Professional Documents

Culture Documents

Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7

Uploaded by

abhijit janaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7

Uploaded by

abhijit janaCopyright:

Available Formats

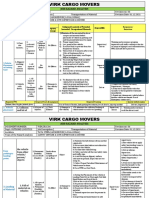

11-2019

BS VI Project

Indian Oil Corporation, Paradip Refinery

Reference

thyssenkrupp

JOB SAFETY ANALYSIS BSVI-HSE-FORMAT-001/19. Rev.01

Industrial Solutions

(India) Page 1 of 7

Job area is considered: Establishment/Project: COMPOSITE JSA No.: TEL/COMPO/JSA/0

Job title: Work for BS-VI PDR.

Contractor / Agency Performing Job: M/s Tuaman Engineering Limited Project No / FOA No: 25284124-8720-

CP-00000012/2019-20/FOA/112

Prepared By: Reviewed By: tkIS India: IOCL:

1. Jagadish Mallick 1. A.K.Bala 1. 1.

Person participating

2. Animesh Sinha 2. Souvik Dey 2. 2.

in Job Safety

Analysis. 3. 3. H.Pattnayak 3. 3.

4. 4.

5. 5.

JOB DESCRIPTION: Erection of cable tray.

Requirement of adding Personal Protection Requirement of adding special equipment or tool

Requirement of Working Permit Equipment.

(Check the relevant box) (Additional list)

Restricted space 1. Safety Shoe 1. Multi Gas Detector 5.

Heating job 2. Safety Helmet 2. 6.

Digging 3. Safety Goggles 3. 7.

Isolation / Energization 4. Hand Gloves 4. 8.

Other job 5. Dust Mask

JSA considering procedure Yes No Comment

BS VI Project Form: Job Safety Analysis

01-2019

11-2019

BS VI Project

Indian Oil Corporation, Paradip Refinery

Reference

thyssenkrupp

JOB SAFETY ANALYSIS BSVI-HSE-FORMAT-001/19. Rev.01

Industrial Solutions

(India) Page 2 of 7

Is JSA establishment participated by job implementing

group?

Is JSA considered by Job implementing group before

carrying out the job?

Is JSA sheet used/ consulted in work implementation?

Is the job carried out step by step?

Do you propose to improve JSA sheet (give in detail)

Is detail of any trouble showing

BS VI Project Form: Job Safety Analysis

01-2019

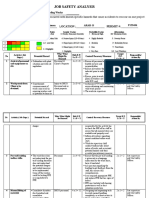

11-2019

BS VI Project

Indian Oil Corporation, Paradip Refinery

Reference

thyssenkrupp

JOB SAFETY ANALYSIS BSVI-HSE-FORMAT-001/19. Rev.01

Industrial Solutions

(India) Page 3 of 7

ACTIVITIES HAZARD/ DANGER CONTROL MEASURE ACTION

Separate the job into Describe all hazards identified for Describe fully all equipment, facility,

the main tasks and each task based on observations and/or procedure controls applicable

record them in and experience. for each hazard.

sequence.

Erection of cable Tray support Fall of support/chances of fire/hand/foot hazard Action taken by Site

Personal Injury Engineer & HSE

Obtain Permit prior to start the work. Personnel

For height work check all workers working at height

should have the valid height pass.

Scaffolding should be checked before work.

Scaffolding bracing, platform blanks (MS only) should be

tied securely.

Lifting tool for the Heavy cable Tray support should semi-

automatic so that manual handling can be reduced

Tools and Tackles for lifting the material should be tested

and should be free from any defects.

Qualified and Trained Rigger and fitters should be put on

the job.

All the persons should have Height pass and should use

safety belt with anchoring when working above 3 meters

from ground.

BS VI Project Form: Job Safety Analysis

01-2019

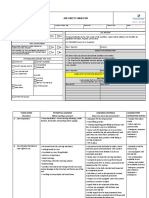

11-2019

BS VI Project

Indian Oil Corporation, Paradip Refinery

Reference

thyssenkrupp

JOB SAFETY ANALYSIS BSVI-HSE-FORMAT-001/19. Rev.01

Industrial Solutions

(India) Page 4 of 7

Erection of cable tray / duct Risk of falling of cable trays /duct and injury due Lifting tools should be tested and free from defects.

to sharp edges. Action taken by Site

Sharp edges should be removed before actually erection of

Personal Injury Engineer & HSE

cable trays. Personnel

Immediately after putting the cable trays on supports J-bolts

or cable tray clamp should be provided/installed.

Safety belt, Helmet and Safety shoes should be used for

personal protection.

Erection of cable tray/duct Care should be taken in such a way that edge of cable

covers tray cover should not damage the laid cables.

Any sharp edge must be removed before starting the

2) Human injury with sharp edge of erection work. Action taken by Site

cable tray cover and falling of cable tray Centre of gravity should be ensured while lifting. Engineer & HSE

covers. Tools and Tackles should be tested and should be free Personnel

from any defects.

Immediately after installation of cable tray covers, it

should be clamp.

Note: - If anything in this JSA requires modification/changes in course of time during execution of the job – another JSA will be done and modified points will be

added.

BS VI Project Form: Job Safety Analysis

01-2019

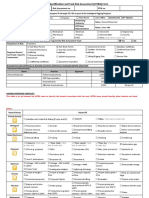

11-2019

BS VI Project

Indian Oil Corporation, Paradip Refinery

Reference

thyssenkrupp

JOB SAFETY ANALYSIS BSVI-HSE-FORMAT-001/19. Rev.01

Industrial Solutions

(India) Page 5 of 7

Prepared by Reviewed by Reviewed by Approved by

(Contractor) (Contractor) (tkIS / IOCL) (tkIS / IOCL)

Name: Name: Name: Name:

Designation: Designation: Designation: Designation:

Signature: Signature: Signature: Signature:

Date: Date: Date: Date:

BS VI Project Form: Job Safety Analysis

01-2019

You might also like

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocument1 pageJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseNo ratings yet

- EPM EHS SP F 040 Boom Truck ChecklistDocument2 pagesEPM EHS SP F 040 Boom Truck ChecklistTamoor MirzaNo ratings yet

- 43 Equipment Erection (Static and Rotary)Document5 pages43 Equipment Erection (Static and Rotary)Hamza DhariwalNo ratings yet

- Jha 2022Document8 pagesJha 2022Sandeep KumarNo ratings yet

- Hazard Identification FormDocument1 pageHazard Identification Formabdulrazzaq hatem100% (1)

- Updated JSA For SAPMTofficeDocument30 pagesUpdated JSA For SAPMTofficeShaikh Abu bakarNo ratings yet

- Night Work NotificationDocument1 pageNight Work NotificationSreekumarNo ratings yet

- MOG-HSEQ-P-xxx Rev P1 PPE ManagementDocument47 pagesMOG-HSEQ-P-xxx Rev P1 PPE ManagementSamerNo ratings yet

- JOB SAFETY ANALYSIS FORMDocument7 pagesJOB SAFETY ANALYSIS FORMIulian Costin IonNo ratings yet

- Guard House Monkey Ladder 01Document5 pagesGuard House Monkey Ladder 01razi khanNo ratings yet

- Schedule B - Attachment I ADDITIONAL AND SPECIFIC REQUIREMENTSDocument35 pagesSchedule B - Attachment I ADDITIONAL AND SPECIFIC REQUIREMENTSxue jun xiangNo ratings yet

- Water Proofing JSADocument9 pagesWater Proofing JSARamNo ratings yet

- Job Safety Analysis Sheet: Erection & Use of ScaffoldingDocument1 pageJob Safety Analysis Sheet: Erection & Use of ScaffoldingSafety ProfessionalNo ratings yet

- MEGHA ENGINEERING HYDRO TEST CHECKLISTDocument1 pageMEGHA ENGINEERING HYDRO TEST CHECKLISTjithin shankarNo ratings yet

- SABIC® LLDPE M500026: Linear Low Density Polyethylene For Masterbatch CompoundingDocument2 pagesSABIC® LLDPE M500026: Linear Low Density Polyethylene For Masterbatch CompoundingAnas AbdoNo ratings yet

- 3.jsa - Arc Welding-NDocument5 pages3.jsa - Arc Welding-NVivek NaikNo ratings yet

- HOT WORK PERMIT Cutting & Grinding of GRP PipesDocument1 pageHOT WORK PERMIT Cutting & Grinding of GRP Pipesadil khanNo ratings yet

- Scaffold Inspection Report-Master ListDocument2 pagesScaffold Inspection Report-Master ListMobin Thomas AbrahamNo ratings yet

- Construction Site Safety Program REV-02Document95 pagesConstruction Site Safety Program REV-0201095902062ahmedNo ratings yet

- JSA G20 Scaffolding Erection DismantlingDocument4 pagesJSA G20 Scaffolding Erection DismantlingemmyNo ratings yet

- NCC-NGPD-HSE-JSA-031 Tubing and Leak TestDocument16 pagesNCC-NGPD-HSE-JSA-031 Tubing and Leak Testbabjihanumanthu100% (1)

- PDF Gi 0002721 2016 Arc Flash CompressDocument23 pagesPDF Gi 0002721 2016 Arc Flash CompressMark DingalNo ratings yet

- 01 JSA CLEANING MgO Rev 05 017 BIDocument7 pages01 JSA CLEANING MgO Rev 05 017 BIMohd KhaidirNo ratings yet

- Appendix A-Job Safety Analysis FormDocument3 pagesAppendix A-Job Safety Analysis Formjiks_i4uNo ratings yet

- JSA Safety AnalysisDocument3 pagesJSA Safety AnalysisLusy Gusti EfendiNo ratings yet

- Smoke Test HIRADocument16 pagesSmoke Test HIRANagendra Kumar SinghNo ratings yet

- Job Safety Analysis for Right-of-Way ClearingDocument5 pagesJob Safety Analysis for Right-of-Way ClearingMoaatazz Nouisri100% (1)

- Lifting Support Risk AssessmentDocument10 pagesLifting Support Risk AssessmentcitraNo ratings yet

- Painting ReportDocument29 pagesPainting ReportDimas Afiefan AmirNo ratings yet

- 972 99 100 (Mobile) : Job Safety AnalysisDocument8 pages972 99 100 (Mobile) : Job Safety AnalysisSreeraj Reghunathan Nair VanmazhyNo ratings yet

- Erection Contractor's ScopeDocument4 pagesErection Contractor's ScopeasifaliabidNo ratings yet

- Installation & Testing of OPGW & UGNMFOC at Uthmaniyah GOSP-10Document10 pagesInstallation & Testing of OPGW & UGNMFOC at Uthmaniyah GOSP-10Subhash Chekka SEC 115KV ProjectNo ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair VanmazhyNo ratings yet

- AL AIN MALL WORK PERMITDocument1 pageAL AIN MALL WORK PERMITVeterano 1968No ratings yet

- GGC-HSEF 037 Site Daily ObservationDocument1 pageGGC-HSEF 037 Site Daily ObservationAmjadNo ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document5 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair Vanmazhy100% (1)

- TBT Attendance Format - NRP WorkersDocument2 pagesTBT Attendance Format - NRP WorkersIsrael Raja AbhilashNo ratings yet

- Catalyst Filling & SeggregationDocument3 pagesCatalyst Filling & SeggregationMohammed MinhajNo ratings yet

- Ewrc SHP Gen Hse Jsa 00040Document12 pagesEwrc SHP Gen Hse Jsa 00040Rickz CabaloNo ratings yet

- Msds 0864 Aquafill Wallfiller Fine en 1Document10 pagesMsds 0864 Aquafill Wallfiller Fine en 1baseet gazaliNo ratings yet

- HITRA For PiggingDocument6 pagesHITRA For PiggingAhmedNo ratings yet

- Safety certificate for EOT craneDocument1 pageSafety certificate for EOT cranemt1742k4No ratings yet

- Confined Space Rescue Plan: Description of The WorkDocument2 pagesConfined Space Rescue Plan: Description of The Workidigiti100% (1)

- JHA For Work PermitDocument1 pageJHA For Work PermitShahid RazaNo ratings yet

- Jsa Piping ErectionDocument9 pagesJsa Piping ErectionEngr Tahir UL HaqNo ratings yet

- Discharge Rod 11kv 3phaseDocument1 pageDischarge Rod 11kv 3phasewaytobhushan100% (1)

- SHEM-SP-08.01 - OMS-316.01General SHE RulesDocument40 pagesSHEM-SP-08.01 - OMS-316.01General SHE RulesAjith Kumar AjithNo ratings yet

- Gi-0006 011Document2 pagesGi-0006 011malika_00No ratings yet

- SHOT BLASTING SAFETYDocument3 pagesSHOT BLASTING SAFETYAkhilesh KumarNo ratings yet

- Method Statement For Cable Terminaton (CP3)Document20 pagesMethod Statement For Cable Terminaton (CP3)Jacky TamNo ratings yet

- JSA For Erection & Dismantling of ScaffoldingDocument4 pagesJSA For Erection & Dismantling of ScaffoldingNoe AranelNo ratings yet

- Job Safety Analysis for Blasting and Painting WorkDocument11 pagesJob Safety Analysis for Blasting and Painting WorkRajuNo ratings yet

- Risk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelDocument3 pagesRisk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelMohamed ElnagdyNo ratings yet

- Jsa For Tie-In Tp-950Document11 pagesJsa For Tie-In Tp-950rexivyNo ratings yet

- JHA (RO Pump)Document4 pagesJHA (RO Pump)Mohamed Faisal KhanNo ratings yet

- JSA SAFETY ANALYSIS FOR DE-ETHANIZER PIPING TESTDocument4 pagesJSA SAFETY ANALYSIS FOR DE-ETHANIZER PIPING TESTMajdiSahnounNo ratings yet

- 07 - Tata Power Scaffold Safety ProcedureDocument24 pages07 - Tata Power Scaffold Safety Procedurehse bsjNo ratings yet

- Experience Letter - Az Abdullah JameelDocument1 pageExperience Letter - Az Abdullah JameelSher DilNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Document4 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaNo ratings yet

- JSA For Fabrication WorksDocument11 pagesJSA For Fabrication Workssurendra behera100% (3)

- Check List For Grouting Work: Material CheckingDocument1 pageCheck List For Grouting Work: Material Checkingabhijit janaNo ratings yet

- File Requirnment: For PaintingDocument6 pagesFile Requirnment: For Paintingabhijit janaNo ratings yet

- Fitup Weldvisual Report Issues FormateDocument1 pageFitup Weldvisual Report Issues Formateabhijit janaNo ratings yet

- JSA for Instrumentation WorkDocument6 pagesJSA for Instrumentation Workabhijit janaNo ratings yet

- Priority Lines For ErectionDocument1 pagePriority Lines For Erectionabhijit janaNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Document4 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaNo ratings yet

- Iso Index Contractor WiseDocument20 pagesIso Index Contractor Wiseabhijit janaNo ratings yet

- Job Description During LockdownDocument4 pagesJob Description During Lockdownabhijit janaNo ratings yet

- Document Number Document Title Rev. NSC/PIUL/PRO-0023 Procedure For Pneumatic Test of RF Pad A2Document4 pagesDocument Number Document Title Rev. NSC/PIUL/PRO-0023 Procedure For Pneumatic Test of RF Pad A2abhijit janaNo ratings yet

- JP-6A MS For Non Shrink Grouting WorksDocument7 pagesJP-6A MS For Non Shrink Grouting Worksabhijit janaNo ratings yet

- Amar Is Good BoyDocument1 pageAmar Is Good Boyabhijit janaNo ratings yet

- Vehicle Log Sheet For IOCL BS-VI Composite Paradip Project (OD 05X 8704)Document1 pageVehicle Log Sheet For IOCL BS-VI Composite Paradip Project (OD 05X 8704)abhijit janaNo ratings yet

- Iso Index Contractor WiseDocument20 pagesIso Index Contractor Wiseabhijit janaNo ratings yet

- Iso Index Contractor WiseDocument20 pagesIso Index Contractor Wiseabhijit janaNo ratings yet

- A Guide To Refinery ProcessDocument35 pagesA Guide To Refinery ProcessBalamurugan100% (3)

- A Guide To Refinery ProcessDocument35 pagesA Guide To Refinery ProcessBalamurugan100% (3)

- Research Proposal PresentationDocument12 pagesResearch Proposal Presentationsyahid aimanNo ratings yet

- Marketbeat: Industrial SnapshotDocument2 pagesMarketbeat: Industrial SnapshotAnonymous Feglbx5No ratings yet

- Nature of OrganizationDocument4 pagesNature of Organizationravikaran123100% (1)

- P24139 Noria Commercial Paper Weekly 20211105Document29 pagesP24139 Noria Commercial Paper Weekly 20211105NiltonBarbosaNo ratings yet

- Measures Chain: © Rummler-Brache Group 1Document2 pagesMeasures Chain: © Rummler-Brache Group 1FABIAN ULISES HERNANDEZ SAUCEDONo ratings yet

- Accelerate Accounting For Power Purchase 2022Document24 pagesAccelerate Accounting For Power Purchase 2022getquit showNo ratings yet

- Chapter 9 ReportDocument44 pagesChapter 9 ReportArt Virgel DensingNo ratings yet

- Garment CM Cost Estimation Using SAM or SMVDocument4 pagesGarment CM Cost Estimation Using SAM or SMVAbdul Rabban100% (3)

- Format - Permit To Work 13.02.06 HSE OCP 01 F-01 R1Document4 pagesFormat - Permit To Work 13.02.06 HSE OCP 01 F-01 R1Gaurav Srivats100% (1)

- IPO Valuation 3E TemplateDocument3 pagesIPO Valuation 3E TemplateLohith Kumar ReddyNo ratings yet

- The Web Project GuideDocument544 pagesThe Web Project GuideSynthaNo ratings yet

- Pt. Rekayasa Industri: Subcontractor Hse Key Performance Indicator Health Safety & EnvironmentDocument5 pagesPt. Rekayasa Industri: Subcontractor Hse Key Performance Indicator Health Safety & EnvironmentDondy Zobitana100% (1)

- MedPlus Health Services Limited Anchor Intimation To Stock ExchangeDocument3 pagesMedPlus Health Services Limited Anchor Intimation To Stock ExchangeRubiks TejNo ratings yet

- Project Manager Role (Job Description)Document3 pagesProject Manager Role (Job Description)Sajjad ahmedNo ratings yet

- ISRM Short NotesDocument7 pagesISRM Short NotesViraj DissanayakeNo ratings yet

- Sri Lanka Nes 4 3 WebDocument104 pagesSri Lanka Nes 4 3 WebRavindu PereraNo ratings yet

- Sales and Distribution of Volvo Eicher Commercial Vehicles: Presented By: Group 3Document27 pagesSales and Distribution of Volvo Eicher Commercial Vehicles: Presented By: Group 3siddhant hingoraniNo ratings yet

- GM0421 Innovation ManagementDocument47 pagesGM0421 Innovation ManagementfeliciainaNo ratings yet

- CHM E-Catalogue 2018Document8 pagesCHM E-Catalogue 2018Pham van QuyetNo ratings yet

- How Samsung Became A Global ChampionDocument6 pagesHow Samsung Became A Global ChampionFayza Azzahra RobbyNo ratings yet

- Buying Grid FrameworkDocument2 pagesBuying Grid FrameworkVIKRANT AHERNo ratings yet

- Supply Chain ManagementDocument24 pagesSupply Chain Managementclaudia indriya ningrumNo ratings yet

- Uda Bin Nordin: Professional Profile Professional ExperienceDocument1 pageUda Bin Nordin: Professional Profile Professional Experienceuda nordinNo ratings yet

- Job Application Form: S No. Qualification Institution Year Major SubjectsDocument4 pagesJob Application Form: S No. Qualification Institution Year Major SubjectskamiahmadNo ratings yet

- Appendix B, Profitability AnalysisDocument97 pagesAppendix B, Profitability AnalysisIlya Yasnorina IlyasNo ratings yet

- Hitungan Keuntungan AkasiaDocument13 pagesHitungan Keuntungan AkasiaPresa KautsarNo ratings yet

- Project Management Improvements at OrionDocument3 pagesProject Management Improvements at OrionDevika KshetrapalNo ratings yet

- Noble Catalogue 2019-20Document38 pagesNoble Catalogue 2019-20Ankit SrivastavaNo ratings yet

- White Simple Student CV ResumeDocument1 pageWhite Simple Student CV Resumekankipati.yeswanthNo ratings yet

- Techniques For Operations EfficiencyDocument296 pagesTechniques For Operations EfficiencyWhatsapp stutsNo ratings yet