Professional Documents

Culture Documents

Product+catalogue-WEB Spreads PDF

Uploaded by

markfoyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product+catalogue-WEB Spreads PDF

Uploaded by

markfoyCopyright:

Available Formats

PRODUCT CATALOGUE

NZ WIDE: 0800 4 SHAWS

CONTENTS

INTRO

Introduction

Wire Rope 4

Shaw’s Wire Ropes have been helping NZ heavy industry take care of business since

Rope Construction 4

1909. We are proud to have forged strong links with a range of industries including

Lay & Interpreting Rope Construction 5

Strand Construction 6 forestry, construction, transport, shipping, oil & gas, mining, and commercial fishing.

Common Rope End Terminations & Lubrication 7 With over a century of experience, we remain 100% focussed on providing exceptional

General Purpose Rope 8 service, quality equipment, practical advice and outstanding value.

Logging Rope 11

Crane Rope 12

Elevator Rope 13

Stainless Steel Rope 14

Why deal with the team at Shaw’s?

Sockets 15

• Expert product and industry knowledge

Wire Rope Clips 16 • NZs largest inventory of wire rope, rigging, and lifting products

• Quality brands and skilled workmanship

Thimbles 18 • Comprehensive wire rope and lifting product traceability systems

• 100% dedication to outstanding service & value

Shackles 20 • Delivery NZ wide

Turnbuckles 25

Chain 27 This catalogue provides generic information on our main product range. Please note that

all specifications are offered as an indicative guide only, and may be subject to change.

Grade 80 Lifting 28 If you require more detailed information, give the team a call on 0800 4SHAWS.

Grade 100 Lifting 30

Chain Lifting Slings 32

Synthetic Slings 33

Blocks 34

Block Components 35

Logging Blocks 36

Snatch, Lashing, Yarding & Rigging Blocks 37

Load Restraint 38

Chain & Lever Blocks 39

Accessories 41

“Excellence is not a skill. It is an attitude”

- Ralph Marston

WIRE ROPES • • •CHAINS • • SHACKLES • • BLOCKS • • RIGGING • • SAFETY NZ WIDE:

WIRE ROPE Rope Construction Lay

WIRE ROPE

Rope is made of individual wires twisted into strands. These preformed strands are then twisted

around the core to complete the rope. The core supports and maintains the circular structure of the

rope.

Ordinary Lay Langs Lay

Wire

The strands rotate around the rope in The strands rotate around the rope in the

the opposite direction to the wires in the same direction as the wires in the strand.

strand.

Strand

Diameter

Right Hand Ordinary Lay Right Hand Langs Lay

Core

Lay

The distance of one complete revolution of a strand

Left Hand Ordinary Lay Left Hand Langs Lay

Rope End View

Strand

Outer Wires

Core

Inner Wires

Interpreting Rope Construction Information

Wire rope construction descriptions follow this format:

Core Types 6 x S (19) + IWRC = 6 Strands, Seale construction, 19 wires, Independent Wire Rope Core.

6 x S (19) + IWRC

Number of Strands

Seale Construction

FC Fibre Core WSC Wire Strand Core IWRC Independent Wire

Polypropylene or natural fibres A single strand is used as the Rope Core 19 Wires Per Strand

are used as the core. Excellent core. Simple and cost effective A small wire rope is used as

flexibility and lubricant - suitable for small diameter the core. Excellent crush and

retention. rope. distortion resistance with Independant Wire Rope Core

longer fatigue life, and high

breaking strength.

4 WIRE ROPES • • •CHAINS • • SHACKLES • • BLOCKS • • RIGGING • • SAFETY NZ WIDE: 5

Strand Construction Common Rope End Terminations

WIRE ROPE

WIRE ROPE When selecting a rope the following key characteristics must be considered.

• Tensile Strength

• Fatigue resistance (flexibility)

• Abrasion resistance Hand Spliced Eye Pressed Thimble Eye

• Crush resistance

• Corrosion resistance

The actual rope use will govern which of the above factors is most important, and which of the following

strand constructions will suit.

Pressed Solid Thimble Eye Pressed Soft Eye

Wire Rope Clips Spelter Socket

S - Seale W - Warrington WS- Warrington Seale Fi - Filler

The outer layer consists The outer layer consists Three layer of wires. Each valley between the

of large outer wires, of pairs of wires (one Seale style outer layer, two layers of wire is

laid over the valleys large and one small) with Warrington style filled with small wire.

created by an inner laid over an inner layer inner layers. This This provides increased Split Wedge Ferrules Flemish Eye

layer of smaller wires. of wires. combines the strength, flexibility and

The number of wires in The number of wires in flexibility of Warrington, crush resistance.

the outer layer is equal the inner layer is half of with Seale style

to the number of wires those in the outer layer. abrasion resistance.

in the inner layer. The This produces excellent Lubrication

large outer wires pro- flexibility, roundness,

duce excellent abrasion and fatigue resistance. Wires and strands are lubricated during manufacture to:

resistance.

• Allow wires and strands to slide easily past each other

• Provide a coating on the metal surfaces and prevent corrosion.

Over time it is important to replace rope lubricant to avoid premature rope failure.

DO DONT

Be aware that lubricant attracts abrasive particles Use bar oil, or used engine oil - these contain

(sand, dust, scoria etc.) abrasive particles.

Apply when the rope is bending (slowly!) through a Use diesel or petrol - these solvents will flush out

sheave or drum, “opening up” the rope. lubricant remaining in the rope.

Plan application to minimise damage.

6 WIRE ROPES • • •CHAINS • • SHACKLES • • BLOCKS • • RIGGING • • SAFETY NZ WIDE: 7

General Purpose 6x19 Class General Purpose 6x36 Class

WIRE ROPE

WIRE ROPE

Use Information Use Information

General engineering, construction, agriculture, logging & fishing. Winching, lifting and multiple sheave applications (conditions where flexibility is important).

Minimum Breaking Load Approx Weight Minimum Breaking Load Approx Weight

Diameter Diameter

In Metric Tonnes Kg/M In Metric Tonnes Kg/M

180KG/MM2 195KG/MM2 180KG/MM2 195KG/MM2

MM 1770N/MM2 1910N/MM2 FC IWRC MM 1770N/MM2 1910N/MM2 FC IWRC

FC IWRC IWRC FC IWRC IWRC

6 2.13 2.16 2.62 0.139 0.155 6 x S (19) + FC 6 x S (19) + IWRC 6 2.17 2.16 2.69 0.142 0.158 6 x Fi (29) + FC 6 x Fi (29) + IWRC

7 2.89 3.15 3.57 0.189 0.211 7 2.95 3.15 3.67 0.194 0.216

8 3.79 4.11 4.67 0.247 0.275 8 3,87 4.11 4.79 0.253 0.282

9 4.80 5.20 5.91 0.312 0.348 9 4,89 5.20 6.06 0.321 0.356

10 5.92 6.42 7.29 0.386 0.430 10 6.04 6.42 7.47 0.396 0.440

11 7.14 7.77 8.82 0.467 0.520 6 x FS (19) + IWRC 6 x W (19) + IWRC 11 7.29 7.77 9.04 0.479 0.533 6 x WS (31) + IWRC

6 x WS (31) + FC

12 8.52 9.25 10.50 0.556 0.619 12 8.67 9.25 10.80 0.570 0.634

13 9.98 10.80 12.30 0.652 0.727 13 10.18 10.80 12.60 0.669 0.744

14 11.6 12.60 14.30 0.756 0.843 14 11.8 12.60 14.70 0.776 0.863

16 15.2 16.40 18.70 0.988 1.10 16 15.5 16.40 19.20 1.01 1.13

18 19.2 20.80 23.60 1.25 1.39 18 19.6 20.80 24.30 1.28 1.43

20 23.7 25.70 29.20 1.54 1.72

6 x Fi (25) + FC 6 x Fi (25) + IWRC 20 24.2 25.70 29.90 1.58 1.76 6 x WS (36) + FC 6 x WS (36) + IWRC

22 28.6 31.10 35.30 1.87 2.08 22 29.2 31.10 36.20 1.92 2.13

24 34.0 37.0 42.0 2.22 2.48 24 34.7 37.00 41.0 2.28 2.53

26 39.9 43.40 49.30 2.61 2.91 26 40.7 43.4 48.10 2.68 2.98

28 46.4 50.40 57.20 3.02 3.37 28 47.4 50.40 55.80 3.10 3.45

32 61.0 65.70 72.90 3.70 4.08 32 61.7 65.70 72.90 4.05 4.51

6 x WS (26) + FC 6 x WS (26) + IWRC 6 x SeS (37) + FC 6 x SeS (37) + IWRC

36 78.1 83.30 92.20 5.13 5.70

38 87.0 92.80 103 5.72 6.36

40 96.6 103.0 114 6.33 7.04

General Purpose 6x24 Class 44 117 124.0 134 7.66 8.52

Use Information 48 137 148 159 8.32 9.17

Lashing and retaining rope for transport, civil engineering & shipping. 52 161 174 187 9.76 1.08

6 x WS (41) + FC 6 x WS (41) +IWRC

54 174 187 201 10.53 11.61

Minimum Breaking 56 187 201 216 11.32 12.48

Diameter

Load In Metrictonnes Approx Weight

180KG/MM2 Kg/M

MM

1770N/MM2

8 3.22 0.212 General Purpose Small Diameter Galvanised Wire Ropes

6 x 24 + 7 FC

9 4.07 0.269 Use Information

10 5.03 0.332 General engineering and industry applications.

11 6.09 0.401

12 7.28 0.478 7x7 Construction 7x19 Construction 1x7 Construction

13 8.49 0.561 Diameter Minimum Diameter Minimum Diameter Minimum

Breaking Weight Breaking Weight Breaking

14 9.90 0.651 Load Load Load Weight

Kg/100M Kg/100M

Kg/100M

16 12.90 0.850 MM KG MM KG

MM

KG

grade 1300

18 16.3 1.08 1.5 142.7 0.96 1.5 134.9 0.86

6 3934 17

20 20.2 1.33 2 254.8 1.57 2 239.8 1.52

7.5 4587 27.3

22 24.5 1.61 2.5 407.7 2.07 2.5 374.7 2.38

24 29.1 1.91 3 579.9 3.49 3 540.3 3.42

26 34.1 2.24 4 1040 6.29 4 958.2 6.09

28 39.4 2.60 5 1624 9.83 5 1498 9.52

30 45.2 2.99 6 2320 13.94 6 2161 13.8

32 51.4 3.40 7 3158 18.98 7 2938 18.7

34 58.1 3.83 8 4124 24.79 8 3833 24.3

7x7 7 x 19 1x7

8 WIRE ROPES • • •CHAINS • • SHACKLES • • BLOCKS • • RIGGING • • SAFETY NZ WIDE: 9

WIRE ROPE PVC Coated Cable Logging Rope

WIRE ROPE

Use Information Use Information

General purpose security cable, barrier cable, gym equipment and safety applications. For ground based and cable logging applications.

Regular Logging Rope

Minimum Breaking

Diameter (mm)

Load Approx Weight

Construction Colour

Wire Coated Kg/100M Minimum

Kg Weight Per

Diameter Diameter Diameter Breaking

Construction Metre Common Application

Load

2.0 3.0 7X7 Galvanised Clear 254.8 1.6 7x7 Inch Metric Metric Tonnes Kg

2.5 4.0 7X7 Galvanised Red 407.7 2.5

- 9.0 6X19 IWRC 5.20 0.35 Strawline

4.0 6.0 7X19 Urethane Black 958.2 6.5 6 x S (19) + IWRC

- 10.0 6X19 IWRC 6.42 0.43 Strawline

4.0 6.0 7X19 Galvanised Clear 958.2 6.3

7/16 11.2 6X19 IWRC 7.77 0.54 Strawline

5.0 7.0 7X19 Galvanised Clear 1549 4.95

1/2 12.7 6X19 IWRC 10.80 0.73 Tagline

10.0 12.0 7X19 Galvanised Clear 5993 19.8

7 x 19 9/16 14.3 6X19 IWRC 12.60 0.88 Small Tail

5/8 16.0 6X26 IWRC 16.42 1.10 Tail+ Strops

3/4 19.0 6X26 IWRC 23.15 1.55 Main+Tail+Strops

7/8 22.2 6X26 IWRC 32.22 2.13 Main+Tail+Strops 6 x Fi (25) + IWRC

1 25.4 6X26 IWRC 43.44 2.78 Sky+ Main+ Guys

Small Diameter Ropes for Agriculture and Horticulture 1-1/8 28.6 6X19 IWRC 52.56 3.52 Skyline+Guys

1-1/4 31.8 6X25 IWRC 65.77 4.35 Skyline+Guys

Use Information

1-3/8 35.0 6X25 IWRC 78.72 5.27 Skyline+Guys

General farming and horticultural applications.

6 x WS (26) + IWRC

Minimum Breaking

Diameter Approx Weight

Construction Use Load

Kg/100M Swaged Logging Rope

mm Kg

4 7X7 Galvanised Irrigator Wire 1040 6.29 Minimum

Weight Per

4 7X19 Galvanised Irrigator Wire 958.2 6.09 Diameter Breaking

Construction Metre Common Application

7x7 Load

4 7X7 Stainless 316 Cowshed/Irrigator 1030 6.29

Inch Metric Metric Tonnes Kg

5 7X7 Galvanised Irrigator Wire 1624 9.83

1/2 12.7 6x26 IWRC 14.48 0.878 Main+Tail

5 7X19 Galvanised Irrigator Wire 1498 9.52

9/16 14.3 6x26 IWRC 18.33 1.071 Main+Tail

5 7X7 Stainless 316 Cowshed/Irrigator 1620 9.83

5/8 16.0 6x26 IWRC 21.72 1.301 Main+Tail

6 1X7 Galvanised Grade 1300 Kiwifruit Support 3934 17

11/16 17.5 6x26 IWRC 27.15 1.547 Main+Tail

7.5 1X7 Galvanised Grade 1300 Kiwifruit Support 4587 27.3 7 x 19 3/4 19.0 6x26 IWRC 31.31 1.818 Main+Tail+Sky

7/8 22.2 6x26 IWRC 42.62 2.753 Main+Tail+Sky

1 25.4 6x26 IWRC 55.78 3.482 Main+Sky+Guy

1-1/8 28.6 6x26 IWRC 63.94 4.301 Sky+Guy

1-1/4 31.8 6x26 IWRC 78.93 5.209 Sky+Guy

1x7

Power Swaged Logging Rope

Minimum

Weight Per

Diameter Breaking

Construction Metre Common Application

Load

Inch Metric Metric Tonnes Kg

1/2 12.7 6x25 IWRC 17.2 0.977 Main

9/16 14.3 6x26 IWRC 21.9 1.237 Main+Tail

5/8 16.0 6x26 IWRC 26.2 1.527 Main+Tail

11/16 17.5 6x26 IWRC 32.3 1.848 Main+Tail

3/4 19.0 6x26 IWRC 38.9 2.199 Main+Tail

7/8 22.2 6x26 IWRC 51.5 2.993 Main+Tail

1 25.4 6x26 IWRC 66.9 3.909 Main+Sky+Guy

10 WIRE ROPES • • •CHAINS • • SHACKLES • • BLOCKS • • RIGGING • • SAFETY NZ WIDE: 11

Crane Rope Elevator Rope

WIRE ROPE

WIRE ROPE VeroTop Hoisting Rope

Drako 250T - 8 Strand Steel Core Rope (IWRC)

Use Information

A non rotating Hoist rope for tower and mobile cranes, with a high breaking load and strong resitance

Use Information

to drum crushing. For high unguided applications.

Ideally suited to medium duty traction drive elevators.

Minimum Breaking Load Minimum Breaking Load

Diameter Tensile Strength Tensile Strength Approx Weight

Advantages

1960 N/Mm2 2160 N/mm2 Kg/100M • Rounder than 6 strand rope - more contact points between the rope & sheave groove

MM KN T KN T • Flexible with good fatigue resistance, and low maintainance requirements.

10 91.80 9.36 99.00 10.10 48.9 • Low permanent and elastic elongation, with high breaking load capacity.

12 133.40 13.60 143.10 14.59 71.3 35 X 7

13 155.70 15.88 167.00 17.03 81.6 Minimum Breaking Load

Diameter Approx Weight

14 182.70 18.63 195.90 19.98 93.9 MM Kg/100M

KN T

15 208.10 21.22 223.20 22.76 108.9

8 43.3 4.41 27.1

16 235.20 23.98 252.20 25.72 123

9 54.8 5.59 34.3

17 263.10 26.83 282.20 28.78 138.6

10 67.7 6.90 42.3

18 299.80 30.57 321.60 32.79 154.2

NON ROTATING 11 81.9 8.35 51.2

19 335.60 34.22 359.90 36.70 171.1 8 x 19 W IWRC

12 97.4 9.93 60.9

20 369.40 37.67 396.20 40.40 190.4

13 114 11.62 71.5

21 404.00 41.20 433.40 44.19 209.2

14 133 13.56 82.9

22 450.20 45.91 482.90 49.24 228

16 173 17.64 108

23 481.20 49.07 516.10 52.63 250.5

24 534.80 54.53 573.50 58.48 272.3

25 579.20 59.07 621.30 63.35 295 PARALLEL

STRANDS

26 627.20 63.95 672.60 68.59 323.4

28 727.20 74.15 779.90 79.53 372.5 Drako 8x19 FC 8 Strand Suspension Ropes

30 831.30 84.77 891.60 90.92 427.1

32 953.90 97.27 1020.10 104.02 504 Use Information

Suspension ropes for traction drive elevators.

Advantages

VeroPro 8 Luffing Rope • World’s most common traction suspension rope configuration.

• High flexibility with a fibre core, small wire diameter, and good fatigue resistance.

Use Information

• Rounder than a 6 strand rope - more contact points between the rope and the sheave groove.

A Luffing rope for container handling cranes, mobile harbour cranes, and lifting

applications with guided loads. Should be used for applications where the rope is fixed at both ends.

8 x 19 S FC 8 x 19 W FC

Minimum Breaking Load

Diameter Tensile Strength Approx Weight Minimum Breaking Approx Minimum Breaking Approx

1960 N/mm2 Diameter Load 1570 N/mm2 Diameter Load 1570 N/mm2

Kg/100M Weight Weight

MM MM

MM KN T KN T Kg/100M KN T Kg/100M

14 174.96 17.84 89 8 30.4 3.10 21.5 8 31.6 3.22 22.2

15 202.51 20.65 102.6 8 x 16 IWRC 9 38.4 3.91 27.3 9 40.0 4.08 28.1 8 x 19 S - FC

16 229.1 23.36 116.9 9.5 42.8 4.36 30.4 10 49.4 5.04 34.7

17 254.8 25.98 132.3 10 47.4 4.83 33.7 11 59.7 6.09 42.0

18 288.3 29.4 145.9 11 57.4 5.85 40.7 12 71.1 7.25 50.0

19 323.1 32.95 163.7 12 68.3 6.96 48.5 13 83.4 8.50 58.6

20 354.6 36.16 181.5 13 80.2 8.18 56.9 16 126.0 12.84 88.8

21 388.7 39.64 198 PARALLEL 14 93.0 9.48 66.0 8 x 19 W - FC

STRANDS

22 433.2 44.17 220.1 15 107.0 10.91 75.7

23 470.7 48 240.1 15.5 114.0 11.62 80.8

24 513.7 52.38 261 16 121.0 12.33 86.1

25 557.6 56.86 282.3 18 154.0 15.70 109.0

26 606.5 61.84 306.9 19 171.0 17.43 121.0

12 WIRE ROPES • • •CHAINS • • SHACKLES • • BLOCKS • • RIGGING • • SAFETY NZ WIDE: 13

Stainless Steel Closed Spelter Socket Green Pin ®

SOCKETS

WIRE ROPE Use Information Material: High tensile steel GS21Mn5.

For marine, construction and architectural applications. Safety Factor: MBL equals 5 x WLL.

Finish: Painted green or hot dipped galvanised.

1 x 19 7x7

Diameter Minimum Breaking Load Diameter Minimum Breaking Load Working Diameter Width Length Thickness Opening Weight

(KG) Approx (KG) Approx

Load Inside Inside

Weight Weight Wire Rope Bow Bow Each

MM AISI AISI MM AISI AISI Limit Bow Bow

Kg/100M Kg/100M

302+304 316 302+304 316

T mm B mm C mm A mm D mm E mm F mm G mm KG

1 96 84 0.495 1.2 122 100 0.63

4 11-13 51 30 140 59 17.5 22.5 14 0.7

1.5 215 180 1.11 1.5 170 136 0.96

5 14-16 67 36 162 65 21 26 17.5 1.3

2 380 320 1.98 2.0 290 242 1.57

8 18-19 76 42 194 78 27 32 21 2.1

2.5 600 500 3.1 2.5 460 378 2.7

10 20-22 92 47 224 90 33 38 24 3.6

3 830 720 4.46 3 660 545 3.54

12.6 23-26 104 57 253 103 36 44 28 5.3

3.5 1140 1030 6.07 4 1140 968 6.29 16 27-30 114 63 282 116 39 51 32 7

4 1490 1285 7.93 5 1790 1509 9.83 20 31-36 127 70 312 130 43 57 38 9.7

5 2330 1999 12.4 6 2570 2330 14.2 25 37-39 136 79 358 155 51 63 41 13

6 3320 2876 17.8 7 3400 3160 19.3 32 40-42 146 83 390 171 54 70 44 17

7 4490 3549 24.3 8 4080 3875 25.2 40 43-48 171 93 443 198 55 76 51 26

8 5700 4640 31.7 9 5200 4650 31.8 50 49-54 193 100 502 224 62 82 57 37.5

9 7200 5874 40.1 10 6300 5750 39.3 64 55-60 216 112 548 247 73 92 63 50

10 8830 7250 49.5 12 8950 8270 56.7 80 61-68 241 140 597 270 79 102 73 65

11 10500 8770 59.9 14 12200 11200 77.1 90 69-75 273 159 644 286 79 124 79 94

12 12400 10401 71.3 16 15900 14700 101 100 76-80 292 171 686 298 83 133 86 110

13 14500 14000 83.7 18 20100 18600 128 120 81-86 311 184 743 311 102 146 92 145

14 16700 16200 97.1 20 24800 23000 157 140 87-93 330 197 788 330 102 159 99 168

16 21500 20400 127 22 29600 27800 190

Open Spelter Socket

Material: High Tensile Steel GS21Mn5.

Safety Factor: MBL equals 5 x WLL.

Finish: Painted green or hot dipped galvanised.

7 x 19

Diameter Minimum Breaking Load Working Diameter Width Length Weight

(KG) Approx Load Opening

Weight Limit Wire Rope Pin Inside Inside Each

MM AISI AISI Kg/100M

302+304 316 T mm C mm B mm A mm D mm E mm Kg

2.0 280 226 1.7 4 11-13 25 25 142 38 14 1

1 x 19

2.5 440 354 2.7 5 14-16 30 32 171 48 17.5 1.8

3 625 510 3.42 8 18-19 35 38 205 58 21 3.2

4 1090 907 6.09 10 20-22 41 44 235 68 24 4.6

5 1700 1490 9.52 12.6 23-26 51 51 275 75 28 8.0

6 2460 2039 13.8 16 27-30 57 57 306 85 32 11

8 4100 3630 24.3 20 31-36 63 63 338 95 38 16

7x7 25 37-39 70 76 394 127 41 23

9 5450 4840 30.8

32 40-42 76 76 418 127 44 27

10 6580 5670 38.1

40 43-48 89 89 468 133 51 41

12 9480 8158 54.8

50 49-54 95 101 552 180 57 58

13 10900 10100 64.3

64 55-60 108 113 598 196 63 85

14 12600 11115 74.6

80 61-68 121 127 654 212 73 118

16 16100 14470 97.4

7 x 19 90 69-75 127 133 696 215 79 155

18 20400 18100 123

100 76-80 133 146 737 219 86 173

120 81-86 140 159 788 228 92 230

140 87-93 152 171 852 242 99 265

14 WIRE ROPES • • •CHAINS • • SHACKLES • • BLOCKS • • RIGGING • • SAFETY NZ WIDE: 15

Open Wedge Socket Green Pin ® Wire Rope Clips Type B to EN 13411 - 5 Green Pin ®

WIRE ROPE CLIPS

SOCKETS Material: High Tensile Steel GS21Mn5.

Safety Factor: MBL equals 5 x WLL.

Material: Bridge - Drop forged high tensile steel SAE 1035 or SAE 1045.

Standard: EN 13411 - 5 Type B

Finish: Painted green or hot dipped galvanised. Finish: Hot dipped galvanised.

Diameter Width Length Thickness Weight Diameter Width Length Thickness Height Weight

Working

Load To Centre Side 100

Limit Wire Rope Pin Eye Inside Each Wire Rope Inside Bow Thread Base Base Base

Pin Plates pcs

T mm D mm F mm C mm A mm B mm E mm Kg Inch mm A mm C mm B mm D mm E mm F mm G mm Kg

F

1/8 4 5 12 24 11 24 21 10 2

1.25 7-8 16 36 18 129 110 9 0.8

2 9-10 20 46 21 165 142 11 1.7 3/16 5 6 15 31 13 29 24 13 4

3.2 11-13 25 57 25 174 146 12 2.1 1/4 7 8 19 34 13 37 30 18 8

5 14-16 30 70 31 211 176 15 4 5/16 8 10 22 45 19 43 33 19 14

B A

6.3 18-19 35 80 38 252 212 16 7 3/8 10 11 26 49 19 49 42 25 19

8 20-22 41 95 44 288 240 19 10

7/16 11 12 30 60 25 58 46 26 31

12.6 24-26 51 110 51 329 274 22 15

1/2 13 13 30 61 25 58 48 31 34

16 27-29 57 130 57 375 310 25 21

9/16 15 14 33 72 32 63 52 31 36

20 30-32 64 146 63 423 350 28 31 E

C

5/8 16 14 33 74 32 64 54 36 45

20 34-36 64 148 69 474 400 28 37

D 3/4

25 37-39 70 153 76 527 450 30 51 20 16 38 86 37 72 57 38 68

32 40-42 76 160 76 580 500 33 64 7/8 22 19 45 98 41 80 62 40 108

40 43-48 89 186 89 643 550 39 96 1 26 19 48 108 46 88 67 47 113

50 49-52 95 194 101 737 640 46 130 11/8 30 19 51 117 51 91 73 48 140

64 54-58 108 230 114 775 660 54 180

11/4 34 22 59 130 54 105 79 56 207

80 60-68 121 250 127 960 835 60 275

13/8 36 22 60 140 59 108 79 58 234

90 72-76 133 270 146 1135 1000 76 440

11/2 40 22 66 147 60 112 85 64 266

100 81-86 140 300 159 1250 1100 79 510

5/8 42 25 70 161 67 121 92 67 329

1

13/4 46 29 78 174 70 134 97 76 441

2 52 32 86 195 78 150 113 85 603

Wire Rope Clips Type A to EN 13411 - 5 Wire Rope Clips to DIN 741

Material: Bridge - malleable steel. U Bolt - mild steel. Material: Bridge - casted; U Bolt - mild steel

Standard: EN 13411 - 5 Type A (formerly DIN 1142) Standard: DIN 741

Finish: Electro galvanised. Finish: Electro galvanised.

Diameter Width Length Thickness Height Weight Diameter Width Length Thickness Height Weight

Wire Rope Inside Bow Thread Base Base Base Each Wire 100

Inside Bow Thread Base Base Base

Rope pcs

mm A mm C mm B mm D mm E mm F mm G mm Kg

mm A mm C mm B mm D mm E mm F mm G mm Kg

5 4 12 25 14 25 13 13 2

3 4 9 20 12 21 10 10 1.4

6.5 5 14 32 17 30 16 14 4

5 5 11 24 13 23 11 10 1.5

8 7 18 41 20 39 20 18 8.2

6 5 13 28 15 26 12 11 2.1

10 7 20 46 24 40 20 21 9.2

8 6 16 34 19 30 14 15 4.1

12 10 24 56 28 50 25 24 21.5

10 8 19 42 22 34 18 17 6.8

13 11 29 64 29 55 28 29 27.5

11 8 20 44 22 36 19 18 7.2

14 12 28 66 31 59 30 28 39.5

13 10 24 55 30 42 23 21 13

16 12 34 76 35 64 32 35 43 14 10 25 57 30 44 23 22 13.5

19 12 37 83 36 68 33 40 49 16 12 29 63 33 50 26 26 21

22 14 41 96 40 74 34 44 68 19 12 32 75 38 54 29 30 28

26 18 46 111 50 84 38 51 117 22 14 37 85 44 61 33 34 40

30 18 54 127 55 95 41 59 140 26 14 41 95 45 65 35 37 44

34 22 60 141 60 105 45 67 213 30 16 48 110 50 74 37 43 66

40 24 68 159 65 117 49 77 268 34 16 52 120 55 80 42 50 85

40 16 58 140 60 88 45 55 104

16 WIRE ROPES • • •CHAINS • • SHACKLES • • BLOCKS • • RIGGING • • SAFETY NZ WIDE: 17

Standard Thimbles Green Pin ® Solid Thimbles Green Pin ®

THIMBLES

THIMBLES Material: Mild Steel. Material: Cast mild Steel (GTW 40)

Standard: EN 13411 - 1 (formerly BS 464) Standard: DIN 3091

Finish: Hot dipped galvanised. Finish: Self Coloured.

Diameter Width Length Thickness Weight Diameter Width Weight

Wire Rope Groove Inside Inside Back 100 pcs Length 100

Wire Rope Groove

pcs

Inch A mm D mm B mm C mm E mm Kg

1/4 mm D mm A mm B mm C mm E mm Kg

6 20 48 30 3.5 5.4

8 14 9 40 66 - 18

5/16 8 22 54 33 4 5.7

10 18 11 50 82 - 32

3/8 10 25 64 38 4.8 7.6

12 21 13 60 98 - 52

7/16 13 29 73 41 4.8 14.2

14 25 16 70 114 - 80

1/2 14 32 80 44 5.6 18

16 28 18 80 130 16 90

9/16 15 32 80 44 5.6 18.9 18 31 20 90 145 18 121

5/8 17 41 98 59 7.9 34 20 35 22 100 161 20 161

11/16 19 44 108 67 7.9 39.7 22 38 24 110 177 22 211

3/4 20 51 124 73 9.5 62.4 24 41 26 120 193 24 271

13/16 21 51 124 73 9.5 62.4 26 44 29 130 209 26 355

7/8 28 47 31 140 224 28 420

23 57 133 83 9.5 75.6

15/16

32 53 35 160 256 32 630

25 64 146 92 10.3 106

36 59 40 180 288 36 884

1 27 70 162 108 10.3 125

40 65 44 200 320 40 1100

1 1/8 29 76 178 111 12.7 151

44 70 48 220 352 44 1500

1/4 33 95 197 133 12.7 204

1

Thimbles: Heavy Duty Stub End

Material: Mild Steel.

Standard: n/a.

Finish: Electro galvanised.

Diameter

Wire Rope Groove

Width

Inside

Length

Inside

Thickness

Back

Weight

100 pcs

Tubular Thimbles

mm A mm D mm B mm C mm E mm Kg Material: Mild Steel.

8 8 22 51 35 4 6 Standard: n/a.

10 10 30 64 47 4 7 Finish: Painted.

12 12 35 76 57 5 14

14 14 45 89 65 6 22 Diameter Width Weight

Length Thickness Height

16 16 50 102 76 6 24 Wire Rope Inside 100 pcs

18 18 53 114 86 8 43 mm A mm C mm B mm D mm Emm Kg

20 20 60 127 94 9 65 10 12 23 90 4 8 0.25

22 22 65 140 107 10 93 12 15 27 105 5 10 0.42

24 24 70 152 114 10 102 14 17 27 115 5 10 0.5

28 28 80 178 130 10.5 135 16 19 32 120 5 12 0.6

32 32 100 203 157 10.5 162 18 22 35 140 5 15 0.75

36 36 115 229 177 12 363 22 25 45 180 6 16 1.4

40 40 120 254 198 12 376 24 28 45 180 7 16 1.75

44 44 130 279 214 15 608 26 30 47 195 7 18 2

50 50 140 305 215 20 960 32 35 60 215 7 22 2.4

56 56 160 356 245 20 1400 38 45 70 260 7 27 3.3

64 64 180 407 275 20 1700 44 50 75 280 7 28 4.06

18 WIRE ROPES • • •CHAINS • • SHACKLES • • BLOCKS • • RIGGING • • SAFETY NZ WIDE: 19

SHACKLES Bow Shackles with Screw Collar Pin Green Pin ® Sling Shackles: Bow Shackles with Safety Bolt Green Pin ®

SHACKLES

Material: Bow and pin high tensile steel, Grade 6, quenched and tempered. Material: Bow and pin high tensile steel, Grade 8, quenched and tempered.

Safety Factor: MBL equals 6 x WLL. Safety Factor: MBL equals 5 x WLL.

Standard: EN 13889, meets requirement of US Fed Spec RR-C-271, type IVA Class 2, Grade A. Finish: Shackle bow painted silver, pin painted green.

Finish: Hot dipped galvanised.

Working Diameter Width Length Weight Working Bearing

Diameter Width Length Thickness Weight

Load Load Surface

Limit Bow Pin Eye Eye Inside Bow Inside Bolt Each

Limit Bow Pin Eye Eye Inside Bow Inside Bolt Nut Each

T A mm B mm C mm D mm E mm G mm J mm F mm H mm I mm Kg

T A mm B mm C mm D mm E mm G mm J mm F mm H mm I mm K mm L mm Kg

0.33 5 6 12 5 9.5 16 26 22 36 29.5 0.02

40 55 51 109 45 84 140 235 199 331 252 38 97 21

0.5 7 8 16.5 7 12 20 34 29 48.5 38 0.05

55 60 57 115 55 90 160 270 240 389 294 45 100 30

0.75 9 10 20 9 13.5 22 40 32 56 46.5 0.1

75 68 70 125 54 110 185 317 290 473 327 54 120 48

1 10 11 22.5 10 17 26 46 36.5 63.5 54 0.14

125 85 80 154 85 137 220 390 366 583 426 64 150 92

1.5 11 13 26.5 11 19 29 51 43 74 59.5 0.19

150 94 95 179 89 147 253 434 391 645 435 50 170 140

2 13.5 16 34 13 22 32 58 51 89 73 0.36

200 110 105 199 100 158 280 482 481 759 470 50 205 205

3.25 16 19 40 16 27 43 75 64 110 89 0.63

250 126 120 227 110 179 300 530 542 859 519 60 240 264

4.75 19 22 46 19 31 51 89 76 129 103 1.01

300 135 134 245 122 195 350 620 601 947 575 70 265 360

6.5 22 25 52 22 36 58 102 83 144 119 1.5

400 160 160 293 145 231 370 690 576 985 675 80 320 580

8.5 25 28 59 25 43 68 118 95 164 137 2.21

500 170 180 328 160 263 450 790 681 1131 748 90 339 780

9.5 28 32 66 28 47 75 131 108 185 153 3.16

600 190 200 348 170 289 490 865 741 1234 809 100 370 980

12 32 35 72 32 51 83 147 115 201 170 4.31

700 200 215 392 190 315 540 901 751 1284 879 100 400 1360

13.5 35 38 80 35 57 92 162 133 227 186 5.55

800 218 230 420 200 342 554 947 851 1426 942 110 420 1430

17 38 42 88 38 60 99 175 146 249 203 7.43

900 242 255 466 220 368 580 1023 851 1488 1023 120 440 1650

25 45 50 103 45 74 126 216 178 300 243 12.84

1000 260 270 490 240 399 614 1107 851 1532 1103 120 460 2120

35 50 57 111 50 83 138 238 197 331 272 18.15

1250 285 300 510 260 452 650 1182 931 1666 1227 150 530 3700

42.5 57 65 130 57 95 160 274 222 377 310 26.29

1500 285 320 550 280 483 680 1253 950 1710 1300 150 560 4000

Bow Shackles with Safety Bolt

Material: Bow and pin high tensile steel, Grade 6, quenched and tempered. Super Shackles: Bow Shackles with Safety Bolt

Safety Factor: MBL equals 6 x WLL.

Material: Bow and pin alloy steel, Grade 8, quenched and tempered.

Standard: EN 13889, meets requirement of US Fed Spec RR-C-271, type IVA Class 3, Grade A.

Safety Factor: MBL equals 5 x WLL.

Finish: Hot dipped galvanised.

Standard: Meets requirement of US Fed Spec RR-C-271, type IVA Class 3, Grade B.

Finish: Hot dipped galvanised. (175 tonne shackle is painted)

Working Diameter Width Length Thickness Weight

Load

Limit Bow Pin Eye Eye Inside Bow Inside Bolt Nut Each

Working Diameter Width Length Thickness Weight

T A mm B mm C mm D mm E mm G mm J mm F mm H mm I mm K mm Kg

Load

0.5 7 8 16.5 7 12 20 34 29 48.5 42 4 0.06 Limit Bow Pin Eye Eye Inside Bow Inside Bolt Nut Each

0.75 9 10 20 9 13.5 22 40 32 56 50 5 0.11 T A mm B mm C mm D mm E mm G mm J mm F mm H mm I mm K mm Kg

1 10 11 22.5 10 17 26 46 36.5 63.5 60 8 0.16 3.3 13.5 16 34 13 22 32 58 51 89 82 13 0.44

1.5 11 13 26.5 11 19 29 51 43 74 67 11 0.22 5 16 19 40 16 27 43 75 64 110 98 17 0.79

2 13.5 16 34 13 22 32 58 51 89 82 13 0.42 7 19 22 46 19 31 51 89 76 129 114 19 1.26

3.25 16 19 40 16 27 43 75 64 110 98 17 0.74 9.5 22 25 52 22 36 58 102 83 144 130 22 1.88

4.75 19 22 46 19 31 51 89 76 129 114 19 1.18 12.5 25 28 59 25 43 68 118 95 164 150 25 2.78

6.5 22 25 52 22 36 58 102 83 144 130 22 1.77 15 28 32 66 28 47 75 131 108 185 166 27 3.87

8.5 25 28 59 25 43 68 118 95 164 150 25 2.58 18 32 35 72 32 51 83 147 115 201 178 30 5.26

9.5 28 32 66 28 47 75 131 108 185 166 27 3.66 21 35 38 80 35 57 92 162 133 227 197 33 6.94

12 32 35 72 32 51 83 147 115 201 178 30 4.91 30 38 42 88 38 60 99 175 146 249 202 19 8.79

13.5 35 38 80 35 57 92 162 133 227 197 33 6.54 40 45 50 103 45 74 126 216 178 300 249 23 15

17 38 42 88 38 60 99 175 146 249 202 19 8.19 55 57 57 117 57 83 138 252 197 341 286 26 22.0

25 45 50 103 45 74 126 216 178 300 249 23 14.22 85 70 70 143 70 105 180 320 260 437 344 32 42.0

35 50 57 111 50 83 138 238 197 331 269 26 19.85 120 83 83 162 83 127 190 356 329 535 403 40 70.0

42.5 57 65 130 57 95 160 274 222 377 301 29 28.33 150 95 95 208 91 147 238 428 400 647 511 50 112

55 65 70 145 65 105 180 310 260 433 330 32 39.59 175 105 108 238 102 169 275 485 410 688 561 60 160

20 WIRE ROPES • • •CHAINS • • SHACKLES • • BLOCKS • • RIGGING • • SAFETY NZ WIDE: 21

“Some people dream of success... while others wake up early and work hard at it”

22 WIRE ROPES • • •CHAINS • • SHACKLES • • BLOCKS • • RIGGING • • SAFETY NZ WIDE: 23

Wide Mouth Shackles: Bow Shackles with Safety Bolt Green Pin ®

TURNBUCKLES

SHACKLES Material: Bow and pin alloy steel, Grade 8, quenched and tempered.

Safety Factor: MBL equals 6 x WLL

Finish: Hot dipped galvanised.

Diameter Width Length Thickness Working Weight

Load

Bow Pin Eye Eye Inside Bow Inside Bolt Nut Limit Each

A B C D E G J F H I K

T Kg

mm mm mm mm mm mm mm mm mm mm mm

38 42 88 38 106 159 235 216 319 248 19 16 12.5

45 50 103 45 127 175 265 248 370 296 24 25 18

50 57 118 50 146 207 307 273 411 338 27 30 25

65 70 145 65 165 213 343 314 487 389 33 55 48

75 83 166 75 184 254 404 330 530 432 40 75 70

Turnbuckles: Eye - Jaw

Material: Drop forged high tensile steel

SAE 1035 or 1045

Sunken Hole Shackles: Flush Pin Dee Shackles Safety Factor: MBL equals 5 x WLL.

Material: Bow and high tensile steel, Grade 6, quenched and tempered. Standard: ASTM F1145 - 92

Safety Factor: MBL equals 6 x WLL. (Formerly US Fed Spec FF - T - 791b).

Standard: Meets requirement of US Fed Spec RR-C-271, type IVA Class 2, Grade A. Finish: Hot dipped galvanised.

Finish: Hot dipped galvanised.

Working Diameter Width Length Weight Working Diameter Width Length Thickness Weight

Opening

Load Size Hole Load Pin Eye Inside Closed Open Inside Inside Closed Take Up

Bow Pin Eye Eye Inside Inside Bolt Each Thread Eye Eye Jaw Jaw Each

Limit Limit Jaw Jaw Eye Position Positiion Jaw Eye Position

T A mm B mm C mm D mm E mm F mm G mm H mm I mm Kg T A mm F mm H mm I mm J mm B mm C mm E mm K mm L mm G mm Inch D mm Kg

2 13.5 16 34 13 22 43 81 51 11 0.34 0.54 3/8 8 21 9 13 302 416 22 28 65 8 6 13 0.51

3.25 16 19 40 16 27 51 97 63 11 0.6 1 1/2 9.5 25 12 18 338 452 26 36 80 10 6 16 0.89

4.75 19 22 46 19 31 59 112 74 11 0.98 1 1/2 9.5 25 12 18 414 585 26 36 80 10 9 16 1.10

6.5 22 25 52 22 36 73 134 85 13 1.26 1 1/2 9.5 25 12 18 490 719 26 36 80 10 12 16 1.31

8.5 25 28 59 25 43 85 154 99 13 2.14 1.59 5/8 13 33 14 21 394 508 33 43 98 13 6 18 1.58

9.5 28 32 66 28 47 90 167 110 17 3.05 1.59 5/8 13 33 14 21 470 641 33 43 98 13 9 18 1.84

12 32 35 72 32 51 94 180 122 17 3.56 1.59 5/8 13 33 14 21 546 775 33 43 98 13 12 18 2.22

13.5 35 38 80 35 57 115 209 135 17 5.17 2.36 3/4 15.5 41 17 25 432 546 38 53 113 16 6 23 2.34

17 38 42 88 38 60 127 230 145 17 6.84 2.36 3/4 15.5 41 17 25 508 679 38 53 113 16 9 23 2.72

2.36 3/4 15.5 41 17 25 584 813 38 53 113 16 12 23 2.95

2.36 3/4 15.5 41 17 25 737 1080 38 53 113 16 18 23 3.30

Commercial Shackles: Dee Shackles with Screw Collar Pin 3.27 7/8 19 48 20 31 625 854 44 59 118 18 12 27 4.35

3.27 7/8 19 48 20 31 778 1121 44 59 118 18 18 27 5.46

Material: Mild Steel, untreated, Grade 3.

4.54 1 22 54 22 36 524 638 52 74 155 20 6 30 4.66

Finish: Electro galvanised or self coloured.

Note: Not to be used for lifting applications. 4.54 1 22 54 22 36 676 905 52 74 155 20 12 30 6.35

4.54 1 22 54 22 36 829 1172 52 74 155 20 18 30 7.98

Diameter Width Length Weight 4.54 1 22 54 22 36 980 1437 52 74 155 20 24 30 7.39

Bow Pin Eye Inside Inside 100pcs 6.9 1 1/4 29 67 29 45 760 989 73 88 197 25 12 44 10.92

A mm B mm C mm D mm E mm Kg 6.9 1 1/4 29 67 29 45 912 1255 73 88 197 25 18 44 11

5 5 10 10 20 1.47 6.9 1 1/4 29 67 29 45 1064 1521 73 88 197 25 24 44 12.9

6 6 12 12 24 2.56 9.71 1 1/2 35 80 32 54 823 1052 70 105 215 27 12 52 13.1

8 8 16 16 32 6.06 9.71 1 1/2 35 80 32 54 975 1318 70 105 215 27 18 52 14.7

10 10 20 20 40 11.8 9.71 1 1/2 35 80 32 54 1128 1585 70 105 215 27 24 52 17.8

11 11 22 22 44 15.8 12.7 1 3/4 41 90 38 60 1060 1403 85 119 254 33 18 59 22.3

12 12 24 24 48 20.5 12.7 1 3/4 41 90 38 60 1213 1670 85 119 254 33 24 59 27.5

14 14 28 28 56 32.5 16.78 2 51 108 45 69 1315 1772 93 146 308 39 24 64 42.9

16 16 32 32 64 48.5 27.22 2 1/2 57 143 51 79 1486 1943 114 165 344 39 24 75 68

19 19 38 38 76 94.7 34.02 2 3/4 70 156 57 83 1562 2019 110 178 381 42 24 89 91

24 WIRE ROPES • • •CHAINS • • SHACKLES • • BLOCKS • • RIGGING • • SAFETY NZ WIDE: 25

Closed Body Rigging Screws: Jaw - Jaw Grade 80 Short Link Stud Link Chain

TURNBUCKLES

CHAIN

Finish: Painted Black. Finish: Self Coloured.

Material: Mild Steel. E

Safety Factor: MBL equals 5 x WLL. Minimum D

Size Breaking Load Weight

Working

Finish: Hot dipped galvanised (end fittings of 6 & 8 mm rigging screws are electro galvanised). Load Limit

D P E Breaking Weight P

Load mm T Kg/M

T mm mm mm T Kg/M 25 37 14.2

Working Diameter Width Length Weight 32 58 22.3

Opening 1.5 7 21 10 6.3 1.1

Load Jaw Closed Open

Thread Pin Jaw Body Inside Jaw Each 34 70 26.9

Limit Eye Position Position 2 8 24 11 8.2 1.4

3.15 10 30 14 12.8 2.2 42 97 37.0

T A mm E mm I mm H mm B mm C mm D mm F mm G mm Kg

5.3 13 39 18 21.6 3.7 50 139 53.8

0.2 6 5 13 20 100 175 255 19 7 0.16

0.32 8 6 14 24 108 199 282 25 9 0.27 8 16 48 22 32.8 5.6

0.5 10 8 19 28 125 222 320 26 10.5 0.45 11.2 19 57 26 46.3 7.8 Mooring Chain

15 22 66 30 62.0 10.6

0.7 12 10 22 34 195 320 479 32 13 0.85 Finish: Self Coloured.

1.2 16 12 28 42 230 388 572 39 18 1.57 21.2 26 78 35 86.5 14.8

1.5 20 16 33 51 270 454 672 46 20 2.67 31.5 32 96 43 131.5 21.6 Safe Working

Size Weight

Load

2.2 22 20 38 55 295 490 730 55 25 3.68

mm T Kg/M

3.2 24 22 46 70 325 558 819 63 30 5.3 Grade 80 Mid Link E

D

16 2.31 5.3

4.8 33 30 60 82 370 681 977 85 38 12 Finish: Painted Black. 20 3.67 8.1

6 39 33 76 85 400 710 1017 86 45 14.2 P

24 5.34 11.6

8.5 45 39 86 100 400 760 1050 105 50 20.8 Minimum

D P E Breaking Weight

11 48 45 92 118 400 820 1110 120 58 24 Load

mm mm mm T Kg/M Transport Short Link Grade 70

10 40 14 12.8 2.0 Finish: Self Coloured. To AS/NZS 3411.

13 55 20 21.6 3.3

Closed Body Rigging Screws: Eye - Jaw 16 65 22 32.8 5.0 Size

Lashing

Capacity

Weight

Material: Mild Steel. 19 75 29 46.3 7.1 mm T Kg/M

Safety Factor: MBL equals 5 x WLL. 22 88 30 62.2 9.4 7.3 3 1.14

Finish: Hot dipped galvanised (end fittings of 6 & 8 mm rigging screws are electro galvanised). 8 4 1.4

Grade 80 Long Link E

D

10 6 2.15

Working Diameter Width Length Weight Finish: Painted Black. 13 9 3.49

Opening

Load Jaw Inside Closed Open Jaw Eye

Thread Pin Jaw Body Jaw Each P

Limit Eye Eye Position Position Inside Inside

T A mm E mm I mm H mm K mm B mm C mm D mm F mm J mm G mm Kg D P E

Minimum

Breaking Weight Chain Joining Links

Load

0.2 6 5 13 20 11 100 170 248 19 11 7 0.14

mm mm mm T Kg/M Minimum

0.32 8 6 14 24 12 108 189 273 25 12 9 0.24 Size Breaking Weight

6 35 10 4.6 0.6 Load

0.5 10 8 19 28 13 125 216 306 26 13 10.5 0.53

9 53 15 10.4 1.4 mm T Kg/M

0.7 12 10 22 34 15 195 323 478 32 30 13 0.83

11 64 18 15.7 2.1 7 1.5 0.09

1.2 16 12 28 42 20 230 384 569 39 40 18 1.49

13 80 22 21.6 2.9 10 3.15 0.27

1.5 20 16 33 51 24 270 455 665 46 50 20 2.54

13 5.3 0.44

2.2 22 20 38 55 24 295 493 723 55 50 25 3.34

16 8 0.83

3.2 24 22 46 70 28 325 552 802 63 56 30 4.65

4.8 33 30 60 82 35 370 673 963 85 70 38 10.5 Grade 100 Short Link

6 39 33 76 85 40 400 718 1018 86 80 45 12.8 Finish: Painted Black. Hammerlocks

E

8.5 45 39 86 100 45 400 760 1050 105 90 50 20.8 D

Minimum Working G80

11 48 45 92 118 45 400 820 1110 120 100 58 24 Working Size Weight

D P E Breaking Weight P Load Limit Chain size

Load Limit

Load mm T mm Kg

T mm mm mm T Kg/M 8 2.0 7&8 0.2

1.5 6 18 8 6.1 0.8 10 3.2 10 0.3

2.5 8 24 11 10.2 1.4 13 5.3 13 0.7

4 10 30 14 16.3 2.3 16 8.0 16 1.1

6.7 13 39 18 26.5 3.8 20 12.5 19 & 20 1.9

10 16 48 22 41.0 5.6 22 15.0 22 3

16 20 60 29 64.2 9.4 26 21.2 26 4.6

32 31.5 32 8.6

26 WIRE ROPES • • •CHAINS • • SHACKLES • • BLOCKS • • RIGGING • • SAFETY NZ WIDE: 27

Grade 80

GRADE 80 LIFTING

GRADE 80 LIFTING

The following table relates

to all Grade 80 components

Chain diameter

Working Load

Limit Choker Hook Clevis Grab Hook

mm T For chain diameter 7mm to 16mm. For chain diameter 7mm to 20mm.

7-8 2

10 3.2

13 5.4

16 8.0

20 12.8

22 15.8

26 20.6

32 32.2

Connecting Links Shortening Hooks

For chain diameter 7mm to 32mm. For chain diameter 7mm to 20mm.

Single and Multiple Oblong Links

To suit chain diameter 7 - 32mm.

Chain Coupler Clevis Egg Link

For chain diameter 7mm to 32mm. For chain diameter 7mm to 32mm.

Clevis Sling Hook Swivel Safety Hook

For chain diameter 7mm to 20mm. For chain diameter 7mm to 20mm.

Clevis Safety Hook Eye Safety Hook

For chain diameter 7mm to 20mm. For chain diameter 7mm to 20mm.

28 WIRE ROPES • • •CHAINS • • SHACKLES • • BLOCKS • • RIGGING • • SAFETY NZ WIDE: 29

Grade 100

GRADE 100 LIFTING

GRADE 100 LIFTING Top of the range chain sling systems for coupling, shortening & lifting.

Master Grab MG

For single slings Safety Hook GBK

Working Chain Working Chain

L A E H Weight L B G H Weight

Load Limit Size Load Limit Size

T mm Kg T mm Kg

2.5 8 171 92 60 18 0.9 2.5 8 119 36 20 22 0.8

4 10 211 113 75 22 1.8 4 10 150 47 22 29 1.4

6.7 13 261 138 90 26 3.5 6.7 13 172 53 29 38 2.7

10 16 311 157 105 31 6.1 10 16 208 68 30 45 4.4

Duo Master Grab MGD Swivel Griplatch Safety Hook LBK

For two leg slings.

Working Chain Working Chain

L A E H Weight L B C E A G H Weight

Load Limit Size Load Limit Size

T mm Kg T mm Kg

3.5 8 171 100 75 21 1.3 2.5 8 177 37 27 38 12 20 22 1.1

5.6 10 211 124 90 24 2.3 4 10 214 47 37 44 15 22 29 2.0

9.5 13 262 149 105 31 5.2 6.7 13 262 53 45 48 19 29 38 3.8

14 16 310 175 120 35 7.9 10 16 324 68 66 61 25 30 45 7.1

Master Link MF

For 1,2,3 & 4 Leg Slings. Safety Hook EGKN with latch

Working Working Chain

Chain Size L E D Weight L B G H Weight

Load Limit Load Limit Size

T 1 Leg 2 Leg 3-4 Leg Kg T mm Kg

4 10 8 6 140 80 17 0.8 2.5 8 95 28 17 23 0.5

7.5 13 10 8 160 95 22 1.5 4 10 121 35 23 31 1

10 16 13 10 190 110 28 2.5 6.7 13 145 42 28 38 2.1

17 20 16 13 240 140 34 5.2 10 16 170 52 36 46 3.9

28 22, 26 20, 22 16, 20 250 150 42 7.7 16 20 209 61 42 60 7.6

C Grab CG C Grab CGD

For use with master links & eye hooks. For use with master links.

Working Chain Working Chain

L B E H Weight L B E H Weight

Load Limit Size Load Limit Size

T mm Kg T mm Kg

2.5 8 107 12 32 24 0.7 3.5 8 107 12 32 29 1.1

4 10 134 15 40 29 1.5 5.6 10 134 15 40 37 2.2

6.7 13 172 18 52 38 3.2 9.5 13 173 19 48 48 5.4

10 16 215 22 64 47 6.1 14 16 215 22 64 57 9.1

Grab Hook GG C - Lok CL

For use with master links, eye hooks & chokes.

Working Chain

L B Weight

Load Limit Size

Working Chain

L B E H Weight

T mm Kg Load Limit Size

2.5 8 57 10.5 0.4 T mm Kg

4 10 83 12 0.9 2.5 8 58 12 32 24 0.5

6.7 13 97 16 1.8 4 10 74 15 40 29 1.0

10 16 124 20 3.1 6.7 13 94 18 52 38 2.0

16 20 147 26 7.0 10 16 119 22 64 48 3.8

30 WIRE ROPES • • •CHAINS • • SHACKLES • • BLOCKS • • RIGGING • • SAFETY NZ WIDE: 31

Grade 80 Chain Slings (Working Load Limit in Tonnes) Round Slings

SYNTHETIC SLINGS

CHAIN LIFTING SLINGS To standard EN 1492 - 2.

Safety Factor: 7:1

Single Leg 0° 2 Leg 3 & 4 Leg - Same Ratings Endless

Safe Working Load (Kgs)

Lifting

Mode

Colour

Factor 1.4 Factor 1 Factor 2.1 Factor 1.5

Chain Ø Factor 1

ß 0~45° ß 45~60° ß 0~45° ß 45~60° Factor 1.6

(mm) 0°

0~90° 90~120° 0~90° 90~120° Straight Pull (kg) Choker Hitch (kg) Basket Pull (kg) Basket 90O (kg) Basket 120O (kg)

7 1.50 2.12 1.50 3.15 2.24 2.50 Violet 1000 800 2000 1400 1000

8 2.00 2.80 2.00 4.25 3.00 3.15 Green 2000 1600 4000 2800 2000

10 3.15 4.25 3.15 6.70 4.75 5.00 Yellow 3000 2400 6000 4200 3000

13 5.30 7.50 5.30 11.20 8.00 8.50 Grey 4000 3200 8000 5600 4000

16 8.00 11.20 8.00 17.00 11.80 12.50 Red 5000 4000 10000 7000 5000

19 11.20 16.00 11.20 23.60 17.00 18.00 Brown 6000 4800 12000 8400 6000

20 12.50 17.00 12.50 26.80 19.00 20.00 Blue 8000 6400 16000 11200 8000

22 15.00 21.20 15.00 31.50 22.40 23.60 Orange 10000 8000 20000 14000 10000

Grade 100 Chain Slings (Working Load Limit in Tonnes) Flat Woven ‘Super Slings’

To AS 1353.1-1997

Safety Factor: 8:1 (Orange 12t Slings 7:1)

Single Leg 0° 2 Leg 3 & 4 Leg - Same Ratings Endless

Double Ply

Safe Working Load (Kgs)

Lifting

Mode

Colour Width

Factor 1.4 Factor 1 Factor 2.1 Factor 1.5

Chain Ø Factor 1

ß 0~45° ß 45~60° ß 0~45° ß 45~60° Factor 1.6

(mm) 0°

0~90° 90~120° 0~90° 90~120°

7 2.00 2.80 2.00 4.20 3.00 3.20 mm Straight Pull (kg) Choker Hitch (kg) Basket Pull (kg) Basket 90O (kg) Basket 120O (kg)

8 2.50 3.50 2.50 5.25 3.75 4.00 Violet 25 1000 800 2000 1400 1000

10 4.00 5.60 4.00 8.40 6.00 6.40 Green 50 2000 1600 4000 2800 2000

13 6.70 9.50 6.70 14.00 10.00 10.70 Yellow 75 3000 2400 6000 4200 3000

16 10.00 14.00 10.00 21.20 15.00 16.00 Grey 100 4000 3200 8000 5600 4000

20 16.00 22.40 16.00 33.60 24.00 25.60 Red 125 5000 4000 10000 7000 5000

Brown 150 6000 4800 12000 8400 6000

Blue 200 8000 6400 16000 11200 8000

Use of Chain Slings Maintainance of Chain Slings Orange 250 10000 8000 20000 14000 10000

Orange 300 12000 9600 24000 16800 12000

• Keep a register of all slings in use. • Chains should be inspected prior to use.

• Never lift with a twisted chain. • Periodic thorough examination must be carried out at

• Chain slings should be shortened with a least every 12 months or more frequently according to

shortening hook, never by knotting. statutory regulations, type, and frequency of use.

• Protect the chain against sharp edges by proper padding. • Chains with bent links or with cracks or gouges in the

• Never point load a hook - the load should always seat links should be replaced, as should deformed components

correctly in the bowl of the hook. such as bent master links, opened up hooks and any

• Always use the correct size sling for the load, allowing fitting showing signs of damage.

for the included angle and possibility of unequal loading.

• The master link should always be able to move freely on

the crane hook.

• Avoid shock loading at all times.

32 WIRE ROPES • • •CHAINS • • SHACKLES • • BLOCKS • • RIGGING • • SAFETY NZ WIDE: 33

Block Components ROPEMASTER® Tail and Scabbing Blocks ROPEMASTER®

BLOCKS

BLOCKS External Features

Draw Pins

Yoke

Line Guard

Side Plates

Axle

Sheave

Internal Features 108R 110R

Yoke

Line Guard

Draw Pins

Side Plates

Side Plates

Sheave Pin Nut

Adjustable Bearing

Sheave 112R 513A 515A

Retainer + Sheave Pin Nut

Retainer Lock

Block Rope Size Sheave Size Safe working Load Weight Application

Name (inch) (inch) (Kg) (Kg)

108R 1/2 - 5/8 8 x 1 1/2 7,257 13.6 Tail

Bearing 110R 1/2 - 5/8 10 x 1 3/4 7,257 17.2 Tail

112R 1/2 - 5/8 12 x 1 3/4 7,257 21.3 Tail

Bearing Cup

Sheave Pin 513A 3/4 - 7/8 13 x 2 1/2 13,607 28.6 Tail + Rider

515A 7/8 - 1 15 x 2 1/2 13,607 33.1 Tail + Rider

* Shaw’s stock a full range of replacement parts.

34 WIRE ROPES • • •CHAINS • • SHACKLES • • BLOCKS • • RIGGING • • SAFETY NZ WIDE: 35

Single Sheave Snatch Block

BLOCKS

BLOCKS

Swivel top Shackle model (Hook Top model also available)

Working

Sheave Size Rope Diameter Weight

Model Load Limit

mm mm T Kg

SB4S 4BS 100 10 - 13 4.0 6.8

SB8S 6BS 150 16 -19 8.0 13.2

Lashing Snatch Block Single Sheave

Swivel Oval Eye Model

Working

Sheave Size Rope Diameter Weight

Model Load Limit

mm mm T Kg

LLB6 1L 150 20-22 5.0 11.0

Rigging Block

RM 2214 RB2143 FB12 Y Type with shackle

Working

Sheave Size Rope Diameter Weight

Rider Blocks Fall Block Model

mm mm

Load Limit

T Kg

Y-3 75 12 0.75 1.15

Rope Size Sheave Size Safe working Weight Rope Size Sheave Size Safe working Weight

Block Load Block Load

Name Name

Inch Inch Kg Kg Inch Inch Kg Kg

RM 2214 1 1/8 - 1 1/4 14 X 2 1/2 19,958 58.9 FB12 7/8 12 20,000 130

Yarding Block

RB2143 1 1/8 - 1 1/4 21 20,000 137

Swivel Oval Eye Model

Working

Sheave Size Rope Diameter Weight

Model Load Limit

mm mm T Kg

YBO 100 100 8 1 1.9

YBO 125 125 9 1.5 3.6

YBO 150 150 12 2 6

YBO 200 200 16 4 12.5

Maintenance

RM 83 506 508 • Grease regularly (daily or at least weekly). We frequently see blocks damaged due to bearings running dry.

• Keep the side plates screwed tight.

• Be careful grabbing blocks with the loader grapple.

Tommy Moore (or Rig Up) Blocks

Matching Rope Diameter to Sheave Groove Size

Safe Working Opening

Rope Size Sheave Size Throat Width Weight

Block Name Load Height

Kg Inch Inch Inch Inch Kg

RM83 6803 1/2 - 5/8 8X3 41/2 43/4 19.0

506 6803 3/8 - 5/8 6X2 3 11/2 10.9

508 13608 1 - 11/4 8 X 41/2 51/2 6 32.7

RIGHT WRONG WRONG

36 WIRE ROPES • • •CHAINS • • SHACKLES • • BLOCKS • • RIGGING • • SAFETY NZ WIDE: 37

Ratchet Load Binder Chain Blocks

CHAIN & LEVER BLOCKS

LOAD RESTRAINT Chain Size Lashing Capacity Capacity

Chain

Chain Falls

Effort To Lift

Weight

Diameter Rated Load

mm Kg

T mm Kg Kg

10 4500

0.5 5.0 1 24 10.5

13 6700

1T 6.3 1 29 12.5

2T 7.1 1 36 21

3T 8.0 2 36 36

Lever Load Binder 5T 9.0 2 39 42

Chain Size Lashing Capacity

mm Kg

7.3 2300

8 3000

10 4500 Lever Blocks

13 6700

Hand Pull to

Rated Load Standard Lift Weight

Lift Full Load

T M Kg Kg

Twitching Bar 0.8 1.5 29 6.0

Heavy duty to suit Lever Load Binder 1.0 1.5 36 6.2

1.6 1.5 34 8.3

2.5 1.5 37 11.6

Heavy Duty Ratchet Tie Downs 3.2 1.5 37 16.0

9 m: 2.5 tonne lashing capacity. 6.3 1.5 38 27.0

6 m: 1 tonne lashing capacity. 9.0 1.5 39 42.0

6 m: 0.75 tonne lashing capacity.

Transport Short Link Grade 70

Hardened and tempered with Zinc Chromate finish. Pocket Lever Blocks

Compliant with AS/ NZS 4344-2001 G70 Slip Hook

Hand Pull to

Rated Load Standard Lift Weight

Lashing Working Load Lift Full Load

Chain Size Weight Chain Size

Capacity limit Kg M Kg Kg

mm T Kg/M mm T 250 1 20 1.6

7.3 3 1.14 8 1.5 500 1.2 31 2.6

8 4 1.4 10 2.5

10 6 2.15

13 9 3.49

G70 Lug Links

Unilok Shackle Chain Size

Working Load

limit Kito Clips

mm T

Working Load

Pin Dia WLL Rope Diameter

Limit 8 1.5

T mm

T 10 2.5

0.75 8 - 10

7 1.12

1.5 12 - 14

9 1.5

10 2.0

G70 Grab Hook 3.0 16 - 20

12 3.15

Working Load

Chain Size

16 5.3 limit

20 8.0 mm T

24 11.2 8 3.0

30 21.2 10 4.5

38 WIRE ROPES • • •CHAINS • • SHACKLES • • BLOCKS • • RIGGING • • SAFETY NZ WIDE: 39

Girder Clamps Marlin Spikes Splicing Hammer

ACCESSORIES

CHAIN & LEVER BLOCKS Working

Flange Headroom Weight

Size (inch): 8, 10, 14, 16, 20, 24, 27. 430 mm, 2.2 kg.

Model Load Limit

T mm mm Kg

WGC 10 1 75 - 230 86 - 129 4.8

WGC 30 3 80 - 320 141 - 201 9.5

WGC 100 10 90 - 320 136 - 186 18.0

Swaging Pliers

600 mm model.

300 mm model.

Bench model.

Drum Lifters

• 1 tonne working load limit. Morse Starret Wire Rope Cutter Felco Wire Rope Cutters

• 6mm G80 alloy steel chain. Sizes: C7, C9, C12, C16

• Lifts drums with or without lids (loaded and empty drums). Max Rope

Model Diameter

inch

1 3/4

1A 1

2 11/4

Shindaiwa Cut Off Saw Wire Rope Lubricant

Tough and Compact. Specialist low viscosity lubricant,

Cuts up to 2” diameter wire rope. for penetrating through to the

Wellculip Wire Pull Winch (Tirfor Style) rope core.

Model WPW 08 WPW 16 WPW 32

Rated Lift (Wll) (T) 0.8 1.6 3.2

Rated Pull (Wll) (T) 1.3 2.6 5.2

Rope Movement Per Stroke (mm) 52 55 28

Effort As Rated Load (Kg) 29 40 45

Master Padlock

Handle Lenght (mm) 800 1120 1120

Weight (Without Rope) (Kg) 7.5 16 26

Ferrule Punch

Rope Diameter (mm) 8.5 11.5 16.5

To suit 10 – 16mm chain.

Rope Size Number of

Standard Rope Length (M) 20 20 20 Model Ferrule Size

inch dies

Rope & Collector Weight (Kg) 8 14 24

Standard 5/8, 3/4 B5, B6 1

Large 5/8, 3/4, L6, L7, L8, 2

7/8, 1 B5, B6

Wire Rope Socks

For pulling single or connected wire rope ends.

40 WIRE ROPES • • •CHAINS • • SHACKLES • • BLOCKS • • RIGGING • • SAFETY NZ WIDE: 41

CONTACT

Freephone

0800 4 SHAWS

or 07 823 4029

@

Email

sales@wireropes.co.nz

Fax

07 823 4059

Postal Address

P.O. Box 962, Cambridge,

3450, New Zealand

Physical Address

9 - 13 Albert Street, Cambridge,

3450, New Zealand

“Opportunity is missed by most because it is dressed in overalls

and looks like work.”

42 WIRE ROPES • • •CHAINS • • SHACKLES • • BLOCKS • • RIGGING • • SAFETY NZ WIDE: 43

NZ WIDE: 0800 4 SHAWS

You might also like

- Items of Work For RoadsDocument6 pagesItems of Work For Roadsjhc1123No ratings yet

- Kiswire General Purpose RopesDocument28 pagesKiswire General Purpose Ropesdaviko313No ratings yet

- Meat PieDocument13 pagesMeat Piecrispitty100% (1)

- Ancient Skies of Northern Europe: Stars, Constellations, and The Moon in Nordic MythologyDocument12 pagesAncient Skies of Northern Europe: Stars, Constellations, and The Moon in Nordic MythologyoldenglishblogNo ratings yet

- 1926 PapionianDocument108 pages1926 PapionianPLCS_FoundationNo ratings yet

- Wire Rope PDFDocument31 pagesWire Rope PDFMuhammad Zefrian SyahputraNo ratings yet

- OriginalDocument362 pagesOriginalAbdellatef HossamNo ratings yet

- Steel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringDocument19 pagesSteel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringAshba13No ratings yet

- Bonnet Assembly For Broadshear Rams: Shearing Bonnet For Use With TL and Evo BopsDocument1 pageBonnet Assembly For Broadshear Rams: Shearing Bonnet For Use With TL and Evo BopsDJNo ratings yet

- BOPRAMS Series700-1Document3 pagesBOPRAMS Series700-1Surya Prakash DubeyNo ratings yet

- Blowout Preventers CompressedDocument28 pagesBlowout Preventers CompressedMuthia AstriNo ratings yet

- 528DR 027 Intro To DrillingDocument129 pages528DR 027 Intro To DrillingarashNo ratings yet

- Iadc Roller Cone ClassificationDocument2 pagesIadc Roller Cone Classificationknn52unnNo ratings yet

- Fishing EquipmentDocument8 pagesFishing EquipmentRizwan FaridNo ratings yet

- Fishing Tools - Internal Catch Taper Taps: Product Line ProductDocument2 pagesFishing Tools - Internal Catch Taper Taps: Product Line ProductrezaNo ratings yet

- WellheadsDocument17 pagesWellheadsLogy Mohamed ElrweedyNo ratings yet

- Machinery Selection-Books06Document146 pagesMachinery Selection-Books06miningnova2100% (1)

- Christopher Franklin - Handbook of Oil and Gas Operations PDFDocument281 pagesChristopher Franklin - Handbook of Oil and Gas Operations PDFHaitham AbdulrazzakNo ratings yet

- Plaster & Wald Consulting Corp.: Fill in Shaded AreasDocument2 pagesPlaster & Wald Consulting Corp.: Fill in Shaded AreasmarvinNo ratings yet

- Celula pw4c3Document2 pagesCelula pw4c3Euclides Alexadre BernardelliNo ratings yet

- Stacey Oil Services Drill Pipe Float Valves Pullers Baffle Plates Float Subs BrochureDocument27 pagesStacey Oil Services Drill Pipe Float Valves Pullers Baffle Plates Float Subs BrochureKeshav Pujeri100% (1)

- 16 BHA Tally FormatDocument2 pages16 BHA Tally FormatShraddhanand MoreNo ratings yet

- Blow Out PreventorDocument6 pagesBlow Out PreventorCesar Valdivia MontañoNo ratings yet

- Drilling Contracts: Contract Type Effect On Operator Effect On ContractorDocument206 pagesDrilling Contracts: Contract Type Effect On Operator Effect On ContractorMohammed Zubair AhmedNo ratings yet

- Load Cells PDFDocument228 pagesLoad Cells PDFVănPhùngLươngNo ratings yet

- Anullar BOPDocument5 pagesAnullar BOP0926828260sNo ratings yet

- Types: Ram Blowout PreventerDocument5 pagesTypes: Ram Blowout Preventerrczj2008No ratings yet

- Taper Tap: Product CatalogDocument1 pageTaper Tap: Product CatalogYudha SatriaNo ratings yet

- Gate Valve 2-1/16" 5K/10K/15K Type FC, Api-6a, Petrotrim ServicesDocument1 pageGate Valve 2-1/16" 5K/10K/15K Type FC, Api-6a, Petrotrim ServicesPetrotrim ServicesNo ratings yet

- 5 - Mud PumpsDocument16 pages5 - Mud PumpsAli Shan KakarNo ratings yet

- Emsco FB13/1600 Module Exploded ViewDocument3 pagesEmsco FB13/1600 Module Exploded ViewJESUS ANTONIO100% (1)

- Manual FMS 275 VarcoDocument101 pagesManual FMS 275 VarcoJuan RuizNo ratings yet

- Tubulars and Tubular Services Catalog: DrilcoDocument29 pagesTubulars and Tubular Services Catalog: DrilcoDoni KurniawanNo ratings yet

- Peco CatalogDocument152 pagesPeco CatalogClaudio Israel Godinez SomeraNo ratings yet

- Instruction Manual 6460: Lead Seal Cementing Type Casing PatchDocument10 pagesInstruction Manual 6460: Lead Seal Cementing Type Casing PatchRagui StephanosNo ratings yet

- Tubing ManDocument30 pagesTubing ManГалинаNo ratings yet

- Fishing Bumper Subs: Instruction Manual 4460Document15 pagesFishing Bumper Subs: Instruction Manual 4460Foros IscNo ratings yet

- Fishing Jars Brochure PDFDocument5 pagesFishing Jars Brochure PDFLincoln ZhaoXi100% (1)

- HH SwivelDocument3 pagesHH SwivelHoracio LafuenteNo ratings yet

- Successfully Drills Through Total Losses Zones, Saves 17.6 DaysDocument2 pagesSuccessfully Drills Through Total Losses Zones, Saves 17.6 DaysAriel Della TorreNo ratings yet

- HY10 1630US 5 2012-Bladder AccumulatorsDocument14 pagesHY10 1630US 5 2012-Bladder AccumulatorsAlejandro GilNo ratings yet

- Drill String SlidesDocument93 pagesDrill String SlidesAyush RawatNo ratings yet

- Magnum Composite Plug Catalog 06-30-10 PDFDocument21 pagesMagnum Composite Plug Catalog 06-30-10 PDFEmad JamshidiNo ratings yet

- JointDocument2 pagesJointJohnNo ratings yet

- Handing Tools CPMCDocument32 pagesHanding Tools CPMCcristinelb100% (1)

- Bha & Drill ColarsDocument6 pagesBha & Drill Colarswasim78622No ratings yet

- CDT Drill StringDocument19 pagesCDT Drill StringSohaib RashidNo ratings yet

- Ame Rigs Brief Table ComDocument1 pageAme Rigs Brief Table ComMarvin TolentinoNo ratings yet

- TM 120 Daily and Weekly Inspection and Maintenance TasksDocument23 pagesTM 120 Daily and Weekly Inspection and Maintenance TasksAlejandra Noguera GiraldoNo ratings yet

- F-1600 Triplex Pump 泥浆泵: Parts List 6-A)Document27 pagesF-1600 Triplex Pump 泥浆泵: Parts List 6-A)waleedNo ratings yet

- Hydril Mac IIDocument4 pagesHydril Mac IIFabian Romero BecerraNo ratings yet

- Drilling FormulasDocument5 pagesDrilling FormulasJoshua RosensteinNo ratings yet

- Cameron Hydraulic Gate Valves Type F & FCDocument3 pagesCameron Hydraulic Gate Valves Type F & FCJuan Sebastian Diaz CuadrosNo ratings yet

- IDS 350PE Top DriveDocument2 pagesIDS 350PE Top Drivealan camposNo ratings yet

- HBM SP4M - Maximum Accuracy Single Point Load CellDocument3 pagesHBM SP4M - Maximum Accuracy Single Point Load CellDennis AlexanderNo ratings yet

- Driil CollersDocument15 pagesDriil Collersamol modakNo ratings yet

- 10.750 in 73.20 PPF 0.672 in SM-C110 VAM KSX SC75 Ref.13-04-17Document1 page10.750 in 73.20 PPF 0.672 in SM-C110 VAM KSX SC75 Ref.13-04-17Ahmed ElwanyNo ratings yet

- Logan Surface Bumper Sub (English)Document10 pagesLogan Surface Bumper Sub (English)Gianfranco Exequiel Sebastian GarciaNo ratings yet

- Camesa TechBulletin-022Document1 pageCamesa TechBulletin-022FauzanNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- 16 MATERIAL HANDLING - MasterDocument55 pages16 MATERIAL HANDLING - MasterSinter PlanningNo ratings yet

- Wire Rope CatalogueDocument51 pagesWire Rope CatalogueRAJAT DEO AGRAWALNo ratings yet

- NSI CatalogueDocument28 pagesNSI Catalogueado31No ratings yet

- Presentasi Wire Rope ADocument40 pagesPresentasi Wire Rope ADoddy Indrawan100% (1)

- Stud Lok Stringer To Stud FixingDocument8 pagesStud Lok Stringer To Stud Fixingsattar12345No ratings yet

- Nailon Plates 01 - 2017Document2 pagesNailon Plates 01 - 2017sattar12345No ratings yet

- A Guide To Farm Tracks and Stream Crossing Design and ManagementDocument2 pagesA Guide To Farm Tracks and Stream Crossing Design and Managementsattar12345No ratings yet

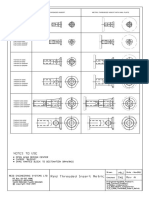

- Reid Threaded Insert MetricDocument1 pageReid Threaded Insert Metricsattar12345No ratings yet

- Basf Masterpolyheed 8840 TdsDocument2 pagesBasf Masterpolyheed 8840 Tdssattar12345No ratings yet

- 3 6 - Crossings - Temporary Crossings 2 0Document3 pages3 6 - Crossings - Temporary Crossings 2 0sattar12345No ratings yet

- Denso PasteDocument2 pagesDenso Pastesattar12345No ratings yet

- TD VSL Multistrand-EcDocument1 pageTD VSL Multistrand-Ecsattar12345No ratings yet

- Fosroc Expandafoam Closed Cell TDSDocument2 pagesFosroc Expandafoam Closed Cell TDSsattar12345No ratings yet

- Ss 4259Document1 pageSs 4259sattar12345No ratings yet

- Denso Paste S105Document2 pagesDenso Paste S105sattar12345No ratings yet

- PBB0310 Butyl Sealant TapeDocument1 pagePBB0310 Butyl Sealant Tapesattar12345No ratings yet

- DensoHi TackPrimerDocument2 pagesDensoHi TackPrimersattar12345No ratings yet

- Flooring: Sika® Technology and Concepts For Flooring and CoatingDocument56 pagesFlooring: Sika® Technology and Concepts For Flooring and Coatingsattar12345No ratings yet

- Plate SizeDocument1 pagePlate Sizesattar12345No ratings yet

- PN060511Document1 pagePN060511sattar12345No ratings yet

- Applications: TYPE: RutileDocument1 pageApplications: TYPE: Rutilesattar12345No ratings yet

- Specification For Lighting Columns: NotesDocument9 pagesSpecification For Lighting Columns: Notessattar12345No ratings yet

- Primacorelw-71 en PDFDocument2 pagesPrimacorelw-71 en PDFsattar12345No ratings yet

- Bridges: Data SheetDocument2 pagesBridges: Data Sheetsattar12345No ratings yet

- Superarc LA-75: Conformances Key FeaturesDocument2 pagesSuperarc LA-75: Conformances Key Featuressattar12345No ratings yet

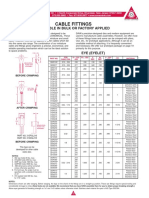

- Cable Fittings: Available in Bulk or Factory AppliedDocument8 pagesCable Fittings: Available in Bulk or Factory Appliedsattar12345No ratings yet

- Atlas Specialty Metals: Stainless Steel Wire & BarDocument29 pagesAtlas Specialty Metals: Stainless Steel Wire & Barsattar12345No ratings yet

- Tie Bolt Hole Repair SystemDocument1 pageTie Bolt Hole Repair Systemsattar12345No ratings yet

- 0911 Zeomighty SpecsDocument4 pages0911 Zeomighty Specssattar12345No ratings yet

- Microbial Induced Corrosion (MIC) Attack of Concrete in Sewage ApplicationsDocument2 pagesMicrobial Induced Corrosion (MIC) Attack of Concrete in Sewage Applicationssattar12345No ratings yet

- Inorganic Antimicrobial Additive For Concrete Corrosion ControlDocument2 pagesInorganic Antimicrobial Additive For Concrete Corrosion Controlsattar12345No ratings yet

- Proline Table-Top Machines Z005 Up To Z100: Product InformationDocument2 pagesProline Table-Top Machines Z005 Up To Z100: Product InformationErika Mae EnticoNo ratings yet

- Soal DescriptiveDocument4 pagesSoal DescriptiveLuh SetiawatiNo ratings yet

- 2005 Sea-Doo 3D RFIDocument124 pages2005 Sea-Doo 3D RFIJessica DziakNo ratings yet

- Concept Paper Group 1Document9 pagesConcept Paper Group 1Kaime KeilarNo ratings yet

- Freight ForwardingDocument43 pagesFreight ForwardingEuroline NtombouNo ratings yet

- Montague Street Cable Car, Wall Street FerryDocument23 pagesMontague Street Cable Car, Wall Street FerryBob DiamondNo ratings yet

- Consola Phonic CELEUS800 en EspañolDocument32 pagesConsola Phonic CELEUS800 en EspañolRoberto BurgosNo ratings yet

- Unicast Rotary Breaker Wear Parts: Cast To Last. Designed For Hassle-Free Removal and ReplacementDocument2 pagesUnicast Rotary Breaker Wear Parts: Cast To Last. Designed For Hassle-Free Removal and ReplacementAugusto TorresNo ratings yet

- CekocideDocument1 pageCekocideKaren Claire HorcaNo ratings yet

- ISO 8861 Blower Engine RoomDocument28 pagesISO 8861 Blower Engine Roommohammad choirul huda100% (1)

- CW9 Identifying Functions 5Document2 pagesCW9 Identifying Functions 5Xavier BurrusNo ratings yet

- DSP Lab RecordDocument97 pagesDSP Lab RecordLikhita UttamNo ratings yet

- Spesifikasi Vista 120 S Patient Monitor - StandardDocument2 pagesSpesifikasi Vista 120 S Patient Monitor - StandardHadi AtmojoNo ratings yet

- View Result - CUMS Comprehensive University Management System - M.K.Bhavnagar University Powered by AuroMeera A College Management System ProviderDocument1 pageView Result - CUMS Comprehensive University Management System - M.K.Bhavnagar University Powered by AuroMeera A College Management System ProviderKiaanNo ratings yet

- In-Lab Sharp-Edged Orifice Meter ReportDocument9 pagesIn-Lab Sharp-Edged Orifice Meter ReportLiliane AlameddineNo ratings yet

- MSC in Subsea Engineering - Flexible Pipe Analysis Lecture JP 2023Document67 pagesMSC in Subsea Engineering - Flexible Pipe Analysis Lecture JP 2023Fakey LaazNo ratings yet

- Reglas Digitales Mitutoyo Scale Units Linear ScalesDocument31 pagesReglas Digitales Mitutoyo Scale Units Linear ScalesAngelmambrinNo ratings yet

- EngineeringDocument107 pagesEngineeringSuezakumeNo ratings yet

- Research PaperDocument2 pagesResearch PaperCyril FragataNo ratings yet

- FAB-3021117-01-M01-ER-001 - Rev-0 SK-01 & 02Document91 pagesFAB-3021117-01-M01-ER-001 - Rev-0 SK-01 & 02juuzousama1No ratings yet

- Coord Angle and BearingDocument18 pagesCoord Angle and BearingvNo ratings yet

- The Mole ConceptDocument12 pagesThe Mole ConceptVictor OkosunNo ratings yet

- Irving Hallowell - Ojibwa Ontology, Behavior and World ViewDocument24 pagesIrving Hallowell - Ojibwa Ontology, Behavior and World ViewFa Di LaNo ratings yet

- Wednesday 12 June 2019: ChemistryDocument32 pagesWednesday 12 June 2019: ChemistryMohammad KhanNo ratings yet

- Unit Operation QBDocument7 pagesUnit Operation QBsmg26thmayNo ratings yet

- Apple Computer Inc. v. Burst - Com, Inc. - Document No. 146Document39 pagesApple Computer Inc. v. Burst - Com, Inc. - Document No. 146Justia.comNo ratings yet