Professional Documents

Culture Documents

Contributions of Different Standards and Codes For The Design of Silo: A Review

Uploaded by

Freddie KooOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Contributions of Different Standards and Codes For The Design of Silo: A Review

Uploaded by

Freddie KooCopyright:

Available Formats

The Asian Review of Civil Engineering

ISSN: 2249 - 6203 Vol. 5 No.2, 2016, pp.27-33

© The Research Publication, www.trp.org.in

Contributions of Different Standards and Codes for the Design of Silo:

A Review

S.Chithra1 and G.Indupriya2

1

Assistant Professor in Civil Engineering,

2

M.E. Structural Engineering Student,

Government College of Technology, Coimbatore, Tamil Nadu, India

E-Mail: ergpriya@gmail.com

Abstract - Determination of loads play significant role in the roof with suitable man hole. The foundation of the silo may

design of silo. The silo is a structure used for storage of bulk be mat, raft or pile based on the soil condition.

materials, in which the loads due to stored materials has to be

taken into account in addition to wind load and seismic load. Silos are considered as special structures as its design is

The various codes and standards stipulate guidelines for the based on the properties of materials stored. In addition to

silo design. The four codes studied and compared in this paper

the loads that are acting on the normal structures such as

viz., a) Indian Standard IS 4995 - 1974 b) American Concrete

Institute ACI 313 – 97 c) German Standard DIN 1055 – 6: 2005 wind, seismic and external loads, the silos are specially

– 03 and d) British Standard BS EN 1991-4: 2006. Though, the designed for the loads that are induced by the stored

analysis and design of silo cannot be performed using single materials. Engineers ensure that the silo is built to be strong

code, the lack of compatibility among various codes makes the and stable enough to resist structural loads and loads due to

designers difficult in designing the silo. The consideration of materials stored. The pressure exerted by the stored material

minor modifications in the analysis and design of silo makes it on the side of a bin varies with the processes and

possible to construct and operate safe and economical silo. The arrangements of filling and emptying operations. Due to this

aim of this paper is to compare and briefly describe about the variation, it is extremely difficult to analyze the pressure

superiority and limitations of four codes.

exerted on the walls of the bins. The approximate methods

Keywords : Silo design codes and standard; Silo classification;

suggested by Janssen are commonly followed for the

Material induced loads; Flow pattern; Hopper geometry.

calculation of pressure in most cases [3]. Based on the types

I. INTRODUCTION and properties of the stored materials, the loads imparted by

the stored materials on the bins may vary. The silo walls are

Silos and bunkers are the structures meant for storing subjected to horizontal, vertical and frictional shear. The

materials like food grains, cement, coal, ore, crushed stone, magnitude and distribution of these shears and pressure over

gravel, clinker etc., in large quantities. The bunker is a the height of the bin depends on the properties of the

shallow structure whereas the silo is a tall structure. In materials and its filling conditions (i.e. filled or discharged).

general, bunkers or bins are used to store gravel, stone and

coal whereas cement and grains are stored in silos [1]. They During the design process, the loads such as wind and

can be constructed as either ground supported or elevated. seismic loads, stress due to temperature difference, potential

With the advent of green revolution, there is a need for the expansion of the material stored and the settlement of the

proper storage of huge quantity of crops for future use after foundation are to be considered [4].

it has been harvested. To fulfill this demand of storing crops

and grains, the construction of silos became essential. The II. CODES CONSIDERED IN THE STUDY

silo plays a vital role in agricultural, industrial and military A. Indian Standard - IS 4995 : 1974

domain for the purpose of storing materials. Before 1960’s,

people stored the materials in bins which was designed by The guidelines recommended by the Bureau of Indian

guessing. The research of Andrew W.Jenike in 1960’s has Standard for the design of reinforced concrete silos were

provided the base for the bin design. The silos designed by explained in ‘Criteria for Design of Reinforced concrete

traditional techniques are inadequate due to the application bins for the storage of Granular and Powdery materials’.

of simplified methods in the complex situations [2]. The silos load determination is described in Part 1 – General

Requirements and assessment of Bin loads. The criteria for

The materials for construction of silos comprises of steel or the design of the silo are given in Part 2 – Design Criteria.

reinforced concrete. The silo mainly consists of bin and In 1968, this standard was published by considering the

hopper for storing and discharging materials respectively. requirements of structural design for food grain storage bins

For the purpose of self cleaning and emptying, the silo is (silos) [5]. In the year 1974, the revision was adopted to

supported on a number of columns. The bin is covered by a design silo for storing all kinds of materials in addition to

27 TARCE Vol.5 No.2 July-December 2016

S.Chithra and G.Indupriya

food grains. The physical nature of the materials to be 1. Dead load of the structure

stored in the bins are taken into account and the code 2. Superimposed loads due to material handling &

classified the stored materials as granular and powdery transportation machinery

materials as shown in Table1. 3. Bin loads as specified under Part I of IS 4995 - 1974

4. Live load (for roof only) recommended as per IS:

TABLE 1 CLASSIFICATION OF MATERIALS 875-1964

5. Wind load recommended as per IS: 875-1964

Particle 6. Seismic loads recommended as per IS: 1893-1975

Materials

size 7. Thermal load

Granular > 0.2 mm

Powdery < 0.06 mm The effect due to temperature variation is considered in the

design of silo in IS codal provision only. This has two

The Part 1 of this standard has given the guidelines for the positive impacts. First, this consideration is highly

assessment of bin loads exerted by the stored material based beneficial for the silo design located in India with varying

on the different treatments taking into account the granular climatic conditions throughout the country. Secondly, if the

or powdery nature of the material. This standard deals with thermal variation due to the material to be stored is

various types of bins namely circular, polygonal or considered, some minor problems can be avoided. For

interstice bins. The definition of terms such as silo, bunker instance, if cement is stored in the silo, the heat released

and interstice bins is presented in Table 2. from cement leads to cracking of silo wall due to thermal

effect. The walls of the circular bins, polygonal bins and

TABLE 2 DEFINITIONS OF TERMS interstice bins are designed considering the stress, wall

thickness and the crack width. As per Indian standard codal

Silo Bunker Interstice bins provisions, it is possible to design hoppers of any shape like

Bins of Bin formed out of conical, pyramidal etc.

Bins of square

circular or space enclosed by

or rectangular in

polygonal in battery of B. American Concrete Institute - ACI 313 : 1997

plan

plan interconnected bins

ACI 313 – 91 was superseded by ACI 313 – 97 which was

The governing factors for the computation of bin loads are adopted as a standard of the American Concrete Institute on

bulk density W, angle of internal friction Φ, angle of wall January 7, 1997[6]. The material, design and construction

friction δ and pressure ratio λ. The values of W and Φ are requirements for the concrete silos are covered in ACI

based on the type of the stored material. The δ and λ values standard. The recommendations for the cast-in place or

depend on the physical nature of the material and it’s filling precast silos are also mentioned. This standard provides the

conditions (i.e. filling or discharged). The bin loads are static and dynamic loading cases from funnel flow, mass

categorized as a) Horizontal load or horizontal pressure flow, concentric flow and asymmetric flow in the silos.

(P h ), b) Vertical load or vertical pressure (P v ) and c)

Frictional wall load or frictional wall pressure (P w ). The loads to be considered while designing the silos are

dead load, live load, wind load, seismic load, thermal loads,

In general, the Janssen’s theory is used for the assessment of external loads and the force due to differential settlement of

bin loads. The maximum value of the above mentioned foundations. The reinforcement details such as diameter of

pressures (P h , P v & P w ) exerted by the stored material bars and spacing of bars in the vertical and horizontal

during normal filling and emptying operations is calculated. direction, lap splices and provisions of dowels are

The condition of homogenization, rapid filling and thoroughly explained in ACI standard. The reinforcement

pneumatic emptying is to be considered, when the powdery detail to be provided at the wall openings due to the

materials are to be stored in the bin. During homogenization existence of pressure zone is also described clearly. The

condition, the lateral and vertical pressures depend on the above recommendations are highlighted in ACI standard

volume of empty space in the bin. Therefore, the following and it helps the users in the effective design of silos.

condition is adopted. As per this code, the pressure due to initial filling, air

pressure and pressure during discharge of stored materials

P h = P v = 0.6 WZ, which should not be less than the are computed against silo walls and hoppers. While

pressures evaluated for normal filling and emptying. determining the pressures and loads on walls, the flow

pattern like concentric flow pattern and asymmetric flow

The lateral pressure during rapid filling and pneumatic

pattern are considered as the concentric flow pattern arises

emptying of a silo is calculated. In the unloading stage, the

during the initial filling and the asymmetric flow pattern

eccentric emptying of bin causes increase in bin loads. The

arises during the discharge of materials.

following loading conditions and effects are considered

while designing the various components of silo namely roof,

The pressures are also calculated for funnel flow hoppers,

bin walls, ring girder, hopper bottom, supporting columns

mass flow hoppers, flat bottom and homogenizing silos. The

and foundation.

TARCE Vol.5 No.2 July-December 2016 28

Contributions of Different Standards and Codes for the Design of Silo: A Review

direct hoop tension due to horizontal pressures along with Where,

combined tension and bending due to non uniform pressures

h c – height of vertical walled segment of silo from the

are taken for the design of circular silo walls in the pressure

transition to the equivalent surface

zone. The combined tension, flexure and shear due to

d c – characteristic dimension of silo interior cross section

horizontal pressure are considered for the walls of square,

t – silo wall thickness

rectangular or polygonal silos. As the walls below pressure

zone are subjected to vertical and lateral loads, it is designed

The classification of the dimensioning conditions based on

as bearing walls. The circumferential and meridional tensile

the silo capacity is given in Table 3.

membrane forces are acting on the conical hopper walls

whereas the combined tensile membrane forces, flexure and

TABLE 3 CLASSIFICATION BASED ON SILO CAPACITY

shear are acting on the pyramidal hopper walls. The

foundation is designed as per ACI 318 “Building Code

Standardized

Requirements for Structural Concrete and Commentary”. Description

Categories

Category 3 Silos capacity > 10000 tonnes

C. German standard - DIN 1055 – 6: 2005 – 03

All silos not covered in another

Category 2

The German standard DIN 1055 – ‘Actions on structures, class

Part - 6 - Design loads for buildings: Loads in Silo bins’ Category 1 Silos capacity < 100 tonnes

was recommended by Pieper and his colleagues after

performing extensive research in this area. This standard The values of the solids properties such as the Specific

was first published in 1964 and revised twice in the year gravity γ, coefficient of wall friction μ, horizontal load ratio

1987 and 2005 [7]. The German standard DIN 1055 was the K and angle of internal friction Φ are considered in the

first code to provide helpful rules to design engineers for evaluation of loads. The flow pattern during discharge

calculating silo loads as the effect of stored materials on the which may be categorized as follows should be considered

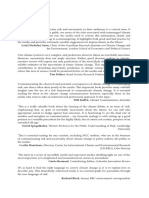

silo walls were included in the load calculation. The in the design given in Figure 1[7].

German standard was produced from the late draft of the

British standard BS EN 1991 – 4 : 2006 and published as 1. Mass flow

DIN 1055 – 6: 2005 – 03.The German translation of the

British standard DIN EN 1991 – 4(2006) has superseded the 2. Funnel flow

DIN 1055 – 6: 2005.

a. Internal Parallel funnel flow

Generally, the material stored in the silo was considered as b. Internal convergent funnel flow

Bulk material and the particle size less than 0.05mm was c. Eccentric parallel funnel flow

particularly referred as powdery bulk material. The type of d. Eccentric convergent funnel flow

materials to be stored in the silo is not given much

importance. The following limitations are provided in the 3. Mixed flow

design rules of silos such as a) geometric limitations, b)

limitations on the stored bulk materials and c) limitations on a. Concentric mixed flow

the filling and discharge arrangements. b. Fully eccentric mixed flow

The classifications of silos are described below: c. Partially eccentric mixed flow

a. Based on the aspect ratio hc/dc (i.e. slimness) The actions on silos are classified as

1. Silo with braced wall, h c /d c ≤ 0.4 1. Variable actions

2. Low silo, 0.4 < h c /d c <1.0 a. Loads due to stored particulate solids

3. Silo of medium slimness silo, 1.0 < h c /d c <2.0 2. Variable stationary actions

4. Slim silo, h c /d c ≥ 2.0

R

a. Symmetric loads

b. Gas pressure loads by pneumatic

b. Based on the wall thickness conveying

c. Eccentric loads

1. Thick walled silo , d c /t < 200 3. Variable free actions

2. Thin walled silo , d c /t > 200 a. Reference Surface loads

4. Extra ordinary actions

c. Based on the wall surface a. Loads due to dust explosions

1. Polished (D1),

2. Smooth (D2),

3. Rough (D3),

4. Corrugated (D4).

29 TARCE Vol.5 No.2 July-December 2016

S.Chithra and G.Indupriya

and discharge. The symmetric load and reference surface

load should be calculated for filling and discharging

conditions for the different silos (i.e. silos based on slimness

and wall thickness). The loads on the vertical walls of the

silos, silo hoppers (shallow or flat inclined) and silo bottoms

(flat) are also evaluated. The hopper design was applicable

for conical and cuneiform shaped hoppers.

D. British Standard - BS EN 1991 – 4: 2006

The Eurocode was published in October 2005 which was

adopted by the European Committee for standardization

(CEN) [8].The British standard BS EN 1991 – 4: 2006

‘Eurocode 1 – Actions on Structures’ was the English

version of the Eurocode. The Part 4: Silos and Tanks of this

standard cover the design of the silos and tanks.

The terms mentioned in DIN 1055 – 6: 2005 – 03 and BS

EN 1991 – 4 : 2006 with more or less same meaning is

Fig.1 Basic flow Profiles given in the Table 4.

The actions on the silo should be evaluated by taking the

range of particulate solid properties, variation in the surface

friction condition, silo geometry and the methods of filling

TABLE 4 TERMS MENTIONED IN CODES

DIN 1055 – 6: 2005 – 03 BS EN 1991 – 4: 2006

Bulk material Stored solids

Slimness Slenderness

Silo with braced wall Retaining silo

Low silo Squat silo

Silo of medium slimness Intermediate slenderness silo

Slim silo Slender silo

Thick walled silo Thick walled circular silo

Thin walled silo Thin walled circular silo

Specific gravity Bulk unit weight

Horizontal load ratio Lateral pressure ratio

Funnel flow Pipe flow

Reference Surface Load Patch Load

Variable stationary actions Variable Fixed actions

Extra ordinary actions Accidental actions

Flat inclined hopper Steep hopper

Cuneiform hoppers Wedge shaped hoppers

TARCE Vol.5 No.2 July-December 2016 30

Contributions of Different Standards and Codes for the Design of Silo: A Review

III. SUMMARY

The four codal provisions for the design of silo are described individually and the comparison between them is presented in

Table 5.

TABLE 5 COMPARISON OF FOUR CODES

BS EN 1991 – 4:

IS 4995 - 1974 ACI 313 - 97 DIN 1055 -6: 2005 - 03

2006

Materials stored is Granular &

Granular Bulk material Stored solids

defined as Powdery

Based on

Based on slimness &

Silo Classification No No slenderness & wall

wall thickness

thickness

Bulk unit weight γ,

Bulk Density W, Weight per unit Speci�ic Gravity γ,

Coefficient of wall

Angle of internal volume γ, Lateral Coefficient of wall

friction µ, Angle of

Vital Parameters friction φ, Angle pressure ratio k, friction µ, Angle of

internal friction ϕ,

of wall friction δ, Coefficient of internal friction ϕ,

Lateral pressure

Pressure ratio λ friction µ’ Horizontal load ratio k

ratio k

Obtained from tests & Obtained from tests

Numerical Values Directly given for

No values provided as lower and & provided as lower

of Solids properties each materials

upper limit value and upper limit

Loads during Horizontal load, Horizontal load,

Symmetric load & Symmetric load &

filling & vertical load & vertical load &

Reference surface load Patch load

discharging Frictional load Frictional load

Computation of Based on

Based on materials Based on Silos Based on Silos

Loads materials

Geometric,

Effect of hot stored Geometric, Materials,

Materials, Filling &

Limitations No material is not Filling & discharging

discharging

considered arrangements.

arrangements.

Based on Capacity

Classification of Based on Capacity of

No No of stored material

action assessment stored material

Walls – Concentric

and Asymmetric Mass flow, Pipe

Flow Pattern Mass flow, Funnel flow

No flow, Hoppers – flow and Mixed

during discharge and Mixed flow

Funnel and Mass flow

flow

Applicable hopper Conical and Conical and Cuneiform Conical and Wedge

All shapes

shapes for design Pyramidal hoppers hoppers shaped hoppers

Pressure zone For calculation of

No No No

consideration wall pressure

Check and

Crack Width

limitations are Calculation given As per DIN 1045 – 1 As per EN 1992

calculation

given

Particle size No limitation No limitation ≯0.03 d c ≯0.03 d c

Reinforced details,

Column & Mentioned Mentioned No No

Foundation design

IV. GENERAL DISCUSSION ABOUT THE CODES

A. Solids Properties density is used in the design of feeder and also in the

calculation of the pressures and bin loads. The cohesiveness

The material properties will dictate the silo bin design. The of the material is used in the analyses of arching and

important solids properties considered for the design of the ratholes behavior. The arches prevent the material to

silo are bulk density, wall friction, angle of internal friction discharge by forming obstructions whereas the ratholes

and pressure ratio. All the four codes mentioned the solids cause erratic discharge. But the cohesive strength

properties. The wall friction is adopted for calculating consideration is not provided in the codes.

hopper angles for mass flow and internal friction. The bulk

31 TARCE Vol.5 No.2 July-December 2016

S.Chithra and G.Indupriya

B. Material remains in the hopper along its walls. The bulk solids are

discharged for most of the bins with the funnel flow pattern.

For the design of silo, the codes suggested that the material The flow obstructions occur when the forces opposing

should be coarse, free flow and non degradable. The particle motion exceed the forces due to gravity. The arches and

size greater than 3 mm are considered as coarse. The free ratholes are obstructions formed in the funnel flow pattern.

flow for bulk materials cannot be expected in various Due to this, the material caking and segregation are found to

materials in all the cases. It is to be noted that, no arching or occur. The bin may fail due to material caking which cause

ratholes should be formed in the free flowing material. The unexpected structural loading. Also, there is no chance for

DIN 1055 – 6: 2005- 03 and BS EN 1991 – 4: 2006 fluidized powders to deaerate. The problems experienced in

provided the limitation for the material stored in bins, such the funnel flow pattern can be rectified in mass flow pattern.

that it must be the free flowing material. As per this The mass flow pattern is the best suited flow pattern for

limitation, the silo cannot be designed for non free flowing cohesive materials and powders. Almost all the codes,

material. except IS 4995 – 1974 had given the description about flow

pattern.

C. Bin Geometry

V. CONCLUSION

The primary design objective when determining the bin

geometry is to ensure that bulk solid will flow with the This paper looks over the superiority and limitations of the

effects of gravity and without flow obstructions [7, 9, 10]. four codes namely Bureau of Indian Standard (BIS),

In general, all codes recommended that, the bin may be American Concrete Institute (ACI), German Standard (DIN)

circular, square or rectangular in shape. The square or and British Standards Institution (BSI). For the sake of

rectangular straight sided wall has large cross sectional area complete, logical and relevant analysis, this study has been

compared to the circular wall bin. They are easy to divided into two parts. In the first part, each code was

fabricate. The drawback of the straight sided flat walls is thoroughly studied and the basic concepts behind each code

suspected to bending due to pressure. But the circular wall were explained. The second part presents the comparison

cylindrical bin resists internal pressure through hoop and discussion of similarities and dissimilarities of each

tension. The provision of thinner walls and less code and the analysis of the parameters involved in the

reinforcement is enough for the cylindrical bins. The round design of the silo. The insight of loads exerted by the stored

bins tend to empty more easily due to lack of corners for the materials and external forces to the silo is significant for

stored material to become wedged and encrusted. designing the safe silo. A slight modifications in the

parameters, namely the effect of the thermal variation and

D. Hopper Shape the properties of stored materials, if taken into account in

the analysis of silo, the discrepancies associated with

The majority of the weight of the stored solids is act on the various codes can be further reduced.

hopper, so that the design of hopper is difficult in filling

stage than the discharging stage [1, 11-20]. The conical or REFERENCES

wedge shaped hoppers are recommended as per the codes.

The term wedge shaped hoppers as mentioned in BS EN [1] H. Li . Analysis of steel silo structures on discrete supports. Ph.D

Thesis, University of Edinburgh, Scotland, UK. 1994.

1991 -4:2006 are referred as cuneiform hoppers in DIN

[2] M. Wojcik ,G.G. Enstad ,M. Jecmenica . Numerical calculations of

1055 – 6: 2005 – 03 and pyramidal hoppers in IS 4995 - wall pressures and stresses in steel cylindrical silos with concentric

1974. The hopper angle depends on the friction of the and eccentric hoppers. Particulate Science and Technology.

material. The steep hopper angle is provided for the high VoL..21:,pp. 247 – 258 . 2003.

[3] Rotter JM. Silo and hopper design for strength, Chapter3 in bulk

friction material and shallow hopper angle for the low solids handling – equipment selection and operation. In:

friction material. The angle of the wedge shaped hoppers is McGlincheyD, editor. Oxford: Blackwell, pp.99–134. , 2008.

10-12º less than the conical hopper angle (i.e.) wedge [4] Adem Dogangun, Zeki Karaca, Ahmet Durmus and Halil Sezen.

shaped hoppers have steep hopper angle. The outlet Cause of damage and failures in silo structures. Journal of

performance of constructed facilities, ASCE. Vol. 23, No.2,

diameter of the conical hopper is twice the outlet width of :pp.65-71., 2009.

the wedge shaped hopper. The length of the wedge shaped [5] BIS 4995: 1974. Criteria for Design of Reinforced concrete bins

hopper is three times its width and it has maximum flow for the storage of Granular and Powdery materials, Bureau of

rate. Indian Standard.1974.

[6] ACI 313: 1977. Standard practice for design and construction of

concrete silos and stacking tubes for storing granular materials ,

E. Flow Pattern American Concrete Institute. 1977.

[7] DIN 1055 -6: 2005- 03 , Actions on structures, Part - 6 Design

The flow pattern of the material depends on the internal loads for buildings: Loads in Silo bins: German Standard 2005.

[8] BS EN 1991-4: 2006 , Actions on structures. Part 4: Silos and

friction and friction between the materials and hopper walls. tanks: Eurocode 1, British Standards Institution. 2006.

The material flows without obstructions are referred as mass [9] GM. Baxter ,RP. Behringer. Pattern formation in flowing sand.

flow. In funnel flow, some of the material moves in the Physical Review Letters,.Vol. 62,No. 24 :pp. 2825–2828., 1989.

center of the hopper whereas, the rest of the material [10] CS. Campbell . Granular material flows–an overview. Powder

Technology,Vol. 162, No.3 ,:pp. 208–229. 2006.

TARCE Vol.5 No.2 July-December 2016 32

Contributions of Different Standards and Codes for the Design of Silo: A Review

[11] GG. Enstad On the theory of arching in mass flow hoppers. Chem [16] JM. Rotter, Flow and pressures in silo structural integrity

Engineering Science, VoL.30:,pp. 1273–83., 1975. assessments. In: Proceedings of the international symposium:

[12] DV. Khakhar ,AV Orpe ,JM. Ottino Surface flow of granular reliable flow of particulate solids III. Porsgrunn, pp.281–9, 1999.

material: model and experiments in heap formation. Journal of [17] JM. Rotter Guide for the economic design of circular metal silos.

Fluid Mechanics,.Vol. 441: pp. 255–264., 2001. London and NewYork: SponPress. 2001.

[13] JY. Ooi , JM. Rotter . Elastic and plastic predictions of the storing [18] JG. Teng , JM. Rotter , The strength of welded steel silo hoppers

pressures in conical hoppers. Transactions of Mechanical under filling and flow pressures. Journal of Structural Engineering,

Engineering, Institution of Engineers, Australia, vol. ME 14 (3); ASCE,.Vol. 117, No.9, :pp. 2567–83. 1991

pp.165–169., 1989. [19] JK. Walters . A theoretical analysis of stress in silos with vertical

[14] JM. Rotter The effect of increasing grain moisture content on the walls. Chem Engineering Science,.Vol. 28 ,NO.3,:pp.779–89,

stresses in silo walls. Investigation Report S444, School of Civil 1973.

and Mining Engineering, University of Sydney, Sydney, Australia. [20] M. Walker An approximate theory for pressures and arching in

1983. hoppers. Chem Engineering Science,.21:975–97, 1966.

[15] JM. Rotter Shell structures, the new European standard and

current research needs. Thin-Walled Structures,. Vol. 31(1-3):pp.

3–23., 1998.

33 TARCE Vol.5 No.2 July-December 2016

You might also like

- To Study The Analysis, Design and Behavior of Corrugated Steel SiloDocument7 pagesTo Study The Analysis, Design and Behavior of Corrugated Steel SiloMohammed AlnasharNo ratings yet

- Engineering Materials 2: An Introduction to Microstructures, Processing and DesignFrom EverandEngineering Materials 2: An Introduction to Microstructures, Processing and DesignNo ratings yet

- Design and Analysis of Storage Vessel (Silo) : ISSN: 2455-2631 © May 2019 IJSDR - Volume 4, Issue 5Document19 pagesDesign and Analysis of Storage Vessel (Silo) : ISSN: 2455-2631 © May 2019 IJSDR - Volume 4, Issue 5Peter IosifidisNo ratings yet

- Composite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)From EverandComposite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Rating: 4 out of 5 stars4/5 (10)

- IJSDR190491Document21 pagesIJSDR190491RohimNo ratings yet

- The Open Construction and Building Technology JournalDocument17 pagesThe Open Construction and Building Technology JournalffyuNo ratings yet

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- Indian StandardDocument20 pagesIndian StandardAamaniVeeranamNo ratings yet

- EAC REPORTDocument25 pagesEAC REPORT13 Vedant DamodareNo ratings yet

- IS 4995 (Part 2) 1974Document25 pagesIS 4995 (Part 2) 1974Nagaraju ChintaNo ratings yet

- IRJAES - Plan Analysis and Design of A Circular RCC SiloDocument6 pagesIRJAES - Plan Analysis and Design of A Circular RCC SiloM.RajivNo ratings yet

- Elastic, Plastic and Yield Design of Reinforced StructuresFrom EverandElastic, Plastic and Yield Design of Reinforced StructuresNo ratings yet

- A Review Study On Silos For Safe Storage of Food GrainDocument2 pagesA Review Study On Silos For Safe Storage of Food GrainEditor IJTSRDNo ratings yet

- Group & Pile Research ProjectDocument38 pagesGroup & Pile Research ProjectAlphaNo ratings yet

- Group Members: 1. Sachittra Ranasinghe 2. Mohamed Siyath 3. Sahl Buhary 4. Mohamed Juhry 5. Mohamed HiyasDocument38 pagesGroup Members: 1. Sachittra Ranasinghe 2. Mohamed Siyath 3. Sahl Buhary 4. Mohamed Juhry 5. Mohamed Hiyasmominul hoqueNo ratings yet

- Analysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFDocument7 pagesAnalysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFesatjournalsNo ratings yet

- Structural Design of Steel Bins and SilosDocument36 pagesStructural Design of Steel Bins and Silosyoussefayay92% (12)

- IS 4995 (Part 1) 1974Document20 pagesIS 4995 (Part 1) 1974Sumit Narayan0% (1)

- Master of Engineering in Civil (Structures)Document39 pagesMaster of Engineering in Civil (Structures)suhasNo ratings yet

- Case ProjectDocument47 pagesCase ProjectAshish LoyaNo ratings yet

- Silos and Bunkers-4Document13 pagesSilos and Bunkers-4chalakhdNo ratings yet

- Economical Design of BunkersDocument13 pagesEconomical Design of BunkersKalai Selvan100% (1)

- Standard Design of SilosDocument12 pagesStandard Design of SilosTarun VermaNo ratings yet

- 4 Commentary On Standard Practice For Design and Conbstruction of Concrete Silos and Stacking Tubes For Storing Granular Materials ACI 313-97Document20 pages4 Commentary On Standard Practice For Design and Conbstruction of Concrete Silos and Stacking Tubes For Storing Granular Materials ACI 313-97Nikki Marlo CruzNo ratings yet

- Functions of pile types and piles used in constructionDocument4 pagesFunctions of pile types and piles used in constructionWillie Jay CoreaNo ratings yet

- Pillar Design PaperDocument10 pagesPillar Design PaperAnand sharmaNo ratings yet

- IJSRDV5I80421Document5 pagesIJSRDV5I80421Pooja C PNo ratings yet

- Design of Small Diameter Frictional Piles and Cases StudyDocument71 pagesDesign of Small Diameter Frictional Piles and Cases StudyLeung Liang50% (2)

- Seismic Design Considerations For Pile Foundation EmgineeringDocument4 pagesSeismic Design Considerations For Pile Foundation EmgineeringtaosyeNo ratings yet

- Functions of pile types and constructionDocument4 pagesFunctions of pile types and constructionpankajNo ratings yet

- Review On Thin Shell Cylindrical Steel SilosDocument5 pagesReview On Thin Shell Cylindrical Steel SilosMaurizio FalconieriNo ratings yet

- The Functions of Pile Types and Piles Used in Construction: April 2018Document4 pagesThe Functions of Pile Types and Piles Used in Construction: April 2018ahmedNo ratings yet

- The Problem and Its BackgroundDocument4 pagesThe Problem and Its BackgroundSuzaku KururugiNo ratings yet

- Comparison of Seismic Behavior of A Structure With Composite and Conventional ColumnsDocument7 pagesComparison of Seismic Behavior of A Structure With Composite and Conventional ColumnsEphrata MussieNo ratings yet

- Hospital JoournalDocument22 pagesHospital Joournalvgujju5No ratings yet

- BunkerDocument7 pagesBunkerSrinivasan GanesanNo ratings yet

- Materials: Types of Piles and PileDocument35 pagesMaterials: Types of Piles and Pilemuhammad siddiqNo ratings yet

- ACI 313R-97: Reported by ACI Committee 313Document20 pagesACI 313R-97: Reported by ACI Committee 313DIDIER ANGEL LOPEZ RINCONNo ratings yet

- National Workshop On Is - 456-2000Document96 pagesNational Workshop On Is - 456-2000Thomas MartinNo ratings yet

- Indian Standard: Criteria For Design of Steel Bins For Storage of Bulk MaterialsDocument27 pagesIndian Standard: Criteria For Design of Steel Bins For Storage of Bulk MaterialsajayaghimireNo ratings yet

- Circular vs Rectangular Concrete Tank Cost AnalysisDocument7 pagesCircular vs Rectangular Concrete Tank Cost Analysis1Bnesa3No ratings yet

- Stress Analysis of Silo Hopper: by G. Sangareeswari U. GanesanDocument9 pagesStress Analysis of Silo Hopper: by G. Sangareeswari U. GanesanGANESANMECH05No ratings yet

- Damage Assessment and RehabilitationDocument3 pagesDamage Assessment and Rehabilitationmusiomi20052542No ratings yet

- Filler SlabDocument4 pagesFiller Slabthusiyanthanp100% (1)

- Analysis and Design of RC ChimneysDocument6 pagesAnalysis and Design of RC ChimneysIsha PatelNo ratings yet

- Design, Analysis and Comparison of Underground Rectangular Water Tank by Using STAAD Provi8 SoftwareDocument6 pagesDesign, Analysis and Comparison of Underground Rectangular Water Tank by Using STAAD Provi8 SoftwareNitin shepurNo ratings yet

- Monolithic DomesDocument19 pagesMonolithic DomesISLAVATH SANDHYANo ratings yet

- Is-11682.1985 (Staging For Overhead Water Tanks)Document27 pagesIs-11682.1985 (Staging For Overhead Water Tanks)amithcivil100% (2)

- 4th Semester RCC Notes 170745Document32 pages4th Semester RCC Notes 170745Santosh67% (3)

- Code - Commentary On Is 1905Document117 pagesCode - Commentary On Is 1905Mustufa F KanjetaNo ratings yet

- Ijfeat: Comparative Analysis of Cold Form Steel and Hot Rolled Steel Structure For Static Shed Type Steel StructureDocument7 pagesIjfeat: Comparative Analysis of Cold Form Steel and Hot Rolled Steel Structure For Static Shed Type Steel StructureMITHUN BDMLNo ratings yet

- Steels For Bearings Gonidakis Christopoulos MasterDocument21 pagesSteels For Bearings Gonidakis Christopoulos MasterrezabarzanNo ratings yet

- Advantages and Disadvantages of Using ConcreteDocument19 pagesAdvantages and Disadvantages of Using ConcreteTANKO BAKONo ratings yet

- Interlocking Paver BlocksDocument5 pagesInterlocking Paver BlocksfaresNo ratings yet

- 80410-19 - TPJC - Drainage Markup - KZXDocument1 page80410-19 - TPJC - Drainage Markup - KZXFreddie KooNo ratings yet

- Vol. 4 (4) - Dec. 2013: Professor, Department of Civil Engineering, Menoufia University, Shebin El-Kom, EgyptDocument12 pagesVol. 4 (4) - Dec. 2013: Professor, Department of Civil Engineering, Menoufia University, Shebin El-Kom, EgyptFreddie KooNo ratings yet

- Ferrocement Water TanksDocument35 pagesFerrocement Water TanksFreddie KooNo ratings yet

- Defu Barrier ConceptDocument1 pageDefu Barrier ConceptFreddie KooNo ratings yet

- Hilti PROFIS Engineering 3.0.81 Anchor DesignDocument15 pagesHilti PROFIS Engineering 3.0.81 Anchor DesignFreddie KooNo ratings yet

- Comparison SPTDocument8 pagesComparison SPTسجى EngNo ratings yet

- Rawlplug-HPTIIZF-20160 23122022Document7 pagesRawlplug-HPTIIZF-20160 23122022Freddie KooNo ratings yet

- Drafts 80637 Typical Connection R1Document16 pagesDrafts 80637 Typical Connection R1Freddie KooNo ratings yet

- Design of Micropile FoundationDocument7 pagesDesign of Micropile FoundationEncik BadrulNo ratings yet

- Drafts 80637 Typical Connection R1Document16 pagesDrafts 80637 Typical Connection R1Freddie KooNo ratings yet

- Y 5 G 3 AbftyqDocument7 pagesY 5 G 3 AbftyqFreddie KooNo ratings yet

- Fire Shutter: SHD +42.000 7th StoreyDocument3 pagesFire Shutter: SHD +42.000 7th StoreyFreddie KooNo ratings yet

- Design Part 2 - TWIDocument9 pagesDesign Part 2 - TWIFreddie KooNo ratings yet

- 1082 Rawlplug en R Hptii ZF Zinc Flake ThroughboltDocument8 pages1082 Rawlplug en R Hptii ZF Zinc Flake ThroughboltFreddie KooNo ratings yet

- Design - Part 3 - TWIDocument9 pagesDesign - Part 3 - TWIFreddie KooNo ratings yet

- Design - TWIDocument7 pagesDesign - TWIFreddie KooNo ratings yet

- Transport Impact Assessment Guidelines - 28 Sep 2017Document78 pagesTransport Impact Assessment Guidelines - 28 Sep 2017Ed SalangaNo ratings yet

- V4 Eurocode2Part4 Booklet 160x160 enDocument15 pagesV4 Eurocode2Part4 Booklet 160x160 ensubham sahuNo ratings yet

- Design of Piles - Danish Practice: April 2016Document31 pagesDesign of Piles - Danish Practice: April 2016Freddie KooNo ratings yet

- 01-Slides-D & C of Driven RC Piles-7 Aug 18-BriefDocument144 pages01-Slides-D & C of Driven RC Piles-7 Aug 18-BriefFreddie KooNo ratings yet

- Design - Part 1 - TWIDocument9 pagesDesign - Part 1 - TWIFreddie KooNo ratings yet

- 0677Document8 pages0677Jack DoverNo ratings yet

- OrmanN - Challenges of Sewer Rehab WS Dec2016Document2 pagesOrmanN - Challenges of Sewer Rehab WS Dec2016Sen HuNo ratings yet

- Protection of Public Sewerage System PDFDocument13 pagesProtection of Public Sewerage System PDFFreddie KooNo ratings yet

- Characteristic Values of Geo Parameters in EC7Document12 pagesCharacteristic Values of Geo Parameters in EC7Freddie KooNo ratings yet

- Design Considerations and Guidelines in The Use of Grade 600 Steel Reinforcements For Reinforced Concrete ConstructionDocument11 pagesDesign Considerations and Guidelines in The Use of Grade 600 Steel Reinforcements For Reinforced Concrete ConstructionFreddie KooNo ratings yet

- Why Choose Magnesium?: Materials Science Forum April 2009Document6 pagesWhy Choose Magnesium?: Materials Science Forum April 2009Freddie KooNo ratings yet

- Please Do Not Remove This Page: Thank You For Do Wnloading This Docum Ment From The Rmit R Research R RepositoryDocument9 pagesPlease Do Not Remove This Page: Thank You For Do Wnloading This Docum Ment From The Rmit R Research R RepositoryFreddie KooNo ratings yet

- Thrust Block For Pipelines - Case Study of Water Sup-Ply Scheme For A Town BerinagDocument6 pagesThrust Block For Pipelines - Case Study of Water Sup-Ply Scheme For A Town BerinagsatyamNo ratings yet

- Decking For Micropile PDFDocument2 pagesDecking For Micropile PDFFreddie KooNo ratings yet

- HandbookDocument154 pagesHandbookTrisphere Media TechnologiesNo ratings yet

- APC Easy UPS 1000VA Floor/Wall Mount 230V UPS Spec SheetDocument3 pagesAPC Easy UPS 1000VA Floor/Wall Mount 230V UPS Spec SheetÁrea de IngenieríaNo ratings yet

- Analysis of Amino AcidsDocument3 pagesAnalysis of Amino AcidsRinaldi SukarnoNo ratings yet

- PoisonedfoodDocument10 pagesPoisonedfoodMare JNo ratings yet

- MB Module 1Document29 pagesMB Module 1sophieNo ratings yet

- (Reuters Institute For The Study of Journalism) James Painter - Climate Change in The Media - Reporting Risk and Uncertainty-I. B. Tauris (2013)Document192 pages(Reuters Institute For The Study of Journalism) James Painter - Climate Change in The Media - Reporting Risk and Uncertainty-I. B. Tauris (2013)Thomas Ravelly Batista dos SantosNo ratings yet

- Data Analysis and Research MethodologyDocument2 pagesData Analysis and Research MethodologyNitishaNo ratings yet

- Parts 1 and 2 Notes On The Coinage of Julian The ApostateDocument9 pagesParts 1 and 2 Notes On The Coinage of Julian The ApostateΣπύρος ΑNo ratings yet

- FAO Fisheries & Aquaculture - Cultured Aquatic Species Information Programme - Penaeus Vannamei (Boone, 1931)Document14 pagesFAO Fisheries & Aquaculture - Cultured Aquatic Species Information Programme - Penaeus Vannamei (Boone, 1931)Dalis FaNo ratings yet

- SE-409 Aluminium Enclosure SE-409-0-0-A-0-11284: RevisionDocument1 pageSE-409 Aluminium Enclosure SE-409-0-0-A-0-11284: RevisionAhmet MehmetNo ratings yet

- Danny Debois: Tips for Effective Whip Speeches in DebateDocument2 pagesDanny Debois: Tips for Effective Whip Speeches in DebateJOSE FRANCISCO VERGARA MUÑOZNo ratings yet

- Cbse Ix-X Social Science 2022-23 PisDocument52 pagesCbse Ix-X Social Science 2022-23 PisAditi JaniNo ratings yet

- Algorithms to calculate, compare, and determine valuesDocument3 pagesAlgorithms to calculate, compare, and determine valuesLee Anne AngelesNo ratings yet

- Sep. Gravimetrica - CromitaDocument13 pagesSep. Gravimetrica - Cromitaemerson sennaNo ratings yet

- 9.06&9.01social Psychology JournalDocument17 pages9.06&9.01social Psychology JournalMatthew CheungNo ratings yet

- m2 Arithmetic SequenceDocument9 pagesm2 Arithmetic Sequenceedmund roseteNo ratings yet

- Organic Chemistry Lesson on Cyclic HydrocarbonsDocument12 pagesOrganic Chemistry Lesson on Cyclic HydrocarbonsShamarie Love MaribaoNo ratings yet

- Phrasal Verbs ListDocument85 pagesPhrasal Verbs ListVirginia E. C.No ratings yet

- Listado 13Document436 pagesListado 13Abel Hernandez SoteloNo ratings yet

- An Introduction To The Philosophy of Physics by Marc Lange PDFDocument340 pagesAn Introduction To The Philosophy of Physics by Marc Lange PDFMohamad Daoud100% (1)

- Ahon BangkeroDocument29 pagesAhon BangkeroMickaela Kassandra ParanNo ratings yet

- A Survey of Control Approaches For Unmanned Underwater Vehicles 19.8.2023 - Ver4.0Document15 pagesA Survey of Control Approaches For Unmanned Underwater Vehicles 19.8.2023 - Ver4.0Dr Agus BudiyonoNo ratings yet

- Ilham Shalabi, Imam Muhammad Bin Saud Islamic UniversityDocument20 pagesIlham Shalabi, Imam Muhammad Bin Saud Islamic Universityaron victoryNo ratings yet

- CP3 Assignment1Document2 pagesCP3 Assignment1Rea Dominique CabanillaNo ratings yet

- Élan VitalDocument3 pagesÉlan Vitalleclub IntelligenteNo ratings yet

- The Range and Application of Phast and Safeti Explosion Models For Facility Siting Work - 3 December - PresentationDocument60 pagesThe Range and Application of Phast and Safeti Explosion Models For Facility Siting Work - 3 December - PresentationsushantNo ratings yet

- TextMesh Generation of Realistic 3D Meshes From Text PromptsDocument25 pagesTextMesh Generation of Realistic 3D Meshes From Text Prompts黃偉宸No ratings yet

- School of Mathematics and Statistics Spring Semester 2013-2014 Mathematical Methods For Statistics 2 HoursDocument2 pagesSchool of Mathematics and Statistics Spring Semester 2013-2014 Mathematical Methods For Statistics 2 HoursNico NicoNo ratings yet

- State of Nature Alternatives 1 2 3Document10 pagesState of Nature Alternatives 1 2 3Michael Allen RodrigoNo ratings yet

- BiographyDocument3 pagesBiographyPatricia Anne Nicole CuaresmaNo ratings yet