Professional Documents

Culture Documents

Permit To Work Procedure PDF

Permit To Work Procedure PDF

Uploaded by

DEEP PATELOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Permit To Work Procedure PDF

Permit To Work Procedure PDF

Uploaded by

DEEP PATELCopyright:

Available Formats

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

Permit-To-Work (PTW) Procedure

Rev

Reason for Revision Prepared By Checked By Approval by

No.

Rev 00 First Release - - -

Sunil Bartakke Navendra Singh Vijay Chourey

Standardization of

Rev 01 (Head-Biogas & (Group Head – P & (Chief – Corp

Procedure

Lavasa Project) CB; Corp Safety.) Safety)

Alignment With SAP's

Permit-To-Work Navendra Singh

Rev 02 Vijay Chourey

(PTW)Management Sudhir Kumar (Head – Operation

Process (Corporate (Chief – Corp

Safety; Corp

Safety) Safety)

Safety.)

Note: Uncontrolled once printed Page 1 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

Contents

Section Description Page No.

1.0 OBJECTIVES 3

2.0 SCOPE 3

3.0 EXPECTED RESULTS 3

4.0 ACCOUNTIBILITY & RESPONSIBILITY 3

5.0 GLOSSARY / DEFINITION 6

6.0 PROCEDURE 7

7.0 RECORDS 14

8.0 TRAINING & COMMUNICATION 14

9.0 VERIFICATION 14

10.0 EXCEPTION 14

11.0 REFERANCES 14

12.0 REVIEW 15

13.0 ATTACHMENTS/APPENDIX 15

- Annexure-1 : Permit- To-Work (PTW) - Status Sequence 16

- Annexure-2 : Permit -To-Work (PTW) Issuance Process 18

- Annexure-2 : Sheet 2 - Permit-To-Work (PTW) Return Process 19

- Annexure-3 : SAP Permit-To-Work (PTW) Process Flow 20

(Tabular Form)

- Annexure-4 : SAP Standard Report 21

- Annexure-5 : Permit-To-Work (PTW) Revalidation 22

(TPSMS/CSP/PTW/008/FORM/001)

- Annexure -6 {Tool-Box-Talk (TBT) TPSMS/CSP/PTW/008/FORM/ 23

002}.

Note: Uncontrolled once printed Page 2 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

1. OBJECTIVE:

To provide a standardized & uniform procedure for obtaining authorization to perform jobs

require special consideration to ensure the safety of personnel, and protection of facilities

by using a safe system of work and clear understanding between the working agencies /

departments involved.

2. SCOPE:

This procedure applies to all operating and project sites of Tata Power Group

companies.

3. EXPECTED RESULTS:

3.1. Manage jobs being done under Permit-To-Work (PTW) safely.

3.2. Control of incidents in Jobs related to Permit-To-Work (PTW).

3.3. Compliance to Regulatory requirements related to Permit-To-Work.

4. ACCOUNTABILITY & RESPONSIBILITY:

4.1 ACCOUNTABILITY: Concerned Division’s Heads / SBU Heads / Assets Custodian.

4.2 RESPONSIBILITY: Working department, Contractors.

4.2.1 SBU Head / Assets Custodian:

Implement and manage the PTW system and provide necessary resources of

expertise in its application.

Implement, apply, monitor and audit the Permit-To-Work System within the

respective area.

Delegate various levels of authority in accordance with needs, subject to

appropriate training and competency.

Oversee training programs for Permit Acceptors, Permit Issuers, Permit

Approvers, Area Operators and Gas Testers as applicable.

Ensure that those who are appointed as Permit Acceptors, Permit Issuers,

Approvers and Area Operators are certified and competent to undertake the role.

Ensure updated list persons certified and competent for PTW are available.

Preferably list to be displayed at conspicuous location.

Ensure regular audit of PTW process as a whole.

Receive feedback from the users of the PTW system.

4.2.2 Permit Creator / Initiator / Applicant / Acceptor

The permit creator / initiator / acceptor / Applicant is a person who initiate the PTW and

after its approval he accept it for performing the job. He / She shall be responsible for

executing the entire job in full compliance with the PTW requirements. His/her

responsibilities include the following:

Note: Uncontrolled once printed Page 3 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

Understand the potential hazards involve in the job.

Ensuring that LOTO is performed at all points as applicable before the

commencement of the job.

Understand how the hazards are controlled.

Know the emergency situations likely to occur in the job / area and actions to be taken

including evacuation procedure.

Ensure that the Permit Holder understands all the hazards and controls, explaining

them to the workers, and ensure that the controls are maintained throughout the

execution of job.

Inform all people who may be directly / indirectly affected by the job.

Know the status of the job at all times, till its completion.

Transfer duties formally as and when required.

Know how to mitigate a possible incident, safe closure of job at such time, rescue of

men and material, arrange / administer medical aid if required.

Knowledge of first aid and its administration.

Is aware of the on-site emergency plan.

Lead and take care of his group at times of emergencies.

Permit Creator / Initiator / Applicant / Acceptor is typically maintenance engineer or

equivalent, however terminology of this designation may vary based upon hierarchy/

organization chart.

4.2.3 Permit Issuer / Issuing Authority (Control Room Engineer)

The Permit Issuer shall be responsible for review the information provided and amend if

required.

The Permit Issuer shall be responsible for the following:

Confirm that all hazards associated with the job have been identified, assessed,

managed and all relevant parties have provided their inputs and agree with the

precautions.

Ensure that the PTW contains scope of the job and the documented controls

mentioned are adequate to ensure that the job can be completed safely.

Ensure that all necessary supporting PTWs / Certificates / Checklist / JSA / drawings

are attached or referred to in the PTW.

Ensure that the Permit Acceptor knows the exact location and scope of the job, all the

hazards that may be present and all the precautions and controls that must be taken

and maintained during execution of the job.

Confirm that all operational preparations, including process clearance and isolations,

de-energizing and de-pressurizing have been completed.

Lock out and Tag out (LOTO) shall be performed as per Tata Power LOTO procedure

(TPSMS/CSP/LOTO/001) and isolation shall be done as per Standard Operating

Procedure.

Confirm that the job site is safe for the job to proceed.

Specify on the PTW any additional precautions that need to be taken during the job.

Note: Uncontrolled once printed Page 4 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

Identify any conflicts between the proposed job and other jobs in the area, and if

necessary, cross-reference necessary controls in all such PTWs.

Inform all persons who may be affected by the job.

Know the status of the job at all times till it's completion,

Ensure shift handover includes all ongoing or suspended PTWs with the upcoming

Permit issuer.

Permit Issuer / Issuing Authority is typically Control Room Engineer or equivalent, however

terminology of this designation may vary based upon hierarchy/ organization chart.

4.2.4 Permit Approver: Shift Incharge shall be a Permit Approver. The Permit Approver

shall be responsible for ensuring that the hazards have been evaluated, adequate

controls are provided and precautions are specified in the PTW. He/she is responsible

for the following:

Know the hazards including potential hazards and confirming that all hazards

associated with the job have been identified, assessed and managed and all relevant

agencies / Departments have provided their inputs and agreed with the precautions.

Know how to control and manage hazards involve in the job.

Verify that the job area is safe to commence and carryout job, including checking that

representative atmospheric sampling results are within the acceptable limits.

Ensure that the PTW contains scope of the job and the documented controls

mentioned are adequate to ensure that the job can be completed safely.

Ensure that all necessary supporting PTWs / Certificates / Checklist / JSA / drawings

are attached or referred to in the PTW.

Confirm that the Permit Holder has been explained the exact location of the job, all the

hazards & risks that may be present and all the precautions and controls are taken

care of.

Confirm that all operational preparations, including process clearance, isolations, de-

energizing and de-pressuring etc. have been completed.

Approve the PTW.

Permit Approver is typically Shift In- Charge or equivalent, however terminology of this

designation may vary based upon hierarchy/ organization chart.

4.2.5 Permit Holder - Person who is supervising the working party at the site and

executing the job.

The Permit Holder shall be responsible for commencing and completing the authorized

job while fully complying with all the requirements as mentioned in PTW. His / Her

responsibilities include the following:

Know and understand the potential hazards involved in the job.

Know and understand how the hazards are controlled.

Know the right kind of PPEs required, ensure correct use and compliance thereof.

Note: Uncontrolled once printed Page 5 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

Know the emergency situations likely to occur in the job / area and actions to be taken

including evacuating the area.

Deliver the Tool-Box-Talk (TBT) to the workers involved prior to commence the job

and record the same.

4.2.5 Individuals working within the PTW system should ensure that:

• Received and understood safety instructions during TBT on the particular job and

they understand the hazards and the precautions taken or to be taken.

• Shall not start any job without valid PTW and TBT.

• In case of stop work, the site and any equipment they are using is left in a safe

condition

• If in any doubt or if circumstances change, they must stop work and consult with their

supervisor / Permit holder.

5 GLOSSARY/ DEFINITIONS:

PTW - Permit-To- Work

Permit-To-Work (PTW) system: A PTW system is a formal written system used to control

and execute certain types of jobs safely, which are identified as potentially hazardous. It is

also a means of communication between different departments, plant supervisors,

operators, agencies etc.

Permit Creator / Initiator / Applicant / Acceptor: The Permit Creator / Initiator / Acceptor

/ Applicant is a person who initiate the PTW and after its approval he accept it for

performing the job. He / She shall be responsible for executing the entire job in full

compliance with the PTW requirements. Permit Creator / Initiator / Applicant / Acceptor is

typically maintenance engineer or equivalent, however terminology of this designation may

vary based upon hierarchy/ organization chart.

Permit Issuer / Issuing Authority (Control room engineer): The Permit Issuer shall be

responsible for review the information provided and amend if required. Permit Issuer /

Issuing Authority is typically Control Room Engineer or equivalent, however terminology of

this designation may vary based upon hierarchy/ organization chart.

Permit Approver: Shift Incharge shall be a Permit Approver. The Permit Approver

shall be responsible for ensuring that the hazards have been evaluated, adequate

controls are provided and precautions are specified in the PTW. Permit Approver is

typically Shift In- Charge or equivalent, however terminology of this designation may

vary based upon hierarchy/ organization chart.

Permit Holder: Person who is supervising the working party at the site and executing the

job. The Permit Holder shall be responsible for commencing and completing the authorized

job while fully complying with all the requirements as mentioned in PTW.

Job Safety Analysis: Job safety analysis (JSA) is a procedure which helps integrate

accepted safety and health principles and practices into a particular task or job. In a

Note: Uncontrolled once printed Page 6 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

JSA, for each basic step of the job, it is to identify potential hazards and to recommend

the safest way to do the job.

6 PROCEDURES:

6.1 Applicability:

Valid Permit-To-Work (PTW) and approve Job Safety Analysis (JSA) shall be taken for all

jobs other than approved exception list. Exception list shall be prepared at each division

and shall be approved by division chief.

The Plant / installation which is completely under the supervision / custody of External party

/ contractor; as a principle employer, company has to ensure the PTW system must be in

place. Such PTW system those are from external party / contractors shall be approved by

concerned division chief.

6.2 Preparation

6.2.1 Co-ordination: It is important to ensure that job requiring PTW, shall be planned

and coordinated in order to avoid risks caused by simultaneous activities.

6.2.2 Planning : Careful planning of job requiring a PTW shall take place to ensure:

• Appropriate approval for the job.

• All persons in charge of areas which may be affected are made aware and hence

take precautions against possible interaction with other work activity

• Sufficient time to identify all potential hazards, implement precautions and prepare

the worksite. One suggested technique of achieving this is a Job Safety Analysis.

6.2.3 Job safety Analysis (JSA): Job safety Analysis (JSA) shall be done directly into the

system or alternatively it can be done externally and uploaded in the system.

6.2.4 Types of Permit-To-Work (PTW): The types of work for which PTW systems shall

be applied include maintenance and repair, inspection, testing, construction,

dismantling, modification and cleaning.

The types of Permit-To-Work (PTW) as per SAP-EHS include:

- General Permit

- Confined Space Entry Permit

- Electrical Permit

- Excavation Permit

- Hot Permit

- Lifting and slinging Permit

- Project Nature Permit

- Radiography Permit

- Working at Height Permit

Note: Uncontrolled once printed Page 7 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

6.2.5 Cross Reference: The objective of cross reference is to ensure that no interaction

takes place between work activities which might endanger the safety of personnel or the

installation. The PTW issuer shall, by knowledge of work going on in his area of

responsibility, be aware of potential interaction when issuing multiple PTWs for the same

piece of equipment or system, or where there may be potential conflict with adjacent work

activities.

Such situations should be minimized by careful planning and suitable precautions which

should include an appropriate method of cross referencing the different tasks.

It may be that the interacting activities are covered by separate PTW issuers, in such cases

close co-ordination shall be necessary.

6.2.6: Process Flow of Permit-To-Work (PTW) in SAP:

SAP Notification Allotment to Maintenance Engineer

(By Operation Dept.) (By Concerned Head)

Self-Approval PTW Preparation NO Is it high

(Maintenance Engineer) (Maintenance Engineer) risk Job?

Yes

Approval of PTW

(Concerned Head) Safety Approval

(Safety Head)

PTW Clear Refer to Control Room Engineer

(By Shift In charge) for LOTO (Shift In charge)

PTW Acceptor PTW approved LOTO applied

(Maintenance Engineer) (Shift In charge) (Control Room Engineer)

PTW Holder Tool-Box-Talk (TBT) Site Restoration

(Supervisor) & Job Execution & PTW Closure

(Supervisor)

Note: Uncontrolled once printed Page 8 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

For all high risk jobs and Project nature Job, it is mandatory to take approval to

safety while processing the PTW.

If the job is high risk in nature then concerned Head has to change the status to High Risk

Job (HRJB) while assigning the Notification to Person responsible. Only concerned Head is

authorized to set the User Status LRJB & HRJB.

Permit initiator while preparing permits can still change job as high risk even if Concern

head has marked it as low risk.

If the Notification Status is “High Risk Job”, system will not allow to delete the concerned

Head & Safety Approvals in all types of PTW. If User tries to delete the Approvals, System

will show error message.

Concerned Safety Advisor shall check the adequacy of control measures defined in PTW

and JSA for all such high risk jobs. He may further recommend additional control measures

before grant of approval. At PTW clearing stage s/he is responsible to give their inputs in

JSA & PTW and during this s/he may not visit site, however subsequently during site visit

s/he shall check deployment of control measures.

Line management is wholly responsible for the implementation of JSA & PTW at site which

has been cleared by safety. Tool box talk (TBT) shall be done prior to start of each job and

to be recorded as per Annexure -6 {Tool-Box-Talk (TBT) TPSMS/CSP/PTW/008/FORM/

002}.

PTW shall be displayed at site or alternatively it should be made available at site. Permit

Holder shall remain present at site during entire period of job.

6.2.7 Extension of Permit-To-Work (PTW): In order that effective control is maintained in

changing circumstances there shall be a limit on the life of a permit. Depending on

the job, extension of all PTW other Project Nature Permit shall be up to 7 days.

Maximum extension in case of project nature permit may be upto 30 days. It shall be

necessary to intimate about the extension of PTW to all concerns involved. All

concerns shall maintain all existing controls measures in place as mentioned in

PTW & JSA.

6.2.8 Tagging: An essential ingredient of any safe system of work is the method and

integrity of the isolation procedure. The isolation principle to be adapted, prior to carry

out maintenance or repair, will be determined by a number of factors e.g. potential for

pressure, dangerous substances, lack of oxygen, moving machinery etc. It is beyond

the scope of this document to provided guidance on the isolation required for each

potential hazards, please refer Standard operating procedure of each equipments and

Tata Power LOTO procedure - TPSMS/CSP/LOTO/001. In case isolations are required,

Note: Uncontrolled once printed Page 9 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

the Issuing Authority will maintain the required isolations. Electrical team will be involved

in this step if electrical isolations are required.

The following additional points should be considered within the isolation

procedures:

• Complex isolations should be planned and recorded on a working drawing. This

should be discussed between the Permit Issuer and Permit Acceptor to ensure all

isolation points are clearly understood and agreed. The marked up drawing should

be readily available to all concerned. Consideration should be given to attaching a

copy to the PTW.

• It is essential that the isolation standard is commensurate with the type of job being

carried out, plant operating conditions and other local influences.

• Isolation procedures should include all energy sources, i.e. mechanical, electrical,

hydraulic pressure etc.

• The tag or key number should be recorded on the PTW form or on a separate form

which should in turn be cross referenced and attached to the PTW form.

• isolation should only be applied and removed on instruction from the person issuing

the PTW

• If more than one task is to be carried out on part of a plant or piece of equipment,

there is a risk that on completion of one of the tasks the isolations are removed and

the equipment is put back into service. Controls should be in place to prevent

premature de-isolation where dual tasks are involved

• if the work is not able to be completed within the shift the site should be checked by

both the Permit Acceptor and the Permit Issuer to ensure it is left in a safe condition

and equipment cannot be reinstated until all job shall be properly completed

• If the PTW is suspended, the status of the job site should be left on display in a

suitable location e.g. Control Room, and the isolation padlock keys kept in a secure

place to ensure no unauthorized access.

All persons authorized to carry out isolations should be assessed for their competence prior

to appointment i.e. they should

• Be suitably qualified

• Have experience on the plant/equipment

• Have received specific instructions on the plant, methods of isolation etc.

• Be able to demonstrate their knowledge by examination.

Their areas of responsibility shall be made quite clear.

6.2.9 Gas Testing: PTW preparation may involve a consideration of the likely presence of

flammable or toxic gases, or oxygen deficiency/enrichment, at the worksite.

Note: Uncontrolled once printed Page 10 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

Where such a consideration is necessary then gas testing shall be undertaken.

Persons involved in gas testing shall be adequately trained in the use of gas testing

equipment, and in the interpretation of results.

The responsibility of what to test for, where to take samples, and the minimum number of

samples to take should lie with the Permit Issuer. Gas testing shall be done as close to the

commencement of work as possible.

Results of any gas testing shall be recorded and timed, as per Tata Power confined space

entry procedure (TPSMS/CSP/CSE/003- Annexure 05/form No

TPSMS/CSP/CSE/003/FORM/003). In case ambient parameters changes beyond

acceptable levels during the work, the PTW shall be suspended.

6.2.10 Signatures: Once PTW approved, auto generated mail shall go to Permit

Initiator to execute the job as requested in PTW. Signature of Permit Holder and

respective field operation engineer (area / equipment owner) shall be taken on initial

issue of PTW and thereafter for revalidation on each day/shift as applicable.

6.3 Process

6.3.1 Display of Permit-To-Work (PTW): It is important that permits shall be displayed so

the persons who need to be aware of them, or to refer to them, are able to do so.

Copies should normally be distributed/displayed as follows:

• At the worksite. Where this is not practicable (e.g. at an exposed location), the

Permit Acceptor of the job should retain the copy, having ensured that the working

party members are familiar with its content and control measures.

• At the main control / co-ordination room, where these should be displayed in a

systematic arrangement.

6.3.2 Revalidation: Permit-To-Work (PTW) should be revalidated in order that the Permit

Issuer can satisfy himself that the conditions under which the PTW was originally

issued remain unchanged to allow work to continue.

Revalidation shall be done on next day before start of the same job as per

Annexure 5 Permit-To-Work (PTW) Revalidation

(TPSMS/CSP/PTW/008/FORM/001). It can be revalidated upto 7 days only except

project nature permit. For project nature permit revalidation may be done upto 30

days. The maximum validity of the permits is defined and revalidation beyond this

period are not allowed. In such cases, the PTW is closed and a new PTW shall be

issued.

6.3.3 Suspension: In the event of any of the following circumstances occurring during the

course of an activity under permit, the Permit Holder must refer back to the Permit Issuer

(through Permit Acceptor) on the appropriate course of action:

Note: Uncontrolled once printed Page 11 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

The specified equipment or tools to be used not being available.

Any changes in the type and nature of work.

Occurrence of any condition / situation during the progress of the work that was not

anticipated.

Any change in the process condition or the surrounding. (E.g. unexpected release of

gas from a nearby tank).

An emergency in the area.

Any change in the weather condition.

6.3.4 Shift Hand-overs: Shift changeovers can be one of the most vulnerable times for the

PTW system. The failure to pass on information or the correct information has been

shown to be the cause of many accidents. There is sufficient overlap to allow proper

review and discussion of the status of all Permit-To-Work.

Written means of communicating information can be by:

• PTW Log Book

• PTW Files

• Display Boards

• Computer Screen/Print Out

Or a combination of any of the above. Whichever arrangements are adopted, the

shift handover arrangement shall be monitored regularly to ensure its continued

effectiveness.

6.3.5 Action in an Emergency / break down situation: During emergencies, when

working party is not able to generate notification, PM order and hence PTW; in such

situation control room will use WCT6 and WCT7 to create safety tag number for the

outage. However, maintenance engineer will have to generate - notification, PM

order, PTW subsequently and attach safety tag (by using WCLE & WCD transaction)

number. No safety norms to be violated and standard SOP to be followed. For more

details please refer "SAP – PM Training Manuals (Use of WCT6 & WCT7 -

Guidelines Emergency Outages) available at Sangam web page at following path -

Saarthi > Project Saarthi > Training > Module > Plant Maintenance (PM) > 2.

PM Processes - Others> 06. Creating Safety Tags (WCT6 & WCT&) without

PTW-Emergency Outages.

6.3.6 Monitoring: The monitoring of the PTW shall be during entire span of job execution

by Permit Holder.

Note: Uncontrolled once printed Page 12 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

6.3.7 Trial Required After Maintenance Work: If trial of equipment is required to be

taken after the maintenance work is completed, the temporary un-tagging cycle is

initiated. (Refer Tata Power LOTO procedure (TPSMS/CSP/LOTO/001 Rev 01) 6.5

Temporary Removal of Lockout/Tag out Devices)

Process is initiated by authorized person by activating the button “Untag temporarily” in the

work clearance document, and system status is updated as BTUG - Untag temporarily.

(Annexure-1 Permit- To-Work (PTW) - Status Sequence)

Tags are removed from the field and system is restored to original condition. After the tags

are removed and the system condition is restored the authorized person activates a button

in the work clearance document “Temporarily untagged” and the system status is up-dated

as ETUG – Temporarily Untagged.

Trial is taken for the system and after successful completion of the trial, the authorized

person activates the button “Tagged” in the Work Clearance document and system status

is updated as ETG – Tagged.

If trial is unsuccessful then Maintenance team (Permit Initiator) have two options based on

the scenario.

If work can be done to rectify the problem, then the isolations of the field equipments will be

done again using the temporary untagging cycle as explained above. Temporary untagging

cycle will be repeated using the same tags and field equipments will be isolated. Work will

be executed in the equipment and further trial will be taken.

However, if work cannot be executed again and a scope change in work is required then

the PTW shall be closed. Untagging of the field equipments will be done and work

clearance document shall be closed. Scope change in work shall be handled by creating a

sub order through Work Order Management and new PTW will be created.

6.4 Completion

6.4.1 Work Completion: When the maintenance work is completed then maintenance

person indicates in the work order system that work is completed by activating Work

Completed Button on order header and the System Status is updated to WOCO –

Work completed.

Order operations are confirmed and order is updated with a system status as CNF –

Confirmed.

Note: Uncontrolled once printed Page 13 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

6.4.2 Closing of Permit-To-Work (PTW): After the Work is completed the Permit-To-

Work (PTW) is surrendered and the PTW is closed and the System Status is updated as

CLSD – Closed.

The system provides a facility to automatically set CLSD status on the Permit-To-Work

(PTW) when Maintenance order gets WOCO status.

6.4.3 Un-Tagging Process: After the Permit-To-Work (PTW) is surrendered then un-

tagging process is initiated by activating the button “Untag” in the Work clearance

document and the System status is up-dated as BUG – Untag.

System is restored to original condition as per the un-tagging conditions in the Work

Clearance document and tags are removed from the field equipment and with proper

housekeeping of job site.

Authorized person will activate the button “Untagged” in the Work Clearance Document and

the system status is updated as EUG – Untagged.

6.4.4 Closing the work Clearance Documents: After untagging of the isolation the Work

Clearance Document is closed and the system status is updated as CLSD – Closed.

6.4.5 Closing of Maintenance Order: After the PTW is closed, the order is technically

completed and the system status is set to TECO – Technically Completed. The

order cost is then settled by the finance section to the respective cost center and

order is business completed and system status is up-dated as CLSD - Completed.

6.4.6 Housekeeping: Housekeeping shall be ensured before the start of job as well as

after the completion / cancellation of job. Permit-To-Work (PTW) shall be closed only

after restoration of housekeeping of the Job site.

7 Records:

Filled Permit-To-Work (PTW) – Retention Period - One year

Filled Permit-To-Work (PTW) Revalidation (TPSMS/CSP/PTW/008/FORM/001) -–

Retention Period - One year

Record of Tool-Box-Talk (TBT) TPSMS/CSP/PTW/008/FORM/ 002} – Retention

Period - One year

8 TRAINING & COMMUNICATION

8.1 Training of Permit-To-Work procedure shall be carried out to cover for following-

(i) Permit Issuer,

(ii) Permit acceptor,

Note: Uncontrolled once printed Page 14 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

(iii) Permit Holder,

(iv) Permit approver.

List of trained and competent person in PTW as a Permit Issuer, acceptor, holder &

approval shall be displayed at conspicuous location.

8.2 Initial Communication to be done through Corporate Communication, Email and

subsequently shall be made available at safety portal at Sangam

9 VERIFICATION

Verification of implementation shall be done during Permit-To-Work (PTW) procedure audit,

field safety visit and site inspections.

10 EXCEPTION: Any Exception to this procedure shall only be done as per Document

Control .Procedure (TPSMS/GSP/DC/014).

11 REFERENCES

EPM 04.01.02 - Safe Working Procedures

Indian Factory Act 1948 and State Factory Rules (As amended)

SAP PM Work Permit Management Process - PM_Work_Permit_Management_04

Excavation Safety (Shoring and Sloping) Procedure - TPSMS/CSP/EXS/002

Tata Power LOTO Procedure - TPSMS/CSP/LOTO/001

Tata Power Job Safety Analysis (JSA) Procedure - TPSMS/CSP/JSA/009

Tata Power Hazard Identification & Risk Assessment (HIRA) Procedure -

TPSMS/GSP/HIRA/005

Tata Power Confined Space Entry Procedure - TPSMS/CSP/CSE/003

Tata Power Work At Height Procedure - TPSMS/CSP/WAH/004

12 REVIEW: Review of this procedure shall be done as and when but not later than once

in every three (03) years. Typical Factors like Changes in legislation, Review of

Incident Reports, Inspection & Audit findings, Feedback from users,

Recommendations in Incident investigation reports may be inputs for the review and

revision of the procedure.

13 ANNEXURES:

Annexure-1: Permit- To-Work (PTW) - Status Sequence

Annexure-2: Sheet 1 - Permit -To-Work (PTW) Issuance Process

Sheet 2 - Permit-To-Work (PTW) Return Process

Annexure - 3: SAP Permit-To-Work (PTW) Process Flow (Tabular Form)

Note: Uncontrolled once printed Page 15 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

Annexure -4: SAP Standard Report

Annexure-5: Permit-To-Work (PTW) Revalidation

(TPSMS/CSP/PTW/008/FORM/001)

Annexure-6: Tool-Box-Talk (TBT) TPSMS/CSP/PTW/008/FORM/ 002}

Annexure -1

Permit- To-Work (PTW) - Status Sequence

During the process of the isolations, execution and completion of work, the system status of

Header and Item level gets up-dated based on the processing phase. The processing

phase could be as follows –

- Tagging Phase

- Un-tagging phase

- Temporary Un-tagging Phase

System Description Remarks

Status

CRTE Created When the Work Clearance Document is created the system

status is set to CRTE – Created.

PREP Prepared After review of the Work Clearance Document Header and

Item data the WCD system status is set to PREP –

Prepared. This will allow for the approval and Tagging

process.

CHNG Change WCD status PREP is revoked.

CLSD Closed After the items are untagged the WCD status is set to

CLSD – Closed and the WCD is completed in the system.

ITG Initial Tagging WCD items system status is set to ITG – Initial Tagging

Condition Condition when the WCD is set to Prepared condition. The

items cannot be deleted from the WCD document after ITG

status is set to the items.

PROC Processing When the Tagging process is initiated System status is set

to Processing.

BTG Begin Tagging WCD items system status is set to BTG- Begin Tagging

status when tagging process is initiated by activating the

“TAG” button.

PTAG Print Tag WCD items status is set to “PTAG” status when tag printing

button is activated for printing the Tags from the system

ETG End of WCD items system status is set to “ETG” - Tagged status

Tagging when “Tagged” button is activated after the items are

physically isolated and tags are placed on the isolated

items.

INAC Inactivated WCD item status is set to INAC- Inactivated status if WCD

item is not relevant and items already have system status

ITG.

Note: Uncontrolled once printed Page 16 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

BTUG Begin WCD items status is set to “BTUG” status when “Untag

Temporary Temporarily” button is activated for Trial purposes.

Untagging

ETUG End of WCD items status is set to “ETUG” status when

Temporary “Temporarily Untagged” button is activated after conditions

Tagging are restored for trial purposes.

TEST TEST Cycle Permit trial cycle in progress

PTST Print Test Tag WCD items get “PTST” status when tag printing button is

activated for printing the Tags from the system for test

cycle.

UNT Untaggable WCD items get UNT – Untaggable status to indicate items

can be untagged.

BUG Begin WCD items get “BUG” untag status when “Untag” button is

Untagging activated to begin Untagging Process

EUG End of WCD items are set to “ETG” Untagged status when

Untagging “Untagged” button is activated.

Note: Uncontrolled once printed Page 17 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

Annexure-2

Sheet 1

Permit -To-Work (PTW) Issuance Process

Note: Uncontrolled once printed Page 18 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

Annexure- 2

Sheet 2

Permit-To-Work (PTW) Return Process

Note: Uncontrolled once printed Page 19 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

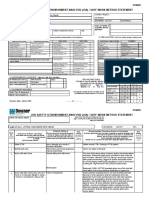

Annexure- 3

SAP Permit-To-Work (PTW) Process Flow (Tabular Form)

Work Work Step Description SAP T-code/Out of

Step # SAP/Other

Permit Issuance Process

1 Create Work permit in maintenance order IW31/IW32

2 Identify affected departments & types of work IW32/IPMD

permit required for the job like PTW (Hot Work

Permit, Confined Space)

3 Attach JSA/HIRA if required

4 Prepare the work Permit & inform operations for WCLE

approvals.

5 Can maintenance of equipment be done? (YES:7 Manual

NO:6)

6 Reject the work Permit Document with comment WCLE

and Email alert to all the concerned Dept

7 Approve Permit WCLE

8 Are other maintenance dept involved? (YES:9 Manual

NO:12)

9 Notify relevant departments Workflow

10 Preparedness is ensured Manual

11 Confirm preparedness WCLE

12 Print Permit Document & TAGS WCLE

13 Carry out Isolations at site/LOTO & inform the Manual

concerned to activate the work Permit

14 Safety tags are assigned Manual

15 Activate Work Permit/Tagging WCLE

16 Email alert to person who created the order Workflow

Permit Return Process

1 Job is executed in field Manual

2 Clear WCD and LOTO WCLE

3 Is Equipment trail required (YES 4, NO 10) Manual

4 Take Operating Permit

5 Trail Taken Manual

6 Record Results

7 Is Trail is OK (YES 10 NO 8)

8 Create new WCD/Safety Tags WCLE

Note: Uncontrolled once printed Page 20 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

9 Carry Out LOTO Manual

10 All permits are returned & Work Permit is WCLE

closed/Untagging

11 Email alert will be sent to Shift In Charge/Section Manual

Head for breakdown Main for Equipment Category

A and B

Annexure- 4

SAP Standard Report

Report title Transaction Comment

code ( SAP GUI)

List Work Approvals IP16 A list of all work approvals will be displayed

with respective status such as ‘created’,

‘closed’, etc.

List Work Clearance WCL6 A list of all work clearance applications will

Applications be displayed

List maintenance IW39 A list of all selected maintenance orders is

orders displayed.

Equipment list IH08 An equipment list with general data and

more information.

List of Work Clearance WCL2 A list of all work clearance document

Document templates templates will be displayed

Note: Uncontrolled once printed Page 21 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

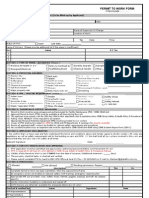

TPSMS/CSP/PTW/008/FORM/001 Annexure- 5

Permit-To-Work (PTW) Revalidation

Details: Day 2 Day 3 Day 4 Day 5 Day 6 Day 7

Date:

Time: From

Time :To

Signature & Name of

Permit Issuer

Signature & Name of

Permit Accepter / Holder

Signature & Name of Area

Operator (if applicable)

Note: Uncontrolled once printed Page 22 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

TPSMS/CSP/PTW/008/FORM/002 Annexure- 6

Tool-Box-Talk (TBT) Record

Tool-Box-Talk (TBT) Date :

Location/Venue :

Permit-To-Work (PTW) No. :

Time :

Tool Box Talk conducted by :

Name of the Contractor / dept. :

Name of the Contractor’s Supervisor :

Number of Workmen Present :

COMMON POINTS TO BE STATUS Brief Discussion on Job to be performed

DISCUSSED

Use of proper PPEs

Use of proper Tools

Barriers & Signs

Emergency Vehicle & First

Aid Box

Enquiry of Health Status

SN. Name of the Workmen Gate Pass No. Sign

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Note: Uncontrolled once printed Page 23 of 23

Document Title

The Tata Power Company Ltd

Permit-To-Work Procedure

Document Ref No.

TPSMS/CSP/PTW/008 Rev 02 Date of Issue: 16/01/2017

15

Sign & Name of Tool-Box-Talk (TBT) conducted by:

Note: Uncontrolled once printed Page 24 of 23

You might also like

- 01 - Tata Power LOTO ProcedureDocument17 pages01 - Tata Power LOTO Procedurehse bsjNo ratings yet

- Work at Height Procedure: Document Ref NoDocument16 pagesWork at Height Procedure: Document Ref NoDharmavir Singh100% (1)

- Hazard Identification & Risk Assessment (HIRA) - ProcedureDocument16 pagesHazard Identification & Risk Assessment (HIRA) - ProcedureDivakar80% (10)

- Scaffold Safety ProcedureDocument24 pagesScaffold Safety ProcedureRajib MondalNo ratings yet

- Lift Elevator SafetyDocument17 pagesLift Elevator SafetyPraful E. PawarNo ratings yet

- LOTO Procedure PDFDocument17 pagesLOTO Procedure PDFSatyadip Teraiya50% (2)

- 04 - Tata Power Work at Height ProcedureDocument21 pages04 - Tata Power Work at Height Procedurehse bsjNo ratings yet

- Jsa For Mechanical Activity: H/M/L H/M/LDocument1 pageJsa For Mechanical Activity: H/M/L H/M/Ljithin shankarNo ratings yet

- The Tata Power Company LTD Lock Out Tag Out (LOTO) ProcedureDocument17 pagesThe Tata Power Company LTD Lock Out Tag Out (LOTO) ProcedureGilbert GillNo ratings yet

- HSE-000-For-0005 Preliminary Incident Report FormDocument1 pageHSE-000-For-0005 Preliminary Incident Report Formernesto100% (2)

- Electrical Safety ProcedureDocument33 pagesElectrical Safety ProcedurePraful E. Pawar100% (1)

- Contractor Health - Safety - Environment Management System - CHSEMSDocument124 pagesContractor Health - Safety - Environment Management System - CHSEMSAmarNo ratings yet

- Task Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)Document3 pagesTask Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)andreNo ratings yet

- 11 - Tata Power Safety Document Control ProcedureDocument15 pages11 - Tata Power Safety Document Control Procedureloganathan100% (1)

- 08 - Tata Power Permit To Work ProcedureDocument24 pages08 - Tata Power Permit To Work Procedurehse bsjNo ratings yet

- 02 - Tata Power Excavation Safety ProcedureDocument21 pages02 - Tata Power Excavation Safety Procedurehse bsj100% (1)

- 05 - Tata Power Heavy Equipment Safety ProcedureDocument24 pages05 - Tata Power Heavy Equipment Safety Procedurehse bsj100% (1)

- Visitors Safety InductionDocument1 pageVisitors Safety InductionCaptainNo ratings yet

- 13 - Tata Power Management of Change (MOC) ProcedureDocument12 pages13 - Tata Power Management of Change (MOC) Procedurehse bsjNo ratings yet

- 19 - Tata Power PPE Procedure - 01122021Document20 pages19 - Tata Power PPE Procedure - 01122021jacobpm2010No ratings yet

- Ofs Permit To Work FormDocument2 pagesOfs Permit To Work FormZ Babar KhanNo ratings yet

- JSA For Welding in Boiler PDFDocument2 pagesJSA For Welding in Boiler PDFSravan Dasari100% (3)

- Work Permit SystemDocument42 pagesWork Permit SystemDamien Gracious K.D100% (2)

- 03 Confined Space Entry PDFDocument18 pages03 Confined Space Entry PDFBudi SantonyNo ratings yet

- 010 - Permit To Work Procedure Feb 2013Document61 pages010 - Permit To Work Procedure Feb 2013vdeviv100% (1)

- 3 SPS Sop RCC FullDocument14 pages3 SPS Sop RCC FullDwitikrushna RoutNo ratings yet

- Procedure For Lock-Out Tag-Out (LOTO) : Dalmia Cement (Bharat) LTDDocument33 pagesProcedure For Lock-Out Tag-Out (LOTO) : Dalmia Cement (Bharat) LTDparthaNo ratings yet

- Job Safety Analysis: Operating A Metal LatheDocument3 pagesJob Safety Analysis: Operating A Metal LatheSafety DeptNo ratings yet

- Batteries Handling Disposal ProcedureDocument17 pagesBatteries Handling Disposal ProcedureBALAJINo ratings yet

- Permit To Work Corporate StandardDocument17 pagesPermit To Work Corporate StandardLozhashop ID100% (2)

- Scaffold Safety ProcedureDocument24 pagesScaffold Safety ProcedureAlif Rahmat Febrianto100% (1)

- Permit To Work Procedure (10.11.2018)Document20 pagesPermit To Work Procedure (10.11.2018)Bebe BucătaruNo ratings yet

- Safety Induction TrainningDocument10 pagesSafety Induction TrainningJustin Ranjit100% (1)

- PTWDocument2 pagesPTWMazhairil Paet100% (1)

- Working at Height Risk AssessmentsDocument1 pageWorking at Height Risk AssessmentsRajan GuptaNo ratings yet

- LS-LSIT Video Exam Preparation Course WorkbookDocument330 pagesLS-LSIT Video Exam Preparation Course WorkbookChris SzychowskiNo ratings yet

- JSA For Chimney Works 17.09.2021Document2 pagesJSA For Chimney Works 17.09.2021Brenden PalanithangamNo ratings yet

- T&D-HSE-PRC-0030 Transportation Safety ProcedureDocument12 pagesT&D-HSE-PRC-0030 Transportation Safety ProcedureDamalie100% (1)

- 14 - Tata Power PSSR ProcedureDocument10 pages14 - Tata Power PSSR Procedurehse bsjNo ratings yet

- HSE Action PlanDocument7 pagesHSE Action Planmazen fakhfakhNo ratings yet

- Nishant - SAP PSDocument4 pagesNishant - SAP PSniteshsh31No ratings yet

- 09 - Tata Power Safety - Audit - ProcedureDocument9 pages09 - Tata Power Safety - Audit - ProcedureloganathanNo ratings yet

- Permit To Work ProcedureDocument46 pagesPermit To Work ProcedureMauro MLR60% (5)

- JSA G17 Lift Container With Crane PDFDocument4 pagesJSA G17 Lift Container With Crane PDFsetiawanaji407100% (1)

- HIRADC COSHH Antifreeze or CoolantDocument3 pagesHIRADC COSHH Antifreeze or CoolantwisnukerNo ratings yet

- Operational Control Procedures BhelDocument124 pagesOperational Control Procedures BhelKrishnan Rajappan100% (3)

- Hira - Mov Valve Inspection & MaintenanceDocument8 pagesHira - Mov Valve Inspection & MaintenanceAbzad HussainNo ratings yet

- Training and Development ProgramsDocument74 pagesTraining and Development ProgramsVivek Anand100% (1)

- HIRA FormatDocument2 pagesHIRA FormatSachin Yashwant kumbharNo ratings yet

- Permit To WorkDocument12 pagesPermit To WorkRaymund Pilayre100% (2)

- 01 - Tata Power LOTO ProcedureDocument21 pages01 - Tata Power LOTO Procedurehse bsjNo ratings yet

- PTW System ProcedureDocument59 pagesPTW System ProcedureSiva Subramaniyan100% (5)

- Ppe Matrix - FTDocument1 pagePpe Matrix - FTAkhilesh Pandey100% (2)

- Permit To Work ProcedureDocument10 pagesPermit To Work Proceduremasahin100% (1)

- PR08 Permit To WorkDocument10 pagesPR08 Permit To WorkMuhammad WaleedNo ratings yet

- Lesson Plan in Science 7Document4 pagesLesson Plan in Science 7angeline vacalaresNo ratings yet

- Type and Typography - The Designers Type Book - Ben RosenDocument403 pagesType and Typography - The Designers Type Book - Ben RosenAndrea RominaNo ratings yet

- Consequence Management Sytem EsepplDocument1 pageConsequence Management Sytem Eseppluttam mishra100% (2)

- A Guide To Facilitating Adult Learning PDFDocument30 pagesA Guide To Facilitating Adult Learning PDFmarcgleb100% (1)

- Press On Permit To Work SystemDocument7 pagesPress On Permit To Work SystemashwaniNo ratings yet

- Tool Box Talk - 8 Lifting EquipmentDocument2 pagesTool Box Talk - 8 Lifting EquipmentMoaatazz Nouisri100% (1)

- The Essential Guide To Performance HiringDocument12 pagesThe Essential Guide To Performance HiringZiaul HaqueNo ratings yet

- OCP For Welding Gas CuttingDocument2 pagesOCP For Welding Gas CuttingManu Sharma0% (1)

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisDocument2 pagesBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechNo ratings yet

- SOP of HSE TrainingDocument6 pagesSOP of HSE TrainingRaza Muhammad SoomroNo ratings yet

- Request For Permit To Work (PTW) - Contactor Application: PLTG 75 MW Paya Pasir MedanDocument2 pagesRequest For Permit To Work (PTW) - Contactor Application: PLTG 75 MW Paya Pasir MedanDimas Dwi SwarnaNo ratings yet

- Permit To Work ProcedureDocument24 pagesPermit To Work ProcedureAnjali ShuklaNo ratings yet

- Keihin - SAP S4 / HANA 1709 Impl Ementation: Weekly Status Report From 27/jul/2018 To 03/aug/2018Document12 pagesKeihin - SAP S4 / HANA 1709 Impl Ementation: Weekly Status Report From 27/jul/2018 To 03/aug/2018niteshsh31No ratings yet

- Investigation Report: BiochemistryDocument1 pageInvestigation Report: Biochemistryniteshsh31No ratings yet

- Nitesh Sharma: Sap Eam/Lam/Wcm - Lead ConsultantDocument1 pageNitesh Sharma: Sap Eam/Lam/Wcm - Lead Consultantniteshsh31No ratings yet

- WCM Infotag 2010 Ams GDF Suez enDocument29 pagesWCM Infotag 2010 Ams GDF Suez enniteshsh31No ratings yet

- Warehouse WorkerDocument3 pagesWarehouse WorkerRakesh BabuNo ratings yet

- ES 27 SummaryDocument54 pagesES 27 SummaryDeanz TinioNo ratings yet

- Realism & ContructivismDocument15 pagesRealism & ContructivismRowly Pearl Iradiel NedicNo ratings yet

- PresentabotDocument3 pagesPresentabotapi-268559396No ratings yet

- Lesson Plan ActDocument2 pagesLesson Plan ActElizabeth GanoNo ratings yet

- Win95 in DosboxDocument5 pagesWin95 in Dosboxjfy14152No ratings yet

- Writing To PersuadeDocument10 pagesWriting To Persuadeshumaila parveenNo ratings yet

- Ch.03 Single DOF Systems - Governing Equations PDFDocument15 pagesCh.03 Single DOF Systems - Governing Equations PDFDUY Đỗ NgọcNo ratings yet

- 2006 Physics Written Examination 1 PDFDocument38 pages2006 Physics Written Examination 1 PDFpappadutNo ratings yet

- Chapter 1-4Document57 pagesChapter 1-4Lj YouNo ratings yet

- BDocument26 pagesBMax MaxNo ratings yet

- Untitled PDFDocument1 pageUntitled PDFdeclanNo ratings yet

- Bioethics ReflectionDocument3 pagesBioethics ReflectionDanielle Sy EncinaresNo ratings yet

- Weblogicadminmanagedserversautomaticmigration 130324181906 Phpapp01 PDFDocument12 pagesWeblogicadminmanagedserversautomaticmigration 130324181906 Phpapp01 PDFSai KadharNo ratings yet

- Bhuta Vidya Nature Worship 2016 - 2017 v10 PDFDocument15 pagesBhuta Vidya Nature Worship 2016 - 2017 v10 PDFCyber Security ExpertsNo ratings yet

- Public Catalogue: AvailableDocument3 pagesPublic Catalogue: Availableपराग राणेNo ratings yet

- PSY 120 OutlineDocument4 pagesPSY 120 OutlinegeNo ratings yet

- Elix Essential Manual Millipore - Water-PurificationDocument54 pagesElix Essential Manual Millipore - Water-PurificationDino Sk100% (1)

- Seminar 2Document26 pagesSeminar 2Manan GaurNo ratings yet

- List of Institutions & Courses of Engineering Colleges Included in Online Counselling Option Filling Year 2010-11Document6 pagesList of Institutions & Courses of Engineering Colleges Included in Online Counselling Option Filling Year 2010-11Engineering CounsellingNo ratings yet

- Ch01 ISMDocument52 pagesCh01 ISMZi Yi TanNo ratings yet

- En 13130-23Document16 pagesEn 13130-23fatmaahmed331993tankoilNo ratings yet

- Nature of Learner LanguageDocument28 pagesNature of Learner LanguageGenesis LaborNo ratings yet

- Rel Alg Tutorial 3Document3 pagesRel Alg Tutorial 3shiva darshanNo ratings yet