Professional Documents

Culture Documents

MH-Diesel-Generator-Hazard-Assessment - PDF Master Hire PDF

Uploaded by

Rajesh gpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MH-Diesel-Generator-Hazard-Assessment - PDF Master Hire PDF

Uploaded by

Rajesh gpCopyright:

Available Formats

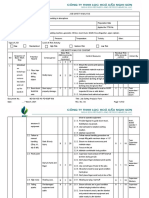

SAFETY MANAGEMENT SYSTEM

Plant and Equipment Risk Assessment

Hired From All Master Hire Stores Generator - Diesel Assessed By: Steven Jose

Equipment:

Equipment Signature:

Location: Manufacturer Make: Various

Details

Risk Level

Risk Level after Risk

Hazard Action Required Hierarchy of Hazard and Risk Treatment (Complete Hazard Treatment

(Refer to risk

Yes/No Control Report Form) (Refer to risk

matrix)

matrix)

Entanglement

Can anyone’s hair, clothing, gloves, necktie, jewellery, cleaning Yes MEDIUM Elimination Observe all safety instructions in MEDIUM

No Substitution

brushes, rags or other materials become entangled with moving Isolation owners’ manual

parts of the plant, or materials in motion? Engineering Wear appropriate PPE

Administration

PPE Check area is clear before starting

machine

Crushing

Can anyone be crushed due to: Yes MEDIUM Elimination Observe all safety instructions in MEDIUM

No Substitution

Material falling off the plant? Isolation owners’ manual

Uncontrolled or unexpected movement of the plant or its Engineering Wear appropriate PPE

Administration

load? PPE Check area is clear before starting

Lack of capacity for the plant to be slowed, stopped or machine

immobilized? Do not remove guards or operate with

The plant tipping or rolling over? doors open

Parts of the plant collapsing? Stop engine before conducting

Coming in contact with moving parts of the plant during maintenance

testing, inspection, use, maintenance, cleaning or repair? Keep body parts away from rotating

Being thrown off or under the plant? parts

Being trapped between the plant and materials or fixed

structures?

Other factors?

Cutting, Stabbing and Puncturing

Can anyone be cut, stabbed or punctured due to? Yes MEDIUM Elimination Observe all safety instructions in MEDIUM

No Substitution

Coming in contact with sharp or flying objects? Isolation owners’ manual

Coming in contact with moving parts of the plant during Engineering Wear appropriate PPE

Administration

testing, inspection, operation, maintenance, cleaning or PPE Check area is clear before starting

repair of the plant? machine

Plant, parts of the plant or work pieces disintegrating? Do not remove guards or operate with

Work pieces being ejected? doors open

Authorised by: General Manager - Safety & Personnel Date: 4/07/2013 Review Date: JULY 2015 Issue No: 1 Page 1 of 6

This is an uncontrolled copy printed on 4/07/2013

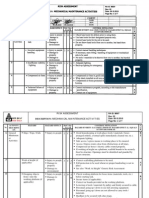

SAFETY MANAGEMENT SYSTEM

Plant and Equipment Risk Assessment

The mobility of the plant? Stop engine before conducting

Uncontrolled or unexpected movement of the plant? maintenance

Other factors? Keep body parts away from rotating

parts

Shearing

Can anyone’s body parts be: Yes MEDIUM Elimination Observe all safety instructions in MEDIUM

No Substitution

Sheared between two or more parts of the plant, or Isolation owners’ manual

between a part of the plant and a work piece or structure? Engineering Wear appropriate PPE

Administration

PPE Check area is clear before starting

machine

Do not remove guards or operate with

doors open

Stop engine before conducting

maintenance

Keep body parts away from rotating

parts

Friction

Can anyone be burnt, gain abrasions etc due to: Yes MEDIUM Elimination Observe all safety instructions in LOW

No Substitution

Contact with moving parts or surfaces of the plant, or Isolation owners’ manual

material handled by the plant? Engineering Wear appropriate PPE

Administration

PPE Check area is clear before starting

machine

Do not remove guards or operate with

doors open

Stop engine before conducting

maintenance

Keep body parts away from rotating

parts

Striking

Can anyone be struck by moving objects due to: Yes LOW Elimination Observe all safety instructions in LOW

No Substitution

Uncontrolled or unexpected movement of the plant or Isolation owners’ manual

material handled by the plant? Engineering Wear appropriate PPE

Administration

Plant, parts of the plant or work pieces disintegrating? PPE Check area is clear before starting

Work pieces being ejected? machine

Mobility of the plant?

Other factors?

Authorised by: General Manager - Safety & Personnel Date: 4/07/2013 Review Date: JULY 2015 Issue No: 1 Page 2 of 6

This is an uncontrolled copy printed on 4/07/2013

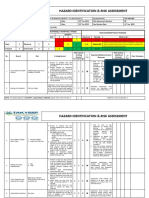

SAFETY MANAGEMENT SYSTEM

Plant and Equipment Risk Assessment

High Pressure Fluid

Can anyone come into contact with? Yes MEDIUM Elimination Observe all safety instructions in MEDIUM

No Substitution

Fluids under high pressure in normal use, in the instance Isolation owners’ manual

of plant failure? Engineering Wear appropriate PPE

Administration

PPE

Electrical

Can anyone be injured by electrical shock or burnt due to: Yes HIGH Elimination Observe all safety instructions in HIGH

No Substitution

The plant contacting live electrical conductors? Isolation owners’ manual

Plant working close to electrical conductors? Engineering Wear appropriate PPE

Administration

Overload of electrical circuits? PPE Check area is clear before starting

Damaged or poorly maintenance electrical leads or machine

cables? Only qualified electrical personnel to

Damaged electrical switches? conduct electrical work or repairs on

Water near electrical equipment? machine

Lack of isolation procedures?

Other factors

Explosion

Gases, vapors, liquids, dusts or other substances triggered by the Yes MEDIUM Elimination Observe all safety instructions in MEDIUM

No Substitution

operation of the plant or by materials handled by the plant? Isolation owners’ manual

Engineering Check pressure lines/systems are clear

Administration

PPE before conducting repairs or

maintenance and correctly connected

before starting machine

Wear appropriate PPE

Slipping, tripping and Falling

Can anyone using the plant, or in the vicinity of the plant, slip, Yes LOW Elimination Observe all safety instructions in LOW

No Substitution

trip or fall due to: Isolation owners’ manual

Uneven or slippery work surfaces? Engineering Wear appropriate PPE

Administration

Poor housekeeping, such as shavings in the vicinity of the PPE Check area is clear before starting

plant, spillage not cleaned up? machine

Obstacles being placed in the vicinity of the plant?

Other factors?

Authorised by: General Manager - Safety & Personnel Date: 4/07/2013 Review Date: JULY 2015 Issue No: 1 Page 3 of 6

This is an uncontrolled copy printed on 4/07/2013

SAFETY MANAGEMENT SYSTEM

Plant and Equipment Risk Assessment

High Temperature

Can anyone: Yes MEDIUM Elimination Observe all safety instructions in MEDIUM

No Substitution

Come into contact with objects at high temperature? Isolation owners’ manual

Be injured by fire? Engineering Wear appropriate PPE

Administration

PPE Check area is clear before starting

machine

Temperature and Thermal Comfort

Can anyone suffer ill-health due to: Yes Elimination

No Substitution

Exposure to high or low temperatures? Isolation

Failure of air conditioning equipment? Engineering

Administration

PPE

Suffocation

Can anyone be suffocated due to: Yes HIGH Elimination Observe all safety instructions in owners’ HIGH

No Substitution

Lack of oxygen, or atmospheric contamination? Isolation manual

Engineering Wear appropriate PPE

Administration

PPE Check area is clear before starting

machine

Use in well-ventilated area

Ergonomics

Can anyone be injured due to: Yes LOW Elimination Observe all safety instructions in owners’ LOW

No Substitution

Poorly designed seating? Isolation manual

Repetitive body movements? Engineering Wear appropriate PPE

Administration

Constrained body posture or the need for excessive PPE Check area is clear before starting

effort? machine

Design deficiency causing physical or personal stress?

Inadequate or poorly placed lighting?

Lack of consideration given to human error or human

behavior?

Mismatch of the plant with human traits and natural

limitations?

Other factors?

Authorised by: General Manager - Safety & Personnel Date: 4/07/2013 Review Date: JULY 2015 Issue No: 1 Page 4 of 6

This is an uncontrolled copy printed on 4/07/2013

SAFETY MANAGEMENT SYSTEM

Plant and Equipment Risk Assessment

Other Hazards

Can anyone be injured or suffer ill-health from exposure to: Yes MEDIUM Elimination Observe all safety instructions in owners’ MEDIUM

No Substitution

Chemicals? Isolation manual

Toxic gases or vapors? Engineering

Administration

Wear appropriate PPE

Fumes? PPE Check area is clear before starting

Dust? machine

Noise? Use in well-ventilated area

Vibration?

Radiation?

Other Factors?

Further Comments: A Specific Risk Assessment on site must been undertaken prior to plant operation?

Checklist: Hazard Report form for discrepancies reported

Copy kept on Risk Management File

Authorised by: General Manager - Safety & Personnel Date: 4/07/2013 Review Date: JULY 2015 Issue No: 1 Page 5 of 6

This is an uncontrolled copy printed on 4/07/2013

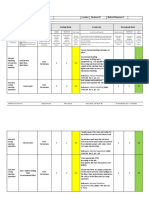

SAFETY MANAGEMENT SYSTEM

Plant and Equipment Risk Assessment

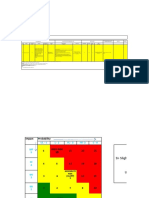

Hazard / Risk Matrix

Reference: Workplace Health and Safety Queensland - Risk Assessment - Supplement 2

Risk Management Code of Practice 2007

Step 1 Determine Likelihood – What is the possibility of the event happening?

Criteria Description

Almost certain Expected in most circumstances. Event is a common problem

Likely Will probably occur in most circumstances. Event is known to have occurred at this site or it has happened

Possible Might occur at some time Event could occur at the site or I’ve heard of it happening

Unlikely Could occur at some time Event is not likely to occur at the site or I have not heard of it happening

Rare May occur only in exceptional circumstances Event is practically impossible.

Step 2 Determine Consequence - What will be the result if it happens? Step 3 Determine the risk score

Classification Example detail description CONSEQUENCE

Insignificant No injuries LIKELIHOOD Insignificant Minor Moderate Major Catastrophic

Minor First aid treatment only; spillage contained at site. Almost certain 3 High 3 High 4 Acute 4 Acute 4 Acute

Moderate Medical treatment; spillage contained but with outside help. Likely 2 Medium 3 High 3 High 4 Acute 4 Acute

Major Extensive injuries; loss of production Possible 1 Low 2 Medium 3 High 4 Acute 4 Acute

Catastrophic Death; toxic release of chemicals

Unlikely 1 Low 1 Low 2 Medium 3 High 4 Acute

Rare 1 Low 1 Low 2 Medium 3 High 3 High

Step 4 Record risk score against the job sequence steps

(Note – Risk scores have no absolute value and should only be used for comparison and to engender discussion.)

Score Action

4

ACT NOW – Urgent – do something about the risks immediately. Requires immediate attention.

A: Acute

3

Highest management decision is required urgently.

H: High

2

Follow management instructions.

M: Medium

1

OK for now. Record and review if any equipment/ people/ materials/ work processes or procedures change.

L: Low

Authorised by: General Manager - Safety & Personnel Date: 4/07/2013 Review Date: JULY 2015 Issue No: 1 Page 6 of 6

This is an uncontrolled copy printed on 4/07/2013

You might also like

- Capital Market and Portfolio ManagementDocument258 pagesCapital Market and Portfolio ManagementJagat Patel0% (1)

- Hot Work TRA Workshop NightDocument3 pagesHot Work TRA Workshop Nightmarvin100% (1)

- Mechanical Maintenance Risk Assessment ProjectDocument11 pagesMechanical Maintenance Risk Assessment Projectvictor100% (1)

- JOB SAFETY ANALYSISDocument21 pagesJOB SAFETY ANALYSISThái Đạo Phạm Lê100% (1)

- Job Hazard Assessment For Cable TestingDocument4 pagesJob Hazard Assessment For Cable TestingSamuel Carlos100% (2)

- Best Forex TipsDocument11 pagesBest Forex TipsSena Rashi100% (1)

- Mechanical Maintenance ActivitesDocument7 pagesMechanical Maintenance ActivitesJhun Aquino50% (2)

- Risk Assessment: Project Site Area: Asphalt Cutting LocationDocument4 pagesRisk Assessment: Project Site Area: Asphalt Cutting LocationRaza Ali Khan100% (7)

- All HiraDocument40 pagesAll Hirarameese muhammed100% (1)

- Grinding ActivityDocument1 pageGrinding ActivityKrishna Patil100% (2)

- Risk Assessment - Confined Space. SESA-BFIM-RA-CS-001Document13 pagesRisk Assessment - Confined Space. SESA-BFIM-RA-CS-001Abdul WasayNo ratings yet

- Pump Installation Risk AssessmentDocument17 pagesPump Installation Risk AssessmentAnandu Ashokan75% (8)

- HIRA & EAI For Installation of LT Supply StationDocument12 pagesHIRA & EAI For Installation of LT Supply StationDEBASISH KHADANGA100% (1)

- RA For Man Lift OperationDocument6 pagesRA For Man Lift Operationalla malikNo ratings yet

- JSA Electrical Maintenance LCSDocument8 pagesJSA Electrical Maintenance LCSmohamed yasinNo ratings yet

- RA Templates PipingDocument28 pagesRA Templates Pipingkla_alkNo ratings yet

- Risk Assessment For Installation of Drainage Pipes and FittingsDocument8 pagesRisk Assessment For Installation of Drainage Pipes and Fittingsfaizan khan100% (1)

- Safe Work Practices On High Voltage CablesDocument35 pagesSafe Work Practices On High Voltage CablesMohammed K. HayderNo ratings yet

- Electrical System Risk AssessmentDocument6 pagesElectrical System Risk AssessmentFrancis Enriquez Tan83% (12)

- Job Safety Analysis (Jsa) Piling Activity: Document No: Rev. 01 Date: 12.03.2021Document7 pagesJob Safety Analysis (Jsa) Piling Activity: Document No: Rev. 01 Date: 12.03.2021Sanjay Kumar GhadaiNo ratings yet

- TRA of Lifting of EquipmentsDocument3 pagesTRA of Lifting of EquipmentsandreNo ratings yet

- Working at Heights RiskDocument3 pagesWorking at Heights Riskmyo lwin75% (4)

- Risk Assessment For Dismantling of Temporary ServicesDocument17 pagesRisk Assessment For Dismantling of Temporary ServicesAnandu AshokanNo ratings yet

- DOCUMENT Loop Checking Activities JHADocument8 pagesDOCUMENT Loop Checking Activities JHAFrancis Enriquez Tan83% (6)

- MBB Cases 2020Document170 pagesMBB Cases 2020Usman Aziz100% (1)

- Risk Assessment For Air BlowingDocument8 pagesRisk Assessment For Air BlowingAriel Dela Cruz100% (5)

- Installation Safety AnalysisDocument5 pagesInstallation Safety AnalysisLeo PascualNo ratings yet

- 2 - Pulling CablesDocument5 pages2 - Pulling CablesAhmed KhaledNo ratings yet

- Hira Register: Grasim Industries Limited, Vilayat Bharuch (Gujarat)Document3 pagesHira Register: Grasim Industries Limited, Vilayat Bharuch (Gujarat)Mithlesh Singh75% (4)

- LOTO Permit to WorkDocument2 pagesLOTO Permit to WorkIonian TribeNo ratings yet

- Risk Assessment - Placing of Transformer - TTSDocument6 pagesRisk Assessment - Placing of Transformer - TTSnsadnan100% (2)

- JSA For Installation of Fire PumpsDocument2 pagesJSA For Installation of Fire Pumpsperquino oasan100% (3)

- Risk Assessment Work at HeightDocument3 pagesRisk Assessment Work at HeightSathi sh0% (1)

- Revised Risk Assessment-Concrete Coring-1Document5 pagesRevised Risk Assessment-Concrete Coring-1riyazkader83% (12)

- Job Safety Analysis for Diesel Generator OperationDocument5 pagesJob Safety Analysis for Diesel Generator Operationajmalvk100% (4)

- Risk Assessment Distribution Board DB Junction Box Junction Box InstallationDocument6 pagesRisk Assessment Distribution Board DB Junction Box Junction Box InstallationAnonymous HeA9HEbtDmNo ratings yet

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDocument6 pagesRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- AFA HIRA - Electrical Control PanelDocument30 pagesAFA HIRA - Electrical Control PaneljavedNo ratings yet

- Psychiatric Nursing Notes: LegalDocument47 pagesPsychiatric Nursing Notes: Legalsurviving nursing schoolNo ratings yet

- HIRA - RadiographyDocument3 pagesHIRA - RadiographyHiralal PattanayakNo ratings yet

- Plant and Equipment Risk Assessment Fgoc - NewDocument13 pagesPlant and Equipment Risk Assessment Fgoc - Newmajid khanNo ratings yet

- Gas Cutting Work: Hazard Identification and Risk AssessmentDocument3 pagesGas Cutting Work: Hazard Identification and Risk AssessmentAchalere Shekhar Kashinath100% (2)

- Caretaker Risk Assessment Working at HeightDocument9 pagesCaretaker Risk Assessment Working at HeightMohamed Ali Maher100% (2)

- Electrical Department Risk Assessment FormDocument4 pagesElectrical Department Risk Assessment FormTheRedHarimau75% (4)

- Cable PullingDocument4 pagesCable Pullingtrndem0% (1)

- APC-HSE-HSMS-00527 - Lone WorkingDocument5 pagesAPC-HSE-HSMS-00527 - Lone WorkingRajesh gpNo ratings yet

- Risk Assessment - Lifting OperationsDocument3 pagesRisk Assessment - Lifting Operationsdnmule100% (2)

- JSA for TIE in on Chiller piping south of general officeDocument4 pagesJSA for TIE in on Chiller piping south of general officemyo lwinNo ratings yet

- 005 Risk Assessment T&C Fire Suppression SystemDocument10 pages005 Risk Assessment T&C Fire Suppression SystemJohn RazaNo ratings yet

- Jsa For Fuel Pump Operation - Spill Clean-UpDocument1 pageJsa For Fuel Pump Operation - Spill Clean-Upwahyu nugrohoNo ratings yet

- Risk Assessment For Tightness TestDocument8 pagesRisk Assessment For Tightness TestAriel Dela Cruz100% (1)

- JSA - Hydro-Testing of Pipe & EquipmentDocument1 pageJSA - Hydro-Testing of Pipe & EquipmentRajuNo ratings yet

- RAMS Example 1Document11 pagesRAMS Example 1sppNo ratings yet

- Job Hazard Analysis Welding Operations: Attachment 4Document3 pagesJob Hazard Analysis Welding Operations: Attachment 4mujahed.ahmed4253063No ratings yet

- Job Hazard Analysis Welding Operations: Attachment 4Document3 pagesJob Hazard Analysis Welding Operations: Attachment 4mujahed.ahmed4253063No ratings yet

- DLF PCC HiraDocument6 pagesDLF PCC HiraskfahimuddinNo ratings yet

- JSA Hydrant Pipe LineDocument7 pagesJSA Hydrant Pipe Lineakshay pradeepNo ratings yet

- IGEM - G - 7 - Introduction & ScopeDocument10 pagesIGEM - G - 7 - Introduction & ScopeDevon CressyNo ratings yet

- Job Hazard Analysis For Crane DismantlingDocument2 pagesJob Hazard Analysis For Crane DismantlingKamlesh Bule Lonari100% (2)

- BCP Testing SceneriosDocument7 pagesBCP Testing Scenerioskavita_2910No ratings yet

- HIRA For Loading or Unloading ActivityDocument4 pagesHIRA For Loading or Unloading ActivityMD Abdullah100% (2)

- KBC White Paper - RAM Turnaround StrategyDocument6 pagesKBC White Paper - RAM Turnaround Strategywgzheng2001No ratings yet

- Hazard Identification and Risk Assessment Form: Location Activities Hazard ControlsDocument6 pagesHazard Identification and Risk Assessment Form: Location Activities Hazard ControlsVikas SinghNo ratings yet

- Brand Valuation Interbrand PDFDocument8 pagesBrand Valuation Interbrand PDFPazGonzaga100% (1)

- Insulation of Ducting and PipingDocument1 pageInsulation of Ducting and PipingKrishna Patil100% (1)

- Fall PreventionsDocument16 pagesFall PreventionsRajesh gp100% (1)

- CDI-T 5th Management (1-12)Document124 pagesCDI-T 5th Management (1-12)Felipe CamposNo ratings yet

- Work at Height Rescue Plan: Purpose of Working at Heights RescuesDocument4 pagesWork at Height Rescue Plan: Purpose of Working at Heights RescuesRajesh gp100% (1)

- Diesel Generator Hazard Assessment PDF Master HireDocument6 pagesDiesel Generator Hazard Assessment PDF Master HireMuhammad MalikNo ratings yet

- Review Material For Traditional Life InsuranceDocument2 pagesReview Material For Traditional Life InsuranceS4M1Y4100% (1)

- PD_8010-5-2015Document78 pagesPD_8010-5-2015jasonNo ratings yet

- HSW2 Workplace Risk AssessmentDocument3 pagesHSW2 Workplace Risk AssessmentNoel Nico Fernando100% (1)

- ISO 17025 Lab Risk Assessment: September 2019Document6 pagesISO 17025 Lab Risk Assessment: September 2019Elena Iulia CucoleaNo ratings yet

- ISO 17025 Lab Risk Assessment: September 2019Document6 pagesISO 17025 Lab Risk Assessment: September 2019Elena Iulia CucoleaNo ratings yet

- Risk Management in Construction ProjectsDocument7 pagesRisk Management in Construction ProjectsAntonyNo ratings yet

- Genie E Series Slab Scissor Lift Operation PDFDocument11 pagesGenie E Series Slab Scissor Lift Operation PDFRajesh gpNo ratings yet

- Risk Assessment For Cable LayingDocument5 pagesRisk Assessment For Cable Layingpopamino50% (2)

- 024 - Mobile Scaffold Inspection ChecklistDocument1 page024 - Mobile Scaffold Inspection ChecklistFaiez AripiNo ratings yet

- Relationship Building and Understanding Mira Road MarketDocument49 pagesRelationship Building and Understanding Mira Road MarketAnand KothaneNo ratings yet

- TFU-Risk Assessment RA-11 - Use of Grooving & Threading MachinesDocument1 pageTFU-Risk Assessment RA-11 - Use of Grooving & Threading Machinesarshin wildanNo ratings yet

- Risk Assessment Form: 1 Biophysical HazardsDocument5 pagesRisk Assessment Form: 1 Biophysical HazardsGajendran Sriram33% (3)

- HIRA - Hydro TestDocument3 pagesHIRA - Hydro TestHiralal PattanayakNo ratings yet

- Hira DineshDocument11 pagesHira DineshDurai GunasekaranNo ratings yet

- Plant and Equipment Risk Assessment Fgoc - NewDocument12 pagesPlant and Equipment Risk Assessment Fgoc - Newmajid khanNo ratings yet

- Ensuring That Plumbing Drainage Products Are Fit For PurposeDocument40 pagesEnsuring That Plumbing Drainage Products Are Fit For PurposeRajesh gpNo ratings yet

- WATER M WP 3 D35 Risk AssessmentDocument53 pagesWATER M WP 3 D35 Risk AssessmentPrexie tomparNo ratings yet

- SOP On Preventive MeasuresDocument20 pagesSOP On Preventive MeasuresRajesh gpNo ratings yet

- A Risk Assessment Approach: Qualification of A HVAC System in Aseptic Processing Area Using Building Management SystemDocument10 pagesA Risk Assessment Approach: Qualification of A HVAC System in Aseptic Processing Area Using Building Management SystemRajesh gpNo ratings yet

- Boiler RiskAssessment PDFDocument15 pagesBoiler RiskAssessment PDFRajesh gpNo ratings yet

- Use of Electric Pallet TruckDocument2 pagesUse of Electric Pallet TruckRajesh gpNo ratings yet

- Ensuring That Plumbing Drainage Products Are Fit For PurposeDocument40 pagesEnsuring That Plumbing Drainage Products Are Fit For PurposeRajesh gpNo ratings yet

- Boiler Ra1: Environmental Risk Assessment:: Summary Information: Make Location Fuel Area To Be ServicedDocument5 pagesBoiler Ra1: Environmental Risk Assessment:: Summary Information: Make Location Fuel Area To Be ServicedRajesh gp100% (1)

- WATER M WP 3 D35 Risk AssessmentDocument53 pagesWATER M WP 3 D35 Risk AssessmentPrexie tomparNo ratings yet

- Sra0005 PlumbingDocument10 pagesSra0005 PlumbingRajesh gpNo ratings yet

- Sra0020 Lone WorkingDocument6 pagesSra0020 Lone WorkingRajesh gpNo ratings yet

- Sra0021 Domestic Gas WorksDocument12 pagesSra0021 Domestic Gas WorksRajesh gpNo ratings yet

- Sra0005 PlumbingDocument10 pagesSra0005 PlumbingRajesh gpNo ratings yet

- 14 RA SolderingDocument2 pages14 RA SolderingRajesh gpNo ratings yet

- Risk Assessment Guide ENGLISH 2Document2 pagesRisk Assessment Guide ENGLISH 2Rajesh gpNo ratings yet

- Sra0028 Stress ManagementDocument5 pagesSra0028 Stress ManagementRajesh gpNo ratings yet

- Sra0010 Demolition WorksDocument9 pagesSra0010 Demolition WorksRajesh gpNo ratings yet

- 37 RA CableLoomDocument3 pages37 RA CableLoomRajesh gpNo ratings yet

- General All Areas - RADocument8 pagesGeneral All Areas - RARajesh gpNo ratings yet

- Audit HURLING CO (B)Document5 pagesAudit HURLING CO (B)GOH SZE MENG JOYCELYNE100% (1)

- TCS Corporate Sustainability ReportDocument147 pagesTCS Corporate Sustainability ReportSabyasachi DuttaNo ratings yet

- Research Papers Related To Sri Lanka Software IndustryDocument7 pagesResearch Papers Related To Sri Lanka Software Industryefeq3hd0No ratings yet

- Dfadsfadfagffdfasdfadfadfas FaDocument16 pagesDfadsfadfagffdfasdfadfadfas FaTyrone DomingoNo ratings yet

- Indiabulls Securities LTD: DerivativesDocument12 pagesIndiabulls Securities LTD: DerivativesMOHAMMED KHAYYUMNo ratings yet

- Evolution of Risk ManagementDocument8 pagesEvolution of Risk Managementten hrndzNo ratings yet

- DNV Se 0080Document27 pagesDNV Se 0080Myoung ChoiNo ratings yet

- CN Investor Presentation enDocument63 pagesCN Investor Presentation enMarcin MirskiNo ratings yet

- Risk and Return: Lessons From Market History: Mcgraw-Hill/IrwinDocument24 pagesRisk and Return: Lessons From Market History: Mcgraw-Hill/Irwinfiza akhterNo ratings yet

- CRR BK 5thed.2015 10.27Document402 pagesCRR BK 5thed.2015 10.27Ching RasalanNo ratings yet

- Environment Management NotesDocument12 pagesEnvironment Management NotesShreyansh JainNo ratings yet

- Archives of Indian Psychiatry April 2009Document64 pagesArchives of Indian Psychiatry April 2009Ganpat VankarNo ratings yet

- Karnataka Co-Operative Milk Producers Federation Limited - India Ratings and ResearchDocument11 pagesKarnataka Co-Operative Milk Producers Federation Limited - India Ratings and ResearchDebabrata SahanaNo ratings yet

- Noise Code of Practice 2004Document38 pagesNoise Code of Practice 2004Tuan Suhaimi SallehNo ratings yet

- HSF - 02 Incident Accident Investigation ReportDocument4 pagesHSF - 02 Incident Accident Investigation ReportMazen HussienNo ratings yet

- Psa 500Document19 pagesPsa 500Anthony FinNo ratings yet

- BOJ Financial Sector Update - IMFDocument70 pagesBOJ Financial Sector Update - IMFVenkatesh RamaswamyNo ratings yet