn100100% (1)

- IX Class Computer Science AbbreviationsDocument7 pagesIX Class Computer Science AbbreviationsAmna FaisalNo ratings yet

- Primavera P6Document2 pagesPrimavera P6tutan12000No ratings yet

- Atecc608B: Cryptoauthentication Device Summary Data SheetDocument30 pagesAtecc608B: Cryptoauthentication Device Summary Data Sheetgino ginelliNo ratings yet

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (3)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeFrom EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo ratings yet

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Workbook to Accompany Maintenance & Reliability Best PracticesFrom EverandWorkbook to Accompany Maintenance & Reliability Best PracticesRating: 3.5 out of 5 stars3.5/5 (3)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- Mastering Drones - A Beginner's Guide To Start Making Money With DronesFrom EverandMastering Drones - A Beginner's Guide To Start Making Money With DronesRating: 2.5 out of 5 stars2.5/5 (3)

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Artificial You: AI and the Future of Your MindFrom EverandArtificial You: AI and the Future of Your MindRating: 4 out of 5 stars4/5 (3)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceFrom EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceRating: 5 out of 5 stars5/5 (9)

- Dark Aeon: Transhumanism and the War Against HumanityFrom EverandDark Aeon: Transhumanism and the War Against HumanityRating: 5 out of 5 stars5/5 (1)

- Collection of Raspberry Pi ProjectsFrom EverandCollection of Raspberry Pi ProjectsRating: 5 out of 5 stars5/5 (1)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.From EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Rating: 4 out of 5 stars4/5 (5)

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessFrom EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessNo ratings yet

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)