Professional Documents

Culture Documents

Kiln and Cooler Formulas PDF

Kiln and Cooler Formulas PDF

Uploaded by

Guillermo Càceres0 ratings0% found this document useful (0 votes)

14 views2 pagesOriginal Title

kiln and cooler formulas cementequipment.org.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views2 pagesKiln and Cooler Formulas PDF

Kiln and Cooler Formulas PDF

Uploaded by

Guillermo CàceresCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

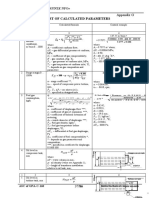

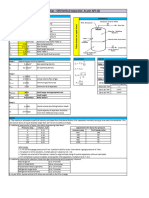

Kiln Performance & Efficiency

S. Description Symbol Formula Example

No.

1 Degree of filling DF 3.2 * P P 6000 7500

3

% Deff * n * s Deff 4.76 4.76

P Clinker production, tpd n 4 4.5

Deff Burning zone effective diameter, mts S 3.5 3.5

n Kiln speed, rpm DF 12.72 14.13

s Kiln slope, % Target 14-16 14-16

2 Thermal loading TL Formula-1 F 15680 19760

or Gcal/hr/m2 F * NCV NCV 4500 4500

Burning zone loading A * 1000 * 1000 A 17.79 17.79

F Fuel rate in kiln, kg/hr TL 3.97 5.00

NCV Net calorific value of fuel, kcal/kg-fuel Target 4.0-5.0 4.0-5.0

A Burning zone cross-sectional area, m2

Formula-2 P 6000 7500

P*H H 282 282

A * 24 * 1000 A 17.79 17.79

P Clinker production, tpd TL 3.96 4.95

H Specific heat consumption in kiln, kcal/kg-clinker Target 4.0-5.0 4.0-5.0

A Burning zone cross-sectional area, m2

3 Volumetric loading VL P P 6000 7500

tpd/m3 A*L A 17.79 17.79

P Clinker production, tpd L 61 61

A Burning zone cross-sectional area, m2 VL 5.53 6.91

L Kiln length, mts Target 5.0-6.0 5.0-6.0

4 Material residence time in kiln RTK 19 * L L 61 61

min Deff * n * s Deff 4.76 4.76

L Kiln length, mts n 4 4

Deff Burning zone effective diameter, mts S 3.5 3.5

n Kiln speed, rpm RTK 17.4 17.4

s Kiln slope, % Target 20-25 20-25

5 Clinker residence time in cooler RTC 1.55 * A * Ps A 131.6 131.6

(Empirical relationship from min P Ps 1200 1200

F.L. Smidth) A Cooler grate cross-sectional area, m2 P 6000 7500

Ps Static pressure at clinker droping area, mmWg RTC 40.8 32.6

P Clinker production, tpd Target 20-25 20-25

6 True CO2 in kiln exit gas TCO2 100 * ( CO2 + CO ) CO2 36.5 36.5

vol% 100 + ( 1.89 * CO ) - ( 4.78 * O2 ) CO 0.002 0.002

CO2 Kiln exit gas CO2, vol% O2 4.2 4.2

CO2 Kiln exit gas CO, vol% TCO2 45.7 45.7

O2 Kiln exit gas O2, vol% Target - -

7 Excess air EA 79 * O2 O2 2.8 2.8

% 0.21 * ( 100 - CO2 ) - O2 CO2 26.5 26.5

O2 O2 content in gas, vol% EA 17.5 17.5

CO2 CO2 content in gas, vol% Target 10-15 10-15

8 Radiation heat losses RHL 4 * 10-8 * ( T4 - t4 ) T 517 517

kcal/hr/m2 T Radiating body temperature, K t 305 305

t Ambient air temperature, K RHL 2512 2512

Target - -

9 Convection heat losses CHL 80.33 * ( ( T + t ) / 2 )-0.724 * ( T - t )1.333 T 443 443

kcal/hr/m2 T Radiating body temperature, K t 308 308

t Ambient air temperature, K CHL 760 760

Target - -

10 Forced convection heat losses FCHL 28.03 * ( ( T + t ) / 2 )-0.351 * v0.805 * D-0.195 * ( T - t ) T 525 525

(when wind speed > 3.0 m/s) kcal/hr/m2 T Radiating body temperature, K t 302 302

t Ambient air temperature, K v 5 5

v Wind speed, m/s D 4.15 4.15

D Radiating body diameter, mts FCHL 2088 2088

Target - -

11 %Ash absorption in clinker %AA CC * Ash CC 26 26

% P Ash 15 15

CC Coal consumption, tph P 208 208

Ash Ash content in fuel (as fired basis), % %AA 1.88 1.88

P Clinker production, tph Target - -

Kiln Performance & Efficiency

S. Description Symbol Formula Example

No.

12 Raw Mix:Clinker ratio RMCK 100 - %AA %AA 1.74 1.74

(dust to kiln) - 100 - LOI LOI 35.58 35.58

%AA %Ash absorption, % RMCK 1.525 1.525

LOI Loss on ignition of raw mix, % Target - -

13 Raw Mix:Clinker ratio RMCS ( 100 - %AA ) * 100 %AA 1.74 1.74

(dust to silo) - ( 100 - LOI ) * ( 100 - DL ) LOI 35.58 35.58

%AA %Ash absorption, % DL 8.5 8.5

LOI Loss on ignition of raw mix, % RMCS 1.667 1.667

DL Dust losses from preheater, % Target - -

14 Heat of reaction HR ( 4.282 * CaCO3 * RMCK ) + ( 3.085 * MgCO3 * RMCK ) CaCO3 75.1 75.1

or kcal/ + ( 222 * Al2O3 / ( 100 - LOI ) ) + ( 11.6 * CH2O * RMCK ) RMCK 1.53 1.53

Theoretical heat required to kg-clinker - ( 511.6 * SiO2 / ( 100 - LOI ) ) - ( 59 * Fe2O3 / ( 100 - LOI ) ) MgCO3 1.6 1.6

produce 1 kg of clinker - ( 1000 * ( K2O + Na2O ) / ( 100 - LOI ) ) LOI 34.5 34.5

or - ( 79 * C * RMCK ) - ( 32 * S * RMCK ) Al2O3 4.17 4.17

Clinkerisation heat CaCO3 CaCO3 content in kiln feed, % CH2O 1.05 1.05

RMCK Kiln feed:Clinker ratio, - SiO2 13.47 13.47

(including Heat of combustibles) MgCO3 MgCO3 content in kiln feed, % Fe2O3 2.41 2.41

LOI LOI content in kiln feed, % K2O 0.38 0.38

Al2O3 Al2O3 content in clinker, % Na2O 0.27 0.27

CH2O Water of crystalisation in kiln feed, % C 0.2 0.2

SiO2 SiO2 content in clinker, % S 0.04 0.04

Fe2O3 Fe2O3 content in clinker, % HR 389 389

K2O K2O content in clinker, % Target - -

Na2O Na2O content in clinker, %

C Carbon content in kiln feed, %

S Sulphur as pyrites in kiln feed, %

15 False air w.r.t. mix FAMO ( O2mix - O2gas ) * 100 O2mix 3.6 3.6

(based on O2 analysis) % 21 - O2gas O2gas 2.8 2.8

O2mix O2 content in mixture of gas, vol% FAMO 4.4 4.4

O2gas O2 content in unmixed gas, vol% Target 5-7 5-7

16 False air w.r.t. gas FAGO ( O2mix - O2gas ) * 100 O2mix 3.6 3.6

(based on O2 analysis) % 21 - O2mix O2gas 2.8 2.8

O2mix O2 content in mixture of gas, vol% FAGO 4.6 4.6

O2gas O2 content in unmixed gas, vol% Target 5-7 5-7

17 False air w.r.t. mix FAMC ( CO2gas - CO2mix ) * 100 CO2mix 32.1 32.1

(based on CO2 analysis) % CO2gas CO2gas 34.5 34.5

CO2mix CO2 content in mixture of gas, vol% FAMC 7.0 7.0

CO2gas CO2 content in unmixed gas, vol% Target 5-7 5-7

18 False air w.r.t. gas FAGC ( CO2gas - CO2mix ) * 100 CO2mix 32.1 32.1

(based on CO2 analysis) % CO2mix CO2gas 34.5 34.5

CO2mix CO2 content in mixture of gas, vol% FAMC 7.5 7.5

CO2gas CO2 content in unmixed gas, vol% Target 5-7 5-7

19 Cooler Loading Cla P P 6000 7500

tpd/m2 A A 131.6 131.6

P Clinker production, tpd CL 45.59 56.99

A Cooler cross-sectional area, m2 Target 45-60 45-60

20 Cooler Loading CLw P P 6000 7500

tpd/m W W 4 4

P Clinker production, tpd CLw 1500 1875

W Cooler Width, m Target 1500 1500

You might also like

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- Steam Table IAPWS-If97 v2010.0Document8 pagesSteam Table IAPWS-If97 v2010.0cemal gümrükçüoğluNo ratings yet

- Astm B 594Document9 pagesAstm B 594Dinesh Gupta100% (1)

- Rexx ProgsDocument10 pagesRexx ProgsRaveesh BhatNo ratings yet

- Lesson Plan CompleteDocument49 pagesLesson Plan CompleteGifty AppiahNo ratings yet

- Chemistry in Focus A Molecular View of Our World 6th Edition Tro Test BankDocument18 pagesChemistry in Focus A Molecular View of Our World 6th Edition Tro Test Bankrussellsmithnjcoydzkfm100% (14)

- RBMWizardDocument286 pagesRBMWizardJesus EspinozaNo ratings yet

- 3 - Heating - Calculation - Tool - EmptyDocument7 pages3 - Heating - Calculation - Tool - EmptyThaigroup CementNo ratings yet

- Peripheral DevicesDocument24 pagesPeripheral DevicesG.m. Raja100% (1)

- RIL-PSV Calculation SheetDocument4 pagesRIL-PSV Calculation SheetAkashNo ratings yet

- Blending and AgitationDocument18 pagesBlending and AgitationSivanand SNo ratings yet

- Flare Calc Sheet API - RP 521Document13 pagesFlare Calc Sheet API - RP 521ionutlaur86100% (1)

- Cement Kiln Pyro BalanceDocument44 pagesCement Kiln Pyro BalanceirfanNo ratings yet

- Power CalculationDocument4 pagesPower CalculationGunasekaranNo ratings yet

- Mill Calculation: Plant: Date: Mill: VisaDocument2 pagesMill Calculation: Plant: Date: Mill: VisaThaigroup CementNo ratings yet

- Cement Kiln Pyro BalanceDocument45 pagesCement Kiln Pyro BalanceirfanNo ratings yet

- Sizing Three Phase (Gas - Oil) Horizontal Separator: As Per API 12JDocument1 pageSizing Three Phase (Gas - Oil) Horizontal Separator: As Per API 12JekabudiartiNo ratings yet

- Rectangular Jet Air Nozzles and Swirler Improving Ignition and Flame FormationDocument24 pagesRectangular Jet Air Nozzles and Swirler Improving Ignition and Flame Formationhmaza shakeelNo ratings yet

- Kiln FormulasDocument53 pagesKiln FormulasSHRAVAN KUMARNo ratings yet

- Rotary Kiln - Burning Zone Load CalculationDocument2 pagesRotary Kiln - Burning Zone Load CalculationVijay Bhan100% (1)

- Charcoal Tower Sizing CalculationDocument5 pagesCharcoal Tower Sizing CalculationPrathmesh GujaratiNo ratings yet

- Design and Calculation AgitationDocument18 pagesDesign and Calculation AgitationGLENDA CASINONo ratings yet

- PSV No. Cause Calculation:: ReferenceDocument3 pagesPSV No. Cause Calculation:: ReferencerevinNo ratings yet

- Exposure Calculator Noise Level (L DB) Exposure Duration (Hours)Document2 pagesExposure Calculator Noise Level (L DB) Exposure Duration (Hours)NakkolopNo ratings yet

- Fuel Analysis: A H C N O S M QDocument10 pagesFuel Analysis: A H C N O S M QThaigroup CementNo ratings yet

- Documents - MX Cement Kiln Performance CalculationsDocument13 pagesDocuments - MX Cement Kiln Performance CalculationsBùi Hắc HảiNo ratings yet

- DBE-04499Deng - DisplayDocument163 pagesDBE-04499Deng - DisplayThaigroup CementNo ratings yet

- Useful Equations For Kiln & CoolerDocument7 pagesUseful Equations For Kiln & CoolerAbul Qasim100% (2)

- Distance From Addis Ababa (Capital), KMDocument21 pagesDistance From Addis Ababa (Capital), KMThaigroup CementNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document6 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)баха бахинскийNo ratings yet

- Kiln Performance - Efficiency FormulasDocument12 pagesKiln Performance - Efficiency FormulasMohamed ZayedNo ratings yet

- Vertical Separator SizingDocument3 pagesVertical Separator SizingIRVINGNo ratings yet

- Duoflex Kiln BurnerDocument37 pagesDuoflex Kiln BurnerThaigroup Cement100% (1)

- Agitator Design 11 PDF FreeDocument9 pagesAgitator Design 11 PDF FreeMeisam MomeniNo ratings yet

- Kiln CalculationDocument16 pagesKiln CalculationAbhishekNo ratings yet

- Cement Kiln Performance and EfficiencyDocument8 pagesCement Kiln Performance and Efficiencysubham agrawalNo ratings yet

- Lecture 6 Thermal and Hydraulic Design of Engine CyclesDocument34 pagesLecture 6 Thermal and Hydraulic Design of Engine Cycles8기이규원No ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Екатерина Калашникова100% (1)

- National University of Singapore Department of Mechanical Engineering ME2134 Fluid Mechanics I Tutorial 2 SolutionsDocument19 pagesNational University of Singapore Department of Mechanical Engineering ME2134 Fluid Mechanics I Tutorial 2 SolutionsCl SkyeNo ratings yet

- C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesC Check Value) OT Outside Tolerance (X Is Set)Best Auto TechNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)LIONN TESTE2021No ratings yet

- OT Outside Tolerance (X Is Set)Document4 pagesOT Outside Tolerance (X Is Set)carlos puertoNo ratings yet

- N2 Storage Tank CalDocument3 pagesN2 Storage Tank Calsiby josephNo ratings yet

- 10-102 Endurance CalculationDocument2 pages10-102 Endurance CalculationVenkat KrishnaNo ratings yet

- Heat Design PHT 2Document8 pagesHeat Design PHT 2Nida TasneemNo ratings yet

- EX200-5E 油圧回路図Document1 pageEX200-5E 油圧回路図Colin LeeNo ratings yet

- List of Calculated Parameters: J.S.C. Sumy FRUNZE NPODocument2 pagesList of Calculated Parameters: J.S.C. Sumy FRUNZE NPOShahruh RejepbayevNo ratings yet

- Data SheetsDocument5 pagesData Sheetshector cano moraNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Best Auto TechNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)OFFICE DANACNo ratings yet

- OT Outside Tolerance (X Is Set)Document6 pagesOT Outside Tolerance (X Is Set)carlos puertoNo ratings yet

- 101401-9780 Lionn Auto SoftwaresDocument5 pages101401-9780 Lionn Auto SoftwaresLIONN SOFTWARESNo ratings yet

- 101062-9290 TabelaDocument5 pages101062-9290 TabelaLIONN SOFTWARESNo ratings yet

- Horno - QuemadorDocument13 pagesHorno - QuemadorRoberto Alanez EncinasNo ratings yet

- Flare Calc Sheet API RP 521Document9 pagesFlare Calc Sheet API RP 521Miftahul HudaNo ratings yet

- A3 SeparatorDocument59 pagesA3 SeparatorHaziq YussofNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document5 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)carlos puertoNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Agus WijayadiNo ratings yet

- Charcoal Tower Pressure Drop CalculationDocument5 pagesCharcoal Tower Pressure Drop CalculationNalin GujaratiNo ratings yet

- 9412Document3 pages9412Mihai-Eugen Popa100% (1)

- Ceiling & Floor Type Air Conditioner: Service ManualDocument43 pagesCeiling & Floor Type Air Conditioner: Service ManualCesar Calderon GrNo ratings yet

- 101609-3272 TD PDFDocument3 pages101609-3272 TD PDFadhit_90No ratings yet

- Tabel PropertiesDocument4 pagesTabel Propertiesamirin_kingNo ratings yet

- DataSheet LOMBARDINI (CHD SERIES)Document4 pagesDataSheet LOMBARDINI (CHD SERIES)CristianTeodorescuNo ratings yet

- 970119rev0 Breakout Torque 900HP ECI Toque TrackDocument12 pages970119rev0 Breakout Torque 900HP ECI Toque TrackProyectil De ProyectoNo ratings yet

- Waterheater 150FW (H) S (2) en SchemeDocument1 pageWaterheater 150FW (H) S (2) en SchemeDamian OvidiuNo ratings yet

- 3558783Document44 pages3558783สิทธิไชย อรุณวํฒนชัยNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Nikhil digheNo ratings yet

- Cálculo de Diseño de SeparadoresDocument4 pagesCálculo de Diseño de SeparadoresEdwardNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)СТО Дизель Улан-УдэNo ratings yet

- Beam & Stirrup Design: Change HereDocument12 pagesBeam & Stirrup Design: Change HereAhmad Sharief Bin JaylaniNo ratings yet

- 101402-9770 Test PlanDocument3 pages101402-9770 Test PlanMihai-Eugen Popa100% (1)

- Temperatu Pressure Gas/Co Sio2 (Quart: K Bar Mol MolDocument5 pagesTemperatu Pressure Gas/Co Sio2 (Quart: K Bar Mol MolThaigroup CementNo ratings yet

- Target TemperatureDocument4 pagesTarget TemperatureThaigroup CementNo ratings yet

- Bucket ElevatorDocument4 pagesBucket ElevatorMohamed ShehataNo ratings yet

- VTT Processes GTT Technologies: Use of For Thermochemical CalculationsDocument21 pagesVTT Processes GTT Technologies: Use of For Thermochemical CalculationsThaigroup CementNo ratings yet

- Chemsheet Can Be Used As A Very Powerful Tool at The Heart of A Process Simulation Program To Determine The ChemicalDocument6 pagesChemsheet Can Be Used As A Very Powerful Tool at The Heart of A Process Simulation Program To Determine The ChemicalThaigroup CementNo ratings yet

- Section 7 Test and InspectionDocument12 pagesSection 7 Test and InspectionThaigroup CementNo ratings yet

- PHE Tool For Common PH Stats and CIsDocument13 pagesPHE Tool For Common PH Stats and CIsThaigroup CementNo ratings yet

- DBE-04958eng - Tape Extractor Vacuum SystemDocument27 pagesDBE-04958eng - Tape Extractor Vacuum SystemThaigroup Cement100% (1)

- Compatibility Report For Ball Charge Design Mill 2Document2 pagesCompatibility Report For Ball Charge Design Mill 2Thaigroup CementNo ratings yet

- Information On The Safe Operation of Starlinger MachinesDocument29 pagesInformation On The Safe Operation of Starlinger MachinesThaigroup CementNo ratings yet

- Information On The Safe Operation of Starlinger MachinesDocument29 pagesInformation On The Safe Operation of Starlinger MachinesThaigroup CementNo ratings yet

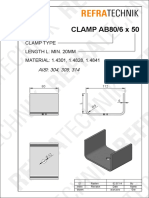

- Clamp - AB80 6 EDocument1 pageClamp - AB80 6 EThaigroup CementNo ratings yet

- Volutec Volumetric Dosing Unit With Feed Station: Technical ManualDocument53 pagesVolutec Volumetric Dosing Unit With Feed Station: Technical ManualThaigroup CementNo ratings yet

- Module 7: Installing, Configuring, and Troubleshooting The Network Policy ServerDocument30 pagesModule 7: Installing, Configuring, and Troubleshooting The Network Policy Server健康生活園Healthy Life GardenNo ratings yet

- Konica 7155Document2 pagesKonica 7155isyo411No ratings yet

- 100 QUESTIONS PDF Data - InterpretationDocument30 pages100 QUESTIONS PDF Data - InterpretationSamraat RaviNo ratings yet

- BTech KukDocument12 pagesBTech KukParmjeet DeswalNo ratings yet

- Kshape ShortDocument8 pagesKshape ShortYumin WangNo ratings yet

- Dry Running Piston CompressorsDocument5 pagesDry Running Piston CompressorsGaurav SinghNo ratings yet

- CH 06Document7 pagesCH 06jjts1No ratings yet

- Neural Network Based Rainfall Prediction SystemDocument6 pagesNeural Network Based Rainfall Prediction SystemBaranishankar100% (1)

- WCD Session 01Document25 pagesWCD Session 01swoneraNo ratings yet

- ALJ - ALS BA e 0722Document59 pagesALJ - ALS BA e 0722dexterpoliNo ratings yet

- DX DiagDocument30 pagesDX Diagshinichi kudoNo ratings yet

- WWW - MINEPORTAL.in: Online Test Series ForDocument6 pagesWWW - MINEPORTAL.in: Online Test Series ForAjeet KumarNo ratings yet

- Technical Brief - IP RatingsDocument2 pagesTechnical Brief - IP Ratingscool_rdNo ratings yet

- IDIPSYDocument22 pagesIDIPSYMd FaheemNo ratings yet

- 1 9780898719451 FMDocument22 pages1 9780898719451 FMtuo.liu.geophysicsNo ratings yet

- 140344Document125 pages140344Dawit AwashNo ratings yet

- Mashuda 2021 J. Phys. Conf. Ser. 1805 012001Document8 pagesMashuda 2021 J. Phys. Conf. Ser. 1805 012001Jose FilhoNo ratings yet

- Decision-Making May Be Defined As The Process of Defining The Problem and Identifying and ChoosingDocument5 pagesDecision-Making May Be Defined As The Process of Defining The Problem and Identifying and ChoosingThe PsychoNo ratings yet

- Z Rail Junction BoxDocument2 pagesZ Rail Junction BoxWenceslao CaminosNo ratings yet

- SOFTWARE Upgrade Method FOR 55591PZ - VJD46 - VJD55Document4 pagesSOFTWARE Upgrade Method FOR 55591PZ - VJD46 - VJD55Shailesh VajaNo ratings yet

- TM T82 PDFDocument2 pagesTM T82 PDFNtizz ShndrNo ratings yet

- GFHGHGDocument24 pagesGFHGHGTefo SethNo ratings yet

- Flexible Pavement PDFDocument92 pagesFlexible Pavement PDFhasif21100% (1)