Professional Documents

Culture Documents

File

Uploaded by

Giang TônCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

File

Uploaded by

Giang TônCopyright:

Available Formats

A-3

Exercise 1

Hydraulics Subject

Automatic lathe Title

To teach the student how to draw the characteristic curve for a pump Training aim

Drawing the hydraulic circuit diagram Problem definition

Practical assembly of the circuit

Determining the various measured values and entering them into the

table

Drawing the characteristic curve for the pump

Drawing conclusions

TP501 • Festo Didactic

A-4

Exercise 1

Exercise The main spindle on an automatic lathe is driven by a hydraulic motor,

while a hydraulic cylinder is used to execute a feed movement of the

workpiece slide. It has been established that the specified speed is no

longer reached during the processing cycle. The pump characteristic

curve is therefore to be evaluated.

Positional sketch

TP501 • Festo Didactic

A-5

Exercise 1

EXERCISE SHEET

System pressure p 15 20 25 30 35 40 45 50 bar Evaluation

Flow rate q l/min

Pump characteristic

How does the flow rate change as the pressure increases? Conclusion

TP501 • Festo Didactic

C-3

Solution 1

Automatic lathe

Circuit diagram, hydraulic

Practical assembly,

hydraulic

TP501 • Festo Didactic

C-4

Solution 1

Components list Item no. Qty. Description

0Z1 1 Hydraulic power pack

0Z2 1 Pressure gauge

1V 1 Shut-off valve

1S 1 Flow sensor

3 Hose line

Solution description Once the hydraulic circuit has been assembled, valve 1V should be fully

opened. Now close this valve slowly to set the first p value as shown on

the pressure gauge 0Z2. The maximum attainable pressure is 60 bar,

governed by a pressure relief valve built into the pump which is set to

this value.

Evaluation System pressure p 15 20 25 30 35 40 45 50 bar

Flow rate q 2.33 2.31 2.29 2.28 2.26 2.24 2.22 2.20 l/min

Pump characteristic

TP501 • Festo Didactic

C-5

Solution 1

As the pressure rises, the pump delivery falls slightly. In theory, the Conclusions

characteristic curve for the pump should be a straight line.The decrease

in pump delivery is due to internal leakage losses, which become

greater as the pressure increases The ratio of the measured pump de-

livery and theoretical pump delivery is the effective volumetric efficiency

of the pump.

For technical reasons, the actual value recorded in this exercise is the

power consumption of the electric motor or the premature opening of the

pressure relief valve. The pump is dimensioned for a maximum pressure

of 250 bar (see data sheet). An electric motor with an appropriately high

rating would be required to achieve this. This would not, however, be

meaningful, since the exercises are carried out with a maximum pres-

sure of 60 bar.

TP501 • Festo Didactic

You might also like

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Conveyor Tensioning Device: TP501 Festo DidacticDocument9 pagesConveyor Tensioning Device: TP501 Festo DidacticGiang TônNo ratings yet

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- A05 PDFDocument8 pagesA05 PDFElmeysNo ratings yet

- Ferry Loading Ramp: TP501 Festo DidacticDocument9 pagesFerry Loading Ramp: TP501 Festo Didacticnanek100% (1)

- Skip Handling: TP501 Festo DidacticDocument7 pagesSkip Handling: TP501 Festo DidacticHossam AbdelhameedNo ratings yet

- Hardening FurnanceDocument8 pagesHardening FurnanceFerariF.ArdiansyahNo ratings yet

- Analog Circuit Design Volume 2: Immersion in the Black Art of Analog DesignFrom EverandAnalog Circuit Design Volume 2: Immersion in the Black Art of Analog DesignNo ratings yet

- Exercise 20Document7 pagesExercise 20islamNo ratings yet

- Manual 1B 01142022Document15 pagesManual 1B 01142022sona-08No ratings yet

- 14.صمام تخفيض الضغط الاتناسبي الكهربائيDocument5 pages14.صمام تخفيض الضغط الاتناسبي الكهربائيالمهندسوليدالطويلNo ratings yet

- Beaker Installation.: Hydraulic Circuit For BreakerDocument7 pagesBeaker Installation.: Hydraulic Circuit For BreakerMasterrNo ratings yet

- Pump EfficiencyDocument14 pagesPump EfficiencyWHfamilyNo ratings yet

- Valve Technology: - by Fabian C. GonzalezDocument106 pagesValve Technology: - by Fabian C. GonzalezNyoman RakaNo ratings yet

- Solenoid Valves (Implement) 966Document6 pagesSolenoid Valves (Implement) 966Ahmed RezkNo ratings yet

- Breaker Piping InstallationDocument11 pagesBreaker Piping InstallationZawminhtunNo ratings yet

- Group 13 Eppr ValveDocument5 pagesGroup 13 Eppr ValveDado OgameNo ratings yet

- Fluid Report Spongbob SquarepantsDocument64 pagesFluid Report Spongbob SquarepantsGehad EssamNo ratings yet

- Control Valve Characteristics StudyDocument19 pagesControl Valve Characteristics StudydhruvNo ratings yet

- Stamping Machine: TP601 Festo DidacticDocument8 pagesStamping Machine: TP601 Festo DidacticSanjar MirzalievNo ratings yet

- Preliminary - MITTEN HPU Only Rev DDocument120 pagesPreliminary - MITTEN HPU Only Rev DFabyano BrittoNo ratings yet

- Improve Control: Level LoopsDocument8 pagesImprove Control: Level LoopsCraigUnderwoodNo ratings yet

- HP135 gear pump testDocument9 pagesHP135 gear pump testPietro Ian AbdonNo ratings yet

- Exp 5 Pump TestDocument5 pagesExp 5 Pump TestalexNo ratings yet

- Introduction to Servo HydraulicsDocument25 pagesIntroduction to Servo HydraulicshellfireNo ratings yet

- Lecture 1 ElectrohydraulicsDocument62 pagesLecture 1 ElectrohydraulicsAhmedNo ratings yet

- ABB TestDocument47 pagesABB TestỐng KhóiNo ratings yet

- GROUP 5 EPPR (Electro Proportional Pressure Reducing) VALVEDocument3 pagesGROUP 5 EPPR (Electro Proportional Pressure Reducing) VALVERiahi RezegNo ratings yet

- Centrifugal Pump CharacteristicsDocument16 pagesCentrifugal Pump CharacteristicsHannan AyubNo ratings yet

- 2142 2 Frequency Response: Semester 5Document9 pages2142 2 Frequency Response: Semester 5Dwayne JohnsonNo ratings yet

- Chapter 2 Hyd PumpDocument8 pagesChapter 2 Hyd PumpManuelNo ratings yet

- Proportional Hydraulics Decoded PDFDocument63 pagesProportional Hydraulics Decoded PDFRobert MarkovskiNo ratings yet

- Part 4 Hydraulic Control Principle and ParametersDocument22 pagesPart 4 Hydraulic Control Principle and ParametersrohanNo ratings yet

- L3 Actuator PDFDocument23 pagesL3 Actuator PDFharishcsharmaNo ratings yet

- Motion control valvesDocument1 pageMotion control valvesSLK Amg55No ratings yet

- GROUP 13 EPPR VALVE OPERATION AND TESTINGDocument6 pagesGROUP 13 EPPR VALVE OPERATION AND TESTINGdeniden2013No ratings yet

- KNC 1101 Chemical Engineering Laboratory I Experiment ManualDocument36 pagesKNC 1101 Chemical Engineering Laboratory I Experiment ManualIzzatiHazwaniNo ratings yet

- Technical Service Manual GuideDocument38 pagesTechnical Service Manual GuideJose Luis DiazNo ratings yet

- Report PumpDocument14 pagesReport PumpDarsshan BatumalaiNo ratings yet

- Workshop Manual Section 1 Heating and Air Conditioning TroubleshootingDocument125 pagesWorkshop Manual Section 1 Heating and Air Conditioning TroubleshootingDmitry BondarNo ratings yet

- Service Manual - Lid45w13n (7312d)Document37 pagesService Manual - Lid45w13n (7312d)jupecas matosinhosNo ratings yet

- Open Ended LabDocument6 pagesOpen Ended LabVishal DhimanNo ratings yet

- S-Lab Manual Exp 6 - Level Flow Process Control (Electronic)Document14 pagesS-Lab Manual Exp 6 - Level Flow Process Control (Electronic)IzhamGhazi0% (1)

- Analysis of Single Pump CharacteristicsDocument8 pagesAnalysis of Single Pump CharacteristicsMuhammad Abdullah Zafar GhauriNo ratings yet

- Control Chapter 5 - RemoteDocument87 pagesControl Chapter 5 - RemoteJhonny PerezNo ratings yet

- Experiment Title: Control Tuning: Figure 1: General Schematic of Feedback ControlDocument9 pagesExperiment Title: Control Tuning: Figure 1: General Schematic of Feedback ControlSehry SyedNo ratings yet

- Training Servo Hydraulic Drive Systems 36Document61 pagesTraining Servo Hydraulic Drive Systems 36Gary Jenkins100% (4)

- Experiment 5: To Create A Pump Characteristic Curve & Be Able To Interpret ItDocument6 pagesExperiment 5: To Create A Pump Characteristic Curve & Be Able To Interpret ItKamil Rasheed SiddiquiNo ratings yet

- Experiment (1) Calibration and Characteristics of A Motorized ValveDocument41 pagesExperiment (1) Calibration and Characteristics of A Motorized ValveKhalid M MohammedNo ratings yet

- Frequency ResponseDocument10 pagesFrequency ResponseClementNo ratings yet

- Vdocuments - MX Cameron Bop Control SystemsDocument38 pagesVdocuments - MX Cameron Bop Control SystemsOPERACIONES TOP OILNo ratings yet

- Control Valve CharacteristicsDocument5 pagesControl Valve CharacteristicsFarhan HazeeqNo ratings yet

- SK330 Trouble Shoot (By Trouble)Document36 pagesSK330 Trouble Shoot (By Trouble)ferdyak1No ratings yet

- Rowan Rig 0082 BOP Control System Operation and Maintenance ManualDocument38 pagesRowan Rig 0082 BOP Control System Operation and Maintenance Manualcarlosorizaba100% (1)

- Lube Oil Function Test ProcedureDocument4 pagesLube Oil Function Test ProcedurebeyNo ratings yet

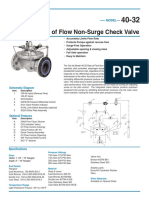

- Rate of Flow Non-Surge Check Valve: ModelDocument2 pagesRate of Flow Non-Surge Check Valve: ModelAndrzej BąkałaNo ratings yet

- Motion Control Training: Training Equipment and ServicesDocument16 pagesMotion Control Training: Training Equipment and Servicesdini WFENo ratings yet

- List - of - Approved - Makes-21-27Document7 pagesList - of - Approved - Makes-21-27VISHAL SINGHNo ratings yet

- QB FMDocument1 pageQB FMAnil ChauvanNo ratings yet

- Agar50series MPFM SpecDocument4 pagesAgar50series MPFM SpecJADNo ratings yet

- Istilah-Istilah Dalam Drilling Day ReportDocument4 pagesIstilah-Istilah Dalam Drilling Day ReportAdventhy RyaNo ratings yet

- PVC Piping Systems-PPFADocument40 pagesPVC Piping Systems-PPFAAmal KaNo ratings yet

- Tds PBT 1130Document2 pagesTds PBT 1130Huyền VũNo ratings yet

- Fan-Coil Unit FCU-097 GMC AIR Data SheetDocument18 pagesFan-Coil Unit FCU-097 GMC AIR Data SheetMartín CanizzoNo ratings yet

- Physics Project 2022-23 - Rough DraftDocument9 pagesPhysics Project 2022-23 - Rough DraftRamchandran IyerNo ratings yet

- Vc-90200.01.03-En Ecoline DJDocument6 pagesVc-90200.01.03-En Ecoline DJGary IrawanNo ratings yet

- Understanding Cloud Point and Hydrotreating Relationships RevisedDocument4 pagesUnderstanding Cloud Point and Hydrotreating Relationships RevisedAshwani KumarNo ratings yet

- Vermeer Rt450e4!05!03z01 PageDocument2 pagesVermeer Rt450e4!05!03z01 PageGustavo BelgranoNo ratings yet

- Andrews' gas liquefaction experimentsDocument3 pagesAndrews' gas liquefaction experimentsRSLNo ratings yet

- Centrifugal CompressorsDocument48 pagesCentrifugal CompressorsSyedahmedkabir IjazfazilNo ratings yet

- Condensation Unit: ObjectiveDocument5 pagesCondensation Unit: ObjectiveAnas UmerNo ratings yet

- Change Data in Shaded Cells for Flow System ModelingDocument3 pagesChange Data in Shaded Cells for Flow System ModelingAlexandre GelsiNo ratings yet

- Predict combustion gas emissivities with simple equationsDocument4 pagesPredict combustion gas emissivities with simple equationsFranny CasasolaNo ratings yet

- Circular Steel Tank Design CalculationDocument9 pagesCircular Steel Tank Design CalculationabbasamuNo ratings yet

- The Burke-Schumann Spray Diffusion Flame in A PDFDocument12 pagesThe Burke-Schumann Spray Diffusion Flame in A PDFricljrNo ratings yet

- Understanding Fluid Mechanics FundamentalsDocument8 pagesUnderstanding Fluid Mechanics FundamentalsKrishnaChaitanyaNo ratings yet

- Week 1Document115 pagesWeek 1Haziq YussofNo ratings yet

- Reynolds Numbers ExperimentDocument7 pagesReynolds Numbers ExperimentSufferedMuch100% (3)

- Gas Lift Pittman - para Revisar PDFDocument8 pagesGas Lift Pittman - para Revisar PDFedi agurto carrascoNo ratings yet

- Piping Design BasisDocument26 pagesPiping Design BasisAnjani Prabhakar100% (4)

- FlowSafe F70PR BulletinDocument16 pagesFlowSafe F70PR BulletinbernabasNo ratings yet

- Properties of saturated water tableDocument1 pageProperties of saturated water tabletemumangga50% (2)

- Tvarovky A Armatury 2022 - AjDocument92 pagesTvarovky A Armatury 2022 - AjJavierNo ratings yet

- Burner Tilt PDFDocument9 pagesBurner Tilt PDFEE POG-III CSTPSNo ratings yet

- Calculation of Insulation Thickness For Pipes The Piping Engineering WorldDocument3 pagesCalculation of Insulation Thickness For Pipes The Piping Engineering WorldEddie FongNo ratings yet