Professional Documents

Culture Documents

MS For Installation of Duct & Accessaries

Uploaded by

Anandu AshokanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS For Installation of Duct & Accessaries

Uploaded by

Anandu AshokanCopyright:

Available Formats

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Method Statement and Risk Assessment for

Installation of Duct & Accessories, at AMC

Connectivity Corridors & Concourse Bridge Project,

AL Maryah island,

ABUDHABI

Project No-M- 1467

Document Ref No: GEMC-MC-A-MST-0012 Rev 0

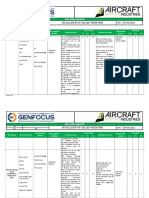

Method Statement Title Installation of Duct & Accessories Doc Ref No: GEMC-MC-A-MST-0012

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 1 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Project name AMC Connectivity Corridors & Concourse Bridge Project Project No M1467

Main Contractor McLaren Construction Ltd. Document No GEMC-MC-A-MST-0012

Title/Task Installation of Duct & Accessories Revision No 00

Document

Date of issue 4/3/2019 Prepared By Syed Faisal

Duration of

Proposed start date 15/3/2019 task 40 week

Contents

Section A Register of Revisions

Section B Scope of Works to be undertaken:

Section C Location of the Project

Section D Location of the Works to be Undertaken with the Project

Section E Site Access/Egress and Access to the Work Zone

Section F Emergency Contacts Details and Procedures:

Section G McLaren Site Specific HSE Safety Induction:

Section H Welfare facilities:

Section I Personal Protective Equipment

Section J Plant/Equipment and tools to be Used

Section K Materials To be used.

Section L Communication/Toolbox Talks/Training Requirements:

Section M Works Permits

Section N Environmental and Waste Management:

Section O Programme for the Works:

Section P Housekeeping and Storage:

Section Q Hygiene and cleanliness

Section R Working At Height

Section S Occupational Health

Section T Sequence of Works/Activities

Appendices

Appendix A Site Logistic Plans and Other Design Information Relative to the Works

Appendix B Crisis/Emergency Plan

Appendix C COSHH Assessments and Material Data Sheets (to be provided by Subcontractor)

Appendix D Risk Assessments (to be provided by Subcontractor)

Appendix E Technical Information (to be provided by the Subcontractor)

Appendix F Risk Assessment

Method Statement Title Installation of Duct & Accessories Doc Ref No: GEMC-MC-A-MST-0012

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 2 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Section A - Register of Revisions

Revision Date Reason for Amendment Amended By Signature Has this amendment been briefed

No (Name) to the operatives involved and have

the operatives signed the register.

This method statement has been prepared in conjunction with the following documents;

1. OSHAD regulation and requirements

2. OHSAD- Code of Practices, HSE Regulations, Technical Guidelines, Mechanisms

3. GR HSE Guidelines and Requirements

4. Federal Environmental Authority Law No 24/1999 and its supplements.

5. Federal Labour Law No 8

6. Articles (3,4,5,7) Local Law No 21/2005 (Waste Management)

7. McLaren SHE Procedures

8. McLaren’s site specific SHEQ Plan (including TMMS, SWMP, EPP).

9. McLaren’s Integrated Management System Policy Statement (IMS) .

Section B- Scope of Works to be undertaken:

The work Describes Installation of Duct and accessories at AMC Connectivity Corridors & Concourse Bridge

Project, Abu Dhabi

The following Critical Hazards have been identified during the preparation of the scope of works, please refer to

the Risk Assessments within Appendix D.

1. Manual Handling Injuries

2. Slip Trips and Falls

3. Fall from Height

4. Use of scaffold/ladders

5. Electrocution

6. Use of Power Tools

7.Falling objects

Section C- Location of the Project

Location of the Project;

Our project is located is located AMC CONCOURSE BRIDGE in between Al Maryah and Galleria Mall as marked

below.

Method Statement Title Installation of Duct & Accessories Doc Ref No: GEMC-MC-A-MST-0012

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 3 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Method Statement Title Installation of Duct & Accessories Doc Ref No: GEMC-MC-A-MST-0012

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 4 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Section D- Location of the Works to be Undertaken within the Project

Add full sketch of the project and mark up your areas of work (logistics plan to be updated)

Method Statement Title Installation of Duct & Accessories Doc Ref No: GEMC-MC-A-MST-0012

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 5 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Section E- Site Access/Egress and Access to the Work Zone

Entrance to the Site will be from Gate no 1 as per attached drawing.

(logistics plan to be attached)

Method Statement Title Installation of Duct & Accessories Doc Ref No: GEMC-MC-A-MST-0012

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 6 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Section F- Emergency Contacts Details and Procedures:

The following staff from both McLaren and Genfocus will be on site during the execution of the works and will be

responsible for managing the works;

Name Position Company Contact Details

Paul Carlin Operations Director McLaren 056-1054691

Luke Watson Project Manager McLaren 052-1022402

Prabhu Srinivasulu Construction Manager McLaren 050-9709963

Joby John HSE Manager (First Aider) McLaren 050-6372060

Evangeline Huerto First Aider McLaren 056-1852727

Jijo Mathew Safety Advisor/First Aider McLaren 055-2152903

Ramil Magano QA/QC Engineer(Fire marshal) McLaren 050-2923058

Biju MEP Engineer McLaren 056-8059139

Syed Faisal Ahmed Project Manager Genfocus 056-5465814

Anu Baby Project Engineer Genfocus 056-5465807

Mohmmed Jasim Mechanical Engineer Genfocus 056-5268312

Prabir Kumar HSE Officer/First Aider Genfocus 0547937312

Murgan HVAC Supervisor Genfocus 0547937313

In case of an Emergency/fire Alarm, all operatives, Staff and Visitors are required to report to the Assembly Point,

which is indicated on the site logistics drawing, as indicated by the symbol below. Where the registers will be

checked to ensure that no one is un-accounted. No one will be allowed to leave the assembly point until the

Emergency response Controller confirms that it is safe to do so.

1 Assembly Point No-01 (TBA)

2 Assembly Point No-02 (TBA)

Please refer to the attached Crisis/Emergency Plan, (Appendix B) which is to be implemented where the need

arises.

The Qualified First Aiders for the Project are listed below, and the first Aid Boxes will be available either in the

Induction/First Aid Room or in the Main Office.

McLaren: (details of First Aiders ) Subcontractors(Details of First Aiders )

Joby John- 050-6372060 Prabir Kumar 0547937312

Jijo Mathew 055-2152903 Anu Baby 056-5465807

Please see below the Emergency contact details

Authority/Company Contact Telephone No.

McLaren Construction Ltd 04-3417964

Police 999

Ambulance 997

GR Emergency No 058-2864950

AMC Emergency No 056-7459621

Section G- McLaren Site Specific HSE Safety Induction:

Method Statement Title Installation of Duct & Accessories Doc Ref No: GEMC-MC-A-MST-0012

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 7 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Prior to any works taking place, all Operatives arriving at AMC project will be required to undergo a

Multiplex/Gulf Related safety induction followed by McLaren Site Safety induction, which will be held in the

induction room, by McLaren’s HSE Representative or other designated person. Once the operatives have received

the site specific safety induction, they then will be briefed on the contents of this RAMS, by their respective Site

Supervisor, from which they will then be required a sign a RAMS Briefing Register (SAF019 UAE) confirming that

they have been briefed and that they fully understand the RAMS and what is expected from them during the

execution of the site works. The Operatives will also be briefed on the Emergency and Security Procedures for the

project, which is also a part of site safety induction programme.

Any operative who will be operating any plant and equipment will be required to produce a copy of their

competency certificate/card carried out by an OSHAD approved third party training provider, to enable McLaren

to issue them with the Plant Operators Authorisation (SAF023 UAE).

Section H- Welfare facilities:

Drinking Water-

Clean drinking water will be provided on site (as per approved Logistics plan) and all operatives are to ensure they

take on enough fluids throughout the day .

Comply with Summer Working Requirements .

Rest areas and toilet-

Rest area and toilets are being provided at site and located as per AMC logistics layout plan

Section I- Personal Protective Equipment (PPE)

The Following Personal Protective Equipment must be worn/be available during the execution of the works

activities

Type of PPE Required Yes No

Safety Helmet (as per standards) Yes

Safety Footwear (as per standards) Yes

Eye protection (as per standards) Yes

Gloves (as per standards) Yes

Hi- viz Vests Yes

Overalls (for operatives only) Yes

Ear protection Yes

Face Respirator No

Body Harness Yes

Respiratory masks No

Others (other specific requirements)

Please ensure that any specific precautions for PPE as identified within MSDS/COSHH assessment or any

specific requirements by supplier/manufacturer are to be complied and adhered to.

List of additional/task specific PPE to be used

1. N/A

2. N/A

3. N/A

4. N/A

Section J- Plant and Equipment to be Used

Method Statement Title Installation of Duct & Accessories Doc Ref No: GEMC-MC-A-MST-0012

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 8 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

It is anticipated that the following Plant and Equipment will be used during the execution of the works; other

items will also be identified on the schedule below;

Drilling machine/ Cutting and grinding machine

Sprit Level/Level threads

Ladder/Mobile Scaffold

Portable Hand Tools

*Note: All relevant competency certificates (as per OHSAD /GR requirements) to be submitted to HSE

Manager/Eng./Advisor prior to start of any activity.

(Below schedule to be completed by subcontractor)

Type of Plant/Equipment to be Used Yes No Type of Plant/Equipment to be Used Yes No

Lifting Yes Cradle No

Mechanical hoist No Excavation shoring No

Mobile elevating working platform No Hand tools Yes

Ladder Yes Electrical tools Yes

Hoist No CAT & Gen Set No

Test Equipment No Ventilation/Extraction Equip No

Task Lighting No Pump No

Scaffolding No Lifting slings/chains Yes

Mobile scaffolds Yes Mechanical plant No

Podium Scaffold No Others:

Section K- Materials To be used.

The following Materials will be utilised during the execution of the works, the Material Data sheets being

provided, which will allow the relevant COSHH assessments to be carried out; (See Appendix C)

Item Material Description Has MSDS been Has the COSHH

provided and Assessment sheet been

attached? completed and attached?

1 Duct and Accessories N/A N/A

2 Sealants Yes yes

3 Adhesive glue yes yes

4 Aluminium foil tape N/A N/A

Section L- Communication/Tool Box Talks/Training Requirements:

Method Statement Title Installation of Duct & Accessories Doc Ref No: GEMC-MC-A-MST-0012

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 9 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Once the RAMS has been briefed to the workforce, we will also hold Tool Box Talk relative to the work activities

being carried out, these will be conducted by the HSE team, in conjunction with the relevant site supervisors, this

will ensure that the message gets across to the workforce, in their own language, thus avoiding any

misinterpretation of the RAMS/Toolbox Talk.

During the Preparation of this RAMS the following training for the staff and operatives has been identified;

Item Description Of Training Has the Training been If not, when will be

completed? (Yes/No) completed(Date)

1 Scaffolding inspection and erection Yes

*Note: All relevant certificates will be submitted prior to works commencing or during induction. Where the

training has not been carried out, it must do so prior to the works/activities commencing.

Section M- Works Permits

The following works permits will be required during the execution of the Works;

Item Description of the Work Permit Permit Issued By Tick only applicable

1 Permit to Enter Confined Space McLaren

2 Permit for Lifting Operations. McLaren

3 Permit to Dig McLaren

4 Permit to work Hot cutting or Welding McLaren

5 Permit to Work in Ceiling Void McLaren

6 Permit for Roof Access McLaren

7 Permit to Work with Ladders, steps McLaren

8 Permit to Work at Height McLaren

9 Permit To Work – Electrical above 110V McLaren

10 Permit To Work with COSHH Items McLaren

11 Permit To Work At External Face of The Building McLaren

12 Permit For Removal of Existing Fall Protections McLaren

Any other permits if required to be added

Section N- Environmental and Waste Management:

During the execution of the project, waste will accumulate. Skips will be provided by McLaren and will be

required to put all waste in the skips provided. All waste will be segregated for recycling as per below sequence

1. Metal

2. Plastic

3. General waste

4. Concrete waste

5. Food waste

6. Hazardous waste

7. Wood Waste

Due to the nature of the works and the actual conditions of the present site, airborne dust will be minimal,

however where necessary the area affected by the installation of the temporary works, the dust will be

suppressed by spraying water.

Drip trays to be placed under plant and generator to catch any excess oil. Approved Waste Collection Contractor

Method Statement Title Installation of Duct & Accessories Doc Ref No: GEMC-MC-A-MST-0012

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 10 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

will then remove excess oil from site in oil containers and sent back to store for collection.

Section O- Programme for the Works.

The works will commence on 15-3-2019 For a duration of 40 week, as the works are scheduled to take place

during day light hours, there will be no requirement for any additional lighting

However if Night shift starts, adequate task lighting to be provided by the subcontractor

Section P- Housekeeping and Storage:

Housekeeping will be carried out as and when required and storage of materials will be in an agreed location ( as

per approved site logistics plan) within the segregated area and as agreed in subcontractor prestart meeting. The

subcontractor will remove from site.

Section Q- Hygiene and cleanliness:

Hygiene and cleanliness are the upmost requirements for the project. All works carried out within the catering

facility should comply with Etihad’s catering Hygiene Procedures and requirements. Compliance of PPE pertaining

to Hygiene and cleanliness to be strictly complied.

Section R- Working at Height

During the preparation of the RAMS, the following activities for working at height have been identified and have

been addressed within the risk assessments within Appendix D. ( to be filled if applicable to your works)

Item Activity Risk Assessment Reference

1 Installation of Duct & accessories Refer attached risk assessment

Section S- Occupational Health

During the preparation of the RAMS, the following Occupational Health items have been reviewed and addressed

within this Method Statement.

Item Description of OH Item Preventative Measures, (see also within the Risk Assessments)

1 Bad Back / sprain due to improper All Operatives will be briefed on correct lifting techniques and

Manual handling avoid heavy lifting altogether

2 Hand/Arm Vibration N/A

3 Construction dust Area will be watered to minimise dust

4 Noise N/A

5 Sun Operatives will be required to wear long sleeve and pants to

avoid direct sunlight UV rays and drink plenty of water to avoid

dehydration

6 Skin Coveralls and gloves required at all times

Method Statement Title Installation of Duct & Accessories Doc Ref No: GEMC-MC-A-MST-0012

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 11 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Section T- Sequence of Works/Activities

The works will be carried out in the following sequences; (Subcontractor to detail out the sequence of work, from offloading the

materials at site to final fix including safety precautions taken during the sequence of works )

1 RAMS to be briefed to all the operatives involved in the work

2 STARRT card to be prepared by assessing the area of work prior starting the work.

3 Supervisor to ensure all operatives have received a McLaren site basic induction

4 Supervisor to ensure all operatives have adequate PPE for the job including Full body harness.

5 Supervisor to ensure all operators having Competent certificate.

6 Supervisor to ensure that the site is clean and ready to start the work

7 Supervisor to ensure adequate tools are provided and should be visibly clean and tidy. Advise Site manager

if more tools are needed.

8 Supervisor to ensure that all materials taken into the facility are covered and equipment’s to be used are

clean & coordination of time for access has been agreed.

9 Supervisor to ensure that all operatives have done proper hand wash prior to entering any Production/

Processing area.

10 Supervisor to ensure that all hygienic PPE has been issued & being worn correctly.

11 Supervisor to ensure that proper barricade and warning signs are provided before starting any activity.

Proper Barricading to be provided for all Ceiling cutting or dust forming activity, and this barricading will be

provided with scaffolding drops with thick plastic sheets around the area to be sealed properly.

12 Supervisor to ensure proper working platforms such as ladders and scaffoldings are been used and make

sure that all the working platforms are having permit to work.

13 Supervisor to ensure that Competent workers are involved for scaffolding erection, dismantling and

inspection.

14 Transportation to site will be as per site requirement. Timing to be agreed with Mclaren

15 Ensuring that unloading of materials is undertaken in designated area.

16 Make sure that the lifting equipment is adequately rated for the specified weight (shown on the rated

plate).

17 When offloading the materials precaution to be taken to avoid damages

18 Procedure

18.1 Off-loading & Handling of GI/PI Ducts

Materials (Ducts & Accessories) will be offloaded from the vehicle manually at site location. Store in charge

18.1.1

/ Supervisor to ensure that off load material load not exceed 20kg/ person

Ensure the area shall be free from debris, levelled and necessary wooden blanks are provided to stack the

18.1.2

properly.

18.1.3 Supervisor/store keeper shall ensure the materials are as per the approvals and required quantities as per

Method Statement Title Installation of Duct & Accessories Doc Ref No: GEMC-MC-A-MST-0012

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 12 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

drawings are unloaded and check for any damages.

18.1.4 Material inspection request to be submitted for McLaren / GHD Approval

18.1.5 Materials will be stored properly under shade and necessary stock registers will be maintained.

Once the MIR is approved, required quantities and accessories will be manually shifted to work place

18.1.6

through material movement route.

18.2 GI Duct Insulation work

18.2.1 Duct & insulation materials shall be transported manually to work location.

18.2.2 Work place shall be free of dust, all duct shall be cleaned prior to insulation

18.2.3 Duct tag numbers to be identified and visibly tagged prior to insulation.

18.2.4 Apply one coat of adhesive over the duct and keep it for drying.

18.2.5 Cut the insulation as required and paste to the GI duct surface. Hold little time till properly bonding.

Foster barriers shall be applied by dipping cotton cloth and wrapping above the duct and ensure proper

18.2.6

bonding with GI duct surfaces. Allow for drying properly.

18.2.7 Ensure all surface is insulated and clean all excess glues & barrios.

18.2.8 Debris shall be removed and duct shall be covered with polythene sheets.

18.2.9 Inspection request to be submitted for McLaren / GHD Approval.

18.3 Installation of GI Ducting

Mobile Scaffolds shall use for the installation works and Safety officer shall ensure that the mobile

18.3.1

scaffolding/ ladder shall have correct tags and with adequate HSE requirement.

The duct route shall be coordinated with other services & necessary marking shall be done along the route.

18.3.2 8mm Hole drilling shall be done on the ceiling purlin/ beam and install threaded rod at 2 meter spacing.

Adequate supports shall be ensured at all turning points and joints.

Duct will be manually lifted to required height, hold properly and fasten the tie rod with bottom channel

18.3.3

under the duct.

Ducts are joined by GI clips, gaskets &fasteners supplied with the duct as required and properly tightened

18.3.4

as per standards. In between flanges approved gaskets shall be used.

18.3.5 Adjust & maintain the duct level throughout and base channels shall be properly tightened.

Site modifications, shall be by cutting the required size and riveting the flanges on the ducts. All burs shall

18.3.6 be removed prior to insulation. Modification shall be done prior to insulating the duct. Ensure the opening

shall match with the airflow/grills/inspection doors installation requirements.

Ensure the accessibility to the duct sensors/devices at high level. All excess rod/channels shall be cut and

18.3.7

removed. All opening shall be temporary closed for dust entry.

18.3.8 Duct labelling shall be done.

18.3.9 Area shall be cleaned, inspection request to be submitted for McLaren / GHD approvals.

18.4 Installation of PI Ducting

Mobile Scaffolds shall use for the installation works and Safety officer shall ensure that the mobile

18.4.1

scaffolding/ ladder shall have correct tags and with adequate HSE requirement.

The duct route shall be coordinated with other services & necessary marking shall be done along the route.

18.4.2 8mm Hole drilling shall be done on the ceiling purlin/ beam and install threaded rod at 2 meter spacing.

Adequate supports shall be ensured at all turning points and joints.

18.4.3 Duct will be manually lifted to required height, hold properly and fasten the tie rod with bottom channel

Method Statement Title Installation of Duct & Accessories Doc Ref No: GEMC-MC-A-MST-0012

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 13 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

under the duct.

Ducts are joined by clips, gaskets &fasteners supplied with the duct as required and properly tightened as

18.4.4

per standards. In between flanges approved gaskets shall be used.

Site modifications, shall be by cutting the required size and riveting the flanges on the ducts. Ensure the

18.4.5

opening shall match with the airflow/grills/inspection doors installation requirements.

Ensure the accessibility to the duct sensors/devices at high level. All excess rod/channels shall be cut and

18.4.6

removed. All opening shall be temporary closed for dust entry.

18.4.7 Area shall be cleaned, inspection request to be submitted for McLaren / GHD approvals.

19 General

Necessary clearances shall be obtained prior to installation. Any mock-up installation approvals required to

19.1

be obtained.

Obtain relevant work permit from EMPLOYERS REPRESENTATIVE and authorities. Ensure all

19.2

inspections/tests are completed and approved prior to installation.

Prior to start the installation, refer to the approved shop drawings related to the area of installation and

19.3 ensure that required materials are available at site as per approved material submittals. Ensure the

approved drawing shall be available at site.

Ensure all control measures stated in the corresponding risk assessment are adhered to when carrying out

19.4

the job

19.5 Duct shall be inspected, inner & outer side cleaned and free from any damages.

19.6 Cold galvanising touch-up paint shall be applied for all GI cut edges.

Method Statement Title Installation of Duct & Accessories Doc Ref No: GEMC-MC-A-MST-0012

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 14 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

APPENDIX A

Site Logistics Plan

Method Statement Title Installation of Duct & Accessories Doc Ref No: GEMC-MC-A-MST-0012

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 15 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

APPENDIX B

CRISIS PLAN

Method Statement Title Installation of Duct & Accessories Doc Ref No: GEMC-MC-A-MST-0012

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 16 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

CRISIS PLAN

1. Upon an incident, being discovered the first member of McLaren’s staff or the site operative

discovering the incident shall inform the Project Manager and Site HSE team through AMC Project

emergency Contact No-056-7459621.

2. Both the HSE Engineer/advisor and the First Aider are to attend the scene with their mobile. The

project Manager or authorised person waits in office ready to contact relevant emergency

services.

3. Both the HSE Engineer/advisor and the first Aider are to assess the situation and put in place the

relevant systems to end/deal with the emergency.

4. Both the HSE Engineer/advisor and the first Aider are to ensure all trades are gathered at the

assembly point and liaise with supervisor to account for all operatives - no person should leave

site.

5. Either the HSE Engineer/advisor or the first Aider phones the project Manager or site receptionist

and informs him/her of which emergency services are required.

6. The Project Manager calls all relevant McLaren staff.

7. Both the HSE Engineer/advisor and the first Aider waits for the emergency services at scene.

8. Once emergency services arrive, The Project Manager will telephone the relevant authorities, i.e.

the HSE/Client’s Safety Advisor/QHSE Manager/McLaren’s operations Director.

9. Both the HSE Engineer/advisor and the first Aider keep trades informed of the situation and

releases trades to return to work or leave site only when emergency services or The Project

Manager instruct that it is safe to do so, and all names of witnesses are recorded.

10. Project Manager or Construction Manager are to arrange for photographs of the scene to be

taken, and if necessary the area to be cordoned.

A full investigation of the Incident is to be carried out, with a written report being submitted the

SHEQ Director, as soon as practicably possible after the incident, including all witness statements,

11. photos of the scene, induction and method statement records, recommendation to prevent a re-

occurrence and what action has been taken since the incident taking place.

Method Statement Title Installation of Duct & Accessories Doc Ref No: GEMC-MC-A-MST-0012

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 17 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

APPENDIX C

COSHH ASSESSMENTS AND MSDS

(Attach if any)

Method Statement Title Installation of Duct & Accessories Doc Ref No: GEMC-MC-A-MST-0012

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 18 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

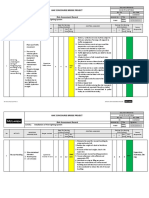

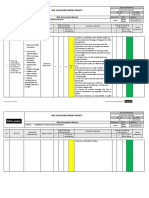

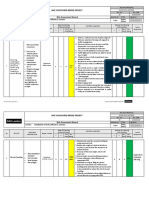

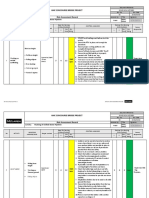

APPENDIX- D

RISK ASSESSMENTS

Method Statement Title Installation of Duct & Accessories Doc Ref No: GEMC-MC-A-MST-0012

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 19 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

APPENDIX-E

TECHNICAL INFORMATION

Method Statement Title Installation of Duct & Accessories Doc Ref No: GEMC-MC-A-MST-0012

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 20 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

Add project/client logo

RISK ASSESSMENT METHOD STATEMENT (RAMS)

Method Statement Title Installation of Duct & Accessories Doc Ref No: GEMC-MC-A-MST-0012

Project Location: AMC Connectivity Corridors & Concourse Bridge Project, AD Revision No : 00

Prepared By Syed Faisal Approved By Revision Date:

SAF-098 (UAE) 09/16 Rev G 21 of 21 RISK ASSESSMENT METHOD STATEMENT

SAF009 08/13 rev B RISK ASSESSMENT &METHOD STATEMENT EVALUATION SHEET

You might also like

- Risk Assessment For Installation of Drainage PipesDocument17 pagesRisk Assessment For Installation of Drainage PipesAnandu Ashokan97% (34)

- Risk Assessment For Installation of Fire Fighting SystemDocument20 pagesRisk Assessment For Installation of Fire Fighting SystemAnandu Ashokan90% (31)

- Risk Assessment For Installation of Water Supply PipeDocument18 pagesRisk Assessment For Installation of Water Supply PipeAnandu Ashokan89% (27)

- Risk Assessment For Installation of Ducts and AccessoriesDocument17 pagesRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan83% (12)

- Method Statement For Structured Cabling System InstallationDocument9 pagesMethod Statement For Structured Cabling System InstallationAnandu Ashokan50% (2)

- 009 Installation of Pumps Risk AssessmentDocument2 pages009 Installation of Pumps Risk Assessmentgangadharan000100% (13)

- Risk Assessment For Installation of Grill, Diffuser and LouversDocument13 pagesRisk Assessment For Installation of Grill, Diffuser and LouversAnandu Ashokan100% (7)

- Installation Method for Gas DetectionDocument2 pagesInstallation Method for Gas DetectionvictorNo ratings yet

- Risk Assessment For Flushing of Chilled Water PipingDocument9 pagesRisk Assessment For Flushing of Chilled Water PipingAnandu AshokanNo ratings yet

- Risk Assessment For Installation of Sanitary WaresDocument14 pagesRisk Assessment For Installation of Sanitary WaresAnandu Ashokan67% (6)

- Risk Assessment For Installation of Sanitary WaresDocument14 pagesRisk Assessment For Installation of Sanitary WaresAnandu Ashokan67% (6)

- Risk Assessment For Installation of Toilet Exhaust FanDocument11 pagesRisk Assessment For Installation of Toilet Exhaust FanAnandu Ashokan67% (3)

- MS For MEP IsolationDocument19 pagesMS For MEP IsolationAnandu Ashokan67% (3)

- RAMS For Testing & Commissioning of HVACDocument42 pagesRAMS For Testing & Commissioning of HVACAnandu AshokanNo ratings yet

- HVAC Duct Work Installation Method StatementDocument3 pagesHVAC Duct Work Installation Method StatementSudath Kularathna100% (1)

- Chilled Water Pipe Installation - ACMVDocument4 pagesChilled Water Pipe Installation - ACMVbinhjuki100% (2)

- Method Statement: Installation Method of Statement For Axial, Centrifugal and Propeller Exhaust FansDocument1 pageMethod Statement: Installation Method of Statement For Axial, Centrifugal and Propeller Exhaust FansSudath Kularathna83% (6)

- Chiller Unit Method Statement PDFDocument5 pagesChiller Unit Method Statement PDFmostafaabdelrazik100% (1)

- Method Statement For Cable Tray and Truncking InstallationDocument9 pagesMethod Statement For Cable Tray and Truncking InstallationAnandu AshokanNo ratings yet

- Method Statement For Water Heaters InstallationDocument9 pagesMethod Statement For Water Heaters InstallationAnandu Ashokan100% (1)

- Non-GBS Specialized Scaffolding Prequal Questionnaire1Document13 pagesNon-GBS Specialized Scaffolding Prequal Questionnaire1RAMIL100% (3)

- MS For Installation of Grills, Diffuser & LouversDocument21 pagesMS For Installation of Grills, Diffuser & LouversAnandu AshokanNo ratings yet

- MS - Installation of MEP ServicesDocument28 pagesMS - Installation of MEP ServicesAnandu Ashokan100% (3)

- MS For Installation of Electrical Containment & Wiring, Cable PullingDocument21 pagesMS For Installation of Electrical Containment & Wiring, Cable PullingAnandu Ashokan100% (1)

- Method of Duct Installation, Insulation, Leak TestingDocument4 pagesMethod of Duct Installation, Insulation, Leak Testinggangadharan00067% (6)

- Method Statement & Risk Assessment Installation of GI Duct WorksDocument17 pagesMethod Statement & Risk Assessment Installation of GI Duct WorksAbu Muhammed Khwaja100% (1)

- Method Statement For Installation of HVAC Duct & AccessoriesDocument63 pagesMethod Statement For Installation of HVAC Duct & AccessoriesAnandu AshokanNo ratings yet

- FHC Installation Method StatementDocument9 pagesFHC Installation Method StatementMeriam DacunesNo ratings yet

- HVAC Installation Step-by-StepDocument12 pagesHVAC Installation Step-by-StepIzaaz Ahamed100% (1)

- Installation & Testing of Sanitary WaresDocument3 pagesInstallation & Testing of Sanitary WaresDong Vanra100% (2)

- Method Statement For Installation of AHU-FAHU PDFDocument19 pagesMethod Statement For Installation of AHU-FAHU PDFbryanNo ratings yet

- Method Statement For LV Cables, Wiring For Lighting and Power InstallationDocument11 pagesMethod Statement For LV Cables, Wiring For Lighting and Power InstallationAnandu Ashokan50% (2)

- Method Statement For Chilled Water PipesDocument5 pagesMethod Statement For Chilled Water PipesImteyaz Ahmad33% (3)

- MOS IMU 1 - Method Statement For DuctworkDocument12 pagesMOS IMU 1 - Method Statement For DuctworkAzwan Awalludin100% (3)

- 001 MEP - Method Floor&Wall PenetrationDocument7 pages001 MEP - Method Floor&Wall PenetrationHa Bao An100% (1)

- Method Statement For Installation of Grill, Diffuser & LouversDocument51 pagesMethod Statement For Installation of Grill, Diffuser & LouversAnandu Ashokan100% (1)

- MS For Installation of SMDB, DB PanelsDocument20 pagesMS For Installation of SMDB, DB PanelsAnandu AshokanNo ratings yet

- Method Statement For Drainage Pipes InstallationDocument11 pagesMethod Statement For Drainage Pipes InstallationAnandu Ashokan100% (4)

- Method Statement LV Distribution Boards InstallationDocument9 pagesMethod Statement LV Distribution Boards InstallationAnandu Ashokan100% (1)

- Method Statement For LV Cables, Wiring For Lighting and Power InstallationDocument11 pagesMethod Statement For LV Cables, Wiring For Lighting and Power InstallationAnandu Ashokan50% (2)

- Method Statement For Earthing and Lightning ProtectionDocument12 pagesMethod Statement For Earthing and Lightning ProtectionAnandu Ashokan100% (1)

- Method Statement For Wiring Accessories InstallationDocument9 pagesMethod Statement For Wiring Accessories InstallationAnandu AshokanNo ratings yet

- RAMS EvaluationDocument3 pagesRAMS EvaluationAnandu AshokanNo ratings yet

- MS For Installation of Grills, Diffuser & LouversDocument21 pagesMS For Installation of Grills, Diffuser & LouversAnandu AshokanNo ratings yet

- En 74Document2 pagesEn 74Azharuddin_kfupm80% (5)

- Cis22 2021Document47 pagesCis22 2021MOHD AFIF BIN MOHD ZALINo ratings yet

- Scaffolding Load DesignDocument80 pagesScaffolding Load Designonin00780% (10)

- MS For Installation of Chilled Water Pipes & FittingsDocument21 pagesMS For Installation of Chilled Water Pipes & FittingsAnandu AshokanNo ratings yet

- MS For Installation of Toilet Exhaust FanDocument20 pagesMS For Installation of Toilet Exhaust FanAnandu AshokanNo ratings yet

- MS For Installation of Air Handling UnitsDocument22 pagesMS For Installation of Air Handling UnitsAnandu AshokanNo ratings yet

- MS For Installation of Sanitary WaresDocument22 pagesMS For Installation of Sanitary WaresAnandu AshokanNo ratings yet

- MS For Installation of Drainage PipesDocument20 pagesMS For Installation of Drainage PipesAnandu Ashokan100% (1)

- MS For Installation of FCUDocument20 pagesMS For Installation of FCUAnandu AshokanNo ratings yet

- MS For Installation of FF Pipes FittingsDocument23 pagesMS For Installation of FF Pipes FittingsAnandu Ashokan100% (1)

- MS For Installation of Chilled Water FlushinDocument27 pagesMS For Installation of Chilled Water FlushinAnandu AshokanNo ratings yet

- MS - Installation of Water Supply PipeDocument20 pagesMS - Installation of Water Supply PipeAnandu Ashokan100% (1)

- MS For Installation of Electrical Wiring & Cable PullingDocument20 pagesMS For Installation of Electrical Wiring & Cable PullingAnandu Ashokan100% (1)

- Method Statement For PEX Pipes and Fittings InstallationDocument9 pagesMethod Statement For PEX Pipes and Fittings InstallationAnandu AshokanNo ratings yet

- Installation of Under Ground Chilled Water PipingDocument18 pagesInstallation of Under Ground Chilled Water PipingAnandu Ashokan100% (1)

- Duct Work Method StatementDocument5 pagesDuct Work Method StatementAla Makram Sunna0% (1)

- RA For Flushing of Chilled Water PipesDocument8 pagesRA For Flushing of Chilled Water PipesAnandu AshokanNo ratings yet

- p103-Stts-gec-Asi-ms-ele-009 - Method Statement For Installation of Light Fitting FixtureDocument5 pagesp103-Stts-gec-Asi-ms-ele-009 - Method Statement For Installation of Light Fitting FixtureAnandu AshokanNo ratings yet

- Method Statement For Installation of Light Fixtures and FittingsDocument6 pagesMethod Statement For Installation of Light Fixtures and Fittingsadeniyi abiolaNo ratings yet

- Installation of Chilled Water PipesDocument6 pagesInstallation of Chilled Water PipesAnandu Ashokan0% (1)

- Method Statement For Installation of Chiller PipeDocument34 pagesMethod Statement For Installation of Chiller Pipebryan92% (12)

- Method of StatementDocument6 pagesMethod of StatementPari Rajendran100% (1)

- Welding Quality Procedure For Chilled Water PipingDocument16 pagesWelding Quality Procedure For Chilled Water PipingAnandu AshokanNo ratings yet

- Method Statement For Installation of Dampers VCDDocument2 pagesMethod Statement For Installation of Dampers VCDamg007100% (2)

- HVAC Split Unit Installation Procedure - Method Statement HQDocument7 pagesHVAC Split Unit Installation Procedure - Method Statement HQEngineer ZiaNo ratings yet

- HVAC Duct Installation MethodDocument5 pagesHVAC Duct Installation MethodburakNo ratings yet

- RA For Installation of Air Colled ChillersDocument8 pagesRA For Installation of Air Colled ChillersAnandu Ashokan100% (2)

- Method Statement For Firefighting Piping Equipment and Accessories InstallationDocument12 pagesMethod Statement For Firefighting Piping Equipment and Accessories InstallationMohamedNo ratings yet

- Work Method Statement FOR HVAC DuctingCopper PipesDocument9 pagesWork Method Statement FOR HVAC DuctingCopper PipesSameer JogasNo ratings yet

- Air Terminal Device Installation MethodDocument13 pagesAir Terminal Device Installation MethodAnish Kumar100% (1)

- Method Statement MechanicalDocument24 pagesMethod Statement Mechanicalsunjay_shanker93% (14)

- Wms Acmv Duct WorksDocument8 pagesWms Acmv Duct Worksfahmi_majid_2No ratings yet

- Method Statement For PPR Pipes and Fittings InstallationDocument9 pagesMethod Statement For PPR Pipes and Fittings InstallationAnandu AshokanNo ratings yet

- p103-Stts-gec-Asi-ms-ele-013 - Method Statement For Installation of Access Control SystemDocument5 pagesp103-Stts-gec-Asi-ms-ele-013 - Method Statement For Installation of Access Control SystemAnandu AshokanNo ratings yet

- Method Statments For Mechanical WorksDocument34 pagesMethod Statments For Mechanical WorksUmar Farooq100% (1)

- Installation of Copper Pipes and Fittings.: Barq Group Risk AssessmentDocument8 pagesInstallation of Copper Pipes and Fittings.: Barq Group Risk AssessmentYousaf Richu67% (3)

- MS For Testing and Commissioning of Electrical SystemDocument21 pagesMS For Testing and Commissioning of Electrical SystemAnandu Ashokan100% (2)

- Method Statement For PPR Pipes and Fittings InstallationDocument9 pagesMethod Statement For PPR Pipes and Fittings InstallationAnandu AshokanNo ratings yet

- Method Statement For PEX Pipes and Fittings InstallationDocument9 pagesMethod Statement For PEX Pipes and Fittings InstallationAnandu AshokanNo ratings yet

- Method Statement For Fire Alarm and Emergency System InstallationDocument9 pagesMethod Statement For Fire Alarm and Emergency System InstallationAnandu Ashokan100% (1)

- Method Statement For GI Conduits InstallationDocument9 pagesMethod Statement For GI Conduits InstallationAnandu AshokanNo ratings yet

- Method Statement For PVC Conduits InstallationDocument9 pagesMethod Statement For PVC Conduits InstallationAnandu AshokanNo ratings yet

- MS Comments SheetDocument1 pageMS Comments SheetAnandu AshokanNo ratings yet

- MS Cover SheetDocument1 pageMS Cover SheetAnandu AshokanNo ratings yet

- MS - Installation of Water Supply PipeDocument20 pagesMS - Installation of Water Supply PipeAnandu Ashokan100% (1)

- MS For Installation of FF Pipes FittingsDocument23 pagesMS For Installation of FF Pipes FittingsAnandu Ashokan100% (1)

- Work at Height - English - 11.07.2013 - Rev C DraftDocument87 pagesWork at Height - English - 11.07.2013 - Rev C DraftMohamad Khalid B HassanNo ratings yet

- Block Work Method StatementDocument19 pagesBlock Work Method StatementjonesNo ratings yet

- Scaffold Inspection Report 1Document2 pagesScaffold Inspection Report 1ronachaif3191No ratings yet

- False Work OshaDocument41 pagesFalse Work OshasuhaemiNo ratings yet

- Pipe Rack Erection JSADocument8 pagesPipe Rack Erection JSARohit Thorat100% (2)

- Federal Register / Vol. 85, No. 20 / Thursday, January 30, 2020 / NoticesDocument4 pagesFederal Register / Vol. 85, No. 20 / Thursday, January 30, 2020 / NoticesIndra MishraNo ratings yet

- Tubular Scaffolding Assembling MethodDocument19 pagesTubular Scaffolding Assembling MethodBilly Otniel100% (1)

- Winner Double Width Aluminium Scaffolding Assembly ProcedureDocument17 pagesWinner Double Width Aluminium Scaffolding Assembly ProceduresrcNo ratings yet

- Articole Column Formwork Framax XlifeDocument3 pagesArticole Column Formwork Framax XlifeClaudiu CiorobitcaNo ratings yet

- SA2-2375 Risk AssessmentDocument12 pagesSA2-2375 Risk AssessmentZameer AhmedNo ratings yet

- Saudi Aramco Scaffold Safety ManualDocument17 pagesSaudi Aramco Scaffold Safety ManualRackie Enriquez83% (6)

- Bill of Quantity: Baner Lifespaces LLPDocument7 pagesBill of Quantity: Baner Lifespaces LLPSales AlufacadesNo ratings yet

- Estimation and Planning Tool For Industrial Construction ScaffoldingDocument9 pagesEstimation and Planning Tool For Industrial Construction ScaffoldingLloyd GalleposoNo ratings yet

- Painting Risk AssessmentDocument22 pagesPainting Risk Assessmentpugal maniNo ratings yet

- Scaff Accessories-Arabic EnglishDocument8 pagesScaff Accessories-Arabic EnglishMohamed AdelNo ratings yet

- Journal of Constructional Steel Research: Tayakorn Chandrangsu, Kim J.R. RasmussenDocument10 pagesJournal of Constructional Steel Research: Tayakorn Chandrangsu, Kim J.R. Rasmussenlokomoko1No ratings yet

- Site Management Construction SupervisionDocument36 pagesSite Management Construction SupervisionTesfuNo ratings yet

- Erect and Dismantle Restricted Heights ScaffoldingDocument25 pagesErect and Dismantle Restricted Heights ScaffoldingHans Oosthuizen0% (1)

- Abstract of cost for Prof. Cabin and False CeilingDocument9 pagesAbstract of cost for Prof. Cabin and False CeilingSHAILENDRANo ratings yet

- JHA PaintingDocument12 pagesJHA Paintingeast100% (1)

- Construction Safety TipsDocument8 pagesConstruction Safety TipsAce PraphuNo ratings yet

- Puja PandalDocument40 pagesPuja PandalSaumya ShuklaNo ratings yet

- Waste Management: I.M. Chethana S. Illankoon, Weisheng LuDocument10 pagesWaste Management: I.M. Chethana S. Illankoon, Weisheng LuMateo Camilo AstudilloNo ratings yet

- DQS352 Assignment 1 GROUP 2 (SCAFFOLDING)Document42 pagesDQS352 Assignment 1 GROUP 2 (SCAFFOLDING)Alessazier GenerNo ratings yet

- BS en 74-1-2005 Couplers, Spigot Pins and Baseplates For Use in Falseworks and ScaffoldsDocument48 pagesBS en 74-1-2005 Couplers, Spigot Pins and Baseplates For Use in Falseworks and ScaffoldsbteentalkNo ratings yet

- Scaffolding Safety TrainingDocument91 pagesScaffolding Safety TrainingZizo Tamim100% (1)