Professional Documents

Culture Documents

Axially Loaded Column Design Examples PDF

Axially Loaded Column Design Examples PDF

Uploaded by

Tanvir Hossain TuhinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Axially Loaded Column Design Examples PDF

Axially Loaded Column Design Examples PDF

Uploaded by

Tanvir Hossain TuhinCopyright:

Available Formats

page

3. AXIALLY LOADED MEMBERS

3.1. Reading Assignment:

Section 1.9 and Sections 8.1 and 8.2 of text.

. Most axially loaded structural members carry some moment in addition to axial load

-- for this discussion, restrict consideration to axial load only.

3.2. Reinforcement of Compression Members

3.2.1. Plain concrete columns prohibited: possibility of bending is always present:

ACI 10.9: 0.01 ≤ As /Ag ≤ 0.08

ACI 10.9.1:

where As = Area of longitudinal reinforcement;

Ag = Total area of column cross section;

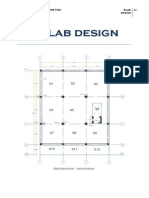

3.2.2. Possible column configuration

a. Tied -- Deformed bars or wires placed normal to column axis

Longitudinal

Different tied arrangements ACI 7.10.5 Rods

and lateral ties

CIVL 4135 36 Axially Loaded Members

page

3.2.2.1. Spacing of Ties to Prevent Longitudinal Bar Buckling

A. Tied column may fail prior to steel yield if shell spalls and longitudinal bars buckle;

B. Insure that bar buckling load is greater than yield load. (σcr > fy)

Assume that bar buckling load is greater than yield load -- Assume a pin--pin bar between ties:

2

P cr = π EI

L2

The moment of inertia of a circular bar is:

4

I = πD

64

and for σcr = Pcr/A = Pcr/(πD2/4)

L

σ cr = π2E

16 (L∕D) 2

Example:

For fy = 40 ksi = σcr

σ cr = π2E → 40 = π2E

16 (L∕D) 2 16 (L∕D) 2

Solving for critical buckling condition

L = 21 D

So, to prevent buckling, space ties more closely than this.

ACI Code requires (ACI-02, Sect 7.10.5.2) that spacing not to be greater than

16 D (D = Diameter of longitudinal bar);

48 tie bar diameter;

Least member dimension.

Other Code requirements are given in ACI-02 Sections 7.10.5.

CIVL 4135 37 Axially Loaded Members

page

b. Spiral:

Circular arrangement of longitudinal bars confined by a continuous wire which spi-

rals around the bars for the entire length of the member;

Longitudinal Rods

and spiral hooping

c. Composite and combination:

Structural steel member encased in concrete or steel pipe filled with concrete

ACI 10.9.2:

at least 4 bars in tied columns

at least 6 bars in spiral columns

at least 3 bars in triangular ties

Note.-- Tied or spiral columns are used in order:

• to prevent buckling of longitudinal bars

• to prevent movement of longitudinal bars during construction.

Bundles of steel bars are sometimes used to prevent congestion. It is shown that they act as a

unit with area as the same as all of the bundle bars.

In buildings columns generally have proportions with the ratio of length to cross section

width (L/h) in the range from about 8 to 12. (use of high strength, more slender column becoming

more popular.)

CIVL 4135 38 Axially Loaded Members

page

3.3. Design Assumptions:

A. Strain compatibility between steel and concrete (to prefect bonding; no slip; mechanical in-

terlocking).

B. Axially loaded only.-- Uniform strain over cross section;

Axial load plus moment.--Strains vary linearly;

Moment only.-- Strains vary linearly.

C. Concrete tensile strength usually zero.

D. The internal forces must be in equilibrium with applied external loads.

E. Plane cross section remains plane after application of loading.

F. Theory is based on real strain--stress relationships.

CIVL 4135 39 Axially Loaded Members

page

3.4. Elastic behavior of column -- Example

See ACI section 10.2

steel

40 Á

compressive Á y = 0.0138 (f y = 40 ksi)

stress 30

ksi Strains the same, stresses much different

20

10 concrete

0

0.001 0.002 0.003

Strain (in/in)

1. Up to f c ≈ 12 f ′ c concrete stress--strain approximately linear. This is known as the

“working” or “service load” range:

2. For strain equality in this range:

fc f Es

Á = Ác = Ás = = s or fs = f

Ec Es Ec c

letting

fs = n fc

Note: “n” is generally rounded to the nearest whole no.

CIVL 4135 40 Axially Loaded Members

page

Adopting the following notation:

Ag = gross section area, (in2)

As = area of steel (in2)

Ac = net concrete area = Ag -- As

P = Axial force on column

Then

P = Ac fc + As fs = Ac fc + nfc As

= fc (Ac + nAs )

Transformed area

As nA s (n − 1)A s

2 2 2

Actual Size Transformed Sec-- Transformed Sec--

tion tion

(a) At = Ac + nAs At = Ag + (n--1)As

(b) (c)

Transformed section in axial compression

The three bars along each of the two faces are thought of as being removed and replaced, at

the same distance from the axis of the section, with added areas of fictitious concrete of total amount

of nAs. Alternatively, as shown in figure c, we can think of the area of the steel bars as replaced with

concrete in which case one has to add to the gross concrete area Ag so obtained only (n --1)As in order

to obtain the same total transformed area.

So, knowing Ac = Ag -- As

P = fc (Ag + (n--1)As )

CIVL 4135 41 Axially Loaded Members

page

3.4.1. Example 1

12”

12”

Given

4 # 8 bars

Assume: f’c = 4000 psi

fy = 40 ksi

area of steel = 4(area of # 8 bars)

4(0.79) = 3.16in2

(see ACI 318 -- bar dimension table, or page iii of class notes)

As

= 3.16 = 0.022 O.K. (ACI-02 Sect. 10.9 0.010 < 0.022 < 0.080)

Ag 144

What axial load will cause concrete to be at its maximum working stress?

Solution

fc = (4000)/2 = 2000 psi

fs = (Es/Ec)fc = n fc

E c = 57, 000 4000 = 3.6 × 10 6 psi

Es = 29x106 psi (always)

Therefore → n = (29,000,000/3,600,000) = 8.04 ≈ 8

P = fc (Ag + (n--1)As ) = 2000[144 + (8--1)x3.16] = 332,000 lb = 332 kips

both steel and concrete behaved elastically.

CIVL 4135 42 Axially Loaded Members

page

3.4.2. Example 2

For the previous example find the axial load P which produces εc = εs = 0.001.

Solution

Á s < 0.001379 → f s = E sÁ s = 29, 000, 000(psi) × 0.001 = 29, 000 psi

See the slow rate curve of text on page 26, read stress in concrete for given strain of 0.001

f c = 2, 400 psi

therefore

P = fc Ac + fs A s

= 2, 400 × (144 − 3.16) + 29, 000 × 3.16

= 338, 016 + 91, 640 = 429, 655 lbs = 430 kips

Steel

stress

40 2.4

0.00139 strain

3.5. Nominal axial load of column Pn ; (Pu = ΦPn ) -- Greatest calculated load

A. Should occur when concrete stress peaks, steel reaches yield -- assume this condition.

B. Concrete stress will not be f’c:

• f’c based on test of standard cylinder; ends confined.;

• f’c depends on the rate of loading;

• Strength of actual column varies over length -- water migrates to top, causing top to be

slightly weaker.

⇒ use fc = 0.85 f’c at nominal load condition

then PN = Ac fc + As fs

= Ac (0.85f’c ) + As fy

for column of previous example:

PN = (144 -- 3.16)(0.85)(4000) + 3.16(40,000) = 605 kips

CIVL 4135 43 Axially Loaded Members

page

3.5.1. Example 3

Consider a rectangular column subjected to axial compression. The material stress--strain relation-

ships have been idealized as shown below.

12--#14 bars

24”

24”

CONCRETE STEEL

60 ksi

5000 psi

E s = 29, 000 (ksi)

E c = 57, 000 f ′ c psi

Á0 Áy

1. Determine the stress in the concrete and stress in the steel if the applied load is equal to 3100

kips.

2. Determine the stress in the concrete and stress in the steel if the applied load is equal to 4050

kips.

See the solution on the next page.

CIVL 4135 44 Axially Loaded Members

page

Solution:

• f’c = 5 ksi

• Ec = 57,000 5000 = 4030 ksi ( Sect 8.5.1 of ACI)

• 12#14 bars As = 27 in2 (from table A.2)

• Es = 29,000 ksi

1. Assume

ε < ε0 or ε < 0.00124 Assume elastic behavior for

ε < εy or ε < 0.00207 both steel and concrete

P = fcAc + fsAs

where Ac = Ag -- As = 24x24 -- 27 = 549 in2

P = 3100 = EcεcAc + EsεsAs Note: ε = εc = εs (perfect bonding)

3100 = (4030)ε(549) + (29000)ε(27)

ε = 3100/(2,212,470 + 783,000) = 0.00103 < 0.00124 o.k.

Assumption was correct.

Therefore we have:

fs = εEs = 0.00103 x 29,000 = 29.9 ksi

fc = εEc = 0.00103 x 4,030 = 4.2 ksi

2. Assume

ε > ε0 or ε > 0.00124 Assume elastic behavior for

ε < εy or ε < 0.00207 steel and inelastic behavior for concrete

P = fc Ac + fs As

4050 = (5.00) x (549) + (29,000) ε (27)

ε = 0.001667 > 0.00124 o.k. Assumption was correct (Concrete

behaves inelastically).

ε = 0.001667 < 0.00207 o.k. Assumption was correct ( Steel behaves

elastically).

fs = εEs = 0.001667 x 29,000 = 48.3 ksi

fc = 5.000 ksi

CIVL 4135 45 Axially Loaded Members

page

3.6. Behavior of Spirally Reinforced Columns

PA

PB

after

spalling

Behavior of Spirally Reinforced and Tied Columns

3.7. Confinement

A. ACI spiral reinforcement ratio based on tests by Richart, Brandtzeg and Brown -- 1928;

(Univ. of Illinois experimental bulletin no. 185).

Using 6” x 12” cylinders, they related lateral confining pressure to axial capacity;

Axial

capacity . .... .....

Psi ... .. . .

.. .. .. .. .

.. . ... .

.. . .. .. .. .. . .

.. . f* = 0.85f’c + 4.0 f’2

. .. . .. .

.. .... .... . .

. .

. ... . .

f’c .

Lateral Confining Pressure

where

f *c =Compressive strength of spirally confined core concrete

0.85 f’c = compressive strength of concrete if unconfined

f’2 = lateral confinement stress in core concrete produced by spiral

CIVL 4135 46 Axially Loaded Members

page

Spiral Column

CIVL 4135 47 Axially Loaded Members

page

B. What sort of lateral confinement can a given spiral provide?

Consider a length of a spiral--wrapped circular section:

for a length “S”:

volume of spiral = Aspπ D (approximately)

Asp volume of concrete = (πD2/4)S

volume of spiral 4A sp

Let às = =

s volume of concrete DS

Calculate equivalent confinement:

f’2DS = 2 Aspfys or f’2 = (ρs fys)/2

from previous research:

D

à sf ys

f c* = 0.85f c′ + 4.0f 2′ = 0.85f c′ + 4.0

2

f c* = 0.85f c′ + 2.0Ã sf ys

D

A spf ys

.. . . . . . . .. .

. .. .. . .. . . ..

. . ..

.. .. .... ........ . ... .. .. . .

.

. . . ... ... . .

. .. .... .. . f 2′ .

. . ..

... . . .... .. . .. . .. . .. ... .. . D

. .. . .. . S .. . . ..

.. . . ... . . .. .. . .. .

. .. . .. .. .

. ..

.. A spf ys

ACI objective is to insure that PB > PN.

Therefore, make sure spiral increases capacity of core enough to make up for loss of shell.

Before shell spalls: PN = As fy + 0.85f’c (Ag -- As )

After shell spalls: PB = As fy + (Acore -- As )(0.85f’c + 2ρs fys )

CIVL 4135 48 Axially Loaded Members

page

Set PB = PN, calculate like terms, expand:

A sf y + 0.85f c′A g − 0.85f c′A s = A sf y + A core(0.85f c′ + 2à sf ys) − A s(0.85f c′) − 2A sà sf ys

Small

Ignore the last term -- very small

then;

0.85f c′(A g − A core) = A core( 2 Ã s f ys )

solve for spiral reinforcement ratio we have:

0.85f c′(A g − A core)

Ãs =

A core( 2f ys )

or

Ãs =

f ys

0.425f c′ A g

A core

− 1

conservatively, change 0.425 to 0.45 to get Eq. 10--6 of ACI-02:

à s = 0.45f c′

f ys

Ag

A core

− 1 Eq. 10--6

which says that the ratio of spiral reinforcement shall not be less than the value given by the equation

above; where fy is the specified yield strength of spiral reinforcement but not more than 60,000 psi.

3.8. Maximum Loads for Spiral Column

Prior to spalling of shell: same as tied column

PA = PN = Asfy + 0.85f’c(Ag -- As)

after spalling of shell:

PB = Asfy + (Acore -- As)(0.85f’c + 2ρsfys)

or

PB = Asfy + (Acore -- As)0.85f’c + (Acore -- As)(2ρsfys)

----------------------------------

CIVL 4135 49 Axially Loaded Members

page

The underlined term is the added capacity of the core resulting from the presence of the spiral.

where will ρs be critical?

High strength concrete (shell carries large loads);

Small columns or square columns;

Columns with large cover.

3.8.1. Example -- Ultimate Strength of Spiral Column

Choose a column with areas equivalent to those of previous example (page 37)

Ag = 144 in2 f’c = 4000 psi

Acore = (π(10.6)2/4) = 87.4 in2 fy = 40 ksi

As = 3.16 in2 s = 1.5 in

fys = 50 ksi

Use (3/8)” diameter spiral: Asp = 0.11

10.6”

As

= 3.16 = 0.022 O.K.

Ag 144

4A sp

Ãs = = 4 × 0.11 = 0.028

DS 10.6 × 1.5 13.5”

Check spiral ratio against ACI requirements

Ãs =

fy

0.45f c′ A g

A core

− 1 87.4

= 0.45 × 144 − 1 × 4 = 0.023 50

Since 0.028 > 0.023, the column satisfies the minimum spiral reinforcement requirements.

Load prior to shell spalling:

PN = As fy + 0.85f’c (Ag -- As ) = 3.16(40) + 0.85(4)(144--3.16)

= 605 kips -- same as tied column. (compare this with the axial

capacity we found in page 37).

After spalling of shell:

PB = As fy + (Acore -- As )(0.85f’c + 2ρs fys )

= 0.85(4)(87.4--3.16) + 2(0.028)(50)(87.4--3.16) + 3.16(40)

= 647.8 kips or 648 kips

CIVL 4135 50 Axially Loaded Members

page

3.9. ACI Provisions for Spiral Columns

ACI 10.3.5.1

φPn (max) = 0.85φ [ Ast fy + 0.85f’c (Ag -- Ast ) ] ACI (10--1)

3.10. ACI Provisions for Tied Columns

ACI 10.3.5.2

φPn (max) = 0.80φ [ Ast fy + 0.85f’c (Ag -- Ast ) ] ACI (10--2)

3.11. Strength and Serviceability

1. ACI assigns two types of safety factors for design:

a. Load factor -- increase design loads (ACI 9.2)

Dead load -- 1.2

Live load -- 1.6

b. Strength reduction factor -- reduce calculated design capacity -- variability of material

and construction.

2. Columns are assigned the following strength reduction factor (ACI 9.3.2.2)

Tied column -- 0.65

Spiral column -- 0.70

spiral column allowed more because of ductility.

CIVL 4135 51 Axially Loaded Members

page

3.12. Example -- Design of Axial Members under Axial Loads

Design a rectangular tied column to accept the following service dead and live loads. Ignore length

effects.

Given:

PD = 142 kips f’c = 4000 psi

PL = 213 kips fy = 60 ksi

Solution: b=? As = ?

We need to find b, h, and As . Sometimes architectural considerations

limit allowable column width and height sizes to a set of given

dimensions. In this case one needs to determine the reinforcement

area and detail the column. For this problem assume that we do not have h=?

any architectural limitations.

Calculate design loads:

P u = 1.2 × P d + 1.6 × P L = 1.2 × 142 + 1.6 × 213 = 511.2 kips

For the first trial use a 12” by 12” column (b = 12 in and h = 12 in). From ACI 10.3.5.1 we have

Pu = φPn (max) = 0.80φ [ Ast fy + 0.85f’c (Ag -- Ast ) ]

P u = 0.80 × 0.65 × [A st × 60 + 0.85 × 4 × (144 − A st)] = 27.8A st + 254.6

therefore

511.2 = 27.8A st + 254.6 → A st = 9.23 in 2

Therefore, use 6--#11 bars with As = 9.37 in2

Check ACI 10.9 #4 Striuup

As

= 9.37 = 0.065 O.K.

Ag 144

ACI Code requires (ACI-02, Sect 7.10.5.2) that spacing not to be greater than 6--#11

12”

16 (bar diameter) = 16 x 1.41 = 22.56 in

48 tie bar diameter = 48 x 0.5 = 24 in (0.5 diameter of #4 ties)

Least member dimension = 12 in.

Use #4 bars for ties with 12 inches of spacing.

12”

CIVL 4135 52 Axially Loaded Members

You might also like

- Design of RCC ColumnsDocument14 pagesDesign of RCC Columnsprashmce100% (1)

- Metal StudDocument24 pagesMetal StudBert EngNo ratings yet

- Design of Reinforced Concrete ColumnsDocument25 pagesDesign of Reinforced Concrete Columnsdashne134100% (4)

- BA Estimating Worksheet 2015 2.1Document45 pagesBA Estimating Worksheet 2015 2.1Bert EngNo ratings yet

- Example 3.5 - Simply Supported Two Way SlabDocument4 pagesExample 3.5 - Simply Supported Two Way SlabMuhammad Farhan GulNo ratings yet

- Liquidation Report FormDocument42 pagesLiquidation Report FormBert Eng50% (2)

- Column DesignDocument87 pagesColumn DesignTariqAziz100% (1)

- The Behaviour of RCC Column in A Multistorey Building 15.02.2015Document6 pagesThe Behaviour of RCC Column in A Multistorey Building 15.02.2015Ahmad AnasNo ratings yet

- The Art of Effective QuestioningDocument39 pagesThe Art of Effective QuestioningBert EngNo ratings yet

- Etabs NotesDocument11 pagesEtabs Noteskarimunnisa sheikNo ratings yet

- Foundation Design: Theory and PracticeFrom EverandFoundation Design: Theory and PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- 02a Biddocs Dotc Caraga Regnlannexbldg 2aDocument6 pages02a Biddocs Dotc Caraga Regnlannexbldg 2aBert EngNo ratings yet

- STRL Design Rules of Thumb PDFDocument11 pagesSTRL Design Rules of Thumb PDFsakti prasanna sahuNo ratings yet

- Beam SlabDocument66 pagesBeam Slabmadkik100% (1)

- Design For Torsion and Shear According To ACI-318-99Document1 pageDesign For Torsion and Shear According To ACI-318-99Sulaiman Mohsin AbdulAzizNo ratings yet

- Analysis of Buildings For Gravity LoadsDocument10 pagesAnalysis of Buildings For Gravity LoadsPrashant SunagarNo ratings yet

- Column Design Design of Short Braced ColumnsDocument17 pagesColumn Design Design of Short Braced ColumnsPimpa MwiingaNo ratings yet

- Design of FootingsDocument42 pagesDesign of Footingsxaekne91% (11)

- Diesel Tank TaluksangayDocument70 pagesDiesel Tank TaluksangayBert EngNo ratings yet

- 003 Moment of Inertia Calculation SheetDocument48 pages003 Moment of Inertia Calculation SheetsitheeqNo ratings yet

- Design of RC Retaining Walls PDFDocument27 pagesDesign of RC Retaining Walls PDFqaiserkhan001No ratings yet

- Two Way Slab DesignDocument16 pagesTwo Way Slab Designgullipalli75% (4)

- 3 Slab DesignDocument32 pages3 Slab Designshadz27100% (1)

- MULTI-PURPOSE DepED PDFDocument8 pagesMULTI-PURPOSE DepED PDFRumylo AgustinNo ratings yet

- Lecture 11-1 Bases by H.J. MtyanaDocument29 pagesLecture 11-1 Bases by H.J. MtyanaHarold Jackson Mtyana100% (1)

- I-2.2 Load Types 2022SFDocument34 pagesI-2.2 Load Types 2022SF鄧和傑No ratings yet

- Column 2Document58 pagesColumn 2Anonymous nQ9Rqm100% (1)

- Column Design Examples PDFDocument2 pagesColumn Design Examples PDFDavid33% (3)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- 425 Serviceability CHP 6 S11Document76 pages425 Serviceability CHP 6 S11aomareltayeb100% (1)

- 8.7.3.1.1 Factored Moment Due ToDocument11 pages8.7.3.1.1 Factored Moment Due ToNheljane Keith Betana RabastoNo ratings yet

- Retaining Wall Design: Ver W4.0.04 - 12 Feb 2021 Title: Cantilever Wall Example Input DataDocument7 pagesRetaining Wall Design: Ver W4.0.04 - 12 Feb 2021 Title: Cantilever Wall Example Input Datarodain najjarNo ratings yet

- Prepared BY Dr. Mohammed Kadhum FekheraldinDocument55 pagesPrepared BY Dr. Mohammed Kadhum Fekheraldinhemantkle2uNo ratings yet

- Structural Design Detailing and Construc PDFDocument40 pagesStructural Design Detailing and Construc PDFIbnuyusoff77No ratings yet

- Design of A Steel Roof TrussDocument49 pagesDesign of A Steel Roof TrusseseemNo ratings yet

- Wind DesignDocument5 pagesWind DesignSedin HodžićNo ratings yet

- Voided Slab SystemDocument17 pagesVoided Slab SystemSkandhanNo ratings yet

- Moment Distribution and Moment Re-DistributionDocument44 pagesMoment Distribution and Moment Re-DistributionJeff Sun100% (1)

- Slenderness Effects in ColumnsDocument11 pagesSlenderness Effects in ColumnsDaniyal AhmadNo ratings yet

- 2a - Design of Spread Footing-Usd MethodDocument27 pages2a - Design of Spread Footing-Usd MethodLouise LuyNo ratings yet

- What Is The Purpose of Literature ReviewDocument5 pagesWhat Is The Purpose of Literature ReviewBert EngNo ratings yet

- Strap Footing TheoryDocument4 pagesStrap Footing TheorySwopnilOjhaNo ratings yet

- 6 Reinforced ColumnsDocument41 pages6 Reinforced ColumnsAnggaWarsitoNo ratings yet

- Lecture7 TrueDocument30 pagesLecture7 TrueSatish KumarNo ratings yet

- Lecture 06-A Tied ColumnsDocument5 pagesLecture 06-A Tied ColumnsArnel G. PetalioNo ratings yet

- Pressure VesselDocument2 pagesPressure VesselBert EngNo ratings yet

- ةحلسملا ةيناسرخلا تآشنملا ميمصت Design Of Reinforced Concrete StructuresDocument47 pagesةحلسملا ةيناسرخلا تآشنملا ميمصت Design Of Reinforced Concrete StructuresMohammed SalemNo ratings yet

- Ce 132 - Geotechnical Engineering 2: Mindanao State University Fatima, General Santos City PhilippinesDocument28 pagesCe 132 - Geotechnical Engineering 2: Mindanao State University Fatima, General Santos City PhilippinesAngelica Curambao100% (1)

- Axial Load Capacity of Columns: (Short) : N ST G ST G ST STDocument9 pagesAxial Load Capacity of Columns: (Short) : N ST G ST G ST STAurora VillalunaNo ratings yet

- Standing Sawtooth Staircase Analysis Design and DetailingDocument8 pagesStanding Sawtooth Staircase Analysis Design and DetailingMahesh SNo ratings yet

- Rectangular Reinforced Concrete BeamDocument60 pagesRectangular Reinforced Concrete BeamMedianna Novita100% (1)

- Design of ConcreteDocument36 pagesDesign of ConcreteDenden Dermawan100% (3)

- Interaction Diagram 6Document35 pagesInteraction Diagram 6Petalio RowenaNo ratings yet

- (LECT-21,22) Prestressed Concrete SlabsDocument22 pages(LECT-21,22) Prestressed Concrete SlabsSushil MundelNo ratings yet

- Failure of Short Columns Case Study PrepDocument17 pagesFailure of Short Columns Case Study PrepAsdar AzisNo ratings yet

- Waffle Slab Two WayDocument19 pagesWaffle Slab Two WayMuhammad MusaabNo ratings yet

- Steel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiDocument6 pagesSteel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- Coefficient Method: Fig. 1: Middle Strips and Column Strips in Each Direction of Two-Way Slab Supported On BeamsDocument7 pagesCoefficient Method: Fig. 1: Middle Strips and Column Strips in Each Direction of Two-Way Slab Supported On BeamsSonny SabidoNo ratings yet

- Design of Continuous Column & Beams According To ACI-codeDocument11 pagesDesign of Continuous Column & Beams According To ACI-codeShanker Lal Meghwar100% (2)

- Column Base Design:: Input DataDocument3 pagesColumn Base Design:: Input DataEng HatemNo ratings yet

- Moment DistributionDocument153 pagesMoment DistributionHerbert P. BacosaNo ratings yet

- Combined Footing Design PDFDocument2 pagesCombined Footing Design PDFRenee100% (1)

- ACI Guidelines For Reinforced ConcreteDocument18 pagesACI Guidelines For Reinforced ConcreteJhyl AquinoNo ratings yet

- Chapter 3. Axially Loaded Members: Plain Concrete Columns Prohibited: Possibility of Bending Is Always PresentDocument25 pagesChapter 3. Axially Loaded Members: Plain Concrete Columns Prohibited: Possibility of Bending Is Always PresentGhaith Al-HouraniNo ratings yet

- Columns 1Document16 pagesColumns 1ShahriazSAMNo ratings yet

- Lecture 5Document60 pagesLecture 5Cecille Grace ReyesNo ratings yet

- Reinforced Concrete Design: Dr. Nader OkashaDocument38 pagesReinforced Concrete Design: Dr. Nader OkashaMohamed Nk100% (1)

- Dma 30-Pueblo List of Customers Under Area-1-4-29-2021Document40 pagesDma 30-Pueblo List of Customers Under Area-1-4-29-2021Bert EngNo ratings yet

- Zamboanga City Water DistrictDocument10 pagesZamboanga City Water DistrictBert EngNo ratings yet

- Brgy. Hall DesignDocument2 pagesBrgy. Hall DesignBert EngNo ratings yet

- Edited - Rehab. Impvt. of Grandstand (8!1!15)Document570 pagesEdited - Rehab. Impvt. of Grandstand (8!1!15)Bert EngNo ratings yet

- Pamucutan Intake No Correction2Document1 pagePamucutan Intake No Correction2Bert EngNo ratings yet

- ResumeDocument2 pagesResumeBert EngNo ratings yet

- Zamboanga Ministers Fellowship May 9Document1 pageZamboanga Ministers Fellowship May 9Bert EngNo ratings yet

- Civil Service Commission Professional or SubDocument7 pagesCivil Service Commission Professional or SubBert EngNo ratings yet

- Effort Oriented-These Are Bosses Who Require Their Subordinates To AlwaysDocument1 pageEffort Oriented-These Are Bosses Who Require Their Subordinates To AlwaysBert EngNo ratings yet

- Frequencies: Jonah Elbert RosarosoDocument2 pagesFrequencies: Jonah Elbert RosarosoBert EngNo ratings yet

- Bloom's Taxonomy: Higher Order Questioning in The Context of Looking at Works of Art and ReadingDocument1 pageBloom's Taxonomy: Higher Order Questioning in The Context of Looking at Works of Art and ReadingBert EngNo ratings yet

- CPM S Curve BroilerDocument4 pagesCPM S Curve BroilerBert EngNo ratings yet