Professional Documents

Culture Documents

Taller Ciclos de Potencia de Vapor 2019 II

Uploaded by

JalverAndresCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Taller Ciclos de Potencia de Vapor 2019 II

Uploaded by

JalverAndresCopyright:

Available Formats

Universidad de Pamplona

Facultad de Ingeniería y Arquitectura

Programa Ingeniería Mecánica

Termofluidos III

Taller Ciclos de Potencia de vapor. 3 INTEGRANTES

Entrega: 25 de noviembre de 2019

Profesor: Juan Carlos Serrano Rico

1. Steam enters the first turbine stage of a vapor power cycle with reheat and regeneration at 32

MPa, 600C, and expands to 8 MPa. A portion of the flow is diverted to a closed feedwater heater at 8

MPa, and the remainder is reheated to 560C before entering the second turbine stage. Expansion through

the second turbine stage occurs to 1 MPa, where another portion of the flow is diverted to a second closed

feedwater heater at 1 MPa. The remainder of the flow expands through the third turbine stage to 0.15

MPa, where a portion of the flow is diverted to an open feedwater heater operating at 0.15 MPa, and the

rest expands through the fourth turbine stage to the condenser pressure of 6 kPa. Condensate leaves each

closed feedwater heater as saturated liquid at the respective extraction pressure. The feedwater streams

leave each closed feedwater heater at a temperature equal to the saturation temperature at the respective

extraction pressure. The condensate streams from the closed heaters each pass through traps into the next

lower-pressure feedwater heater. Saturated liquid exiting the open heater is pumped to the steam

generator pressure. If each turbine stage has an isentropic efficiency of 85% and the pumps operate

isentropically.

a. Sketch the layout of the cycle and number the principal state points.

b. Determine the thermal efficiency of the cycle.

c. Calculate the mass flow rate into the first turbine stage, in kg/h, for a net power output of 500 MW.

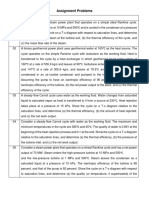

2. Figure P2 shows the schematic diagram of a

cogeneration cycle. In the steam cycle, superheated

vapor enters the turbine with a mass flow rate of 5 kg/s

at 40 bar, 440C and expands isentropically to 1.5 bar.

Half of the flow is extracted at 1.5 bar and used for

industrial process heating. The rest of the steam passes

through a heat exchanger, which serves as the boiler of

the Refrigerant 134a cycle and the condenser of the

steam cycle. The condensate leaves the heat

exchanger as saturated liquid at 1 bar, where it is

combined with the return flow from the process, at 60C

and 1 bar, before being pumped isentropically to the

steam generator pressure. The Refrigerant 134a cycle is

an ideal Rankine cycle with refrigerant entering the

turbine at 16 bar, 100C and saturated liquid leaving the

condenser at 9 bar. Determine,

a. The rate of heat transfer to the working fluid

passing through the steam generator of the steam cycle.

b. The net power output of the binary cycle.

c. The rate of heat transfer to the industrial process.

d. For the heat exchanger unit, determine the net

rate at which exergy is carried in by the gas stream,

the net rate at which exergy is carried out by the water Fig. P2

stream, and the rate of exergy destruction.

You might also like

- Problemario MFCDocument31 pagesProblemario MFCPonce MrlnNo ratings yet

- Problem-Set 2Document20 pagesProblem-Set 2ERROLL ZANDRE NACAYA ANOBARNo ratings yet

- Sheet (3) Regenerative Rankine Cycle A. Review QuestionsDocument6 pagesSheet (3) Regenerative Rankine Cycle A. Review QuestionsHamadaMohassabNo ratings yet

- Problemario MFCDocument80 pagesProblemario MFCBassaldua AlfreedNo ratings yet

- Vapor Power CyclesDocument27 pagesVapor Power Cycleshrithik khannaNo ratings yet

- Problem Set 1Document3 pagesProblem Set 1Anagha ChimankarNo ratings yet

- Tugas 2 MS2230 Sem II 18-19 PDFDocument1 pageTugas 2 MS2230 Sem II 18-19 PDFHanif MuhammadNo ratings yet

- Tutorium steamPowerPlantDocument4 pagesTutorium steamPowerPlantQue LanNo ratings yet

- Assign#4 Vapor CycleDocument3 pagesAssign#4 Vapor Cyclemihreteab ghebregzabherNo ratings yet

- Tutorial Vapor and Combined Power CyclesDocument3 pagesTutorial Vapor and Combined Power CyclesShariff Mohamad Fairuz0% (1)

- Assignemnt 3Document3 pagesAssignemnt 3Nabeel AhmedNo ratings yet

- ME LAB 3 ReportDocument37 pagesME LAB 3 ReportwijawijaNo ratings yet

- #Lecture 2 - Review of Steam Power CyclesDocument27 pages#Lecture 2 - Review of Steam Power Cyclesmohamed EldesokyNo ratings yet

- Electric CarsDocument48 pagesElectric Carsabdokhamis000No ratings yet

- Assignment and Its Solution - Airstandardcycle and VapourcycleDocument24 pagesAssignment and Its Solution - Airstandardcycle and VapourcycleMatthias100% (1)

- Worksheet-1 (Analysis of Steam Power Cycle)Document2 pagesWorksheet-1 (Analysis of Steam Power Cycle)ebrahim aliNo ratings yet

- Vapour Power Cycle - Part 2Document18 pagesVapour Power Cycle - Part 2Shwe Wen LimNo ratings yet

- PPE AssignmentDocument3 pagesPPE AssignmentAshish Kumar SahuNo ratings yet

- DR Ali Jawarneh, Thermodynamics-II: Chapter-10Document12 pagesDR Ali Jawarneh, Thermodynamics-II: Chapter-10احمد حمديNo ratings yet

- Tutorial 1Document4 pagesTutorial 1Anonymous lV8E5mEONo ratings yet

- HW 5 Problem SetDocument3 pagesHW 5 Problem SetJustinTimeNo ratings yet

- FME 421 Thermodynamics IV TutorialDocument3 pagesFME 421 Thermodynamics IV TutorialSebastian AnnanakiNo ratings yet

- 01-Sheet 01Document9 pages01-Sheet 01samir mohamedNo ratings yet

- 8.1prob Sheet Vapor Power CyclesDocument3 pages8.1prob Sheet Vapor Power CyclesAnonymous mXicTi8hB100% (1)

- ASSIGNMENT Me PDFDocument3 pagesASSIGNMENT Me PDFmahfuzNo ratings yet

- Vapor Power Cycles Chapters 10 & 11Document2 pagesVapor Power Cycles Chapters 10 & 11MaykaMidreliDeandraLigutomNo ratings yet

- Vapour and Combine Power CyclesDocument4 pagesVapour and Combine Power CyclesKishore KrishNo ratings yet

- Rankine CycleDocument4 pagesRankine CyclerasekakmNo ratings yet

- Assignment: Problem Solving and Critical Thinking Based QuestionsDocument3 pagesAssignment: Problem Solving and Critical Thinking Based Questionsshashi polojuNo ratings yet

- Wor ShopDocument4 pagesWor ShopDavid Santiago Ayala RodriguezNo ratings yet

- Soal Latihan Termodinamika IIDocument5 pagesSoal Latihan Termodinamika IIPur NomoNo ratings yet

- Tarea de CiclosDocument6 pagesTarea de CiclosSebastiánGarcía100% (1)

- Taller IV - Primera Ley Sistemas Abiertos Primera ParteDocument2 pagesTaller IV - Primera Ley Sistemas Abiertos Primera ParteSteven Gonzalez CardonaNo ratings yet

- Trabajo de Termo Segundo Corte.Document4 pagesTrabajo de Termo Segundo Corte.Marlon HerreraNo ratings yet

- Thermo of MechDocument2 pagesThermo of MecheyobNo ratings yet

- Steam Cycles TutorialsDocument1 pageSteam Cycles TutorialsSakhile Nhlakanipho ZithaNo ratings yet

- Kmem 2216 - Al2Document1 pageKmem 2216 - Al2Daniel WongNo ratings yet

- 11me201 Thermodynamics QuestionsDocument12 pages11me201 Thermodynamics QuestionsJustin Cox0% (2)

- Contoh Penyelesain Soal Termo DuaDocument44 pagesContoh Penyelesain Soal Termo DuaNuisma MaharaniNo ratings yet

- Taller Iv - Primera Ley Sistemas Abiertos Primera ParteDocument2 pagesTaller Iv - Primera Ley Sistemas Abiertos Primera ParteJorge Gomez0% (1)

- Problems On Rankine Cycle - PDFDocument1 pageProblems On Rankine Cycle - PDFchristo_nitinNo ratings yet

- Tutorial 5 - Steam Power CycleDocument2 pagesTutorial 5 - Steam Power CycleDilshan VimukthiNo ratings yet

- Sheet (2) Reheat Rankine CycleDocument4 pagesSheet (2) Reheat Rankine CycleHamadaMohassabNo ratings yet

- Reheat ProblemsDocument1 pageReheat ProblemsJohn paulo ulepNo ratings yet

- 11me201 Thermodynamics QuestionsDocument12 pages11me201 Thermodynamics QuestionsramsastryNo ratings yet

- Vapour Power CycleDocument43 pagesVapour Power CycleSuman HanumanthaNo ratings yet

- Energy Engineering Question Bank - NSDocument7 pagesEnergy Engineering Question Bank - NSNilesh Singh100% (1)

- Aços Carbono Construção CivilDocument5 pagesAços Carbono Construção CivilIrvin WilliamNo ratings yet

- Steam TturbineDocument2 pagesSteam Tturbinemanish_chaturvedi_6No ratings yet

- ETD AssignmentDocument1 pageETD AssignmentbipincitNo ratings yet

- Two Mark Questions: (A) The Exit Velocity, in M/sDocument2 pagesTwo Mark Questions: (A) The Exit Velocity, in M/sRajvir Preet GillNo ratings yet

- Assignment: EME2146 Applied ThermodynamicsDocument1 pageAssignment: EME2146 Applied ThermodynamicsErlangga Sulaiman RazakNo ratings yet

- ATD RAnkin Assignment-2011Document3 pagesATD RAnkin Assignment-2011Mradul Yadav0% (2)

- Contoh Soal TermodinamikaDocument24 pagesContoh Soal TermodinamikaDea FarhaniNo ratings yet

- Thermo ProblemsDocument12 pagesThermo ProblemsElaineNo ratings yet

- Bda 30403Document12 pagesBda 30403wanpudinNo ratings yet

- PSS Ebook 2 GPC SEC ColumnsDocument30 pagesPSS Ebook 2 GPC SEC ColumnselenitabastosNo ratings yet

- Moringa Oleifera Seed As Antibacterial Agent in Water TreatmentDocument6 pagesMoringa Oleifera Seed As Antibacterial Agent in Water TreatmentStephen MooreNo ratings yet

- Experiment 1: Determination of Corrosion Rate of Metals: ObjectiveDocument3 pagesExperiment 1: Determination of Corrosion Rate of Metals: Objective041Mir QazimNo ratings yet

- 4 WP 2013Document8 pages4 WP 2013TUTORKIMNo ratings yet

- Redox ReactionsDocument15 pagesRedox ReactionsAdarsh YadavNo ratings yet

- Bioactive Materials: Presented By-Dr Kajal Bhayani Mds 1 YearDocument78 pagesBioactive Materials: Presented By-Dr Kajal Bhayani Mds 1 YearVidhi ThakurNo ratings yet

- GRADE 6 Ekam - EnaChem (Mixtures)Document4 pagesGRADE 6 Ekam - EnaChem (Mixtures)praschNo ratings yet

- Personal Care: Industrial & Consumer SpecialtiesDocument17 pagesPersonal Care: Industrial & Consumer Specialtiescontentdrive4 drive4No ratings yet

- Petronas Technical Standards: The Design of Glycol ContactorsDocument47 pagesPetronas Technical Standards: The Design of Glycol ContactorsadamNo ratings yet

- Yunus 2014Document10 pagesYunus 2014La Ode Muhamad RusliNo ratings yet

- Concrete Slump Test or Slump Cone TestDocument4 pagesConcrete Slump Test or Slump Cone TestEljoy C. AgsamosamNo ratings yet

- The Complexometric Determination of Calcium and Magnesium in The Same SampleDocument3 pagesThe Complexometric Determination of Calcium and Magnesium in The Same SampleRieska foni YuniarNo ratings yet

- Boilerasn 160513140404Document17 pagesBoilerasn 160513140404jeremygilbertNo ratings yet

- Corrosion Mechanism Prevention Repair Measures of RCC StructureDocument217 pagesCorrosion Mechanism Prevention Repair Measures of RCC StructureAvinash Mandal100% (1)

- Effect of The Tilt Angle of Natural Convection in A Solar Collector With Internal Longitudinal FinsDocument5 pagesEffect of The Tilt Angle of Natural Convection in A Solar Collector With Internal Longitudinal FinsInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Epoxy Curing Agents and ModifiersDocument3 pagesEpoxy Curing Agents and ModifiersNissim Hazar CasanovaNo ratings yet

- 01 CVNG 1005 - Materials LabDocument6 pages01 CVNG 1005 - Materials LabMarly MarlNo ratings yet

- Science: Quarter 4 - Module 2 - Week 2 Behavior of Gases Part 2Document20 pagesScience: Quarter 4 - Module 2 - Week 2 Behavior of Gases Part 2Mary Ann100% (1)

- TLC Staining Procedure TLC Stain Recipe Stain Chemistry / Physics CommentsDocument3 pagesTLC Staining Procedure TLC Stain Recipe Stain Chemistry / Physics CommentsLara DiasNo ratings yet

- Kobel CoDocument4 pagesKobel CoCesar ZarateNo ratings yet

- Stepan: Bio-Terge As-90 BeadsDocument2 pagesStepan: Bio-Terge As-90 BeadsJerily Alzate TapiasNo ratings yet

- The Millennium School, Kurukshetra UT-I (2021-22) Class XI: EnglishDocument3 pagesThe Millennium School, Kurukshetra UT-I (2021-22) Class XI: EnglishYuvraj SinghNo ratings yet

- MT - CatFines-KIT PDFDocument12 pagesMT - CatFines-KIT PDFStefas DimitriosNo ratings yet

- Agstar Operator GuidebookDocument77 pagesAgstar Operator GuidebookQuinta EsenciaNo ratings yet

- Transport MechanismsDocument1 pageTransport MechanismsJayrelle D. SafranNo ratings yet

- Oil and Gas DictionaryDocument47 pagesOil and Gas DictionaryMakutenko Makutenko100% (4)

- Science Reviewer 3rd GradingDocument7 pagesScience Reviewer 3rd GradingSean Irvin MirandaNo ratings yet

- Kluber PresentationDocument79 pagesKluber PresentationZegera MgendiNo ratings yet

- McCabe-Thiele Method 1Document37 pagesMcCabe-Thiele Method 1HariKrishnaBushi100% (2)

- PPIIDocument1,106 pagesPPIIVineeta SharmaNo ratings yet