Professional Documents

Culture Documents

Rotary 1/4 Turn Actuator / Double Acting & Spring Return Models General Actuators & Spring Returns

Uploaded by

thach pha thienOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rotary 1/4 Turn Actuator / Double Acting & Spring Return Models General Actuators & Spring Returns

Uploaded by

thach pha thienCopyright:

Available Formats

Installation, Operation & Maintenance Instructions

ROTARY 1/4 TURN ACTUATOR / DOUBLE ACTING & SPRING RETURN MODELS

Suitable for use in safe area and hazardous gas/dust atmospheres (ATEX)

GENERAL ACTUATORS & SPRING RETURNS

NOTE : ALL REFERENCES IN THIS DOCUMENT TO MODEL 08 ASSEMBLIES ARE SPECIFIC TO THE 2010 REDESIGN. FOR PRE 05/2010

08 MODELS CONTACT KINETROL.

1. INSTALLATION 2. Mounting

Mounting hole sizes – Standard actuator

2.1 Actuator and driven unit must be correctly aligned, i.e.

actuator vane and driven unit must be able to move in same

Number ISO Depth ANSI Thread Depth of

of Thread Thread direction from end stop when coupled together.

of Holes Thread

Model

Position of output

01 4 M4 x 0.7 6mm 8-32 UNC 15/64" square in mid-travel

02 4 M4 x 0.7 8mm 8-32 UNC 5/16"

position.

03 4 M5 x 0.8 10mm 10-24 UNC 3/8"

05 6 M5 x 0.8 10mm 10-32 UNC 3/8"

07 4 M8 x 1.25 16mm 5/16-18 UNC 5/8"

08 4 M8 x 1.25 16mm 5/16-18 UNC 5/8"

09 4 M10 x 1.5 20mm 3/8-16 UNC 25/32” Note:

12 4 M12 x 1.75 24mm 1/2-13 UNC 15/16" Position of output shaft when vane at mid-travel position.

2.2 Take particular care in aligning model 05. 6-hole mounting

14 4 M16 x 2 28mm 5/8-11 UNC 11/8"

means 30° misalignment possible if flange has 60° error

16 4 M24 x 3 38mm 7/8-9 UNC 11/2" and coupling 90° error.

18 4 M30 x 3.5 50mm 11/8-7 UNC 2" 2.3 There must be no end load on actuator drive shaft. Check

clearance between actuator and driven unit drive shaft,

20 8 M30 x 3.5 50mm 11/8-7 UNC 2"

allowing for coupling to be used.

30 8 M30 x 3.5 50mm 11/8-7 UNC 2" 2.4 Care must be taken to ensure concentricity between

actuator shaft and driven unit shaft.

Model 014P has 4 M4 (8-32 UNC) clearance holes. 2.5 Actuator can be mounted in any plane.

2.6 When side loading of actuator shaft is unavoidable, ensure

Mounting hole sizes – DIN/ISO actuators load does not exceed guide lines given in Kinetrol Technical

data sheet TD28.

Model suffix 1 is without Namur. 2.7 Ensure the larger of the output square drives (if different) is

Model suffix 2 is with Namur solenoid valve mounting. used to drive the load.

Model suffix 3 is with ancillary mounting.

Model suffix A is with ancillary mounting and Namur solenoid 3. Drive Coupling

valve mounting. 3.1 Square hole standard drive coupling supplied in mild steel

and may be welded or brazed to coupling part to suit drive

Number of ISO Thread Depth of PCD on driven unit.

Holes Thread NOTE: This is not supplied with ISO/DIN, ISO adaptor or

Model female spring drive models.

3.2 When the mounting is tightened down, check there is

031/3 & 032/A 4 M5 x 0.8 8mm 36mm

minimum 0.5mm (0.020") end play of coupling on actuator

051/3 & 052/A 4 M5 x 0.8 8mm 42mm square drive shaft to avoid end load on actuator shaft.

071/3 & 072/A 4 M6 x 1 10mm 50mm

4. Air/Gas Supply

083 & 08A 4 M8 x 1.25 13mm 70mm

4.1 Operating air pressure should not exceed 7 bar (100 psi).

091/3 & 092/A 4 M8 x 1.25 13mm 70mm

4.2 Air/Gas supply must be reasonably clean and dry and to a

101/3 & 102/A 4 M10 x 1.5 16mm 102mm quality class 4.5.5 (according to ISO standard 8573.1). This

implies 25 micron maximum particle size, 7°C dew point

121/3 & 122/A 4 M10 x 1.5 16mm 102mm

maximum (or lower than ambient temperature below 7°C)

141/3 & 142/A 4 M12 x 1.75 20mm 125mm and 25 mg/cubic metre maximum oil content.

161/3 4 M20 x 2.5 32mm 165mm 4.3 Plastic or other non-conductive tubing is not recommended

for use unless it is proven to comply with EN13463-1-2001

section 7.4.4. Size should be relative to supply/exhaust port

Mounting hole sizes for ISO adaptor models refer to size on actuator concerned. Undersize tubing or fittings will

Kinetrol technical data sheet TD124. restrict actuator performance.

4.4 The actuator can be driven by a hazardous gas as long as:

Mounting hole sizes for female spring return assemblies 4.4.1 The gas is not corrosive (e.g. natural gas “sweet” and

refer to Kinetrol technical data sheet TD121. not “sour” gas is used).

4.4.2 The gases must not be used within their flammable

Note: It is essential that full number of bolts are used and all range.

tightened evenly. Refer to TD 111. 4.5 Air can be passed to the actuator from three different sets of

air port. One is through the side holes for fast response.

CAUTION: Two holes at the rear of the actuator can be unplugged or a

NEVER HAMMER OR USE OTHER UNDUE FORCE ON Namur adaptor fitted for using a Namur standard valve or

ACTUATOR DIECAST CASES. DAMAGE TO INTERNAL SEALING two air holes in the top flange of the actuator by unplugging

FACES WILL RESULT. holes and fitting a Kinetrol positioning product (Models 05-14).

ISSUE DATE Doc.No. TD 129

K 08/12 Trading Estate Farnham Surrey England. GU9 9NU Page 1 OF 8 KF464

AR 5474 / ISS.J - AR 4777 / ISS.H - AR 4726

Installation, Operation & Maintenance Instructions

ROTARY 1/4 TURN ACTUATOR / DOUBLE ACTING & SPRING RETURN MODELS

Suitable for use in safe area and hazardous gas/dust atmospheres (ATEX)

5. Operation In addition, a tube of sealant will be required to seal case

5.1 External stops are strongly recommended when actuator is halves. Spring return units are not user servicable and

operating a mechanism with cantilevered load. However, therefore no spare parts are available other than complete

Kinetrol technical data sheet, TD37, can be used to ensure units and keeper plates for safe spring removal.

load inertia and travel speed remain within allowable limits.

5.2 Second square end of drive shaft may be used for visual 8. Labelling (ATEX)

position indication, emergency manual operation or driving of All Kinetrol actuators that are approved for use in areas

add-on units (positioner, limit switch unit, etc.). where explosives, dust & gases are present, are marked

5.3 If the square sizes are the same both ends spring units can be with one of the following labels:

fitted either end. However, if they are different, always fit the

spring to the larger square end and drive through this end only.

TYPE: XXX-XXX TYPE: XXX-XXX-2100

5.4 Ambient operating temperature range of actuator is -20°C to

Serial No. xxxxxxxx Serial No. xxxxxxxx

80°C. This range may be extended to +100°C with Viton Baseefa 03 ATEX 0443X Baseefa 03 ATEX 0443X

seals. Special care should be taken to ensure that heat II 1GD c 90°C -20°C Ta 80°C II 1GD c 110°C -20°C Ta 100°C

conducted from, for example, a hot valve, does not increase

Category 1 Standard Category 1 Viton

the actuator temperature above these limits. Refer to Kinetrol

technical data sheet TD69 for guidance. A low temperature TYPE: XXX-XXX TYPE: XXX-XXX-2100

version of the actuator, having an ‘L’ at the end of the type Serial No. xxxxxxxx Serial No. xxxxxxxx

code allows the unit to be used at an ambient temperature Tech File KTR118 ATEX Tech File KTR118 ATEX

range of -40°C to 70°C, such actuators may be labelled with II 2GD c 90°C -20°C Ta 80°C II 2GD c 110°C -20°C Ta 100°C

a special ATEX label (see section 8). Category 2 Standard Category 2 Viton

5.5 Visual position indicators are available. Coloured red, made

from Nylon 6, they can be fitted over square shaft at top of TYPE: XXX-XXX L

actuator or top of add-on unit. Serial No. xxxxxxxx

5.6 Ensure environmental conditions, such as corrosive Tech. File KTR118 ATEX

environments, are compatible with the materials of II 2GD c 80°C -40°C Ta 70°C

construction and protective finishes (Kinetrol technical data Low Temperature Label

sheet TD14 refers). If unsure contact Kinetrol. Excessive

corrosion of the actuator may cause it to fail in service.

5.7 Ensure operating speeds are less than 1 m/s for Cat 1 Ensure that the details on the label such as the ambient

atmospheres and 4m/s for cat 2 atmospheres, see table temperature range is suitable for the application.

below for maximum operating travel times: Also ensure that any other equipment fitted to the actuator

5.8 Ensure any build up of dust is removed and regular checks are (e.g. limit switch box or positioner) does not restrict the use

made. within the parameters shown on the above labels. Certificate

Category 1 Category 2 of Conformance, TD125, shows the category of approval

operating time operating time for different sizes of actuator and spring unit.

Model for 90° travel for 90° travel

(sec) (sec)

01 0.056 0.014 9. Adjustment

02 0.067 0.017 9.1 Stroke Adjustment – only applies to models with adjustable

03 0.085 0.021 stops.

05 0.107 0.027 Table of standard stroke

07 0.143 0.036 adjustments available

08 N/A 0.042 Adjustment range available

09 N/A 0.046

Models Each stop

10 N/A 0.047

12 N/A 0.060 03/07/08/09/16/18/20/30 10º

14 N/A 0.081 02/05/14 8º

16 N/A 0.415 01A/10/12 11º

18 N/A 0.545

20/30 N/A 0.540

6. Maintenance Greater adjustment range possible with non-standard stop

Maintenance is limited to replacement of seals when wear screws. Contact KINETROL for details.

affects actuator performance. Seal life will vary according to

application, conditions of cycle frequency, temperature, 9.2 Speed Adjustment

condition of air supply, etc. Detailed seal replacement Slower operation of actuator is possible, without significant

instructions in next section. torque output reduction, by external fitment of flow regulator

valves.

7. Recommended Spare Parts (Refer to pages 5 - 8) Faster operation can be achieved under certain conditions

Standard seal kits, available for each actuator model, consist by fitting quick exhaust valves. For full details contact

of the following: Kinetrol.

- 2 off vane seal - 2 off expander - 2 off shaft seal

- Plus all necessary O-rings, screws, nuts and grease for

all sizes up to model 14.

ISSUE DATE Doc.No. TD 129

K 08/12 Trading Estate Farnham Surrey England. GU9 9NU Page 2 OF 8 KF464

AR 5474 / ISS.J - AR 4777 / ISS.H - AR 4726

Installation, Operation & Maintenance Instructions

ROTARY 1/4 TURN ACTUATOR / DOUBLE ACTING & SPRING RETURN MODELS

Suitable for use in safe area and hazardous gas/dust atmospheres (ATEX)

ACTUATOR SEAL REPLACEMENT INSTRUCTIONS

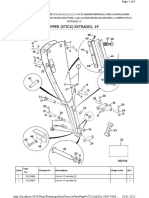

1. DISMANTLING ACTUATOR (see exploded drawing/parts 2.10 After checking that expander and seal are right way round -

list) CAUTION: Before dismantling, check there are no burrs on expander has vane shaped hole, seal has shaft centre line

square drive shafts. If there are, remove to avoid damage to marked - thread first few threads of each bolt into vane.

bearings and shaft seals during removal of case halves. In the 2.11 While holding up side plate, expander and seal, apply a low

case of spring return actuators, remove spring unit (according strength anaerobic adhesive to bolt thread.

to following section) before opening actuator case. 2.12 Screw bolts down and tighten to torques given below.

FOR DISMANTLING/RE-ASSEMBLY INSTRUCTIONS FOR 2.13 Turn vane over then fit seal, expander and side plate over

20/30 SIZE ACTUATOR REFER TO KINETROL TECHNICAL end of bolts. Check orientation as before.

DATA SHEET TD104. 2.14 Screw nuts down thread.

1.1 All models: loosen, but do not remove, all case screws. 2.15 Position vane assembly in coupling on bench, hold head of

1.2 Separate case halves by connecting air line to inlet port and bolt with a spanner, torque up nut to torque specified

blowing them apart. Procedure is safe although producing a in section 2.7.

“bang”. Pull off one case half. Hex Head Bolts

CAUTION: Do NOT hammer diecast castings or shaft end.

It will damage internal sealing surfaces. 01 6lbf./ins 0.07 m kg

1.3 Clean both case halves removing silicone rubber sealant. 07 8lbf./ins 0.09 m kg

Clean joint surfaces of case flange with surgical spirit. 08 10lbf./ins 0.12 m kg

1.4 Replace and lubricate shaft seals.

1.5 Undo vane nuts and bolts (if fitted) and remove old expanders 09 10lbf./ins 0.12 m kg

and seals from vane. Take care not to damage side plates. 10 15lbf./ins 0.17 m kg

Clean vane.Some later models use nuts on one side of vane

12 30lbf./ins 0.35 m kg

with bolts on other side.

3. RE-ASSEMBLING ACTUATOR

2. REASSEMBLY VANE

3.1 Coat bearing bushes and inside both case halves with

Vane sub assembly with studs

molybdenum disulphide grease or grease supplied by

2.1 Check studs are tight through vane and equal length each

KINETROL.

side (if studs are fitted). If not, apply Loctite to thread and

3.2 Lightly and evenly coat joint face on each case half with

relocate correctly in vane.

INSTANT GASKET sealant (up to Model 14) available from

2.2 Model 18: Apply SILASTIC 732 RTV sealant around bottom

Kinetrol (SP057) or Loctite, or SILASTIC 732 RTV sealant

of studs (to prevent air leakage through seal on vane stud

(Model 16 up) obtainable from ironmongers, etc. may be

holes).

used as a substitute. CAUTION: EXCESS SEALANT, if

2.3 Fit new seal over studs after checking profile matches vane

extruded inside case, WILL IMPAIR OPERATION OF

profile.

SEALS. Remove all excess sealant especially from inside

2.4 Fit seal expander – the hole in it shaped like vane outline

edge.

shows correct way round – teeth pointing away from vane.

3.3 Insert vane into one case half, turning it to ease square on

2.5 Fit side plate over studs.

drive shaft through shaft seal. Watch that lip seals at ends

2.6 Fit new nuts to studs after applying Loctite medium strength

of vane easily work down into case without damage.

sealant to threads.

3.4 Fit remaining case half on top of the other, turning it to ease

2.7 Tighten nuts to following torques:

square through shaft seal.

3.5 CAUTION: Check that lip seals are not trapped at case joint

face when Viton seals are fitted. Ensure minimal time delay

01 6 lbf.ins 0.07 m kg

to closing of case once sealant has been applied

02 6 lbf.ins 0.07 m kg

03 6 lbf.ins 0.07 m kg 3.6 Tighten case screws to the following torques:

05 8 lbf.ins 0.09 m kg 01 10 lbf.ins. 0.12 m kg

07 8 lbf.ins 0.09 m kg 02 10 lbf.ins. 0.12 m kg

08 20 lbf.ins 0.23 m kg 03 10 lbf.ins. 0.12 m kg

09 20 lbf.ins 0.23 m kg 05 20 lbf.ins. 0.23 m kg

10 20 lbf.ins 0.23 m kg 07 24 lbf.ins. 0.27 m kg

12 30 lbf.ins 0.35 m kg 08 60 lbf.ins. 0.7 m kg

14 30 lbf.ins 0.35 m kg 09 60 lbf.ins. 0.7 m kg

16 60 lbf.ins 0.69 m kg 10 80 lbf.ins. 0.9 m kg

12 100 lbf.ins. 1.2 m kg

18 60 lbf.ins 0.69 m kg

14 120 lbf.ins. 1.4 m kg

Vane sub assembly with hex head bolts

16 860 lbf.ins. 10 m kg

2.8 Check vane for any obvious defects and make sure it is free

of burrs, then place vane in cradle and place face down an a 18 1140 lbf.ins. 13 m kg

bench or hold in a vice.

2.9 Push hex headed bolts with plain washer through side plate, 3.7 Rotate vane manually to check movement and wipe away

expander (teeth facing towards head of bolt) and seal (base sealant extruded internally.

of seal away from bolt head). 3.8 Allow setting time for sealant before applying test air

pressure.

ISSUE DATE Doc.No. TD 129

K 08/12 Trading Estate Farnham Surrey England. GU9 9NU Page 3 OF 8 KF464

AR 5474 / ISS.J - AR 4777 / ISS.H - AR 4726

Installation, Operation & Maintenance Instructions

ROTARY 1/4 TURN ACTUATOR / DOUBLE ACTING & SPRING RETURN MODELS

Suitable for use in safe area and hazardous gas/dust atmospheres (ATEX)

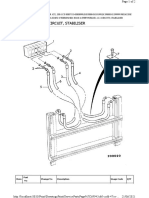

SPRING RETURN UNITS

NOTE : ALL REFERENCES IN THIS DOCUMENT TO MODEL 08 ASSEMBLIES ARE SPECIFIC TO THE 2010 REDESIGN. FOR PRE 05/2010

08 MODELS CONTACT KINETROL.

1. REMOVAL OF SPRING RETURN UNIT pressure until balanced.

WARNING – the wound-up steel springs are storing a large 2.7 Remove keeper plate completely.

amount of energy which, if suddenly released, can be 2.8 Disconnect air supply.

dangerous.

Keeper Plate Square

Spring Housing Shaft Seal

Spring

Base Plate Holding Screws

Base Plate Screw

O Ring Seal

O Ring Seal

(08 only)

Gasket

(O ring on 08)

Inlet Port

Actuator

1.1 A keeper plate strong enough to take full spring torque must 3. ADJUSTMENT SPRING TENSION

be fitted in order to remove S/R unit without releasing spring WARNING: The wound-up steel springs are storing a large

tension. amount of energy which, if suddenly released, can be

Note: Keeper plates and screws available from KINETROL. dangerous.

Refer to table on page 5 for spare part order Numbers. 3.1 Tension Setting Definitions

1.2 Connect air line via pressure regulating valve to actuator air 3.1.1 Optimum setting is when S/R unit is able to provide as

inlet. much output torque on the spring return stroke as that

1.3 Place keeper plate over square shaft protruding from S/R produced by the corresponding air stroke at a particular air

unit. Keeper plates with male squares can be provided for supply pressure.

female drive spring packs. 3.1.2 Differential setting is when S/R unit produces more or

1.4 Increase air pressure slowly until actuator vane turns to less output torque on spring return stroke as that produced by

mid-travel position. (See sketch at 2 of ACTUATOR section.) the corresponding air stroke at a particular air supply

Keeper plate holes will then line up with threaded holes in pressure.

spring housing. 3.1.3 Operating air pressure in these instructions means the

1.5 Insert all screws through keeper plate holes and tighten to actual air supply pressure at which the actuator will be

lock keeper plate in position. Disconnect air supply. operated.

1.6 Separate spring housing from base plate by removing holding

screws. Then remove spring housing. 3.2 Optimum Spring Setting Test

1.7 If necessary to gain access to actuator screws also remove 3.2.1 Detach actuator/spring return from valve or mechanism

base plate by removing screws. Take care with gasket/o ring operated by them.

between base plate and actuator. (Service actuator as 3.2.2 Attach air supply to actuator through pressure

required per Seal Replacement Instructions). regulating valve and gauge with supply shut off at regulator.

3.2.3 Gradually open regulator to increase air supply to

2. REASSEMBLY OF SPRING RETURN UNIT actuator until actuator output shaft just begins to move.

2.1 If necessary replace base plate after replacing gasket (o ring 3.2.4 Note actual pressure at which actuator output shaft

on 08 models only). Ensure the 4 countersunk baseplate fixing moved.

screws are all fitted with o rings (08 models only). 3.2.5 If actual pressure noted at 3.2.4 is about half the

2.2 Ensure actuator vane is in mid-travel position. operating air pressure then spring tension is at optimum.

2.3 Locate spring housing on shaft, (if the actuator square size If actual pressure noted at 3.2.4 is significantly less then half

is different on one end ensure spring is fitted to correct drive operating air pressure then spring tension is below optimum,

end) rotate it to line up holding screw holes with base plate i.e. output torque on S/R stroke will be less than that produced

and replace holding screws. on corresponding air stroke at operating air pressure.

2.4 Connect air supply (as in 1.2) to actuator inlet port.

2.5 Adjust air pressure until it balances the spring tension.

2.6 Loosen keeper plate screws. If air pressure correctly

balancing spring tension will not bind. If binding, adjust air.

ISSUE DATE Doc.No. TD 129

K 08/12 Trading Estate Farnham Surrey England. GU9 9NU Page 4 OF 8 KF464

AR 5474 / ISS.J - AR 4777 / ISS.H - AR 4726

Installation, Operation & Maintenance Instructions

ROTARY 1/4 TURN ACTUATOR / DOUBLE ACTING & SPRING RETURN MODELS

Suitable for use in safe area and hazardous gas/dust atmospheres (ATEX)

Conversely if actual pressure at 3.2.4 is significantly greater WARNING: Spring tension must not be further increased if

than half operating pressure then spring tension is above the air pressure noted at 4.2.4 is 40 p.s.i. or more for standard

optimum, i.e. S/R torque will be greater than air stroke torque. S/R units or 30 p.s.i. for special low air supply types.

Note: If alignment of mounting holes to square is important,

3.3 Tension Adjustment Method (Standard S/R units without then the spring tension should only be moved in 90°

worm drive) increments. This is especially important with female drive

spring units where the mounting angle to the valve will

3.3.1 Equipment/facilities required: determine correct opening/closing of valve.

Air supply with pressure regulator valve and gauge in line.

Keeper plate with bolts and spacers (KINETROL supply). 4. LABELLING (ATEX)

Spanner/tools to suit. All spring units that are suitable for use in explosive areas

Means of securely fixing assembly to a suitable work bench. are labelled with one of the labels as shown in 8 in actuator

3.3.2 Detach actuator/spring return from valve/mechanism. section above.

3.3.3 Connect air supply to actuator with regulator shut off. Ensure that the details on the label such as the ambient

3.3.4 Carry out optimum spring setting test as at 2.2 above to temperature range is suitable for the application.

determine whether spring tension needs to be increased or Also ensure that any other equipment fitted to the spring

decreased. return (e.g. limit switch box or positioner) does not restrict

3.3.5 Gradually open air supply regulator until actuator vane the use within the parameters shown on the above labels.

is at centre of travel (45°) position (see sketch at page 1). Certificate of Conformance, TD125, shows the category of

3.3.6 Place keeper plate over S/R square shaft at top of S/R spring return approval for different sizes of spring units.

unit.

CAUTION: If keeper plate of flat type, spacer washers at 5. SPARE PART ORDER CODES – KEEPER PLATES:

least 3mm (1/8") thick must be used under keeper plate.

SPRING MALE DRIVE FEMALE ISO FEMALE SERRATED

KINETROL die cast keeper plates do not need spacer SIZE DRIVE DRIVE

washers.

3.3.7 If bolt holes of keeper plate do not line up with

01 SP 350 N/A N/A

corresponding tapped holes in S/R unit, carefully open or

close air supply regulator until S/R square shaft turns so that 02 SP 351 N/A N/A

holes do line up. 03 SP 352 SP 1360/1 N/A

3.3.8 Insert and tighten keeper plate bolts.

3.3.9 Shut off air supply to actuator. 05 SP 353 SP 1362/3 SP 1480

3.3.10 Undo and remove all spring housing flange bolts. 07 SP 354 SP 1364 SP 1481

Leave spring housing resting on base plate. 08 SP 904 SP 1378 SP 1483

3.3.11 Turn spring housing in required direction according to:

a) S/R operating direction, i.e. clockwise or 09 SP 356 SP 1365 SP 1482

anticlockwise operation of spring force, and 10 SP 359 SP 1366 SP 1482

b) Tension required to be increased or

12 SP 357 SP 1368 SP 1370 N/A

decreased.

14 SP 358 SP 1371 N/A

NOTE: Larger sizes of actuator/spring return will require 16 SP 360 SP 1372 N/A

spanner and possibly extension bar to turn spring housing

18 SP 361 SP 1373 N/A

through square shaft on S/R unit.

3.3.12 Dependent on the age of S/R unit concerned there will 20 SP 362 SP 1374 N/A

be 12 or 24 bolt holes around the base plate flange (except 30 SP 362 N/A N/A

for 014 and 08 models which have only 4, and 144 model which

now has 36).

Therefore older models (12 holes) can only be adjusted by

For non-standard spring codes please contact Kinetrol.

30° steps, whereas new models can be adjusted by 15° steps

(014 and 08 by 90° steps and current 144 by 10° steps).

3.3.13 As a rough guide 30° adjustment of spring housing

relative to base plate will give 8% change of spring torque

output providing spring is already tensioned within its

operating air pressure range, i.e. standard S/R units between

50 and 80 p.s.i. Low air supply S/R units between 25 and 50

p.s.i. See catalogue for full details.

3.3.14 Maximum adjustment in one step will be 45° controlled

by available vane movement in actuator.

3.3.15 After turning spring housing by amount required (or

possible) line up bolt holes in spring housing and base plate

flanges. Insert flange bolts and tighten nuts.

3.3.16 Carefully open air supply to actuator until side load on

keeper plate bolts is relieved.

3.3.17 Remove keeper plate.

3.3.18 Repeat optimum spring setting test as at 4.2 above.

3.3.19 If necessary, repeat operations 4.3.5 to 4.3.17 to

further increase or decrease spring tension.

ISSUE DATE Doc.No. TD 129

K 08/12 Trading Estate Farnham Surrey England. GU9 9NU Page 5 OF 8 KF464

AR 5474 / ISS.J - AR 4777 / ISS.H - AR 4726

Installation, Operation & Maintenance Instructions

ROTARY 1/4 TURN ACTUATOR / DOUBLE ACTING & SPRING RETURN MODELS

Suitable for use in safe area and hazardous gas/dust atmospheres (ATEX)

5

VANE FIXINGS

EXPLODED VIEW OF A TYPICAL STANDARD ACTUATOR

CASE FIXINGS

2

NAMUR ADAPTOR KIT

3

SP 638

STANDARD VANE

DOWEL PIN

VANE SEAL

3

SHAFT SEAL

EXPANDER

BUSH

AIR PORT SEALING SCREWS

SIDE PLATE

6

CASE

ISSUE DATE Doc.No. TD 129

K 08/12 Trading Estate Farnham Surrey England. GU9 9NU Page 6 OF 8 KF464

AR 5474 / ISS.J - AR 4777 / ISS.H - AR 4726

Installation, Operation & Maintenance Instructions

ROTARY 1/4 TURN ACTUATOR / DOUBLE ACTING & SPRING RETURN MODELS

Suitable for use in safe area and hazardous gas/dust atmospheres (ATEX)

FLANGE SCREWS

1

DIN/ISO FLANGE

COUPLING ORING

THRUST WASHER

4

COUPLING

1

BUSH

CASE FIXINGS

VANE FIXINGS

EXPLODED VIEW OF A TYPICAL ISO/DIN ACTUATOR

SHAFT ORING

3

2

NAMUR ADAPTOR KIT

DIN CASE

1

SP 638

DIN/ISO VANE

VANE SEAL

BUSH

3

EXPANDER

SHAFT SEAL

1

CASE

SIDE PLATE

AIR PORT SEALING SCREWS

DOWEL PIN

6

ISSUE DATE Doc.No. TD 129

K 08/12 Trading Estate Farnham Surrey England. GU9 9NU Page 7 OF 8 KF464

AR 5474 / ISS.J - AR 4777 / ISS.H - AR 4726

Installation, Operation & Maintenance Instructions

ROTARY 1/4 TURN ACTUATOR / DOUBLE ACTING & SPRING RETURN MODELS

Suitable for use in safe area and hazardous gas/dust atmospheres (ATEX)

SPARE PART ORDERING CODES

NOTE : ALL REFERENCES IN THIS DOCUMENT TO MODEL 08 ASSEMBLIES ARE SPECIFIC TO THE 2010 REDESIGN. FOR PRE 05/2010

08 MODELS CONTACT KINETROL.

SPARE PART ORDERING CODES FOR STANDARD ACTUATOR

ITEM DESCRIPTION QTY SPARE NO'S FOR ACTUATORS

NO. 0M0 014 024 034/B 054/B 074/B 084/B 094/B 124/B 144/B 164 184 204 304

1 Seal Kit 1 SP055 SP871 SP041 SP054 SP042 SP043 SP900 SP045 SP046 SP047 SP053 SP048 SP051 SP052

2 Vane assembly 1 SP081 SP872 SP091 SP471 SP121 SP151 SP901 SP212 SP262 SP278 SP371 SP311 SP400 -

3 Case assembly Matched Pair SP083 SP873 SP099 SP479 SP129 SP159 SP902 SP221 SP253 SP283 SP379 SP319 SP399 -

4 Stop assembly 2 - SP874 SP104 SP485 SP138 SP165 SP905 SP227 SP260 SP292 SP384 SP324 SP396 SP396

5 Coupling 1 - SP074 SP106 SP487 SP140 SP167 SP903 SP229 SP264 SP298 SP386 SP326 SP406 SP406

6 Indicator assembly 1 - - SP108 SP489 SP146 SP171 SP171 SP171 SP171 SP171 - - - -

Namur adaptor 1 - - - SP638 - - - -

VARIATIONS FOR OLD STYLE ACTUATOR PARTS

ITEM DESCRIPTION QTY. SPARE NO'S FOR ACTUATORS

NO. 0M0 010 010A 020 030 050 070 080 090 120 140 160 180 200 300

2 Standard Vane

assembly

1 SP081 SP061 SP331 SP091 SP471 SP121 SP151

* SP211 SP241 SP271 SP371 SP311 SP400 -

3 Standard Case

assembly

Matched Pair SP083 SP069 SP338 SP099 SP479 SP129 SP159

* SP221 SP253 SP283 SP379 SP319 SP399 -

6 Indicator assembly 1 - - - SP108 SP489 SP146 SP171 - SP231 SP267 SP301 - - - -

* CONTACT KINETROL

For actuators built to 'ANSI' standard (e.g. 057-100) change spare part number prefix

from 'SP' to 'ASP' (e.g. for actuator 057-100 item 2 becomes ASP142

or for 059-100 item 2 becomes ASP121).

SPARE PART ORDERING CODES FOR ISO/DIN ACTUATOR

ITEM DESCRIPTION QTY. SPARE NO'S FOR ACTUATORS

SPARE NO'S FOR ACTUATORS

NO. 023/A 033/A 053/A 073/A 083/A 093/A 103/A # 123/A 143/A 163/A

1 Seal Kit 1 SP041 SP054 DSP042 DSP043 DSP900 DSP045 SP056 SP046 SP047 SP053

2 Vane assembly 1 SP091 DSP472 DSP142 DSP169 DSP901 DSP212 DSP801 DSP262 DSP283 DSP371

3 Case assembly Matched Pair SP099 DSP480 DSP130 DSP160 DSP902 DSP222 DSP811 DSP263 DSP294 DSP379

4 Stop assembly 2 SP104 SP485 SP138 SP165 SP905 SP227 SP817 SP260 SP292 SP384

6 Indicator assembly 1 SP108 SP489 SP146 SP171 SP171 SP171 SP171 SP171 SP171 -

Namur adaptor - SP638 -

VARIATIONS FOR OLD STYLE ISO/DIN ACTUATOR PARTS

ITEM DESCRIPTION QTY. SPARE NO'S FOR ACTUATORS

SPARE NO'S FOR ACTUATORS

NO. 021 031 051 071 091 101 121 141 161

2 Vane assembly 1 SP041 DSP471 DSP121 DSP151 DSP211 DSP800 DSP241 DSP271 DSP371

3 Case assembly Matched Pair SP099 DSP479 DSP129 DSP159 DSP221 DSP811 DSP253 DSP283 DSP379

6 Indicator assembly 1 SP108 SP489 SP146 SP171 SP231 DSP820 SP267 SP301 -

# NOTE SIZE 10 CASE /VANE CONSTRUCTION IS SIMILAR TO STANDARD ACTUATOR

ISSUE DATE Doc.No. TD 129

K 08/12 Trading Estate Farnham Surrey England. GU9 9NU Page 8 OF 8 KF464

AR 5474 / ISS.J - AR 4777 / ISS.H - AR 4726

You might also like

- Isuzu D-Max 2011 Axle Service ManualDocument162 pagesIsuzu D-Max 2011 Axle Service ManualWilmer Huanga0% (1)

- Lathe Machine CZ1440G-1 ManualDocument32 pagesLathe Machine CZ1440G-1 Manualsecondharbour China100% (1)

- Hydrema 912C Rep - Man GBDocument174 pagesHydrema 912C Rep - Man GBjanezNo ratings yet

- SainSmart Genmitsu CNC Router 3018-User ManualDocument26 pagesSainSmart Genmitsu CNC Router 3018-User ManualFernando MarcanoNo ratings yet

- Travers o V47Document32 pagesTravers o V47Jorge Espinoza100% (1)

- Fo-P-A62 64 66 PDFDocument627 pagesFo-P-A62 64 66 PDFOFAMNo ratings yet

- As Series - Installation Operation and Maintenance Manua1 - 1Document35 pagesAs Series - Installation Operation and Maintenance Manua1 - 1Ramesh BhosleNo ratings yet

- 9812/0010 B4-6-1 Dipper (Stick) Extradig, 14'Document4 pages9812/0010 B4-6-1 Dipper (Stick) Extradig, 14'Виталий РогожинскийNo ratings yet

- Encoder Instructions: M3-3 Thru M3-9 M3-A Thru M3-JDocument4 pagesEncoder Instructions: M3-3 Thru M3-9 M3-A Thru M3-JCharoon SuriyawichitwongNo ratings yet

- Encoder Instructions: M4-3 Thru M4-9 M4-A Thru M4-JDocument4 pagesEncoder Instructions: M4-3 Thru M4-9 M4-A Thru M4-JJose Rolong CNo ratings yet

- ION 6200 RMD Retrofit Instructions: Location & MountingDocument3 pagesION 6200 RMD Retrofit Instructions: Location & MountingAzar TajNo ratings yet

- Fristam FPE-FPDocument65 pagesFristam FPE-FPJúlia LinoNo ratings yet

- InnoVantennas 6-Duo-5070 6el 50-70MHz Dual Band YagiDocument6 pagesInnoVantennas 6-Duo-5070 6el 50-70MHz Dual Band Yagisboonuy331No ratings yet

- XR3C 6 Element Triband Yagi 20-15-10MDocument18 pagesXR3C 6 Element Triband Yagi 20-15-10Msboonuy331No ratings yet

- ... For A Smooth Operation: WWW - Ecoroll.de Mail@ecoroll - deDocument23 pages... For A Smooth Operation: WWW - Ecoroll.de Mail@ecoroll - derodrigo.firstNo ratings yet

- XR5 9 Element 5 Band Yagi 20-17-15-12-10MDocument16 pagesXR5 9 Element 5 Band Yagi 20-17-15-12-10Msboonuy331No ratings yet

- HQ400 ManualDocument29 pagesHQ400 ManualMatthew MattesonNo ratings yet

- Schletter-Product Sheets-Roof Systems-Universal AdapterDocument10 pagesSchletter-Product Sheets-Roof Systems-Universal Adapterf789sgacanonNo ratings yet

- Ds 15 Standard Tool RangeDocument2 pagesDs 15 Standard Tool RangeMOHD FAIRUZ BIN SHAMSUDINNo ratings yet

- Grade-8 Eyenuts: User GuideDocument2 pagesGrade-8 Eyenuts: User GuideNeil WayneNo ratings yet

- XR 6 11 Element 6 Band Yagi 20-17-15-12-10-6MDocument16 pagesXR 6 11 Element 6 Band Yagi 20-17-15-12-10-6Msboonuy331No ratings yet

- Magnetic Pickups Models MP3298, MP7905 and MP7906Document2 pagesMagnetic Pickups Models MP3298, MP7905 and MP7906andreshuertascalderon02No ratings yet

- 9802/9750 B3-3-1 Arms, Loader Shovel LinkageDocument2 pages9802/9750 B3-3-1 Arms, Loader Shovel LinkageMexanik212No ratings yet

- E600 User Manual v1.04 enDocument4 pagesE600 User Manual v1.04 enluisNo ratings yet

- Crankshaft Grinding GuidelinesDocument2 pagesCrankshaft Grinding Guidelinesиван ТрояновNo ratings yet

- TIL03029 TELMA REPLACEMENT ARM TANDEM Rev12jul07Document16 pagesTIL03029 TELMA REPLACEMENT ARM TANDEM Rev12jul07Paulo PereiraNo ratings yet

- Installation Instructions - All DrivesDocument1 pageInstallation Instructions - All Driveseng_moh04No ratings yet

- Anleitung GgvenglishDocument10 pagesAnleitung GgvenglishAdnan HalilovicNo ratings yet

- 4 8drivescrewDocument2 pages4 8drivescrewAhmed Ali TahaNo ratings yet

- Technical Specifications Simple Turnout: 1.1 GeneralDocument9 pagesTechnical Specifications Simple Turnout: 1.1 GeneralKang RondaNo ratings yet

- 2.0 Body Work FrameDocument2 pages2.0 Body Work FrameGarcia CruzNo ratings yet

- Technical Manual For The Strobe XB15UL/ULC Manuel Technique Du Stroboscope XB15UL/ULCDocument12 pagesTechnical Manual For The Strobe XB15UL/ULC Manuel Technique Du Stroboscope XB15UL/ULCCaptainNo ratings yet

- FD202LDocument7 pagesFD202LGrzegorz samuraiNo ratings yet

- Sirena de TonosDocument8 pagesSirena de Tonoselectronica73444939No ratings yet

- Dyapar CPL CouplingsDocument2 pagesDyapar CPL CouplingsAlonso BarreraNo ratings yet

- 10 - SsangYong-Korando - 2012 - EN - US - Manual - de - Taller - Cardan - E1b09bee1eDocument14 pages10 - SsangYong-Korando - 2012 - EN - US - Manual - de - Taller - Cardan - E1b09bee1eMateus FumuassucaNo ratings yet

- Ebore Twin Cutter EnglishDocument7 pagesEbore Twin Cutter EnglishLeandro LechechenNo ratings yet

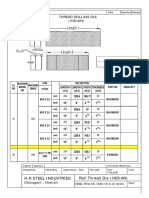

- Roll Thread Die (M16 & 5-8) IndianDocument1 pageRoll Thread Die (M16 & 5-8) IndianTanmay TurulNo ratings yet

- ArcMATE 120ic M20iADocument24 pagesArcMATE 120ic M20iABrendisNo ratings yet

- 100 S Oem S: 102R Low Flow PumpheadDocument2 pages100 S Oem S: 102R Low Flow PumpheadtechniqueNo ratings yet

- 4 9munnylonplugDocument1 page4 9munnylonplugAhmed Ali TahaNo ratings yet

- Diamond Gard Installation Instructions: Mitsubishi Electric Heavy Duty StarterDocument2 pagesDiamond Gard Installation Instructions: Mitsubishi Electric Heavy Duty StarterAlexander David Pino SalazarNo ratings yet

- Drill 32: Instructions Manual Drilling RigDocument20 pagesDrill 32: Instructions Manual Drilling RigPungan IonNo ratings yet

- 9812/7600 F5-2-1 Gearbox, 4WD External Components 449/13160,449/13100Document3 pages9812/7600 F5-2-1 Gearbox, 4WD External Components 449/13160,449/13100heroskNo ratings yet

- STPE600 - Dadi A ProiezioneDocument17 pagesSTPE600 - Dadi A ProiezioneLucaNo ratings yet

- KS300ANT Operator Installation & Commissioning Manual: Product IntroductionDocument22 pagesKS300ANT Operator Installation & Commissioning Manual: Product IntroductionJesus RiosNo ratings yet

- AA02193C STRG Pin Wear Checks and SizesDocument8 pagesAA02193C STRG Pin Wear Checks and SizesSebastiao DuarteNo ratings yet

- SRM-51-47-00 Fastener Pitch and Edge Distance DataDocument13 pagesSRM-51-47-00 Fastener Pitch and Edge Distance DataJelpi Duvan LariosNo ratings yet

- ION6200 Remote Modular Display: Product OptionDocument4 pagesION6200 Remote Modular Display: Product OptionDrìftNo ratings yet

- Hidraulics 2Document43 pagesHidraulics 2Garcia CruzNo ratings yet

- Slip Type ElevatorDocument15 pagesSlip Type ElevatorJohn Jairo Simanca100% (1)

- Docv 2Document5 pagesDocv 2Ionut DumaNo ratings yet

- Catálogo Motores Iman PermanenteDocument32 pagesCatálogo Motores Iman Permanentemass72No ratings yet

- Putting in To OperationDocument7 pagesPutting in To OperationsriyantoNo ratings yet

- Manual Del Fabricante CompletoDocument68 pagesManual Del Fabricante CompletoLUIS PABLO SALVADOR NUÑEZNo ratings yet

- 9802/6220 B1-2-1 Frame, RearDocument3 pages9802/6220 B1-2-1 Frame, RearGarcia CruzNo ratings yet

- BodyworkDocument43 pagesBodyworkGarcia CruzNo ratings yet

- Protable Line Boring MachineDocument13 pagesProtable Line Boring MachineMary SmithNo ratings yet

- Sauer Danfoss TMT Orbital Motor Service ManualDocument40 pagesSauer Danfoss TMT Orbital Motor Service ManualPolavarapu Sreedhar100% (1)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- OM402UNI M 2013 3v3en Part50Document1 pageOM402UNI M 2013 3v3en Part50gia phamletrangNo ratings yet

- OM402UNI M 2013 3v3en Part25Document1 pageOM402UNI M 2013 3v3en Part25thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part24Document1 pageOM402UNI M 2013 3v3en Part24thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part26Document1 pageOM402UNI M 2013 3v3en Part26thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part28Document1 pageOM402UNI M 2013 3v3en Part28thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part29Document1 pageOM402UNI M 2013 3v3en Part29thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part40Document1 pageOM402UNI M 2013 3v3en Part40ngoc phanNo ratings yet

- OM402UNI M 2013 3v3en Part30Document1 pageOM402UNI M 2013 3v3en Part30thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part25Document1 pageOM402UNI M 2013 3v3en Part25thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part20Document1 pageOM402UNI M 2013 3v3en Part20thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part22Document1 pageOM402UNI M 2013 3v3en Part22thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part16Document1 pageOM402UNI M 2013 3v3en Part16thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part23Document1 pageOM402UNI M 2013 3v3en Part23thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part19Document1 pageOM402UNI M 2013 3v3en Part19thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part18Document1 pageOM402UNI M 2013 3v3en Part18thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part19Document1 pageOM402UNI M 2013 3v3en Part19thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part13Document1 pageOM402UNI M 2013 3v3en Part13thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part11Document1 pageOM402UNI M 2013 3v3en Part11thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part8Document1 pageOM402UNI M 2013 3v3en Part8thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part15Document1 pageOM402UNI M 2013 3v3en Part15thach pha thienNo ratings yet

- Setting Light: Instructions For Use Om 402uni - 17Document1 pageSetting Light: Instructions For Use Om 402uni - 17thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part12Document1 pageOM402UNI M 2013 3v3en Part12thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part14Document1 pageOM402UNI M 2013 3v3en Part14thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part7Document1 pageOM402UNI M 2013 3v3en Part7thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part4Document1 pageOM402UNI M 2013 3v3en Part4thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part6Document1 pageOM402UNI M 2013 3v3en Part6thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part9Document1 pageOM402UNI M 2013 3v3en Part9thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part10Document1 pageOM402UNI M 2013 3v3en Part10thach pha thienNo ratings yet

- Instructions For Use Om 402uni - 3Document1 pageInstructions For Use Om 402uni - 3thach pha thienNo ratings yet

- OM402UNI M 2013 3v3en Part5Document1 pageOM402UNI M 2013 3v3en Part5thach pha thienNo ratings yet

- Venplast S.R.L. Ventilatori Industriali - Manuali Di Istruzioni - enDocument27 pagesVenplast S.R.L. Ventilatori Industriali - Manuali Di Istruzioni - enLaurentiu ApostolNo ratings yet

- Operating Instruction/ Assembling Instruction Worm Gear Screw Jacks She, HseDocument27 pagesOperating Instruction/ Assembling Instruction Worm Gear Screw Jacks She, Hsemuhammad afrizalNo ratings yet

- Reciprocating Semi-Hermetic Compressors: Refrigeration, Process Cooling, Air Conditioning, Heating PumpsDocument24 pagesReciprocating Semi-Hermetic Compressors: Refrigeration, Process Cooling, Air Conditioning, Heating PumpsMetin BoyluNo ratings yet

- Instruction Manual VA570 enDocument44 pagesInstruction Manual VA570 enFrancisco PereguéNo ratings yet

- Mark 3 DarcoDocument48 pagesMark 3 DarcoMohammad QasimNo ratings yet

- ATEXDocument1 pageATEXmigelNo ratings yet

- Explosion-Proof Motors Increased Safety Ii 2 G Eexe Ii T3 - T4Document8 pagesExplosion-Proof Motors Increased Safety Ii 2 G Eexe Ii T3 - T4Mani KandanNo ratings yet

- 17526f EK230 en V163Document113 pages17526f EK230 en V163Anonymous RYlOQwK2KNo ratings yet

- Cng-Filter en 05Document24 pagesCng-Filter en 05Andres OspinaNo ratings yet

- Operating Instructions: Lamp ModuleDocument3 pagesOperating Instructions: Lamp ModuleDwiMaryantoNo ratings yet

- DB6-10 Oim R15Document19 pagesDB6-10 Oim R15Vũ Đình QuangNo ratings yet

- Classification Labelling o EquipmentDocument1 pageClassification Labelling o EquipmentAbdul RahmanNo ratings yet

- J01 002 r01 O&M Manual Amot 2230 Temperature ValveDocument20 pagesJ01 002 r01 O&M Manual Amot 2230 Temperature Valvetraod7No ratings yet

- Bimed Ex Stars PDFDocument38 pagesBimed Ex Stars PDFtony6868No ratings yet

- S-18 20Document2 pagesS-18 20Raghavendra MurthyNo ratings yet

- Pneumatic Valve With Diaphragm: Instruction, Use and Maintenance ManualDocument50 pagesPneumatic Valve With Diaphragm: Instruction, Use and Maintenance ManualRicardo CalderonNo ratings yet

- GIS E6 2006-Gas Industry StandardDocument15 pagesGIS E6 2006-Gas Industry StandardQualidadeTFNo ratings yet

- KSB Etabloc Installation ManualDocument66 pagesKSB Etabloc Installation ManualLokesh Modemz50% (2)

- EXTA4Document39 pagesEXTA4Regis RomaryNo ratings yet

- Rele Termico ZEVDocument42 pagesRele Termico ZEVdaroltecNo ratings yet

- ALR 20/A Ex Relay: Installation and Operating InstructionsDocument16 pagesALR 20/A Ex Relay: Installation and Operating InstructionsVictor ESPÌNAQUENo ratings yet

- Service and Operating Instruction Manual Gear (Rotork) : Mi-502 ENDocument20 pagesService and Operating Instruction Manual Gear (Rotork) : Mi-502 ENanastasios filiosNo ratings yet

- 8261 ControlPanels EK00 III enDocument2 pages8261 ControlPanels EK00 III enAndy Kong KingNo ratings yet

- Woodward - Gas Stop Ratio ValveDocument54 pagesWoodward - Gas Stop Ratio ValvelutzzNo ratings yet

- Installation Operation Maintenance 7200CB en USDocument140 pagesInstallation Operation Maintenance 7200CB en USEleno RibeiroNo ratings yet

- Ba Sar2 07 16 Ac2 Profinet enDocument96 pagesBa Sar2 07 16 Ac2 Profinet enErickNo ratings yet

- Process Automation Explosion Protection Equipment Product CatalogueDocument49 pagesProcess Automation Explosion Protection Equipment Product Cataloguebatrarobin100% (1)

- Procesos de Soldadura Fcaw Gmaw Saw SmawDocument48 pagesProcesos de Soldadura Fcaw Gmaw Saw SmawEdward LarensNo ratings yet

- Catalog Single Joint ElevatorDocument55 pagesCatalog Single Joint Elevatorriadh gharsallahNo ratings yet