Professional Documents

Culture Documents

Appendix G Fan Power Calculator

Appendix G Fan Power Calculator

Uploaded by

U DEEPAKOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appendix G Fan Power Calculator

Appendix G Fan Power Calculator

Uploaded by

U DEEPAKCopyright:

Available Formats

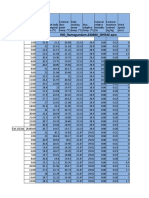

ASHRAE 90.

1-2016 Baseline Fan Power Calculator

Residential Fans (Systems 1 - 2)

Baseline Supply

AHU Name Airflow (CFMS) Pfan (watts) W/cfm

0.0 #DIV/0!

0.0 #DIV/0!

0.0 #DIV/0!

0.0 #DIV/0!

0.0 #DIV/0!

Heated Only Fans (Systems 9 - 10)

Baseline Non- Non-

Mechanical Mechanical

Baseline Supply Supply Fan Pfan Supply Fan Cooling Airflow Cooling Fan Supply Fan

AHU Name Airflow (CFMS) (watts) W/cfm (CFMnmc) Pfan (watts) W/cfm

0.0 #DIV/0! 0.0 #DIV/0!

0.0 #DIV/0! 0.0 #DIV/0!

0.0 #DIV/0! 0.0 #DIV/0!

0.0 #DIV/0! 0.0 #DIV/0!

0.0 #DIV/0! 0.0 #DIV/0!

Nonresidential Constant Volume Fans (Systems 3 - 4, 12 - 13)

Table 6.5.3.1-2

Pressure Drop Design Airflow Table G3.9.1

Baseline Supply Adjustment Through Device Fan Motor

AHU Name Airflow (CFMS) (PD) (CFMD) A bhp Efficiency Pfan (watts) W/cfm

0.0000 0.00 82.5% 0.0 #DIV/0!

0.0000 0.00 82.5% 0.0 #DIV/0!

0.0000 0.00 82.5% 0.0 #DIV/0!

0.0000 0.00 82.5% 0.0 #DIV/0!

0.0000 0.00 82.5% 0.0 #DIV/0!

Nonresidential Variable Volume Fans (Systems 5 - 8)

Table 6.5.3.1-2

Pressure Drop Design Airflow Table G3.9.1

Baseline Supply Adjustment Through Device Fan Motor

AHU Name Airflow (CFMS) (PD) (CFMD) A bhp Efficiency Pfan (watts) W/cfm

0.0000 0.00 82.5% 0.0 #DIV/0!

0.0000 0.00 82.5% 0.0 #DIV/0!

0.0000 0.00 82.5% 0.0 #DIV/0!

0.0000 0.00 82.5% 0.0 #DIV/0!

0.0000 0.00 82.5% 0.0 #DIV/0!

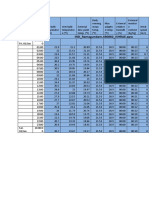

Computer Room Variable Volume Fans (System 11)

Table 6.5.3.1-2

Pressure Drop Design Airflow Table G3.9.1

Baseline Supply Adjustment Through Device Fan Motor

AHU Name Airflow (CFMS) (PD) (CFMD) A bhp Efficiency Pfan (watts) W/cfm

0.0000 0.00 82.5% 0.0 #DIV/0!

0.0000 0.00 82.5% 0.0 #DIV/0!

0.0000 0.00 82.5% 0.0 #DIV/0!

0.0000 0.00 82.5% 0.0 #DIV/0!

0.0000 0.00 82.5% 0.0 #DIV/0!

Table 6.5.3.1-2 Fan Power Limitation Pressure Drop Adjustment

Device Adjustment

Credits

Return or exhaust systems required by code or accreditation 0.5 in. w.c. (2.15 in. w.c. for laboratory and vivarium systems)

standards to be fully ducted, or systems required to maintain air

pressure differentials between adjacent rooms

Return and/or exhaust airflow control devices 0.5 in. w.c.

Exhaust filters, scrubbers, or other exhaust treatment The pressure drop of device calculated at fan system design condition

Particulate Filtration Credit: MERV 9-12 0.5 in. w.c.

Particulate Filtration Credit: MERV 13-15 0.9 in. w.c.

Particulate Filtration Credit: MERV 16 and greater Pressure drop calculated at 2x clean filter pressure drop at

and electronically enhanced filters fan system design condition

Carbon and other gas-phase air cleaners Clean filter pressure drop at fan system design condition

Biosafety cabinet Pressure drop of device at fan system design condition

Energy recovery device, other than coil runaround loop For each airstream [(2.2 x Enthalpy Recovery Ratio) - 0.5] in. w.c.

Coil Runaround Loop 0.6 in. w.c. for each airstream

Evaporative humidifier/cooler in series with another cooling coil Pressure drop of device at fan system design condition

Sound Attenuation Section (fans serving spaces with design 0.15 in. w.c.

background noise goals below NC35)

Exhaust system serving fume hoods 0.35 in. w.c.

Laboratory and vivarium exhaust systems in high-rise buildings 0.25 in. w.c./100 ft of vertical duct exceeding 75 ft

Deductions

Systems without central cooling device -0.6 in. w.c.

Systems without central heating device -0.3 in. w.c.

Systems with central electric resistance heat -0.2 in. w.c.

You might also like

- Automotive Sensor Testing and Waveform AnalysisFrom EverandAutomotive Sensor Testing and Waveform AnalysisRating: 4.5 out of 5 stars4.5/5 (13)

- Process Engineer - Blowdown Valve (BDV) To Flare SystemDocument2 pagesProcess Engineer - Blowdown Valve (BDV) To Flare Systemkenoly123No ratings yet

- 02 Cooling Load Calculation - HAPDocument2 pages02 Cooling Load Calculation - HAPU DEEPAKNo ratings yet

- Rexroth and Atos Valve CompareDocument7 pagesRexroth and Atos Valve Compareback1949No ratings yet

- Marketing Plan (Pizza Hut)Document13 pagesMarketing Plan (Pizza Hut)Anjali10183% (48)

- Steam - Pipe Pressure Drop - From MyChemEDocument11 pagesSteam - Pipe Pressure Drop - From MyChemEkomalrana2007No ratings yet

- MCSet Instruction Manual SchneiderDocument46 pagesMCSet Instruction Manual SchneiderAceel Fitch100% (4)

- Module 1 - Universities and National DevelopmentDocument13 pagesModule 1 - Universities and National DevelopmentTOBI JASPER WANGNo ratings yet

- Supplement - 746026 Rev ACDocument38 pagesSupplement - 746026 Rev ACSvilen PopovNo ratings yet

- Risk Assessment - Installation T&C of Sprinkler SystemDocument12 pagesRisk Assessment - Installation T&C of Sprinkler Systembeho2000No ratings yet

- KP Astrology Shortcut MethodDocument3 pagesKP Astrology Shortcut MethodRaman Sharma100% (2)

- Kubota KX016 4 ENDocument8 pagesKubota KX016 4 ENli longNo ratings yet

- Historical Dictionary of The Philippines 2nd Edition PDFDocument617 pagesHistorical Dictionary of The Philippines 2nd Edition PDFYu Ho100% (2)

- 20.AW .YDVT3 .R410A.SM .EN .05.16.rev01 5Document184 pages20.AW .YDVT3 .R410A.SM .EN .05.16.rev01 5ชวลิตศ์ จิตรเที่ยงNo ratings yet

- Appendix G Fan Power CalculatorDocument3 pagesAppendix G Fan Power CalculatorU DEEPAKNo ratings yet

- HVAC System Cooling Efficiency CalculatorDocument8 pagesHVAC System Cooling Efficiency CalculatorImran AzizNo ratings yet

- Online Calculae SP Wizards - Resources - SFADocument1 pageOnline Calculae SP Wizards - Resources - SFAUmer HanifNo ratings yet

- Constant Velocity Duct DesignDocument5 pagesConstant Velocity Duct DesignJojolasNo ratings yet

- Air Filter Comparison Tool 4 0Document4 pagesAir Filter Comparison Tool 4 0Speedster ExhaltedNo ratings yet

- b20 Blower EnergyDocument22 pagesb20 Blower Energyaziz_priambodoNo ratings yet

- PRODUCT UV-Vis TEMPLATE v.1.2Document798 pagesPRODUCT UV-Vis TEMPLATE v.1.2JavierNo ratings yet

- Ventilator SimulationDocument9 pagesVentilator SimulationItalo Edward Vasquez VargasNo ratings yet

- NPT19 Ratings & Insulation SystemsDocument9 pagesNPT19 Ratings & Insulation Systemsengmohsen.ramadanhotmail.comNo ratings yet

- Chrysam Rev: Residential / Domestic FansDocument6 pagesChrysam Rev: Residential / Domestic FansKSBNo ratings yet

- Wfs 1001Document2 pagesWfs 1001dwi handzNo ratings yet

- 9 Fan TypeDocument1 page9 Fan TypepotatoNo ratings yet

- 140mm - 120mm - 92mm - 80mm 140mm High-Speed - 120mm High-SpeedDocument2 pages140mm - 120mm - 92mm - 80mm 140mm High-Speed - 120mm High-SpeedMarkNo ratings yet

- TUTORIAL DEPRESSURING First (Compatibility Mode)Document26 pagesTUTORIAL DEPRESSURING First (Compatibility Mode)ThamotharanNo ratings yet

- Zehnder CSY Produktdatenblatt Climos 200 Enthalpie (V) CER SI enDocument1 pageZehnder CSY Produktdatenblatt Climos 200 Enthalpie (V) CER SI enAntoNo ratings yet

- F-2000 Model RT: Blue-WhiteDocument22 pagesF-2000 Model RT: Blue-WhiteElber TousNo ratings yet

- 140mm - 120mm - 92mm - 80mm: Highlights Ideal ForDocument2 pages140mm - 120mm - 92mm - 80mm: Highlights Ideal ForBryan PittmanNo ratings yet

- APD72-D Automatic Dehydrator, 0.58 SCFM, 230V AC 50/60 HZDocument2 pagesAPD72-D Automatic Dehydrator, 0.58 SCFM, 230V AC 50/60 HZTrina Ritchell AquinoNo ratings yet

- GEH Service 09 12 18Document98 pagesGEH Service 09 12 18Ivan IvanovNo ratings yet

- DDFC Boiler Effeciency AnalysisDocument21 pagesDDFC Boiler Effeciency AnalysisPublic DemandNo ratings yet

- c200321 (WRFC E)Document2 pagesc200321 (WRFC E)María MarquinaNo ratings yet

- ADDA - 04222021 - AD0412HB - C50 - T1-2303238 Ventiladores de Funete de VSD SAGDocument10 pagesADDA - 04222021 - AD0412HB - C50 - T1-2303238 Ventiladores de Funete de VSD SAGquintanacalzadillasjaimeNo ratings yet

- Light Wings Datasheet enDocument2 pagesLight Wings Datasheet enD. BinaryNo ratings yet

- Katalog Mitsubishi ElectricDocument8 pagesKatalog Mitsubishi ElectricRian HeriawanNo ratings yet

- VO1 - Crockfort Stage Lift - Rev 01 - Claim Submission No 01 - Details Claim VO 01Document2 pagesVO1 - Crockfort Stage Lift - Rev 01 - Claim Submission No 01 - Details Claim VO 01Norita AmeruddinNo ratings yet

- Ieee Mke 1 2020Document61 pagesIeee Mke 1 2020BokeBoke GyiNo ratings yet

- Hiwall Single Split Type Specifications: RAS-10S3KHS-V RAS-13S3KHS-V RAS-18S3KHS-V RAS-24S3KHS-VDocument1 pageHiwall Single Split Type Specifications: RAS-10S3KHS-V RAS-13S3KHS-V RAS-18S3KHS-V RAS-24S3KHS-VKhánh Nguyễn MinhNo ratings yet

- FXMQ-AFVM Ducted Fresh AirDocument8 pagesFXMQ-AFVM Ducted Fresh AirAshraf SialNo ratings yet

- XC80 Service FactsDocument50 pagesXC80 Service FactschrideerNo ratings yet

- Dimensionamentos - Corrente AlternadaDocument31 pagesDimensionamentos - Corrente AlternadaJoão LucasNo ratings yet

- Product Comparison LCC CO2Document6 pagesProduct Comparison LCC CO2needatamboli2926No ratings yet

- Off-Grid Energy UseDocument4 pagesOff-Grid Energy UseDaniel PachecoNo ratings yet

- VSD Datasheet10-11 Rev7Document1 pageVSD Datasheet10-11 Rev7acildeNo ratings yet

- Drystar Edp80 SeriesDocument82 pagesDrystar Edp80 SeriesManoj BNo ratings yet

- Hitachi DC Inverter Duct Ed Spec SheetDocument2 pagesHitachi DC Inverter Duct Ed Spec SheetDavidRobertsonNo ratings yet

- Memoria de Agua PotableDocument11 pagesMemoria de Agua PotableBenito Antonio ANo ratings yet

- Carel Temperature and Humiditify Sensors PDFDocument1 pageCarel Temperature and Humiditify Sensors PDFElşən Yusifoğlu ƏsgərovNo ratings yet

- 2.1 WDHT-CN100.1 Chiller ClivetDocument6 pages2.1 WDHT-CN100.1 Chiller ClivetTony NguyenNo ratings yet

- Tune Report: Count Check Count Unit Category MassDocument3 pagesTune Report: Count Check Count Unit Category MassMarco Villacorta SayreNo ratings yet

- CAIR Motorised ValveDocument4 pagesCAIR Motorised ValveRajeshNo ratings yet

- Apax 502820160920114938Document1 pageApax 502820160920114938Samdan NamhaisurenNo ratings yet

- 13-2-2020revised Screw chiller-1502KWDocument4 pages13-2-2020revised Screw chiller-1502KWthilina lakhithaNo ratings yet

- 01 Jan 2011-Fleet Compliance Summary - TrainingDocument5 pages01 Jan 2011-Fleet Compliance Summary - TrainingChristopher MeyersNo ratings yet

- DED Workshop File NC1 JipapadDocument55 pagesDED Workshop File NC1 JipapadJohn Mark GlobioNo ratings yet

- CRE-DP PumpDocument2 pagesCRE-DP PumpTimNo ratings yet

- MPC PDocument1 pageMPC PPrasad BangaruNo ratings yet

- BQ BXCDocument7 pagesBQ BXCAzazel LuciferNo ratings yet

- BITZER Output Data: Created On: 07.05.2024 09:50:25Document9 pagesBITZER Output Data: Created On: 07.05.2024 09:50:25Elvis Nilton Mires RojasNo ratings yet

- Vertical Multistage: Avm, Avmf SeriesDocument27 pagesVertical Multistage: Avm, Avmf SeriesAnantha MNo ratings yet

- IMax Leaflet Grey W PDocument2 pagesIMax Leaflet Grey W PDONGTA123No ratings yet

- Apax 5017HDocument1 pageApax 5017HSamdan NamhaisurenNo ratings yet

- ABB Component Drives ABB General Machinery Drives: ACS150 Replaces ACS140 ACS350 Replaces ACS140 Replacement GuideDocument12 pagesABB Component Drives ABB General Machinery Drives: ACS150 Replaces ACS140 ACS350 Replaces ACS140 Replacement GuideKichin_ANo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Training PDFDocument1 pageTraining PDFU DEEPAKNo ratings yet

- Building Envelope CommissioningDocument9 pagesBuilding Envelope CommissioningU DEEPAKNo ratings yet

- Model Data Cooling Calculation DataDocument10 pagesModel Data Cooling Calculation DataU DEEPAKNo ratings yet

- Model Data Cooling Calculation DataDocument5 pagesModel Data Cooling Calculation DataU DEEPAKNo ratings yet

- Category: Energy Analyst: Sample Question PaperDocument3 pagesCategory: Energy Analyst: Sample Question PaperU DEEPAKNo ratings yet

- Bangalore Climate DataDocument390 pagesBangalore Climate DataU DEEPAKNo ratings yet

- Temp Diff in RoomsDocument1 pageTemp Diff in RoomsU DEEPAKNo ratings yet

- Sources of Commentary MaterialsDocument22 pagesSources of Commentary MaterialsMary Cherill UmaliNo ratings yet

- Iaetsd-Jaras-Conference Room Booking System Across Multiple Ministriesdepartment in Different BuildingsDocument3 pagesIaetsd-Jaras-Conference Room Booking System Across Multiple Ministriesdepartment in Different BuildingsiaetsdiaetsdNo ratings yet

- EagleBurgmann - E110801 - E1 - High-Pressure Seals For ESPO Pipeline Pumps - 10.11 PDFDocument2 pagesEagleBurgmann - E110801 - E1 - High-Pressure Seals For ESPO Pipeline Pumps - 10.11 PDFkztro066No ratings yet

- Steel Grade: Material Data SheetDocument6 pagesSteel Grade: Material Data SheetFlorinFlorinNo ratings yet

- Annotated BibliographyDocument2 pagesAnnotated BibliographyAshley schewagaNo ratings yet

- Lori Hurley Resume 1-14Document2 pagesLori Hurley Resume 1-14api-224457575No ratings yet

- Preparation of Financial StatementsDocument8 pagesPreparation of Financial Statementsvanessa022799No ratings yet

- Unit 1Document69 pagesUnit 1Harshit AgrawalNo ratings yet

- Vibration of Cooling Tower Fans 2015, Part 1Document7 pagesVibration of Cooling Tower Fans 2015, Part 1Sarawuru LohanNo ratings yet

- 1999 MullenDocument6 pages1999 MullenElisaMiNo ratings yet

- Kształtowniki Giete: Poradnik Projektanta: January 2006Document7 pagesKształtowniki Giete: Poradnik Projektanta: January 2006Maciej GajdaNo ratings yet

- Ssi Report 50-2Document18 pagesSsi Report 50-2Shubham MauryaNo ratings yet

- Chapter 1Document159 pagesChapter 1Adam M KumNo ratings yet

- AlliedCrowds November 2015 ReportDocument7 pagesAlliedCrowds November 2015 ReportCrowdfundInsiderNo ratings yet

- Different Levels of Management in The Form of A Pyramid: Top-Level MangersDocument3 pagesDifferent Levels of Management in The Form of A Pyramid: Top-Level Mangerssalmaan khawerNo ratings yet

- Types of GroupsDocument380 pagesTypes of GroupsCCNo ratings yet

- 01 Measurements - Practice 1Document3 pages01 Measurements - Practice 1Muhammad SamhanNo ratings yet

- Repurposed Research ProjectDocument8 pagesRepurposed Research Projectapi-330705723No ratings yet

- Ewens-Bassett Notation Inorganic Compounds - KauffmanDocument3 pagesEwens-Bassett Notation Inorganic Compounds - KauffmanJuano Valls FerrerNo ratings yet

- Analytical Method Development by High Performance Liquid ChromatographyDocument9 pagesAnalytical Method Development by High Performance Liquid ChromatographyEditor IJTSRDNo ratings yet

- Lli Ip: Downloaded From Manuals Search EngineDocument144 pagesLli Ip: Downloaded From Manuals Search EngineEduardo ArrietaNo ratings yet

- Operation Manual: KQWS-2800-R306Document16 pagesOperation Manual: KQWS-2800-R306Wilman OngNo ratings yet

- Aspirant Evaluation FormDocument2 pagesAspirant Evaluation FormhurshawNo ratings yet