Professional Documents

Culture Documents

Well Design - 2D: Process Flowchart

Uploaded by

Slim.BOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Well Design - 2D: Process Flowchart

Uploaded by

Slim.BCopyright:

Available Formats

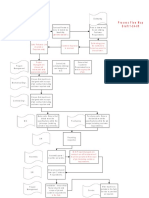

Well Design – 2D

ENM210 Drilling Technology

© The Robert Gordon University 2006 1

Process flowchart

C e m e n t in g

C e m e n t in g p ro g ra m m e

Th is p h a s e o f t h e D e s ig n

Obta in spa c ia l p ro c e s s is d a t a

da ta for fie ld D a t a t r a n s f e r p ro c e d u r e Input & a c q u is it io n a n d G e t s p e c ia lis t

va lida te da ta v a lid a t io n f ro m t h e S e le c t TO C f o r c o n t ra c t o r t o

c lie n t . Th e re m u s t e a c h h o le f o rm u la t e

se ts b e a r e c o rd re c ip e s

s e c t io n f r o m

m a in t a in e d o f t h is L O F b a s is

Obta in lithology, t ra n s f e rt o D e t e rm in e

S c h lu m b e r g e r v o lu m e s p re f lu s h ,

fra c ture a nd C o m p le t e d W e ll

D a t a t ra n s f e r p ro c e d u re Input & D e t e rm in e TO TC s p a c e ra n d

pore pre ssure D e s ig n f o r is o la t io n c em ents then

da ta va lida te da ta

p u rp o s e s p ro d u c e p u m p in g

se ts s c h e d u le

Y es

Obta in w e ll

re quire me nts D a t a t r a n s f e r p ro c e d u r e D rillin g D rills t rin g

Input & T& D , C a s in g W e a r a n d sy stem and BH A

va lida te H y d ra u lic s t u d y O K ? d e s ig n

S e le c t b it a n d B it / B H A s t ra t e g y

No

sy stem w it h d rills t rin g

c o m b in a t io n

T h e re m u s t b e d e s ig n D e s ig n B H A

s t a n d a rd s f o r: S u rv e y d e t a ils t o g iv e D e s ig n D r ills t r in g

D e s ig n T ra je c t o ry

C onduc tor P ro g ra m m e r e q u ire d D L S

C a s in g D e s ig n

S u r f a c e C a s in g D e s ig n

I n t e rm e d ia t e C a s in g s Y es

No P ro d u c t io n C a s in g

P ro d u c t io n L in e r s

P re s s u re S e le c t H o le S u rf a c e

S ize s t o Y es

c o n t a in m e n t ? N o C o llis io n R is k ?

d e liv e r C a s in g

D e s ig n No No

Y es D r illin g F lu id

C an

No b e t t e r S u rv e y

W e ll lif e P ro g ra m m e

D e t e rm in e p ro f ile

c o n s id e ra t io n s ? r e m o v e ris k ?

c o n s t ra in t s : MW and

s u rf a c e C o n f irm F r ic t io n

A re

re s e rv o ir le g is la t io n F a c t o rs

a ll w e ll p o s it io n a l

Y es w e llb o re s t a b ilit y re q u ire m e n t s re q u ire m e n t s

m et?

Tra je c t o ry S e le c t M W

D e s ig n W e ll P la n D rillin g F lu id

W e ll d rillin g p la n f ro m p o r e

W e ll P lo t s p ro g ra m m e

p re s s u re a n d

w e llb o r e s t a b ilit y

© The Robert Gordon University 2006 2

Casing

• Good indication of

competent formations

• Hard enough to allow

deflection of the

drilling tools

• Good estimate of the

speed at which the

borehole can be

deflected

© The Robert Gordon University 2006 3

Segments of a deviated well

• Rig Floor • Hold Section

– Datum for all MD’s – No inclination variation

• Well Reference Pt • DoP / 2nd KoP

– Normally vertically below – S wells

rig • EoD / Eo2ndB

• KoP – Amount of curved section

– Amount drilled from WRP • Target

to get competent formation

– Geological formation

• EoB

• Total Depth

– Curved section to get

– Reservoir exposure to get

• Tangent angle production

© The Robert Gordon University 2006 4

Well Types

• Vertical

0

0 Tie-In 0

Seabed

– Design

1000 1000

2000 2000

• 0º inclination, azimuth

does not matter

3000 3000

– Regular drilled

4000 4000

5000 5000

• > 0º inclination, azimuth

TVD Scale = 1(in):1426.84(ft)

does matter

6000 6000

-400 -200 0 200

– Control drilled

7000 7000

400 400

<<< S Scale = 1(in):300(ft) N >>>

8000 8000

• Depends on the control 200

Tie-In

200

9000 9000

• Can still end up with

RGU_C01

KOP RGU_C01

v1.00

0 0

inclination variation

Seabed

10000 10000

• Could be truly vertical

11000 RGU_C01 RGU_C01 11000 -200 -200

KOP v1.00

12000 12000

-400 -200 0 200

0

Vertical Section (ft) Azim = 0°, Scale = 1(in):1426.84(ft) Origin = 0 N/-S, 0 E/-W <<< W Scale = 1(in):300(ft) E >>>

© The Robert Gordon University 2006 5

Well Types

• J-shaped

-14000 -12000 -10000 -8000 -6000 -4000 -2000 0

Tie-In

0 seabed

0

KOP

– Design

• Build angle2000from a point of 2000

0º inclination along a

curve of a designed radius

4000 4000

on a fixed heading until an EOC (Curve-Hold)

angle is obtained, which,

when maintained

6000 will 6000

intercept a ‘target’ point 0

-10000 -8000 -6000 -4000 -2000 0

0

Keabed

Tie-In

sOP

– Regular drilled variations

8000

-2000

EOC(Curve-Hold)

8000

-2000

• Rate of change of angle -4000 -4000

• Inclinations10000 RGU_SW3

td

-6000

10000

-6000

RGU_SW3

• Azimuths v1.00

-8000 -8000

-14000 -12000 -10000 -8000 -6000 -4000 -2000 0

– Control drilled -10000 -10000

• Better control of variations

RGU_SW3

v1.00 RGU_SW3

td

-10000 -8000 -6000 -4000 -2000 0

© The Robert Gordon University 2006 6

Well Types -7000 -6000 -5000 -4000 -3000 -2000 -1000 0

• S-shaped 0 Tie-In

seabed

KOP

0

– Design 1000 1000

• Build angle from a point of 0º 2000 2000

inclination along a curve of a

designed radius on a fixed 3000

EOC #1 (3D-S)

3000

heading until an angle is

obtained, which, when 4000 4000

maintained will intercept a 5000 5000

secondary curve towards a

‘target’ point and thereafter 6000 6000

intercept the target at a -5000 -4000 -3000 -2000 -1000 0

known inclination and azimuth 7000

RGU_

v1.00 NW5

RGU_NW5 7000

– Regular drilled variations

5000 td 5000

8000 KOP #2 8000

• Rate of change of angle 4000 4000

9000 9000

• Inclinations KOP #2 3000 3000

• Azimuths 10000

2000

10000

2000

– Control drilled 11000

RGU_NW5 1000

11000

1000

• Better control of variations td

RGU_NW5

v1.00

EOC #1 (3D-S)

12000 0 12000 0

sea

Tie

Kbed

OP

-In

-7000 -6000 -5000 -4000 -3000 -2000 -1000 0

-5000 -4000 -3000 -2000 -1000 0

© The Robert Gordon University 2006 7

What’s best..?

• ∞ number of

possibilities

0

200

• Has to be engineered

400 correctly

600

– Mechanical stresses

800

1000

– Hydraulic limitations

1200 • Minimising time

• Maximising

1400

1600

1800

performance

2d-10deg 2d-30deg 2d-45deg 2d-60deg 2d-75deg 2d-90deg

0 200 400 600 800 1000 1200 1400 1600 1800 2000 2200

© The Robert Gordon University 2006 8

Circular Functions

• An arc of a circle is a

segment of the circumference

of the circle.

• Arc length of a circle in

radians = θr

• Arc length of a circle in

degrees = θ π r / 180

© The Robert Gordon University 2006

Circular Functions

Arc AB = 2πR x a/360°

= πR x a/180°

If R = 15m and

a = 60°

C = 2πR

= 2π(15) = 94.2m

Arc AB = π R x a/180

= π(15)(60)/180

= 15.7m

© The Robert Gordon University 2006 10

Build up Rate formula

Ra = Radius in Feet or Meters

BUR is usually in: °/100ft or °/ 30m

a) English units:

BUR = 57.29580 x 100/ Radius (ft)

BUR = 5729.580/ Radius (ft)

Radius (ft) = 5729.580/BUR

b) Metric unit:

BUR = 57.29580 x 30/ Radius (m)

BUR = 1718.870/ R(m)

Radius (m) = 1718.870/BUR

BUR = 5729.58/ ΔTVD

or

BUR = 5729.58/ ΔHD

© The Robert Gordon University 2006

Radius of Curvature

C = 2πRc

= 360 x 100 / BUR

BUR = 360 x 100 / 2πRc in °/100 ft

Rc = 18000 / πBUR in feet

TVD1 = Rc × sinI1

TVD2 = Rc × sinI2

ΔTVD = TVD2 - TVD1

= Rc ( sinl2 - sinI1)

ΔTVD = 5729.58( sinl2 - sinI1)/BUR

© The Robert Gordon University 2006 12

Radius of Curvature

HD1 = Rc - Rc × cosI1

= Rc (1 - cosI1)

HD2 = Rc - Rc × cosI2

= Rc (1 - cosI2)

ΔHD = HD2 - HD1

= Rc (cos I1 - cosI2)

ΔHD = 5729.58(cos I1 - cosI2)/BUR

ΔMD = πRc × (I2 – I1)/360 = length of the arc (ft)

ΔMD = (I2 – I1) x 100/BUR

© The Robert Gordon University 2006 13

Fundamentals

400

500

ΔTVD 400 500

ΔHD

400 500

900 500

200

ΔTVD

90 0

ΔHD

200

© The Robert Gordon University 2006

Determine End of Build

KOP TVD Build Radius

∅

∅ = 500

ΔTVD

EOB TVD = KOP (TVD) +

EOB 900

ΔHD ΔTVD

© The Robert Gordon University 2006

Slant (departure > R)

• Given:

– Wellhead coordinates

– Target coordinates

– Target TVD, V3

• To determine:

– KOP vertical depth, V1

– Build up rate, BUR

– KOP Kick-off point.

– V1 TVD of straight section/surface to

KOP.

– V2 TVD of end of build up.

– V2 - V1 TVD of Build up section with

BUR corresponding to radius of

curvature R.

– V3 - V2 TVD of Tangent section to

total depth.

– D1 Displacement at end of build up.

– D2 Total horizontal displacement of

target.

– Ǿ Maximum inclination of well.

© The Robert Gordon University 2006 16

Slant (R > departure)

• Given:

– Wellhead coordinates

– Target coordinates

– Target TVD, V3

• To determine:

– KOP vertical depth, V1

– Build up rate, BUR

– KOP Kick-off point.

– V1 TVD of straight section/surface to

KOP.

– V2 TVD of end of build up.

– V2 -V1 TVD of Build up section with BUR

corresponding to radius of

– curvature R.

– V3 - V2 TVD of Tangent section to total

depth.

– D1 Displacement at end of build up.

– D2 Total horizontal displacement of target.

– Ǿ Maximum inclination of well.

© The Robert Gordon University 2006 17

S-shaped (R1 + R2) < total target displacement

• Given:

– Wellhead coordinates

– Target coordinates

– Target TVD, V5

• To determine:

– KOP vertical depth, V1

– Build up rate, BUR

– Drop off rate, DOR

– Vertical depth at end of drop, V4

– KOP Kick-off point.

– V1 TVD of straight section/surface to KOP.

– V2 TVD of end of build up.

– V3 TVD of start of drop.

– V4 TVD of end of drop.

– V2 - V1 TVD of Build up section with BUR

corresponding to radius of curvature R1.

– V3 - V2 TVD of Tangent section.

– V4 - V3 TVD of drop section

– D1 Displacement at end of build up.

– D2 Displacement at end of tangent

– D3 Total horizontal displacement of target.

– Ǿ Maximum inclination of well.

© The Robert Gordon University 2006 18

S-shaped (R1 + R2) > total target displacement

• Given:

– Wellhead coordinates

– Target coordinates

– Target TVD, V5

• To determine:

– KOP vertical depth, V1

– Build up rate, BUR

– Drop off rate, DOR

– Vertical depth at end of drop, V4

– KOP Kick-off point.

– V1 VD of straight section/surface to KOP.

– V2 VD of end of build up.

– V3 VD of start of drop.

– V4 VD of end of drop.

– V2 - V1 TVD of Build up section with BUR

corresponding to radius of curvature R1.

– V3 -V2 TVD of Tangent section.

– V4 -V3 TVD of drop section.

– D1 Displacement at end of build up.

– D2 Displacement at end of tangent.

– D3 Total horizontal displacement of target.

– Ǿ Maximum inclination of well.

© The Robert Gordon University 2006 19

Manual Profile Design

© The Robert Gordon University 2006 20

Manual Profile Design

© The Robert Gordon University 2006 21

End of Module

© The Robert Gordon University 2006 22

You might also like

- Lilavat AR GH SC: Ibaipod HI Hool ISCDocument4 pagesLilavat AR GH SC: Ibaipod HI Hool ISCPrakash KapadiaNo ratings yet

- LAW ConsiderationandIntentionDocument1 pageLAW ConsiderationandIntentionYing FerngNo ratings yet

- Process Map 1-24-05Document1 pageProcess Map 1-24-05Giang LuuNo ratings yet

- Requirements estimating process flowDocument1 pageRequirements estimating process flowЕлена КоваленкоNo ratings yet

- Q Q M Indz: BossesliseDocument13 pagesQ Q M Indz: BosseslisePranav MishraNo ratings yet

- RC Construction and Structural SteelworkDocument7 pagesRC Construction and Structural SteelworkBharath AkurathiNo ratings yet

- Ilovepdf MergedDocument8 pagesIlovepdf Mergedbrajeshpandey25No ratings yet

- This Study Resource Was: General Chemistry E 1 F 1 2 N All Work Must Be Sho V IDocument4 pagesThis Study Resource Was: General Chemistry E 1 F 1 2 N All Work Must Be Sho V ISmartunblurrNo ratings yet

- Tploı L: Tablea 10 Oh T LL FR D WDocument9 pagesTploı L: Tablea 10 Oh T LL FR D WNuyul FaizahNo ratings yet

- ThomasDeloney 10230560Document250 pagesThomasDeloney 10230560Nicizak masudaNo ratings yet

- Art 35a J&KDocument2 pagesArt 35a J&KNareshNo ratings yet

- TheDoctrineandLiteratureoftheKabalah 10007220Document534 pagesTheDoctrineandLiteratureoftheKabalah 10007220jurebieNo ratings yet

- Allen Test Papers MainsDocument72 pagesAllen Test Papers MainsSridhar CheeraNo ratings yet

- LAW VfactorsDocument1 pageLAW VfactorsYing FerngNo ratings yet

- LAW VfactorsDocument1 pageLAW VfactorsYing FerngNo ratings yet

- LAW VfactorsDocument1 pageLAW VfactorsYing FerngNo ratings yet

- General Shareholder's Assembly Org ChartDocument1 pageGeneral Shareholder's Assembly Org ChartMihaela PaduraruNo ratings yet

- GlucosamineDocument3 pagesGlucosaminedhanNo ratings yet

- Chapter 12 Inventory and Production Cycle: Learning ObjectivesDocument16 pagesChapter 12 Inventory and Production Cycle: Learning ObjectivesKelvin LeongNo ratings yet

- Chapter 12 Inventory and Production Cycle: Learning ObjectivesDocument16 pagesChapter 12 Inventory and Production Cycle: Learning ObjectivesCastleclash CastleclashNo ratings yet

- TarunDocument1 pageTarunDivyanshu LalNo ratings yet

- CPT 205 - Tutorial 5Document3 pagesCPT 205 - Tutorial 5Nishfaan NaseerNo ratings yet

- Applet Life CycleDocument3 pagesApplet Life CycleshyamNo ratings yet

- Chapter 10 Cash and Funding Strategies: Learning ObjectivesDocument38 pagesChapter 10 Cash and Funding Strategies: Learning ObjectivesZahid UsmanNo ratings yet

- 2013Document5 pages2013abC AdobeNo ratings yet

- Question PDFDocument38 pagesQuestion PDFRoshan ShresthaNo ratings yet

- BlowholesPorosityandUnsoundnessinAluminumAlloyCastings 10581553Document43 pagesBlowholesPorosityandUnsoundnessinAluminumAlloyCastings 10581553shivkeshNo ratings yet

- Modern English GrammarDocument371 pagesModern English GrammarvijayNo ratings yet

- ATreatiseontheMathematicalTheoryoftheMotionofFluids 10030931Document269 pagesATreatiseontheMathematicalTheoryoftheMotionofFluids 10030931jurebieNo ratings yet

- CAPE Caribbean Studies Solutions 2005Document15 pagesCAPE Caribbean Studies Solutions 2005timahNo ratings yet

- Clinical features of dermatophytosisDocument7 pagesClinical features of dermatophytosisrhlzuraNo ratings yet

- Export Clearance Flow ChartDocument2 pagesExport Clearance Flow ChartMuthu KrishnanNo ratings yet

- Building Software Test CompetencyDocument4 pagesBuilding Software Test Competencykishore75No ratings yet

- Doc4 Website GameDocument1 pageDoc4 Website GameLo Long YinNo ratings yet

- Torsion of Prismatic BarsDocument56 pagesTorsion of Prismatic BarsHasiniNo ratings yet

- General-Music Realpiano Rp1Document8 pagesGeneral-Music Realpiano Rp1Sébastien SAMIEZNo ratings yet

- PracticalSheetandPlateMetalWork_10278879Document553 pagesPracticalSheetandPlateMetalWork_10278879Phillip JuanNo ratings yet

- Msts FeedbacksDocument4 pagesMsts Feedbacksapi-339115602No ratings yet

- 5S workplace organization systemDocument1 page5S workplace organization systemallanjulesNo ratings yet

- ATranscriptoftheRegistersoftheWorshipfulCompanyofStationers 10249393Document497 pagesATranscriptoftheRegistersoftheWorshipfulCompanyofStationers 10249393Carlos Pérez SeguraNo ratings yet

- T Ojjjg B&Chddorcjqd甲 /: G A Knowl Dge Paper IiiDocument23 pagesT Ojjjg B&Chddorcjqd甲 /: G A Knowl Dge Paper IiiVishal BantiNo ratings yet

- RE Tutorial 4Document2 pagesRE Tutorial 4Gin ManNo ratings yet

- Introduction Mathematical Portfolio TheoDocument159 pagesIntroduction Mathematical Portfolio Theojmgnsa5405No ratings yet

- The Business of the TheatreDocument110 pagesThe Business of the TheatreFlavia BorbasNo ratings yet

- GMP of NutraceuticalsDocument6 pagesGMP of Nutraceuticalsliakot prantoNo ratings yet

- Our Place in The SunDocument16 pagesOur Place in The SunAlexa Bulayungan FontanillaNo ratings yet

- Impact 3 Student S BookDocument163 pagesImpact 3 Student S BookTanyaNo ratings yet

- Mapa ConceptualDocument1 pageMapa ConceptualRAFAELNo ratings yet

- General Music Service Manual IndexDocument8 pagesGeneral Music Service Manual IndexMeesterNo ratings yet

- Object-oriented programming paradigm questionsDocument18 pagesObject-oriented programming paradigm questionsJatin ThakurNo ratings yet

- PFA Ratrappage 2015Document6 pagesPFA Ratrappage 2015Ez BalehNo ratings yet

- ConstructionAccountingandFinancialManagement - 10015068 344Document1 pageConstructionAccountingandFinancialManagement - 10015068 344VidNo ratings yet

- BCMSN30SG Vol.1Document306 pagesBCMSN30SG Vol.1Gervasio MellinasNo ratings yet

- DifferentialCalculusforBeginners 10004634Document275 pagesDifferentialCalculusforBeginners 10004634Franknire IgNo ratings yet

- Osca AnesthDocument2 pagesOsca AnesthFazil KfNo ratings yet

- EarlyChristianityandPaganism 10150123Document653 pagesEarlyChristianityandPaganism 10150123Túlio Coelho SampaioNo ratings yet

- Fault Tree Analysis-Air BubblesDocument7 pagesFault Tree Analysis-Air BubblesHeart Touching VideosNo ratings yet

- Fault Tree Analysis-Air BubblesDocument7 pagesFault Tree Analysis-Air BubblesHeart Touching VideosNo ratings yet

- Hivern ArroyoDocument1 pageHivern ArroyoCarmen FarromequeNo ratings yet

- All Depths Are Driller's Depth: Job Events SummaryDocument7 pagesAll Depths Are Driller's Depth: Job Events SummarySlim.BNo ratings yet

- Wellbore Seismic ImagingDocument5 pagesWellbore Seismic ImagingselasenuapahNo ratings yet

- Chapter1 PDFDocument7 pagesChapter1 PDFAnditya Sapta RahesthiNo ratings yet

- 13 Mechanical Properties of RocksDocument18 pages13 Mechanical Properties of RocksSlim.BNo ratings yet

- Lithology and Porosity Determination: Mark of SchlumbergerDocument13 pagesLithology and Porosity Determination: Mark of SchlumbergerSlim.B100% (1)

- 3 SP - GR Logs PDFDocument11 pages3 SP - GR Logs PDFSlim.BNo ratings yet

- 5 Porosite Logs PDFDocument24 pages5 Porosite Logs PDFSlim.BNo ratings yet

- Basic Well Log Analysis - Introduction - Oct2013Document35 pagesBasic Well Log Analysis - Introduction - Oct2013Jorge PirelaNo ratings yet

- P15 Wilden PumpsDocument35 pagesP15 Wilden PumpsWalter LrNo ratings yet

- Parts Book Franks 300Document341 pagesParts Book Franks 300Slim.B100% (4)

- Battery SpecsDocument8 pagesBattery SpecsIng Sergio J Poot HuitzNo ratings yet

- Configurations & Parts Identification: Trailer Suspension SeriesDocument19 pagesConfigurations & Parts Identification: Trailer Suspension SeriesSlim.BNo ratings yet

- Fundamentos de Interpretacion de RegistrosDocument9 pagesFundamentos de Interpretacion de RegistrosJoseline TorresNo ratings yet

- Basic Well Log InterpretationDocument12 pagesBasic Well Log InterpretationShahnawaz Mustafa100% (2)

- Chapter 04 - Pore PressureDocument70 pagesChapter 04 - Pore PressureSlim.BNo ratings yet

- T210 PS145 7 - 49 PDFDocument34 pagesT210 PS145 7 - 49 PDFSlim.BNo ratings yet

- Operating and Maintenance GuideDocument100 pagesOperating and Maintenance GuideSlim.BNo ratings yet

- Parts Book & Maintenance Manual: UTB-75-D Unitized Hook BlockDocument16 pagesParts Book & Maintenance Manual: UTB-75-D Unitized Hook BlockSlim.BNo ratings yet

- When Your Gas Reservoir Is Unconventional So Is Our SolutionDocument11 pagesWhen Your Gas Reservoir Is Unconventional So Is Our SolutionIngeniería de Petróleos UnitropicoNo ratings yet

- CAVINSDocument20 pagesCAVINSSlim.BNo ratings yet

- Subsurface Environments: Instructor: Nawarat Intarapanich Course: Basic Petroleum GeologyDocument22 pagesSubsurface Environments: Instructor: Nawarat Intarapanich Course: Basic Petroleum GeologySlim.BNo ratings yet

- SC RE Chap6 LiquidsDocument54 pagesSC RE Chap6 LiquidsweldsvNo ratings yet

- SC RE Chap18 - Immiscible DisplDocument130 pagesSC RE Chap18 - Immiscible DisplSlim.BNo ratings yet

- Chap15 - MBalDocument38 pagesChap15 - MBalSlim.BNo ratings yet

- Chap 17 - Water InfluxDocument57 pagesChap 17 - Water InfluxSlim.BNo ratings yet

- Chap 14 PVTDocument109 pagesChap 14 PVTYujeisly Reina100% (2)

- Formation PressureDocument79 pagesFormation PressureRian MonterryNo ratings yet

- Fluid Flow in Porous MediaDocument206 pagesFluid Flow in Porous MediaSlim.B100% (1)

- Heriot - Watt University - Production Technology IDocument476 pagesHeriot - Watt University - Production Technology IBrahim Letaief75% (12)

- Brent Dev HistoryDocument26 pagesBrent Dev HistorySlim.BNo ratings yet

- Farmakoterapi Penyakit Infeksi: in Infectious Diseases Dewi Rahmawati, M.Farm-Klin.,AptDocument87 pagesFarmakoterapi Penyakit Infeksi: in Infectious Diseases Dewi Rahmawati, M.Farm-Klin.,AptYemima MNo ratings yet

- Wilkinson 2001Document44 pagesWilkinson 2001Toño Gaspar MuñozNo ratings yet

- Digital Fuel Calculation v.1Document4 pagesDigital Fuel Calculation v.1Julian ChanNo ratings yet

- Hospital Food Service: October 2019Document28 pagesHospital Food Service: October 2019Shaikh Sobiya 57No ratings yet

- Monitoring Rock and Soil Mass Performance: To The ConferenceDocument1 pageMonitoring Rock and Soil Mass Performance: To The ConferenceÉrica GuedesNo ratings yet

- Switchword PairsDocument6 pagesSwitchword PairsLaleKulahli100% (7)

- Югоизточна Европа под османско владичество 1354-1804Document531 pagesЮгоизточна Европа под османско владичество 1354-1804auroradentataNo ratings yet

- Attendance: Umut KurtoğluDocument2 pagesAttendance: Umut KurtoğluHavvaNo ratings yet

- UT Dallas Syllabus For Se2370.501 05s Taught by Weichen Wong (Wew021000)Document1 pageUT Dallas Syllabus For Se2370.501 05s Taught by Weichen Wong (Wew021000)UT Dallas Provost's Technology GroupNo ratings yet

- NEM Report - IntroDocument11 pagesNEM Report - IntroRoshni PatelNo ratings yet

- Knowledge, Attitudes and Practices of Nursing Students on Dengue FeverDocument9 pagesKnowledge, Attitudes and Practices of Nursing Students on Dengue FeverElinNo ratings yet

- CCNA Security Instructor Lab Manual v1 - p8Document1 pageCCNA Security Instructor Lab Manual v1 - p8MeMe AmroNo ratings yet

- Crisil DataDocument6 pagesCrisil DataVihang NaikNo ratings yet

- Exploratory Factor AnalysisDocument170 pagesExploratory Factor AnalysisSatyabrata Behera100% (7)

- Nescafe Cold CoffeeDocument24 pagesNescafe Cold CoffeeMuhammad Omer SaeedNo ratings yet

- UX DesignDocument96 pagesUX DesignParisa Zarifi100% (3)

- 4147ictte384 PDFDocument6 pages4147ictte384 PDFKandasamy AsohanNo ratings yet

- (Oxford Studies in Digital Politics) Jack Parkin - Money Code Space - Hidden Power in Bitcoin, Blockchain, and Decentralisation-Oxford University Press (2020)Document297 pages(Oxford Studies in Digital Politics) Jack Parkin - Money Code Space - Hidden Power in Bitcoin, Blockchain, and Decentralisation-Oxford University Press (2020)berpub0% (1)

- Logistic Growth Rate Functions Blumberg1968Document3 pagesLogistic Growth Rate Functions Blumberg1968Jonnathan RamirezNo ratings yet

- The 8 Body ConstitutionsDocument29 pagesThe 8 Body ConstitutionsNiNo ratings yet

- Cookery 9 - Food - PackagingDocument47 pagesCookery 9 - Food - PackagingJP AballeNo ratings yet

- RRB NTPC Cut Off 2022 - CBT 2 Region Wise Cut Off Marks & Answer KeyDocument8 pagesRRB NTPC Cut Off 2022 - CBT 2 Region Wise Cut Off Marks & Answer KeyAkash guptaNo ratings yet

- Organic Compounds ExplainedDocument37 pagesOrganic Compounds ExplainedAlejandro VillanuevaNo ratings yet

- Hotel Training ReportDocument14 pagesHotel Training ReportButchick Concepcion Malasa100% (1)

- Ergonomía y Normatividad en 3Document5 pagesErgonomía y Normatividad en 3Rogers DiazNo ratings yet

- A Survey of English and American Literature Module 1 3Document80 pagesA Survey of English and American Literature Module 1 3Jathalia VillaNo ratings yet

- Y10 ICT End of TermDocument7 pagesY10 ICT End of TermIvy Atuhairwe BisoborwaNo ratings yet

- BS 0812-114 - 1989Document12 pagesBS 0812-114 - 1989عمر عمرNo ratings yet

- LOGIK Fridge Freezer With Water Dispenser LSD55W18 ManualDocument20 pagesLOGIK Fridge Freezer With Water Dispenser LSD55W18 Manualfbunt2777No ratings yet

- TZMmanual PDFDocument8 pagesTZMmanual PDFccardenas3907No ratings yet