Professional Documents

Culture Documents

Vessels: G3 © ICARUS Corporation, 1998

Vessels: G3 © ICARUS Corporation, 1998

Uploaded by

anakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vessels: G3 © ICARUS Corporation, 1998

Vessels: G3 © ICARUS Corporation, 1998

Uploaded by

anakCopyright:

Available Formats

Chapter

Vessels 10

Horizontal Tanks (HT) ....................................................................... 10-3

Vertical Tanks (VT)............................................................................ 10-8

G3 © ICARUS Corporation, 1998.

10-2 ICARUS Reference

© ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-3

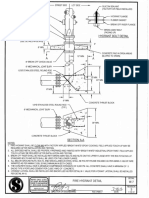

Horizontal Tanks (HT)

Horizontal vessels are commonly used as settling drums, surge tanks, reactors and distillate drums. A settling drum is used

for phase separation between two immiscible liquids. The L/D ratio of a settling drum is normally four. A surge tank or

surge drum is used to maintain a constant flowrate of liquid to a downstream piece of equipment when the flowrate of liquid

from the upstream piece of equipment is fluctuating. The fluctuations in flow rate are absorbed by the surge drum by

allowing the liquid level in this drum to rise and fall. Horizontal drums are frequently filled with catalyst and used as

reactors. Placing catalyst in horizontal vessels allows shallow bed depths and large cross-sectional areas. A typical example

of horizontal vessels being used as reactors is the Claus reactor. A distillate or reflux drum provides space for overhead

condensables from a distillation column to separate from vapors. Surge drums and distillate drums are normally vertical. If

there is settleable water in the feed to these vessels, however, the vessel is erected with a water pot.

The horizontal vessel is a pressure vessel fabricated according to the rules of the specified code (i.e., Section VIII Division 1

of the ASME Code) and erected in the horizontal position. Although the horizontal vessel may be supported by lugs in an

open steel structure, the more usual arrangement is for the vessel to be erected at grade and supported by a pair of saddles.

Cylindrical, pressure/vacuum, code design and construction, includes heads, single wall (base material, clad/lined), saddles/

lugs, nozzles and manholes.

Description Type

Multi-wall design for high pressure service with total wall thickness MULTI WALL

of individual, thin, heat-shrunk cylinders (maximum 2 INCHES

[50 MM] thick) heat shrunk, pressure vacuum design and

construction according to user-designated design code standard.

This item is a horizontal process vessel, the total wall thickness of

which is made up of individual cylinders. Each individual cylinder is

no more than two inches thick. The composite is made as

follows. A cylinder is fabricated with a diameter slightly larger than

the innermost cylinder. This cylinder is expanded thermally, slipped

over the inner cylinder and as it cools, a tight shrink fit is obtained.

This procedure is repeated until the total wall thickness is built up.

Application Symbol: Defines vessel function and related

piping/instrumentation model. Default: *blank*

blank - Standard continuous process vessel

BATCH - Batch process vessel

STORAGE - Storage vessel

RECVR - Receiver

KO - Knock-out drum

Shell Material: For clad plate, specify the backing plate material.

(Cladding is defined below.) See Chapter 28 for materials.

Default: *A 515*.

Capacity: Enter either capacity or diameter and length.

Diameter: Enter either capacity or diameter and length.

Vessel T-T Length: Enter either capacity or diameter and length.

Design Press. - Gauge: If pressure and vacuum entered, design is

for worst case. Default: *15* PSIG [*100* KPA].

Design Vacuum - Gauge: If pressure and vacuum entered,

design is for worst case. Default: pressure.

Design Temperature: Default: 650 DEG F [340 DEG C] ferrous

material; 250 DEG F [120 DEG C] other material.

Operating Temp.: Default: design temperature.

Cladding Material: See Chapter 28; for cladding materials.

Continued on next page

G3 © ICARUS Corporation, 1998.

10-4 ICARUS Reference

Horizontal Tanks (HT) - continued

Description Type

MULTI WALL - continued

Manhole Diameter: Max: 48 INCHES [1,200 MM];

Default: *18* INCHES [*450* MM]

Number of Manholes: Default: *1*.

% All. for Internals: Specify an allowance for internals as a

percent of basic vessel weight. Default: *0.0*.

Diameter of Drip Leg: Drip leg (boot) diameter and length must

be specified if required.

Length of Drip Leg: Drip leg (boot) diameter and length must be

specified if required.

Base Mat’l Thickness: Base material thickness including

corrosion allowance.

Corrosion Allowance: Default: 0.125 INCHES [3 MM] for CS,

0.0 for other materials.

Weld Efficiency %: 50 - 100; ASME/JIS codes only, where

allowed for thin wall vessels; Default: Area Basis.

Stress Relief: Default: See Area Design Basis.

CODE - Provide stress relief if code requires

YES - Provide stress relief

NO - No stress relief required

Cladding Thickness: Default: 1.125 INCHES [3 MM] if cladding

material is specified; otherwise 0.0.

Stiff’g Ring Spacing: Default stiffeners designed for vacuum

only, enter 0.0 if not required.

Head Type Symbol:

ELLIP - 2:1 ellipsoidal

HEMI - Hemispherical

TORI - Torispherical (ASME)

No. Body Flange Sets: Number of sets (pairs) of body flanges of

same diameter as vessel.

Diameter Option: Defines desired diameter as ID or OD;

Default - see Area Design Basis.

OD - Outside diameter

ID - Inside diameter

© ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-5

Horizontal Tanks (HT) - continued

Description Type

Horizontal pressure/vacuum drum. HORIZ-DRUM

Use minus pressure for vacuum design.

The capacity excludes the volume of the heads. If both the vessel

dimensions and capacity are specified, the system-calculated

capacity must agree with the specified capacity to within plus or

minus 10% to avoid an error condition. To secure desired vessel

size, specify the diameter and height directly. A value must be

specified if vessel diameter and/or vessel height (or length) are

not specified. If vessel diameter and height (or length) are

specified, the vessel volume is calculated from these dimensions.

If only vessel capacity is specified, a straight side length-to-diameter

ratio is chosen by the system, considering cost and practicability.

(Default ratio is 2:1.)

Application Symbol: Defines vessel function and related

piping/instrumentation model. Default: *blank*

blank - Standard continuous process vessel

BATCH - Batch process vessel

STORAGE - Storage vessel

RECVR - Receiver

KO - Knock-out drum

Shell Material: For clad plate, specify the backing plate material.

(Cladding is defined below.) See Chapter 28 for materials.

Default: *A 515*.

Capacity: Enter either capacity or diameter and length. The

capacity excludes the volume of the heads.

If both the vessel dimensions and capacity are specified, the

system-calculated capacity must agree with the specified

capacity to within plus or minus 10% to avoid an error condition.

To secure desired vessel size, specify the diameter and height

directly.

A value must be specified if vessel diameter and/or vessel height

(or length) are not specified. If vessel diameter and height (or

length) are specified, the vessel volume is calculated from these

dimensions.

If only vessel capacity is specified, a straight side

length-to-diameter ratio is chosen by the system, considering

cost and practicability.

Diameter: Enter either capacity or diameter and length.

A value must be specified if vessel capacity is not specified. If

both capacity and height (or length) are specified, the diameter is

calculated from these values.

Vessel T-T Length: Enter either capacity or diameter and length.

A value must be specified if vessel capacity is not specified. If

both vessel capacity and diameter are specified, the height (or

length) is calculated from these values.

Design Press. - Gauge: If pressure and vacuum entered, design is

for worst case; Default: *15* PSIG [*100* KPA] pressure.

Design Vacuum - Gauge: If pressure and vacuum entered, design

is for worst case. Default: pressure.

Design Temperature: Default: 650 DEG F [340 DEG C] ferrous

material; 250 DEG F [120 DEG C] other material.

Continued on next page

G3 © ICARUS Corporation, 1998.

10-6 ICARUS Reference

Horizontal Tanks (HT) - continued

Description Type

HORIZ-DRUM - continued

Operating Temp.: Default: design temperature. The operating

temperature is used in the calculation of piping and insulation

thickness.

Cladding Material: See Chapter 28 for cladding materials.

Manhole Diameter: Max: 48 INCHES [1,200 MM];

Default: *18* INCHES [*450* MM].

Number of Manholes: Default: *1*.

% All. for Internals: Specify an allowance for internals as a

percent of basic vessel weight. Default: *0.0*. This value

adjusts vessel weight and cost accordingly.

Diameter of Drip Leg: Drip leg (boot) diameter and length must

be specified if required.

Length of Drip Leg: Drip leg (boot) diameter and length must be

specified if required.

Base Material Thickness: Base material thickness including

corrosion allowance.

Corrosion Allowance: Default: 0.125 INCHES [3 MM] for CS,

0.0 for other materials.

Weld Efficiency %: ASME/JIS codes only, where allowed for

thin wall vessel; Default: Area Basis. Range: 50 - 100.

Stress Relief: Default: See Area Design Basis.

CODE - Provide stress relief if code requires

YES - Provide stress relief

NO - No stress relief required

Cladding Thickness: Default: 0.125 INCHES [3 MM] if cladding

material is specified, otherwise: 0.0.

Stiff’g Ring Spacing: Default stiffeners designed for vacuum only,

enter 0.0 if not required.

Head Type Symbol: If no value is specified, the system selects

the torispherical type and calculates its thickness. If the head is

thicker than the vessel shell, the system selects the 2:1 ellipsoidal

type head thickness. If the head is still thicker than the shell, the

system selects the hemispherical type head.

ELLIP - 2:1 elliposidal

HEMI - Hemispherical

TORI - Torispherical (ASME)

No. Body Flange Sets: Number of sets (pairs) of body flanges of

same diameter as vessel.

Diameter Option: Defines desired diameter as ID or OD;

Default - see Area Design Basis.

OD - Outside diameter

ID - Inside diameter

© ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-7

Horizontal Tanks (HT) - continued

Description Type

Jacketed horizontal pressure/vacuum drum. JACKETED

Application Symbol: Defines vessel function and related

piping/instrumentation model. Default: *blank*

blank - Standard continuous process vessel

BATCH - Batch process vessel

STORAGE - Storage vessel

RECVR - Receiver

KO - Knock-out drum

Shell Material: For clad plate, specify the backing plate material.

See Chapter 28 for materials. Default: *A 515*.

Capacity: Enter either capacity or diameter and length.

Diameter: Enter either capacity or diameter and length.

Vessel T-T Length: Enter either capacity or diameter and length.

Design Press. - Gauge: If pressure and vacuum entered, design

is for worst case; Default: *15* PSIG [*100* KPA].

Design Vacuum - Gauge: If pressure and vacuum entered,

design is for worst case; Default: pressure.

Design Temperature: Default: 650 DEG F [340 DEG C]

ferrous material; 250 DEG F [120 DEG C] other materials.

Operating Temp: Default: design temperature.

Cladding Material: See Chapter 28 for materials.

Jacket Press. - Gauge: Default: *90* PSIG [*620* KPA].

Jacket Type: Default: *FULL*

FULL - Full jacket

PIPE - Half-pipe jacket

Jacket Material: See Chapter 28 for materials. Default: *CS*.

Manhole Diameter: Max: 48 INCHES [1,200];

Default: 18 INCHES [450 MM].

Number of Manholes: Default: *1*.

% All. for Internals: Specify an allowance for internals as a

percent of basic vessel weight. Default: *0.0*.

Diameter of Drip Leg: Drip leg (boot) diameter and length must

be specified if required.

Length of Drip Leg: Drip leg (boot) diameter and length must

be specified if required.

Base Mat’l Thickness: Base material thickness including

corrosion allowance.

Corrosion Allowance: Default: 0.125 INCHES [3 MM] for CS,

0.0 for other material, double if jacketed.

Weld Efficiency %: ASME/JIS codes only, where allowed for

thin wall vessels; Default: Area Basis. Range: 50 - 100.

Stress Relief: Default: See Area Design Basis.

CODE - Provide stress relief if code requires

YES - Provide stress relief

NO - No stress relief required

Cladding Thickness: Default: 0.125 INCHES [3 MM] if cladding

material is specified; otherwise: 0.0.

Stiff’g Ring Spacing: Default stiffeners designed for vacuum

only, enter 0.0 if not required.

Head Type Symbol:

ELLIP - 2:1 elliposidal

HEMI - Hemispherical

TORI - Torispherical (ASME)

No. Body Flange Sets: Number of sets (pairs) of body flanges of

same diameter as vessel.

Diameter Option: Defines desired diameter as ID or OD;

Default: See Area Design Basis.

OD - Outside diameter

ID - Inside diameter

G3 © ICARUS Corporation, 1998.

10-8 ICARUS Reference

Vertical Tanks (VT)

Vertical process vessels are typically used as either surge drums or knock out drums. When used as surge drums, they act

like shock absorbers, maintaining a constant flowrate of liquid out of the vessel regardless of the flowrate into it. If liquid

flows in faster than the constant rate it flows out, the vessel fills with liquid. If liquid flows in slower than the constant rate

it is removed, then the liquid level drops. The liquid level is constantly fluctuating in order to absorb these variations in

flow and maintain a constant flowrate out. When a vertical process vessel is used as a knock out drum, a mixture of gas and

liquid flows into the vessel and this mixture is separated into its gas and liquid components within the vessel. The gas then

flows out the top of the vessel and the liquid flows out the bottom.

Vertical process vessels, as their name indicates, are erected in the vertical position. They are cylindrical in shape with each

end capped by a domed cover called a head. The length to diameter ratio of a vertical vessel is typically 3:1.

Typically, vertical process vessels hold less than 5000 GALLONS.

Vertical tanks include: process, storage applications liquid, gas, solid processing and storage; pressure/vacuum code design

for process and certain storage vessel types; includes heads, single wall, saddles, lugs, nozzles, manholes, legs or skirt, base

ring, davits where applicable.

Description Type

Pressure/Vacuum Service

Cylindrical vertical pressure/vacuum vessel. CYLINDER

Use minus pressure for vacuum design.

Application Symbol: Defines vessel function and related

piping/instrumentation model. Default: *blank*

blank - Standard continuous process vessel

BATCH - Batch process vessel

STORAGE - Storage vessel

RECVR - Receiver

KO - Knock-out drum

Shell Material: For clad plate, specify the backing plate material.

See Chapter 28 for materials. Default: *A 515*.

Capacity: Enter either capacity or diameter and height.

The capacity excludes the volume of the heads. If both the

vessel dimensions and capacity are specified, the system

calculated capacity must agree with the specified capacity to

within plus or minus 10% to avoid an error condition. To secure

desired vessel size, specify the diameter and height directly.

A value must be specified if vessel diameter and/or vessel height

(or length) are not specified. If vessel diameter and height (or

length) are specified, the vessel volume is calculated from these

dimensions. (Default is 2:1.)

If only vessel capacity is specified, a straight side

length-to-diameter ratio is chosen by the system, considering

cost and practicability.

Diameter: Enter either capacity or diameter and height.

A value must be specified if vessel capacity is not specified.

If both vessel capacity and height (or length) are specified, the

diameter is calculated from these values. If both vessel capacity

and diameter are specified, the height (or length) is calculated

from these values.

Vessel T-T Height: Enter either capacity or diameter and height.

See Diameter.

Continued on next page

© ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-9

Vertical Tanks (VT) continued

Description Type

CYLINDER - continued

Design Press. - Gauge: If pressure and vacuum entered, design is

for worst case; Default: *15* PSIG [*100* KPA].

Design Vacuum - Gauge: If pressure and vacuum entered, design

is for worst case; Default: pressure.

Design Temperature: Default: 650 DEG F [340 DEG C] ferrous

material, 250 DEG F [120 DEG C] other material.

Operating Temp.: Default: design temperature.

Skirt Height: Skip if legs required, enter 0.0 if hung in OPEN

structure; Default: 1.5 x diameter.

If the capacity is 10,000 GALLONS [37 M3] or less, the vessel

is designed with 4-feet [1.25 M] pipe legs. For a capacity

greater than 10,000 GALLONS [37 M3], the vessel is designed

with a skirt. The skirt height is calculated as 1.5 x vessel

diameter, with minimum and maximum calculated heights of

4 - 32 FEET [1.25 - 9.5 M].

Leg Height: Skip if skirt required, enter 0.0 if hung in OPEN

structure; Default: *4* FEET [1.25 M]. See Skirt Height.

Wind/Seismic Design: Default: Vessel designed for wind and

seismic loads defined in Project Basis.

W+S - Wind and seismic design required

WIND - Wind design only

SEIS - Seismic design only

NONE - Delete wind and seismic design

Fluid Volume %: For seismic design, fluid volume as a % of

vessel volume (water assumed). Max: 100; Default: *20*.

Manhole Diameter: Max: 48 INCHES [1,200 MM];

Default: 18 INCHES [450 MM].

Number of Manholes: Default: *1*.

% All. for Internals: Default: *0.0*; Specify an allowance for

internals as a percent of basic vessel weight.

Base Mat’l Thickness: Base material thickness including

corrosion allowance.

Corrosion Allowance: Default: 0.125 INCHES [3 MM for CS,

0.0 for other materials.

No. Body Flange Sets: Number of sets (pairs) of body flanges of

same diameter as vessel.

Weld Efficiency %: ASME/JIS codes only, where allowed for

thin wall vessels; Defaults: Area Basis. Range: 50 - 100.

Stress Relief: Default: See Area Design Basis.

CODE - Provide stress relief if code requires

YES - Provide stress relief

NO - No stress relief required

Cladding Material: If no cladding material is specified, the system

assumes that the vessel is not clad regardless of any input for

cladding thickness. See Chapter 28 for materials.

Cladding Thickness: Default: 0.125 INCHES [3 MM] if

cladding material is specified, otherwise 0.0. See Cladding

Material.

Stiff’g Ring Spacing: Default stiffeners designed for vacuum only,

enter 0.0 if not required.

Continued on next page

G3 © ICARUS Corporation, 1998.

10-10 ICARUS Reference

Vertical Tanks (VT) continued

Description Type

CYLINDER - continued

Head Type Symbol: If no value is specified, the system selects

the torispherical type head and calculates the thickness. If the

head is thicker than the vessel shell, the system selects the

2:1 ellipsoidal type head and recalculates the head thickness.

If the head is still thicker than the shell, the system selects the

hemispherical type head.

ELLIP - 2:1 elliposidal

HEMI - Hemispherical

TORI - Torispherical (ASME)

Bottom Head Thick: Base material thickness including corrosion

allowance.

Top Head Thickness: Base material thickness including corrosion

allowance.

Diameter Option: Defines desired diameter as ID or OD; Default:

See Area Design Basis.

OD - Outside diameter

ID - Inside diameter

ASME Design Basis: Applicable only for ASME code design.

See following entries for fatigue data. Default: *D1NF*.

D1NF - ASME Division 1 - no fatigue analysis

D1F - ASME Division 1 - with fatigue analysis

D2NF - ASME Division 2 - no fatigue analysis

D2F - ASME Division 2 - with fatigue analysis

Start-up Cycles x 1000: ASME fatigue only. Thousands of

start-up cycles during the full equipment life.

Range: 5.00 - 0.02.

Pressure Cycles x 1000: ASME fatigue only. Thousands of

deviations from design pressure during equipment life.

Default: *0*.

Pressure Amplitude %: ASME fatigue only. Amplitude of

process deviation as percent of design pressure. Default: *0*.

No. Hydrostatic Test: ASME fatigue only. Number of

hydrostatic tests during the full equipment life. Default: *0*.

Temp. Cycles x 1000: ASME fatigue only. Thousands of

deviations from design temperature in equipment life.

Default: *0*.

Temp. Amplitude %: ASME fatigue only. Amplitude of

temperature as a percent of design temperature. Default: *0*.

© ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-11

Vertical Tanks (VT) continued

Description Type

Multi-wall design for high pressure service. Total wall thickness of MULTI WALL

individual thin heat shrunk cylinders (maximum 2 INCH [50 MM]

thick each).

Application Symbol: Defines vessel function and related

piping/instrumentation model. Default: *blank*

blank - Standard continuous process vessel

BATCH - Batch process vessel

STORAGE - Storage vessel

RECVR - Receiver

KO - Knock-out drum

Shell Material: For clad plate, specify the backing plate material.

See Chapter 28 for materials. Default: *A 515*.

Capacity: Enter either capacity or diameter and height.

Diameter: Enter either capacity or diameter and height.

Vessel T-T Height: Enter either capacity or diameter and height.

Design Press. - Gauge: If pressure and vacuum entered, design is

for worst case. Default: *15* PSIG [*100* KPA].

Design Vacuum - Gauge: If pressure and vacuum entered, design

is for worst case.

Design Temperature: Default: 650 DEG F [340 DEG C] ferrous

material, 250 DEG F [120 DEG C] other material.

Operating Temp.: Default: design temperature.

Skirt Height: Skip if legs required, enter 0.0 if hung in OPEN

structure; Default: 1.5 x diameter.

Leg Height: Skip if skirt required, enter 0.0 if hung in OPEN

structure; Default: *4* FEET [*1.25* M].

Wind/Seismic Design: Default: Vessel designed for wind and

seismic loads defined in Project Basis.

W+S - Wind and seismic design required

WIND - Wind design only

SEIS - Seismic design only

NONE - Delete wind and seismic design

Fluid Volume %: Max: 100; Default: *20*; For seismic design;

fluid volume as a % of volume (water assumed).

Manhole diameter: Max: 48 INCHES [1,200 MM];

Default: *18* INCHES [*450* MM].

Number of Manholes: Default: *1*.

% All. for Internals: Specify an allowance for internals as a

percent of basic vessel weight. Default: *0.0*.

Base Mat’l Thickness: Base material thickness including

corrosion allowance.

Corrosion Allowance: Default: 0.125 INCHES [3 MM] for CS,

0.0 for other materials.

No. Body Flange Sets: Number of sets (pairs) of body flanges of

same diameter as vessel.

Weld Efficiency %: ASME/JIS codes only, where allowed for

thin wall vessels; Range: 50 - 100; Default: Area Basis.

Stress Relief: Default: see Area Design Basis.

CODE - Provide stress relief if code requires

YES - Provide stress relief

NO - No stress relief required

Continued on next page

G3 © ICARUS Corporation, 1998.

10-12 ICARUS Reference

Vertical Tanks (VT) continued

Description Type

MULTI WALL - continued

Cladding Material: See Chapter 28 for cladding materials.

Cladding Thickness: Default: 0.125 INCHES [3 MM] if cladding

material is specified, otherwise - 0.0.

Stiff’g Ring Spacing: Default stiffeners designed for vacuum

only, enter 0.0 if not required.

Head Type Symbol:

ELLIP - 2:1 elliposidal

HEMI - Hemispherical

TORI - Torispherical (ASME)

Bottom Head Thick: Base material thickness including corrosion

allowance.

Top Head Thickness: Base material thickness including corrosion

allowance.

Diameter Option: Defines desired diameter as ID or OD;

Default: see Area Design Basis.

OD - Outside diameter

ID - Inside diameter

ASME Design Basis: Applicable only for ASME code design.

See following entries for fatigue data. Default: *D1NF*.

D1NF - ASME Division 1 - no fatigue analysis

D1F - ASME Division 1 - with fatigue analysis

D2NF - ASME Division 2 - no fatigue analysis

D2F - ASME Division 2 - with fatigue analysis

Start-up Cycles x 1000: ASME fatigue only. Thousands of

start-up cycles during the full equipment life.

Range: 5.00 - 0.02.

Pressure Cycles x 1000: ASME fatigue only. Thousands of

deviations from design pressure during equipment life.

Default: *0*.

Pressure Amplitude %: ASME fatigue only. Amplitude of

process deviation as percent of design pressure. Default: *0*.

No. Hydrostatic Test: ASME fatigue only. Number of

hydrostatic tests during the full equipment life. Default: *0*.

Temp. Cycles x 1000: ASME fatigue only. Thousands of

deviations from design temperature in equipment life.

Default: *0*.

Temp. Amplitude %: ASME fatigue only. Amplitude of

temperature as a percent of design temperature. Default: *0*.

© ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-13

Vertical Tanks (VT) continued

Description Type

Jacketed, cylindrical, vertical pressure/vacuum vessel. JACKETED

Application Symbol: Defines vessel function and related

piping/instrumentation model. Default: *blank*

blank - Standard continuous process vessel

BATCH - Batch process vessel

STORAGE - Storage vessel

RECVR - Receiver

KO - Knock-out drum

Shell Material: For clad plate, specify the backing plate material.

(Cladding is specified below.) Default: *A 515*.

Capacity: Enter either capacity or diameter and height.

Diameter: Enter either capacity or diameter and height.

Vessel T-T Height: Enter either capacity or diameter and height.

Design Press. - Gauge: If pressure and vacuum entered, design is

for worst case. Default: *15* PSIG [*100* KPA].

Design Vacuum - Gauge: If pressure and vacuum entered, design

is for worst case. Default: pressure.

Design Temperature: Default: 650 DEG F [340 DEG C] ferrous

material, 250 DEG F [120 DEG C] other material.

Operating Temp.: Default: design temperature.

Jacket Press. - Gauge: Default: *90* PSIG [*620* KPA].

Jacket Type: Default: *FULL*

FULL - Full jacket

PIPE - Half-pipe jacket

Jacket Material: See Chapter 28 for materials. Default: *CS*.

Skirt Height: Skip if legs required, enter 0.0 if hung in OPEN

structure; Default: *1.5 x diameter*.

Leg Height: Skip if skirt required. Enter 0.0 if hung in OPEN

structure; Default: *4* FEET [*1.25* M].

Wind/Seismic Design: Default: Vessel designed for wind and

seismic loads defined in Project Basis.

W+S - Wind and seismic design required

WIND - Wind design only

SEIS - Seismic design only

NONE - Delete wind and seismic design

Fluid Volume %: Max: 100; Default: *20*; For seismic design;

fluid volume as a % of vessel volume (water assumed).

Manhole Diameter: Max: 48 INCHES [1,200 MM];

Default: *18* INCHES [*450* MM].

Number of Manholes: Default: *1*.

% All. for Internals: Specify an allowance for internals as a

percent of basic vessel weight. Default: *0.0*.

Base Mat’l Thickness: Base material thickness including

corrosion allowance.

Corrosion Allowance: Default: 0.125 INCHES [3 MM] for CS,

0.0 for other material, double if jacketed.

No. Body Flange Sets: Number of sets (pairs) of body flanges of

same diameter as vessel.

Weld Efficiency %: ASME/JIS codes only, where allowed for

thin wall vessels; Range: 50 - 100; Default: Area Basis.

Continued on next page

G3 © ICARUS Corporation, 1998.

10-14 ICARUS Reference

Vertical Tanks (VT) continued

Description Type

JACKETED - continued

Stress Relief: Default: See Area Design Basis.

CODE - Provide stress relief if code requires

YES - Provide stress relief

NO - No stress relief required

Cladding Material: See Chapter 28 for cladding materials.

Cladding Thickness: Default: 0.125 INCHES [3 MM] if cladding

material is specified, otherwise - 0.0.

Stiff’g Ring Spacing: Default stiffeners designed for vacuum

only, enter 0.0 if not required.

Head Type Symbol:

ELLIP - 2:1 elliposidal

HEMI - Hemispherical

TORI - Torispherical (ASME)

Bottom Head Thick: Base material thickness including corrosion

allowance.

Top Head Thickness: Base material thickness including corrosion

allowance.

Diameter Option: Defines desired diameter as ID or OD;

Default: see Area Design Basis.

OD - Outside diameter

ID - Inside diameter

ASME Design Basis: Applicable only for ASME code design.

See following entries for fatigue data. Default: *D1NF*.

D1NF - ASME Division 1 - no fatigue analysis

D1F - ASME Division 1 - with fatigue analysis

D2NF - ASME Division 2 - no fatigue analysis

D2F - ASME Division 2 - with fatigue analysis

Start-up Cycles x 1000: ASME fatigue only. Thousands of

start-up cycles during the full equipment life.

Range: 5.00 - 0.02.

Pressure Cycles x 1000: ASME fatigue only. Thousands of

deviations from design pressure during equipment life.

Default: *0*.

Pressure Amplitude %: ASME fatigue only. Amplitude of

process deviation as percent of design pressure. Default: *0*.

No. Hydrostatic Test: ASME fatigue only. Number of

hydrostatic tests during the full equipment life. Default: *0*.

Temp. Cycles x 1000: ASME fatigue only. Thousands of

deviations from design temperature in equipment life.

Default: *0*.

Temp. Amplitude %: ASME fatigue only. Amplitude of

temperature as a percent of design temperature. Default: *0*.

© ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-15

Vertical Tanks (VT) continued

Description Type

High Pressure Gas/Liquid Storage

Sphere pressure/vacuum design to 3000 PSIG [20500 KPA]. SPHERE

Use minus pressure for vacuum design.

This item is used by chemical, rubber, petroleum and paper industries

for storing large volumes of anhydrous ammonia, butadiene, butane

and other gases at high temperature.

A spherical tank is elevated and supported by legs fabricated from

structural steel columns or pipe. Sphere sizes range as high as

90 FEET in diameter and are typically constructed of high strength

steel. These tanks are commonly used for high pressure storage of

gases and volatile liquids, typically in the range of 5 - 250 PSIG.

Storing volatile liquids at high pressures raises the boiling point of

the liquid and therefore minimizes or eliminates that need for costly

refrigeration equipment to liquify the material being stored.

Shell Material: For clad plate, specify the backing plate material.

See Chapter 28 for materials. Default: *A 515*.

Capacity: Enter either capacity or diameter.

Diameter: Enter either capacity or diameter.

Design Press. - Gauge: -15 - 3,000 PSIG [-100 - 20,5000];

Default: 15 PSIG [100 KPA].

Design Temperature: Max: 1,500 DEG F [815 DEG C];

Default: *68* DEG F [*20* DEG C].

Operating Temp.: Default: design temperature.

Manhole Diameter: Max: 48 INCHES [1,200 MM];

Default: *18* INCHES [*450* MM].

Number of Manholes: Default: *1*.

% All. for Internals: Specify an allowance for internals as a

percent of basic vessel weight. Default: *0.0*.

Base Mat’l Thickness: Base material thickness including

corrosion allowance.

Corrosion Allowance: Default: 0.125 INCHES [3 MM] for CS,

0.0 for other materials.

Cladding Material: See Chapter 28 for cladding materials.

Cladding Thickness: Default: 0.125 INCHES [3 MM]

if cladding material is specified, otherwise - 0.0.

Diameter Option: Defines desired diameter as ID or OD;

Default: see Area Design Basis.

OD - Outside diameter

ID - Inside diameter

ASME Design Basis: Applicable only for ASME code design.

See following entries for fatigue data. Default: *D1NF*.

D1NF - ASME Division 1 - no fatigue analysis

D1F - ASME Division 1 - with fatigue analysis

D2NF - ASME Division 2 - no fatigue analysis

D2F - ASME Division 2 - with fatigue analysis

Start-up Cycles x 1000: ASME fatigue only. Thousands of

start-up cycles during the full equipment life.

Range: 5.00 - 0.02.

Continued on next page

G3 © ICARUS Corporation, 1998.

10-16 ICARUS Reference

Vertical Tanks (VT) continued

Description Type

SPHERE - continued

Pressure Cycles x 1000: ASME fatigue only. Thousands of

deviations from design pressure during equipment life.

Default: *0*.

Pressure Amplitude %: ASME fatigue only. Amplitude of

process deviation as percent of design pressure. Default: *0*.

No. Hydrostatic Test: ASME fatigue only. Number of

hydrostatic tests during the full equipment life. Default: *0*.

Temp. Cycles x 1000: ASME fatigue only. Thousands of

deviations from design temperature in equipment life.

Default: *0*.

Temp. Amplitude %: ASME fatigue only. Amplitude of

temperature as a percent of design temperature. Default: *0*.

© ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-17

Vertical Tanks (VT) continued

Description Type

Spheroid to 750000 GALLONS [2840 M3]. Field erected. SPHEROID

This item is commonly used for storage of gasolines and other

volatile liquids.

Spheroids vary in shape and size, but generally fall into one of the

following categories:

• Hemispheriod: Spherical segments comprising the roof and bottom

of the tank are joined to a cylindrical middle section.

Hemispheriods are used for pressures up to 5 PSI and capacities to

25,000 barrels. For capacities to 50,000 barrels the roof and

bottom are noded.

• Hortonspheriod: Spherical segments are joined together in a

somewhat elliptical shape. Hortonspheroids are capable of

handling storage at pressure from 5 to 30 PSIG.

Hortonspheroids and hemispheroids are designed to rest on a

prepared grade conforming to the shape of the bottom (usually sand).

Spheroidal shaped tanks are often more economical than cylindrical

pressure vessels for storage at pressures greater than 0.5 PSI.

Shell Material: For clad plate, specify the backing plate material.

See Chapter 28 for materials. Default: *A 515*.

Capacity: Enter either capacity or diameter and height.

Range: 60,000 - 750,000 GALLONS [230 - 2,840 M3];

Diameter: Enter either capacity or diameter and height.

Height: Enter either capacity or diameter and height.

Design Press. - Gauge: Range: 0.0 - 15 PSIG [0.0 - 100 KPA];

Default: *15* PSIG [*100* KPA].

Design Temperature: Default: *68* DEG F [*20* DEG C].

Operating Temp.: Default: design temperature.

Manhole Diameter: Max: 48 INCHES [1,200 MM];

Default: *18* INCHES [*450* MM].

Number of Manholes: Default: *1*.

% All. for Internals: Default: Specify an allowance for internals

as a percent of basic vessel weight. Default: *0.0*.

Base Mat’l Thickness: Base material thickness including

corrosion allowance.

Corrosion Allowance: Default: 0.125 INCHES [3 MM] for CS,

0.0 for other materials.

Cladding Material: See Chapter 28 for cladding materials.

Cladding Thickness: Default: 0.125 INCHES [3 MM] if cladding

material is specified, otherwise - 0.0.

Diameter Option: Defines desired diameter as ID or OD;

Default - see Area Design Basis.

OD - Outside diameter

ID - Inside diameter

G3 © ICARUS Corporation, 1998.

10-18 ICARUS Reference

Vertical Tanks (VT) continued

Description Type

Near-Atmospheric Liquid Storage

The available roof types are FLAT, FLOAT, CONE, LIFT, STORAGE

OPEN, INFLT, and INCN.

Flat roof tank

Use minus pressure for vacuum design. Field erected.

Floating roof tanks are frequently used in the storage of Floating roof tank

kerosene and jet fuels. Floating roofs may be installed

inside a tank with a fixed roof or used as a tank’s only

cover. Typically constructed from polyurethane foam

blocks or nylon cloth impregnated with rubber or plastic,

floating roofs are designed to completely contact the

surface of the storage products and thereby eliminate the

vapor space between the product level and the fixed roof.

This feature makes floating roofs desirable for the

following reasons:

1. Reduction of evaporation and breathing losses.

2. Reduction of tank corrosion.

3. Increased safety from fire or explosion.

Floating root tanks are suitable for storage of products

having vapor pressures from 2 to 15 PSIA. Products that

boil at temperatures under the normal range of atmospheric

conditions should not be stored in floating roof tanks.

Cone roof tanks are used for storage of low pressure products Cone roof tank

(e.g., oil, diesel and asphalt.) Cone roof tanks are usually field

fabricated out of carbon steel. Roofs are sloped upward to the

center at a slight angle. Typically, ranging from 50,000 - 1,000,000

GALLONS capacities, they are used for storage of low vapor

pressure products (less than 2 PSIA) when evaporation looses and

breathing losses are not considered important.

Lifter roof tanks are generally field fabricated. They have a Lifter roof tank

minimum capacity of 40,000 GALLONS [152 M2]. Lifter roof

tanks can be specified with pressure from 0 - 0.05 PSIG

[0 - 0.3 KPA] and a maximum temperature of 250 DEG F

[120 DEC C]. The default temperature is *68* DEG F

[*20* DEG C].

Open top tanks are designed and constructed according to Open top tank

user-generated design code standards. Open top tanks have a

maximum temperature of 250 DEG F [120 DEC C]. The default

temperature is *68* DEG F [*20* DEG C].

Continued on next page

© ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-19

Vertical Tanks (VT) continued

Description Type

STORAGE - continued

Shell Material: For clad plate, specify the backing plate

material (cladding is defined below). See Chapter 28 for

materials. Default: *A285C*.

Capacity Units: Unit of measure for the capacity entry. Enter

capacity unit symbol as entered in project specifications. If

units are not changed, enter GALLONS [M3] or

BARRELS [M3].

Capacity: Enter either capacity (see capacity unit entry for units)

or diameter and height.

Diameter: Enter either capacity or diameter and height.

Height: Enter either capacity or diameter and height.

Roof Type: Default: *FLAT*

FLAT - Flat roof tank

CONE - Cone roof tank

FLOAT - Floating roof tank

LIFT - Lifter

OPEN - Open roof tank

INFLT - Internal floater with flat roof

INCN - Internal floater with cone roof

Bottom Type: Default: *FLAT*

FLAT - Single flat bottom

DBL - Double bottom

Design Press. - Gauge: 0.0 - 2.5 PSIG [0.0 - 17 KPA];

Default: *0.05* PSIG [*0.35* KPA].

Design Temperature: Default: *68* DEG F [*20* DEG C].

Operating Temperature: Default: design temperature.

Manhole Diameter: Max: 48 INCHES [1,200 MM];

Default: *18* INCHES [*450* MM].

Number of Manholes: Default: *1*.

% All. for Internals: Specify an allowance for internals as a

percent of basic vessel weight. Default: *0.0*.

Base Mat’l Thickness: Base material thickness including

corrosion allowance.

Corrosion Allowance: Default: *0.125* INCHES [*3* MM]

for CS, *0.0* for other materials.

Cladding Materials: See Chapter 28 for cladding materials.

Cladding Thickness: Default: *0.125* INCHES [*3* MM] if

cladding material is specified; otherwise: *0.0*.

Specific Gravity: Range: 0.2 - 5.0; Default: *1.0*.

Diameter Option: Defines desired diameter as ID or OD;

Default: See Area Design Basis.

OD - Outside diameter

ID - Inside diameter

Diam. Flame Arrestor: Range: 1.0 - 8.0 IN DIAM

[25.0 - 200.0 MM DIAM].

Diam. Conserv. Vent: Range: 1.0- 8.0 IN DIAM

[25.0 - 200.0 MM DIAM].

G3 © ICARUS Corporation, 1998.

10-20 ICARUS Reference

Vertical Tanks (VT) continued

Description Type

Cryogenic storage tank - double wall, superinsulated. CRYOGENIC

Shell Material: See Chapter 28 for materials. Default: *SS304*.

Capacity: Enter either capacity or diameter and height.

Range: 300.0 - 60,000.0 GALLONS [1.20 - 227.00 M3].

Diameter: Enter either capacity or diameter and height.

Vessel t-t Height: Enter either capacity or diameter and height.

Design Press. - Gauge: If both pressure and vacuum are entered,

design is for worst case. Default: 250.0 PSIG [1,720 KPA].

Design Vacuum - Gauge: If both pressure and vacuum are

entered, design is for worst case. Default: pressure.

Design Temperature: Default: -320.0 DEG F [-195 DEG C].

Operating Temp.: Default: design temperature.

Jacket Press. - Gauge: Min: -14.70 PSIG [-100.0 KPA];

Default: -14.70 PSIG [-100.0 KPA]

Jacket Material: See Chapter 28 for materials. Default: *CS*.

Skirt Height: Skip if legs are required. Enter ‘0.0’ if hung in

OPEN structure. Default: 1.5 x diameter.

Leg Height: Skip if legs are required. Enter ‘0.0’ if hung in

OPEN structure. Default: 1.5 x diameter.

Wind/Seismic Design: Default: Vessel designed for wind and

seismic loads defined in Project Basis.

W+S - Wind and seismic design required

WIND - Wind design only

SEIS - Seismic design only

NONE - Delete wind and seismic design

Fluid Volume %: For seismic design, fluid volume as a % of

vessel volume (water assumed).

Manhole Diameter: Max: 48.0 INCHES [1,200.0 MM];

Default: 18.0 INCHES [450.0 MM]

Number of Manholes: Default: *0*.

% All. for Internals: Specify an allowance for internals as a

percent of basic vessel height.

Base Mat’l Thickness: Base material thickness including

corrosion allowance.

Corrosion Allowance: Default: 0.125 INCHES [3 MM] for CS,

0.0 for other materials.

Weld Efficiency %: ASME/JIS codes only, where allowed for

thin wall vessels. Range: 50 - 100; Default: Area Basis.

Stress Relief: Default: See Area Design Basis.

CODE - Provide stress relief if code requires

YES - Provide stress relief

NO - No stress relief

Stiff’g Ring Spacing: Default stiffeners designed for vacuum

only, enter ‘0.0’ if not required.

Head Type Symbol:

ELLIP - 2:1 ellipsoidal

HEMI - Hemispherical

TORI - Torispherical (ASME)

Diameter Option: Defines desired diameter as ID or OD.

Default: See Area Design Basis.

OD - Outside diameter

ID - Inside diameter

© ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-21

Vertical Tanks (VT) continued

Description Type

Flat bottom dome top. FRP to 30000 GALLONS [113 M3], PLAST TANK

HAVAG to 7000 GALLONS [26 M3].

Fiberglass Reinforced Plastic Storage Tank: Filament-wound with a

bisphenol - a polyester resin (e.g., Atlac 282). Flat bottom and dome

top under 2.5 PSIG [16.7 KPA], otherwise dished heads.

Haveg Storage Tank.

Material Selection: Default: *FRP*

FRP - FRP

HAVEG - Haveg

Volume: Volume or diameter + height required input

Range: 1,000 - 30,000 GALLONS [3.8 - 113 M3]

Diameter: Volume or diameter + height input.

Max: 12.0 FEET [93.6 M].

Height: Volume or diameter + height required input.

Gauge Pressure: Range: 0.00 - 15.00 PSIG [0 - 100 KPA];

Default: *0.05* PSIG [*0.3* KPA].

Temperature: Max: 300 DEG F [120 DEG C];

Default: *68* DEG F [*20* DEG C].

Wooden storage tanks to 50000 GALLONS [1890 M3]. WOOD TANK

Material Selection: Default: *CYPRS*

CYPRS - Cypress

REDWD - Redwood

PINE - Pine

FIR - Fir

Volume: Volume or diameter + height required input.

Range: 800 - 50,000 GALLONS [3.1 - 189 M3].

Diameter: Volume or diameter + height required input.

Gauge Pressure: Range: 0.0 - 0.05 PSIG [0.0 - 0.3 KPA].

Default: *0.05* PSIG [*0.3* KPA].

Temperature: Max: 250 DEG F [120 DEG C];

Default: *68* DEG F [*20* DEG C].

G3 © ICARUS Corporation, 1998.

10-22 ICARUS Reference

Vertical Tanks (VT) continued

Description Type

Near-Atmospheric Gas Storage

Telescoping gas holder. GAS HOLDER

Low pressure gas vessel.

Shell Material: For clad plate, specify the backing plate material.

See Chapter 28 for materials. Default: *A285C*.

Capacity: Enter either capacity or diameter and height.

Diameter: Enter either capacity or diameter and height.

Height: Enter either capacity or diameter and height.

Design Press. - Gauge: Range: 0.0 - 2.5 PSIG [0.0 - 17 KPA];

Default: *0.05* PSIG [*0.35* KPA].

Design Temperature: Default: *68* DEG F [*20* DEG C].

Operating Temp.: Default: Design temperature.

Manhole Diameter: Max: 48 INCHES [1,200 MM];

Default: *18* INCHES [*450* MM]

Number of Manholes: Default: *1*.

% All. for Internals: Specify an allowance for internals as a

percent of basic vessel weight. Default: *0.0*.

Base Mat’l Thickness: Base material thickness including

corrosion allowance.

Corrosion Allowance: Default: 0.125 INCHES [3 MM] if

cladding material is specified; otherwise 0.0.

Cladding Material: See Chapter 28 for materials.

Cladding Thickness: Default: 0.125 INCHES [3 MM] if

cladding material is specified, otherwise 0.0.

Diameter Option: Defines desired diameter as ID or OD.

Default: - See Area Design Basis.

OD - Outside diameter

ID - Inside diameter

Atmospheric Solid/Liquid Storage

Cone bottom, flat top storage bin. CONE BTM

Shell Material: For clad plate, specify the backing plate material.

See Chapter 28 for materials. Default: *A285C*.

Capacity: Enter either capacity or diameter and height.

Diameter: Enter either capacity or diameter and height.

Height: Enter either capacity or diameter and height.

Design Press. - Gauge: Min: 0.0 PSIG [0.0 KPA];

Default: 0.05 PSIG [0.35 KPA].

Design Temperature: Default: 68 DEG F [20 DEG C] to

0.05 PSI [0.35 KPA]; else 650 DEG F [340 DEG C] ferrous,

250 DEG F [120 DEG C] other.

Operating Temp.: Default: Design temperature.

Leg Height: Enter ‘0.0’ if bin hung in OPEN structure;

Default: *4* FEET [*1.25* M].

Continued on next page

© ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-23

Vertical Tanks (VT) continued

Description Type

CONE BTM - continued

Manhole Diameter: Max: 48 INCHES [1,200 MM];

Default: *18* INCHES [*450* MM].

Number of Manholes: Default: *1*.

% All. for Internals: Specify an allowance for internals as a

percent of basic vessel weight. Default: *0.0*.

Base Mat’l Thickness: Base material thickness including

corrosion allowance.

Corrosion Allowance: Default: *0.125* INCHES [*3* MM] for

CS, *0.0* for other materials.

No. Body Flange Sets: Number of sets (pairs) of body flanges of

same diameter as vessel.

Stress Relief: Default: See Area Design Basis

CODE - Provide stress relief if code requires

YES - Provide stress relief

NO - No stress relief

Cladding Material: See Chapter 28 for materials.

Cladding Thickness: Default *0.125* INCHES [*3* MM] if

cladding material is specified; otherwise: *0.0*.

Bottom Head Tank: Base material thickness including corrosion

allowance.

Top Head Thickness: Base material thickness including corrosion

allowance.

Diameter Option: Defines desired diameter as ID or OD;

Default - see Area Design Basis.

OD - Outside diameter

ID - Inside diameter

ASME Design Basis: Applicable only for ASME code design.

See following entries for fatigue data. Default: *D1NF*.

D1NF - ASME Division 1 - no fatigue analysis

D1F - ASME Division 1 - with fatigue analysis

D2NF - ASME Division 2 - no fatigue analysis

D2F - ASME Division 2 - with fatigue analysis

Start-up Cycles x 1000: ASME fatigue only. Thousands of

start-up cycles during the full equipment life.

Range: 5.00 - 0.02.

Pressure Cycles x 1000: ASME fatigue only. Thousands of

deviations from design pressure during equipment life.

Default: *0*.

Pressure Amplitude %: ASME fatigue only. Amplitude of

process deviation as percent of design pressure. Default: *0*.

No. Hydrostatic Test: ASME fatigue only. Number of

hydrostatic tests during the full equipment life. Default: *0*.

Temp. Cycles x 1000: ASME fatigue only. Thousands of

deviations from design temperature in equipment life.

Default: *0*.

Temp. Amplitude %: ASME fatigue only. Amplitude of

temperature as a percent of design temperature. Default: *0*.

G3 © ICARUS Corporation, 1998.

10-24 ICARUS Reference

Vertical Tanks (VT) continued

Description Type

Live bottom storage bin. LIVE BTM

Shell Material: For clad plate, specify the backing plate material.

See Chapter 28 for materials. Default: *A285C*.

Capacity: Enter either capacity or diameter and height.

Diameter: Enter either capacity or diameter and height.

Height: Enter either capacity or diameter and height.

Design Temperature: Default: *68* DEG F [*20* DEG C]

Operating Temp.: Default: Design temperature.

Leg Height: Enter ‘0.0’ if bin hung in OPEN structure;

Default: *4* FEET [*1.25* M].

Manhole Diameter: Max: 48 INCHES [1,200 MM];

Default: *18* INCHES [*450* MM].

Number of Manholes: Default: *1*.

% All. for Internals: Specify an allowance for internals as a

percent of basic vessel weight. Default: *0.0*.

Base Mat’l Thickness: Base material thickness including

corrosion allowance.

Corrosion Allowance: Default: *0.125* INCHES [*3* MM] for

CS, *0.0* for other materials.

No. Body Flange Sets: Number of sets (pairs) of body flanges of

same diameter as vessel.

Stress Relief: Default: See Area Design Basis.

CODE - Provide stress relief if code requires

YES - Provide stress relief

NO - No stress relief

Cladding Material: See Chapter 28 for materials.

Cladding Thickness: Default *0.125* INCHES [*3* MM] if

cladding material is specified; otherwise: *0.0*.

Diameter Option: Defines desired diameter as ID or OD;

Default - see Area Design Basis.

OD - Outside diameter

ID - Inside diameter

© ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-25

Vertical Tanks (VT) continued

Description Type

Tile Chests

Tile chests provide tile lined tanks for storage of liquids, suspensions or

slurries. Although tile chests are used in the chemical industry, they

are predominantly used in pulp and paper mills for storing fiber

suspensions at various stages of processing. Chests can be

rectangular or cylindrical and may be concrete or metallic. Various

designs are available depending on the nature of the fluid — high

density, low density.

Tile Chests, rectangular concrete include the follow options. CHEST-REC

• Single tile chest

• Group of tile chests

• One chest in a group of chests.

Grouping Option: PARTGRP is used for one chest in

assemblage, WHLGRP to define an entire assemblage.

Default: *PARTGRP*.

SINGLE - Tile chest is a single stand-alone item

PARTGRP - One chest of a multi-group assemblage

WHLGRP - Entire multi-group assemblage

Length: Enter either chest dimensions or capacity.

Height: Enter either chest dimensions or capacity.

Width: Enter either chest dimensions or capacity.

Chest Capacity: Enter either chest dimensions or capacity. For

WHLGRP only - capacity of entire group, otherwise - capacity

this chest.

Tile/Lining Type: Default: *25RSB*

25RSB - 2.5 INCHES [62 MM] red shale brick

45RSB - 4.5 INCHES [112 MM] red shale brick

80RSB - 8.0 INCHES [200 MM] red shale brick

Tile/Lining %: Percent of chest surface to be lined,

100% = one side; 200% = inside + outside. Max: 200;

Default: 100.

Configuration: Default: *OPEN*

OPEN - Open top chest

CLOSED - Chest has a roof

Installation Option: Default: *GRADE*

GRADE - Tile chest is constructed on grade

STRUCT - Tile chest is within a structure

Capacity of Group: For PARTGRP chest only, capacity of entire

group; Default: 4x chest capacity.

No. Chests in Group: For WHLGRP chest only, enter number of

chests in entire assemblage. Default: *4*.

Partition Lengthwise: Number of full length partitions parallel to

length dimension (may be fraction).

Partition Widthwise: Number of width wide partitions parallel to

width dimension (may be fraction).

Continued on next page

G3 © ICARUS Corporation, 1998.

10-26 ICARUS Reference

Vertical Tanks (VT) continued

Description Type

CHEST-REC - continued

Soil Type Symbol:

SOFT CLAY - Bearing: 2000 PSF [100 KN/M2]

FIRM CLAY - Bearing: 4000 PSF [200 KN/M2]

WET SAND - Bearing: 4000 PSF [200 KN/M2]

SAND+CLAY - Bearing: 4000 PSF [200 KN/M2]

DRY SAND - Bearing: 600 PSF [300 KN/M2]

SAND - Bearing: 8000 PSF [400 KN/M2]

GRAVEL - Bearing: 12000 PSF [600 KN/M2]

SOFT ROCK - Bearing: 16000 PSF [800 KN/M2]

HARDPAN - Bearing: 20000 PSF [1000 KN/M2]

MED-ROCK - Bearing: 30000 PSF [1400 KN/M2]

HARD ROCK. - Bearing: 80000 PSF [3800 KN/M2]

Product Density: Default: *62.4* PCF.

Exclude Excavation %: Exclude portion of calculated quantity if

not required or common with other items. Max: 100;

Default: *0.0*.

Exclude Footings %: Exclude portion of calculated quantity if

not required or common with other items. Max: 100;

Default: *0.0*.

Exclude Floor %: Exclude portion of calculated quantity if not

required or common with other items. Max: 100; Default: *0.0*.

Exclude Wall-Length %: Exclude portion of calculated quantity

if not required or common with other items. Max: 100;

Default: *0.0*.

Exclude Wall-Width %: Exclude portion of calculated quantity if

not required or common with other items. Max: 100;

Default: *0.0*.

© ICARUS Corporation, 1998. G3

Chapter 10: Vessels 10-27

Vertical Tanks (VT) continued

Description Type

Tile Chests, Cylindrical

Low density tile chest with a capacity range of 3000 to CHEST-CYL

300000 GALLONS [12 to 1135 M3]. Chest is available in

concrete or metallic materials of construction.

High density tile chest with a capacity range of 30000 to

1300000 GALLONS [114 to 4921 M3]. Chest is available in

concrete or metallic materials of construction.

Shape Symbol: Default: *CYLLD*

CYLLD - Cylindrical chest, low density stock (CYLLD) (CYLHD)

CYLHD - Cylindrical chest, high density stock

Diameter: Chest dimensions or capacity required.

Height: Chest dimensions or capacity required.

Chest Capacity: Chest dimensions or capacity required.

Tile/Lining Type: Default: *25RSB*

25RBS - 2.5 INCH [62 MM] red shale brick

45RSB - 4.5 INCH [112 MM] red shale brick

80RSB - 8.0 INCH [200 MM] red shale brick

Tile/Lining %: Percent of chest to be lined. 100% = one side;

200% = inside + outside. Max: 200; Default: *100*.

Configuration: Default: *OPEN*

OPEN - Open top chest

CLOSED - Chest has a roof

Installation Option: Default: *GRADE*

GRADE - Tile chest is constructed on grade

STRUCT - Tile chest is within a structure

Soil Type Symbol:

SOFT CLAY - Bearing: 2000 PSF [100 KN/M2]

FIRM CLAY - Bearing: 4000 PSF [200 KN/M2]

WET SAND - Bearing: 4000 PSF [200 KN/M2]

SAND+CLAY - Bearing: 4000 PSF [200 KN/M2]

DRY SAND - Bearing: 600 PSF [300 KN/M2]

SAND - Bearing: 8000 PSF [400 KN/M2]

GRAVEL - Bearing: 12000 PSF [600 KN/M2]

SOFT ROCK - Bearing: 16000 PSF [800 KN/M2]

HARDPAN - Bearing: 20000 PSF [1000 KN/M2]

MED-ROCK - Bearing: 30000 PSF [1400 KN/M2]

HARD ROCK. - Bearing: 80000 PSF [3800 KN/M2]

Product Density: Default: *62.4* PCF [1,000 KG/M3].

Exclude Excavation %: Exclude portion of calculated quantity if

not required or common with other items. Max: 100;

Default: *0.0*.

Exclude Footings %: Exclude portion of calculated quantity if

not required or common with other items. Max: 100;

Default: *0.0*.

Exclude Floor %: Exclude portion of calculated quantity if not

required or common with other items. Max: 100; Default: *0.0*.

G3 © ICARUS Corporation, 1998.

10-28 ICARUS Reference

Vertical Tanks (VT) continued

Description Type

Shell Material: For clad plate, specify the backing plate material. CHEST-MTL

(Cladding is defined below.) Default: *A285C*.

Capacity: Enter either capacity or diameter and height.

Diameter: Enter either capacity or diameter and height.

Height: Enter either capacity or diameter and height.

Tile/Lining Type: Default: *25RSB*

25RSB - 2.4 INCH [62 MM] red shale brick

45RSB - 4.5 INCH [112 MM] red shale brick

80RSB - 8.0 INCH [200 MM] red shale brick

Tile/Lining %: Percent of chest surface to be lined.

100% = one side; 200% = inside + outside. Max: 200;

Default: *100*.

Roof Type: Default: *FLAT*

FLAT - Flat roof tank

CONE - Cone roof tank

FLOAT - Floating roof tank

LIFT - Lifter

OPEN - Open top tank

INFLT - Internal floater with flat roof

INCN - Internal floater with cone roof

Design Press. - Gauge: Range: 0 - 2.5 PSIG [0 - 17.0 KPA];

Default: *0.05* PSIG [*0.35* KPA].

Ignore this field for open top tanks.

Design Temperature: Default: *68* DEG F [*20* DEG C].

Operating Temp.: Default: Design temperature.

Manhole Diameter: Max: 48 INCHES [1,200 MM];

Default: *18* INCHES [450.0 MM].

Number of Manholes: Default: *1*.

% All. for Internals: Specify an allowance for internals as a

percent of basic vessel weight. Default: *0.0*.

Base Mat’l Thickness: Base material thickness including

corrosion allowance.

Corrosion Allowance: Default: *0.125* INCHES [*3* MM]

for CS, *0.0* for other materials.

Cladding Material: See Chapter 28 for cladding materials.

Cladding Thickness: Default: *0.125* INCHES [*3* MM]

for cladding material, otherwise *0.0*.

Specific Gravity: Range: 0.2 - 5.0; Default: *1.0*.

Diameter Option: Defines desired diameter as ID or OD.

Default: See Area Design Basis.

Bottom Type: Default: *FLAT*

FLAT - Single flat bottom

DBL - Double bottom

© ICARUS Corporation, 1998. G3

You might also like

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Mechanical Design: Skirt Design Saddle DesignDocument34 pagesMechanical Design: Skirt Design Saddle DesignSUKANTA DALAINo ratings yet

- Welded Pressure Vessel CalculationDocument7 pagesWelded Pressure Vessel CalculationClark Ivan TorresNo ratings yet

- Summary of Pressure Vessel: By. Mohamed Bassuoni Mechanical Consultant Engineer Senior Technical InstructorDocument41 pagesSummary of Pressure Vessel: By. Mohamed Bassuoni Mechanical Consultant Engineer Senior Technical InstructorDHAVAL PANCHALNo ratings yet

- Design Question & AnswerDocument42 pagesDesign Question & AnswerTian Fung Wang100% (1)

- Pressure Vessels: Avoid Costly Design MistakesDocument8 pagesPressure Vessels: Avoid Costly Design Mistakesmarcel linaNo ratings yet

- Project of Pressure VesselDocument25 pagesProject of Pressure VesselGet Sundays83% (40)

- AST - Tank Shell DesignDocument17 pagesAST - Tank Shell DesignAntony Bruno GenewinNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Mechanical Design of Pressure Vessels - Slides PDFDocument29 pagesMechanical Design of Pressure Vessels - Slides PDFYapGwoChaiPatrick100% (2)

- Finite Element Techniques in Ship Structural DesignDocument33 pagesFinite Element Techniques in Ship Structural DesignRahim Can Peker100% (1)

- End Plate Connection (Both Side Flush) - IS800 - 2007 - 2020.04.22Document11 pagesEnd Plate Connection (Both Side Flush) - IS800 - 2007 - 2020.04.22MANOJNo ratings yet

- Structural Analysis of Landing Strut Madeup of Carbon Fibre Composite MaterialDocument7 pagesStructural Analysis of Landing Strut Madeup of Carbon Fibre Composite MaterialMihaela NastaseNo ratings yet

- Project of Pressure VesselDocument25 pagesProject of Pressure VesselKalkidan DanielNo ratings yet

- Pressure Vessel Training ModuleDocument40 pagesPressure Vessel Training ModuleIdil Fitri100% (1)

- Pressure VesselDocument7 pagesPressure VesselTeuku Muhammad ArrahmanNo ratings yet

- NFPA 13 Automatic Sprinkler Systems Handbook 2019 EditionDocument2 pagesNFPA 13 Automatic Sprinkler Systems Handbook 2019 EditionAob April0% (3)

- Design of Pressure Vessel 1Document55 pagesDesign of Pressure Vessel 1Ezio3511No ratings yet

- Advanced Drilling Practices - Casing DesignDocument92 pagesAdvanced Drilling Practices - Casing DesignGFarizNo ratings yet

- Intro To Pressure VesselDocument19 pagesIntro To Pressure VesselMuhammad Ridhwan100% (1)

- Advanced Drilling Practices - Casing DesignDocument92 pagesAdvanced Drilling Practices - Casing DesignAnonymous H9n5g3aaCENo ratings yet

- Root Cause AC Motor Failure Analysis With Focus On Shaft FailuresDocument43 pagesRoot Cause AC Motor Failure Analysis With Focus On Shaft Failuresharshal161987100% (1)

- What Is Design Interpretation?Document17 pagesWhat Is Design Interpretation?Qaisir MehmoodNo ratings yet

- 3000-DC-2090-4 - Standard Pipe Support DrawingDocument137 pages3000-DC-2090-4 - Standard Pipe Support DrawingAob AprilNo ratings yet

- FreeseDocument15 pagesFreeseBrandon HaleNo ratings yet

- CPE 601 - Pressure VesselDocument126 pagesCPE 601 - Pressure VesselI-hana D'yana100% (1)

- FEA Study On LPG BulletsDocument8 pagesFEA Study On LPG BulletsSpyros DimakisNo ratings yet

- Pressure Vessels ModDocument38 pagesPressure Vessels ModShivahari GopalakrishnanNo ratings yet

- Basic API650-Training PDFDocument75 pagesBasic API650-Training PDFDivyesh PatelNo ratings yet

- Advanced Drilling Practices - Casing Design PDFDocument92 pagesAdvanced Drilling Practices - Casing Design PDFAnonymous H9n5g3aaCE100% (1)

- Static Equipment Updated 1Document37 pagesStatic Equipment Updated 1k.sankaranand100% (2)

- Pressure Vessel Design: Chapter 13: Mechanical Design of Process Equipment by Towler & SinnotDocument40 pagesPressure Vessel Design: Chapter 13: Mechanical Design of Process Equipment by Towler & SinnotEzekielNo ratings yet

- PVElite Design GuidelinesDocument7 pagesPVElite Design Guidelinesndrarly100% (2)

- Pressure Vessel Costly MistakeDocument11 pagesPressure Vessel Costly MistakearjayNo ratings yet

- Vessel DesignDocument28 pagesVessel DesignDinda Naiya AzhariNo ratings yet

- Storage TanksDocument62 pagesStorage Tankstoychom2013No ratings yet

- Vessels LDocument34 pagesVessels LMohammed.abudi1996No ratings yet

- ChE 192 Handout 6a (Storage Tank)Document4 pagesChE 192 Handout 6a (Storage Tank)Aiza CabolesNo ratings yet

- Chapter One: 1.1) Introduction of Pressure VesselDocument55 pagesChapter One: 1.1) Introduction of Pressure VesselAbenezer BirhanuNo ratings yet

- Lecture Mechanical Design of Heat ExchangerDocument46 pagesLecture Mechanical Design of Heat ExchangerDawitNo ratings yet

- Ambo University Hachalu Hundessa CampusDocument22 pagesAmbo University Hachalu Hundessa Campusmagnifco100% (1)

- Project of Pressure VesselDocument23 pagesProject of Pressure VesselMengist GezehagnNo ratings yet

- Vessel VolumesDocument72 pagesVessel VolumesPaula RiveraNo ratings yet

- DP2 Process Design Guidelines With Example Storage Tank DesignDocument4 pagesDP2 Process Design Guidelines With Example Storage Tank DesignNicholasBeresfordNo ratings yet

- Pressure Vessel 1Document12 pagesPressure Vessel 1Deteu CabadongaNo ratings yet

- Pressure Vessel Design by Biruk Solomon BadeDocument76 pagesPressure Vessel Design by Biruk Solomon BadebrookNo ratings yet

- Lecture 8 - MDPE - Design of Nozzles & FlangeDocument26 pagesLecture 8 - MDPE - Design of Nozzles & FlangePatel DhruvilNo ratings yet

- Tks 3245 Perancangan Alat ProsesDocument38 pagesTks 3245 Perancangan Alat Prosesfadhillah ivanNo ratings yet

- PR VesselDocument10 pagesPR Vesselmayukhguhanita2010No ratings yet

- Interview Question.Document7 pagesInterview Question.PankajDhobleNo ratings yet

- Stilling Well PDFDocument13 pagesStilling Well PDFRitesh VishambhariNo ratings yet

- 510 PC Oct04 Qar-Ex1 Closed PSJDocument5 pages510 PC Oct04 Qar-Ex1 Closed PSJCss SfaxienNo ratings yet

- ASTM D1998-97 Section 9.1.3 Thickness Requirements (An Explanation)Document3 pagesASTM D1998-97 Section 9.1.3 Thickness Requirements (An Explanation)Sabrine Ben HmidaNo ratings yet

- Designofpressurevessel 151204055815 Lva1 App6892 PDFDocument19 pagesDesignofpressurevessel 151204055815 Lva1 App6892 PDFQuang VinhhNo ratings yet

- 3.1 Container DesignDocument43 pages3.1 Container Designswami nathanNo ratings yet

- Lecture 4 - Storage SystemsDocument25 pagesLecture 4 - Storage SystemsLouie GresulaNo ratings yet

- Mechanical Design and Design CriteriaDocument32 pagesMechanical Design and Design CriteriaGhost RileyNo ratings yet

- DOUBLE TEES - Technical Data: Span-Load Tables Design Criteria Tolerances Strand LocationsDocument42 pagesDOUBLE TEES - Technical Data: Span-Load Tables Design Criteria Tolerances Strand LocationsRebaz A. OthmanNo ratings yet

- What Is Design Interpretation?Document15 pagesWhat Is Design Interpretation?dhirajNo ratings yet

- Dire Dawa Institute of Technology: Departement of Mechanical EngineeringDocument87 pagesDire Dawa Institute of Technology: Departement of Mechanical EngineeringaberNo ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168From EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168No ratings yet

- Two Clamped Pipe Support Connections For Oil and Gas Brownfield PDocument52 pagesTwo Clamped Pipe Support Connections For Oil and Gas Brownfield PAob AprilNo ratings yet

- Redacted EmailsDocument5 pagesRedacted EmailsAob AprilNo ratings yet

- Hydrant Bolt DetailDocument1 pageHydrant Bolt DetailAob AprilNo ratings yet

- Deluge Valve SystemDocument16 pagesDeluge Valve SystemAob AprilNo ratings yet

- Fire Fighting Drawing: Blow Film Building ComplianceDocument4 pagesFire Fighting Drawing: Blow Film Building ComplianceAob AprilNo ratings yet

- Hydraulic Report - Fire Water For Transforme - 0Document1 pageHydraulic Report - Fire Water For Transforme - 0Aob AprilNo ratings yet

- Delugue Valve. Viking. 1.5 A 2pulg PDFDocument8 pagesDelugue Valve. Viking. 1.5 A 2pulg PDFcmarinvzlaNo ratings yet

- Fire Fighting Drawing: Blow Film Building ComplianceDocument13 pagesFire Fighting Drawing: Blow Film Building ComplianceAob AprilNo ratings yet

- Fire Fighting Drawing: Blow Film Building ComplianceDocument19 pagesFire Fighting Drawing: Blow Film Building ComplianceAob AprilNo ratings yet

- Class Notes - PDF Solids1Document96 pagesClass Notes - PDF Solids1joeNo ratings yet

- SynopsisDocument244 pagesSynopsisAfewerkNo ratings yet

- MCEN1000 Engineering Mechanics Semester 1 2024 Bentley Perth Campus INTDocument15 pagesMCEN1000 Engineering Mechanics Semester 1 2024 Bentley Perth Campus INTjissmon jojoNo ratings yet

- A Back-Analysis of Beliche DamDocument13 pagesA Back-Analysis of Beliche DamOscar EduardoNo ratings yet

- Warping Constant of Open Sections With Arbitrary Profile Geometry Rev 1 2011Document24 pagesWarping Constant of Open Sections With Arbitrary Profile Geometry Rev 1 2011hoojzteNo ratings yet

- Viscosity - WikipediaDocument7 pagesViscosity - WikipediazigaNo ratings yet

- Torsion: Design of Reinforced Concrete Structures IDocument15 pagesTorsion: Design of Reinforced Concrete Structures IMuhammad Junaid100% (1)

- 2017 A10Document2 pages2017 A10Vy ThoaiNo ratings yet

- FEA Analysis of Rectangular Pressure Vessel BoxesDocument13 pagesFEA Analysis of Rectangular Pressure Vessel BoxesIJARSCT JournalNo ratings yet

- Homework GCDocument44 pagesHomework GCThường PhạmNo ratings yet

- Base Plate Analysis Document: 1. TheoryDocument6 pagesBase Plate Analysis Document: 1. TheoryCellprop pvt.No ratings yet

- 7-Geohazards and Disaster MitigationDocument93 pages7-Geohazards and Disaster MitigationAnonymous U6pIEKQghNo ratings yet

- 9 - Åsa - Sällström - Fatigue - Analysis - at - Volvo - Cars Using - DesignLifeDocument19 pages9 - Åsa - Sällström - Fatigue - Analysis - at - Volvo - Cars Using - DesignLifeÖzgün KüçükNo ratings yet

- Corrosion Science: Y. Garbatov, C. Guedes Soares, J. Parunov, J. KodvanjDocument8 pagesCorrosion Science: Y. Garbatov, C. Guedes Soares, J. Parunov, J. KodvanjSachin SukumaranNo ratings yet

- 3 - 2 - MAT601 - FormingDocument19 pages3 - 2 - MAT601 - FormingJOENo ratings yet

- Discussion - Yield Line Analysis of Bolted Hanging ConnectionsDocument1 pageDiscussion - Yield Line Analysis of Bolted Hanging ConnectionsRob TamaccioNo ratings yet

- FinalDocument33 pagesFinalAnonymous sfkedkymNo ratings yet

- Formulas To RememberDocument6 pagesFormulas To Rememberuygurzeren100% (3)

- Gradient Damage Models Coupled With PlasticityDocument17 pagesGradient Damage Models Coupled With PlasticityMiroslav ZivkovicNo ratings yet

- Plane Stress Analysis by FEMDocument30 pagesPlane Stress Analysis by FEMtesfaye gurmesaNo ratings yet

- Machine Design - Lesson 14 Design of ShaftsDocument4 pagesMachine Design - Lesson 14 Design of ShaftsgkarthikeyanNo ratings yet

- STRENGTHDocument16 pagesSTRENGTHJoshBarnacheaNo ratings yet

- SpringDocument16 pagesSpringamitautomaticNo ratings yet

- Chapter 4. Inverse Analysis Procedures For Determining The Tensile Stress-Crack Opening Curve of ConcreteDocument9 pagesChapter 4. Inverse Analysis Procedures For Determining The Tensile Stress-Crack Opening Curve of ConcreteourebooksNo ratings yet

- The Tire CompositeDocument17 pagesThe Tire CompositeDildeep PallipadNo ratings yet