Professional Documents

Culture Documents

Direct Metal Solutions: Precision Production Metal Printing With The DMP Printer Series, 3dxpert Laserform® Materials

Uploaded by

Nalla ThambiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Direct Metal Solutions: Precision Production Metal Printing With The DMP Printer Series, 3dxpert Laserform® Materials

Uploaded by

Nalla ThambiCopyright:

Available Formats

Direct Metal Solutions

Precision production metal printing with the

DMP printer series, 3DXpert™ software and

LaserForm® materials

Go further with Direct Metal Printing

UNLOCK YOUR PRODUCT’S ACCELERATE TIME-TO-MARKET

POTENTIAL Conduct R&D, prototyping and production

With complete design freedom, direct metal all in the same system. DMP users around

3D printed parts can be stronger, lighter, longer the world are designing faster and compressing

lasting and higher performing than machined production times. Transform complex assemblies

or cast assemblies. Manufacture superior that take hundreds of hours to machine and

performing products faster and at a lower assemble into a single high value part printed in

cost than with traditional fabrication methods. hours or days.

STREAMLINE SUPPLY CHAINS INCREASE MANUFACTURING AGILITY

With DMP, you have complete control Metal additive manufacturing requires no

over your production, without relying on tooling, reducing overhead and increasing

specialty components from suppliers. Print economies of scale. You are able to update

entire assemblies on demand, with fewer designs and change your production mix to

components, as needed. meet changing market demands.

CONFORMAL COOLING SIMPLIFIED ASSEMBLIES REDUCED WEIGHT

Direct integration of Replacing a complex assembly, Complex lattice structures

conformal cooling channels this single burner component allow significant weight

into this blow mold increases contains nine under-cuttings reduction for this

efficiency by 30%. and six internal cavities. combustion chamber.

ENHANCED FLUID FLOW TOPOLOGY MASS CUSTOMIZATION

For this turbine inlet guide OPTIMIZATION Designed to perfectly fit

vane, computed fluid dynamics Topology optimized the obstructed zone, this

simulation predicts a 70% aerospace bracket reduces reconstruction corrects the

reduction in shock intensity. weight by 35%. patient’s facial asymmetry.

Flexible Metal AM, ProX DMP 300

exceptional quality

DMP Flex 100, ProX® DMP 200 & 300

The DMP Flex 100, ProX DMP 200 and 300 share a

common architecture to print exceptionally detailed, high

quality parts in an automated and repeatable process

that is ideal for R&D and serial part manufacturing at the

tightest tolerances in direct metal printing.

ProX DMP 200

DMP Flex 100

Dental frames

Tire mold sipes

Aerospace airfoils

INDUSTRY’S BEST SURFACE FINISH UNMATCHED PRECISION

Reduce machining or polishing of final parts. Print the finest features with exceptional accuracy.

CLEAN AND SAFE INTEGRATED METAL PRINTING

Sealed powder loading and recycling prevents ProX DMP printers, 3DXpert™ software and

material contamination and increases operator LaserForm® materials are fine-tuned for process

safety. reliability and repeatability.

EXCEPTIONAL MECHANICAL PROPERTIES PRINT IN CERTIFIED ALLOYS

Roller compaction yields higher density Count on your results with certified LaserForm

and uniform mechanicals. materials and extensively tested print parameters.

3DXPERT FOR FASTER DATA PREPARATION

AND EXCEPTIONAL BUILD OPTIMIZATION

3DXpert software, 3D Systems’ precision metal printing

solution, is delivered with every DMP printer. Benefit from

intelligent design tools and fast build preparation, relying

on the extensively tested build parameter database for your

material of choice. No other software lets you localize print

strategies for increased precision of metal parts.

High precision, high throughput

DMP Flex 350 and DMP Factory 350

DMP Flex and Factory 350, developed from the outcome of nearly half-a-million prints, offers fast build

turnaround times in demanding 24/7 production environments. DMP Flex 350 is upgradeable to DMP Factory

350, which has an integrated material handling system.

INTEGRATED METAL PRINTING LOW TOTAL COST OF OWNERSHIP

DMP printers, 3DXpert™ software and Shared ancillary equipment maximizes printer

LaserForm® materials are fine-tuned for throughput and efficient consumables management

process reliability and repeatability. reduces operating cost.

STRONGER MECHANICAL PROPERTIES HIGH QUALITY POWDER MANAGEMENT

The lowest O2 during builds (<25 ppm) for DMP Factory 350 comes with integrated powder

exceptionally strong parts of high chemical purity. management. An in-unit viewing panel enables

visual inspection of the ultrasonic sieve to ensure

EXTENSIVELY TESTED MATERIALS incident-free operation.

Thousands of hours of parameter optimization

ensure predictable and repeatable print quality

with a broad range of LaserForm materials.

DMP Flex 350

Spinal implant for

improved bone ingrowth

DMP Factory 350

Monolithic complex extrusion

nozzle with mixing channels

DMP MONITORING FOR

REAL-TIME PROCESS MONITORING

Advanced Manufacturing requires close monitoring

of process variables. DMP Monitoring is a process

monitoring and non-destructive quality control

system, providing a wealth of data for informed

decisions on product quality and also serving as

process traceability and documentation for highly

regulated industries.

Metal Alloys for the DMP Series

3D Systems’ broad range of ready-to-run LaserForm® materials is formulated and fine-tuned

specifically for 3D Systems DMP 3D printers to deliver high part quality and consistent part properties.

The print parameter database that 3D Systems provides together with the material has been

extensively developed, tested and optimized in 3D Systems’ part production facilities that hold the

unique expertise of printing 500,000 challenging metal production parts in various materials year

over year. And for your 24/7 production 3D Systems’ thorough Supplier Quality Management System

guarantees consistent, monitored material quality for reliable results.

Heat exchanger with complex cooling Gas burner with integrated cooling High corrosion resistant impeller

channels in LaserForm AlSi10Mg (A) channels in LaserForm Ni718 (A) in LaserForm 316L (A)

Minireactor for scale testing built Partials, copings and bridges Blow mold with conforming holes

in LaserForm 17-4PH (A) production in LaserForm CoCr (C) in LaserForm Maraging Steel (B)

Extra High Productivity Upgrade for LaserForm Ti Gr5 (A) and Ti Gr23 (A)

Count on up to 34% speed increases and decisive per part cost reductions

while maintaining the high level of consistent, repeatable part

quality as published in our LaserForm data sheets.

* Availability varies by printer model

(see details on the last page).

YOUR SCALABLE DMP FACTORY NETWORK

DMP 350 platform is easily scalable for high volume

part production. A central server manages print

jobs, materials, settings and maintenance for 24/7

productivity. Shared resources, including cooling and

powder recycling systems, increase efficiency.

Centralized Process Management

DMP Flex 350

DMP Flex 100 ProX DMP 200 ProX DMP 300

DMP Factory 350

Build volume 3.94 x 3.94 x 3.15 in 5.51 x 5.51 x 3.94 in 9.84 x 9.84 x 12.01 in 10.82 x 10.82 x 14.96 in

(W x D x H)¹ (100 x 100 x 80 mm) (140 x 140 x 100 mm) (250 x 250 x 305 mm) (275 x 275 x 380 mm)

Metal alloy LaserForm CoCr (B) LaserForm CoCr (B) LaserForm CoCr (B) LaserForm Ti Gr1 (A)²

choices with LaserForm 17-4PH (B) LaserForm 17-4PH (B) LaserForm 17-4PH (B) LaserForm Ti Gr5 (A)²

developed print LaserForm Ti Gr23 (A)²

LaserForm CoCr (C) LaserForm LaserForm

parameters

Maraging Steel (B) Maraging Steel (B) NEW LaserForm AlSi7Mg0.6 (A)2

LaserForm AlSi12 (B) LaserForm AlSi12 (B) LaserForm AlSi10Mg (A)²

LaserForm Ni625 (A)³

LaserForm Ni718 (A)³

LaserForm 17-4PH (A)³

LaserForm CoCrF75 (A)³

LaserForm 316L (A)³

LaserForm Maraging Steel (A)³

Layer thickness _________________________ 10 μm - 100 μm _________________________ 10 μm - 100 μm

Preset: 30 μm Preset: 40 μm Preset: 30 and 60 μm

Repeatability _________________________________ x=20 μm, y=20 μm, z=20 μm ____________________________________

Min. feature size __________________ x=100 μm, y=100 μm, z=20 μm _________________ 100 μm

Min. wall

150 μm 150 μm 150 μm 150 μm

thickness

Typical accuracy ± 0.1-0.2% with ± 0.1-0.2% with ± 0.1-0.2% with ± 0.1-0.2% with

± 50 μm minimum ± 50 μm minimum ± 50 μm minimum ± 50 μm minimum

Powder Optional external Optional external Automatic DMP Flex 350:

Management Optional external

DMP Factory 350:

Integrated

Interchangeable DMP Flex 350: Yes

No No No

build modules DMP Factory 350: N/A

Real-time DMP Flex 350: Optional

No No No

monitoring DMP Factory 350: Included

1Maximum available part size using standard build plate 2Set up A ³Set up B Complete specifications available at www.3dsystems.com

Warranty/Disclaimer: The performance characteristics of these products may vary according to product application,

operating conditions, material combined with, or with end use. 3D Systems makes no warranties of any type, express

or implied, including, but not limited to, the warranties of merchantability or fitness for a particular use.

©2018 by 3D Systems, Inc. All rights reserved. Specifications

3D Systems Corporation

subject to change without notice. 3D Systems, the 3D Systems

333 Three D Systems Circle logo, ProX and LaserForm are registered trademarks and

Rock Hill, SC 29730 3DXpert is a trademark of 3D Systems.

www.3dsystems.com

3DS-10201C 11-18

You might also like

- DMP Factory 350: Robust, High Quality Metal AM With Integrated Powder ManagementDocument2 pagesDMP Factory 350: Robust, High Quality Metal AM With Integrated Powder ManagementNalla ThambiNo ratings yet

- Aplicaciones en Fortus 380.Document8 pagesAplicaciones en Fortus 380.Diego Fernando Vázquez BravoNo ratings yet

- Selective Laser Melting System: Flexible, Safe and Efficient Options For Fast ResultsDocument6 pagesSelective Laser Melting System: Flexible, Safe and Efficient Options For Fast ResultsArnold NadasNo ratings yet

- Integrated Cad/Cam For The Sheet Metal Industry: Master Your Manufacturing ProcessDocument8 pagesIntegrated Cad/Cam For The Sheet Metal Industry: Master Your Manufacturing Processvictor LNo ratings yet

- Integrated Cad/Cam For The Sheet Metal Industry: Master Your Manufacturing ProcessDocument8 pagesIntegrated Cad/Cam For The Sheet Metal Industry: Master Your Manufacturing ProcessSalvador Severino CascoNo ratings yet

- Integrated CAD/CAM for Sheet Metal IndustryDocument8 pagesIntegrated CAD/CAM for Sheet Metal IndustrySalvador Severino CascoNo ratings yet

- SLM125Document5 pagesSLM125k2kkhanna105No ratings yet

- Ma Pseries Brochure 2019-DigitalversionDocument6 pagesMa Pseries Brochure 2019-DigitalversioneuphoryNo ratings yet

- 3d Printing TechnologiesDocument1 page3d Printing TechnologiesmalowaNo ratings yet

- Activity 1 NewDocument11 pagesActivity 1 NewsuccesshustlerclubNo ratings yet

- Zebra Z4M PlusDocument2 pagesZebra Z4M PlusSatish NamjoshiNo ratings yet

- Trumatic L 2530 TRUMPF BrochureDocument9 pagesTrumatic L 2530 TRUMPF BrochureJose DiasNo ratings yet

- As BrochureDocument12 pagesAs BrochureDita FebrianaNo ratings yet

- KM BR Powerprint EnuDocument8 pagesKM BR Powerprint EnuAndrzej FrasekNo ratings yet

- Rotometric English Product Guide WebDocument4 pagesRotometric English Product Guide Webkaka punNo ratings yet

- GPM Englisch 01Document11 pagesGPM Englisch 01Budimir MijailovićNo ratings yet

- 3D Printing Technology Comparison: FDM vs. Sla vs. SLS: Written By: FormlabsDocument8 pages3D Printing Technology Comparison: FDM vs. Sla vs. SLS: Written By: Formlabseitan-dalia4971No ratings yet

- Trumpf Laser Systems en PDFDocument44 pagesTrumpf Laser Systems en PDFJuanSebastiánTorresMartínez0% (1)

- 3DpDocument44 pages3DpPooja AngolkarNo ratings yet

- 3d Systems Sla 750 Brochure Usen 2022-04-04 Web 0Document12 pages3d Systems Sla 750 Brochure Usen 2022-04-04 Web 0Alexander Moisés Saldaña AcevedoNo ratings yet

- Ermaksan Epl-PlasmaDocument19 pagesErmaksan Epl-PlasmaMurat KayaNo ratings yet

- Cs 3ds Ge Frustrum DMP 0216 PDFDocument3 pagesCs 3ds Ge Frustrum DMP 0216 PDFPaul VeramendiNo ratings yet

- Flyer Sheet MetalDocument8 pagesFlyer Sheet MetalBG2012No ratings yet

- LPKF Protomat S42: Entry Level System For Precision PCB PrototypesDocument4 pagesLPKF Protomat S42: Entry Level System For Precision PCB Prototypesmap_congNo ratings yet

- Promarker Series: High-Speed Laser Marking As Easy As PrintingDocument4 pagesPromarker Series: High-Speed Laser Marking As Easy As PrintingMiroslav ProdanaNo ratings yet

- Additive Manufacturing Special Report 1018Document33 pagesAdditive Manufacturing Special Report 1018OARIASCO100% (1)

- Applications: Selective Laser Sintering Is The Ideal Solution ForDocument8 pagesApplications: Selective Laser Sintering Is The Ideal Solution FordpksobsNo ratings yet

- Zmorph FAB 2in1Document11 pagesZmorph FAB 2in1Bhavin VadgamaNo ratings yet

- UAV & Other RTM Applications: Design Through Production - We're The RTM Experts!Document2 pagesUAV & Other RTM Applications: Design Through Production - We're The RTM Experts!Angel LagrañaNo ratings yet

- ZT200 Datasheet en GBDocument4 pagesZT200 Datasheet en GBGrazzNo ratings yet

- Laser Engraving Rubber StampsDocument4 pagesLaser Engraving Rubber StampsAnonymous hpUVR2No ratings yet

- OTPL - Introduction PDFDocument31 pagesOTPL - Introduction PDFAnil Kumar H CNo ratings yet

- Rapid Prototyping Processes and OperationsDocument52 pagesRapid Prototyping Processes and OperationsAnuj Reddy100% (1)

- 3DS Thermoplastic-Manufacturing Whitepaper en FINALDocument12 pages3DS Thermoplastic-Manufacturing Whitepaper en FINALjaimeNo ratings yet

- Projet MJP 2500w FAQSDocument3 pagesProjet MJP 2500w FAQSIslah GsmNo ratings yet

- FC TM300iT Manufacturing-System Oct17Document1 pageFC TM300iT Manufacturing-System Oct17KantishNo ratings yet

- Cost-effective laser cutting solutions for any requirementDocument36 pagesCost-effective laser cutting solutions for any requirementNastase EduardNo ratings yet

- Additive Manufacturing at GEDocument56 pagesAdditive Manufacturing at GEfroid1259539100% (2)

- Guide of UltmkrDocument13 pagesGuide of UltmkrkunteshradadiyaNo ratings yet

- Laser Systems enDocument44 pagesLaser Systems enOlivia JacksonNo ratings yet

- Global Brochure PDFDocument16 pagesGlobal Brochure PDFElsa VelazquezNo ratings yet

- 3d Brochure - DEFORM 3DDocument2 pages3d Brochure - DEFORM 3DMrLanternNo ratings yet

- International Truss SYSTEMS (Pty) LTD: Product CatalogueDocument34 pagesInternational Truss SYSTEMS (Pty) LTD: Product Catalogueansara89No ratings yet

- Zebra ZT200 Series Printer DatasheetDocument4 pagesZebra ZT200 Series Printer DatasheetJohnny BarcodeNo ratings yet

- F300i F315i BrochureDocument4 pagesF300i F315i BrochureNabeel SheikhNo ratings yet

- ABS Vs ASA - Spec SheetDocument2 pagesABS Vs ASA - Spec Sheetbloodterry2284No ratings yet

- Amada Laser CuttingDocument8 pagesAmada Laser CuttingMahmud MaherNo ratings yet

- Powdermet Brochure BodycoteDocument6 pagesPowdermet Brochure BodycoteAngel LagrañaNo ratings yet

- 5 Direct Soling MachinesDocument8 pages5 Direct Soling MachinesaverdgueNo ratings yet

- Shipbuilding Catalogue Rev 6Document16 pagesShipbuilding Catalogue Rev 6mtonellyNo ratings yet

- Zebra Z Series: The Price-Performance LeadersDocument2 pagesZebra Z Series: The Price-Performance LeadersoserranomNo ratings yet

- 1327-brochure-lpkf-protomats-s-series-en (1)Document8 pages1327-brochure-lpkf-protomats-s-series-en (1)AlexNo ratings yet

- 1327-brochure-lpkf-protomats-s-series-enDocument8 pages1327-brochure-lpkf-protomats-s-series-enAlexNo ratings yet

- Trumatic L 3050 4050 6050 TRUMPF BrochureDocument12 pagesTrumatic L 3050 4050 6050 TRUMPF BrochureMoez BellamineNo ratings yet

- WWW - Chemtron.asia: Additive Manufacturing SolutionsDocument32 pagesWWW - Chemtron.asia: Additive Manufacturing Solutionsravichandran0506No ratings yet

- FDM 3D PrinterDocument23 pagesFDM 3D PrinterYuvraj MarneNo ratings yet

- ACMA represents Indian auto component industryDocument36 pagesACMA represents Indian auto component industryvenkatesh_1829No ratings yet

- 2018 CommitteeExperts Report 08112018 PDFDocument217 pages2018 CommitteeExperts Report 08112018 PDF15058 ROHIT JACOB VARGHESENo ratings yet

- ST Forest Dwellers Act 2006 e 2Document2 pagesST Forest Dwellers Act 2006 e 2MahiNo ratings yet

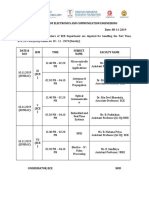

- ECE Department Faculty ScheduleDocument1 pageECE Department Faculty ScheduleNalla ThambiNo ratings yet

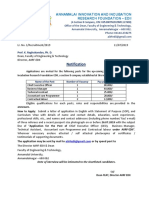

- Key Pointers For The RDM Role - TIEDDocument3 pagesKey Pointers For The RDM Role - TIEDNalla Thambi100% (1)

- IFEX 2020-Brochure PDFDocument4 pagesIFEX 2020-Brochure PDFMadhusudan DasNo ratings yet

- 4.BE ECE PT R 2016-IVSem - Elective - I ELECTRONIC MEASUREMENTS-QBDocument7 pages4.BE ECE PT R 2016-IVSem - Elective - I ELECTRONIC MEASUREMENTS-QBNalla ThambiNo ratings yet

- The Kotak Mahindra Group An Overview: #DiscoverkliDocument6 pagesThe Kotak Mahindra Group An Overview: #DiscoverkliNalla ThambiNo ratings yet

- Feature Article Additive Impact Part 2 - How Additive Manufacturing Could Disrupt Your MarketDocument7 pagesFeature Article Additive Impact Part 2 - How Additive Manufacturing Could Disrupt Your MarketNalla ThambiNo ratings yet

- 3.BE ECE PT R 2016-IVSem - VLSI DESIGN QBDocument6 pages3.BE ECE PT R 2016-IVSem - VLSI DESIGN QBNalla ThambiNo ratings yet

- Em Taking Care of Business Brochure enDocument30 pagesEm Taking Care of Business Brochure enNalla ThambiNo ratings yet

- Agro and Food Processing Sector ProfileDocument14 pagesAgro and Food Processing Sector ProfileNalla ThambiNo ratings yet

- The Power of Additive ManufacturingDocument4 pagesThe Power of Additive ManufacturingNalla ThambiNo ratings yet

- Disaster Mitigation and Management - QBDocument5 pagesDisaster Mitigation and Management - QBNalla ThambiNo ratings yet

- Coronavirus: Lockdown in 75 Districts in IndiaDocument2 pagesCoronavirus: Lockdown in 75 Districts in IndiaNeha MahajanNo ratings yet

- Dip Coimbatore 2015 16 PDFDocument38 pagesDip Coimbatore 2015 16 PDFSun HealthNo ratings yet

- Post Show Report - IFEX 2016-CoimbatoreDocument5 pagesPost Show Report - IFEX 2016-CoimbatoreNalla ThambiNo ratings yet

- AIIRF Advertisement-26july19Document4 pagesAIIRF Advertisement-26july19Nalla ThambiNo ratings yet

- BWR A4 Rating for Malar International's Rs.6 Cr Bank Loan FacilitiesDocument4 pagesBWR A4 Rating for Malar International's Rs.6 Cr Bank Loan FacilitiesNalla ThambiNo ratings yet

- Fabpro 1000 For Dental ApplicationsDocument1 pageFabpro 1000 For Dental ApplicationsNalla ThambiNo ratings yet

- TNSWAN Telephone Directory for Tamil Nadu Government OfficesDocument88 pagesTNSWAN Telephone Directory for Tamil Nadu Government OfficesNalla ThambiNo ratings yet

- Schools Selected For ATL Round 2: S. NO. Atl Code School Name District StateDocument4 pagesSchools Selected For ATL Round 2: S. NO. Atl Code School Name District StateNalla ThambiNo ratings yet

- Exhibitors ListDocument7 pagesExhibitors ListNiraj PandeyNo ratings yet

- 3d Systems MJP 2500 Tech Specs Usen 2017 11 08 WebDocument2 pages3d Systems MJP 2500 Tech Specs Usen 2017 11 08 Webapi-376219710No ratings yet

- Automotive Sector Report FinalDocument35 pagesAutomotive Sector Report Finalpayal joshiNo ratings yet

- Coastal Data PDFDocument133 pagesCoastal Data PDFGayathriNo ratings yet

- Fabpro 1000 Entry-Level Industrial 3D PrinterDocument2 pagesFabpro 1000 Entry-Level Industrial 3D PrinterNalla ThambiNo ratings yet

- IEC 82045 Document Management StandardDocument10 pagesIEC 82045 Document Management StandardPetrovich_215No ratings yet

- 2018 CommitteeExperts Report 08112018 PDFDocument217 pages2018 CommitteeExperts Report 08112018 PDF15058 ROHIT JACOB VARGHESENo ratings yet

- Advertising Media Choices for BBA CourseDocument20 pagesAdvertising Media Choices for BBA CourseAbhishek DuttaGuptaNo ratings yet

- Name of Ratee Department Name: Leyte Normal UniversityDocument5 pagesName of Ratee Department Name: Leyte Normal UniversityAnonymous PcPkRpAKD5No ratings yet

- Narrative Margin Format 1Document27 pagesNarrative Margin Format 1Shira Mae GulfericNo ratings yet

- MCQs IN PROPERTYDocument12 pagesMCQs IN PROPERTYAbegail AtokNo ratings yet

- Chap 9 Tanner - Training & Developing The Sales Force 17022017Document35 pagesChap 9 Tanner - Training & Developing The Sales Force 17022017Osama Riaz100% (1)

- Constructing Test Questions: Table of SpecificationsDocument54 pagesConstructing Test Questions: Table of SpecificationsRetchel Tumlos MelicioNo ratings yet

- A Summer Training Project Report ON: "An Analysis of Financial Statement of A Company"Document5 pagesA Summer Training Project Report ON: "An Analysis of Financial Statement of A Company"NAVEEN ROY67% (3)

- ECCE Speaking Commentary PDFDocument2 pagesECCE Speaking Commentary PDFXara KarraNo ratings yet

- MS'20 BrochureDocument32 pagesMS'20 BrochureIdk IdkNo ratings yet

- Impact of Swami VivekanandaDocument3 pagesImpact of Swami VivekanandaRajesh SarswatNo ratings yet

- COP For Works On Public Streets Sep2018Ed PDFDocument88 pagesCOP For Works On Public Streets Sep2018Ed PDFTan Jee PohNo ratings yet

- Reflection On Distance Learning - CompressedDocument1 pageReflection On Distance Learning - Compressedapi-500622015No ratings yet

- Models of SupervisionDocument4 pagesModels of SupervisionRaquel M. MendozaNo ratings yet

- Assignment 1 Harris Tahir 70033218Document2 pagesAssignment 1 Harris Tahir 70033218Harris Tahir100% (1)

- Cristina Ramirez ResumeDocument1 pageCristina Ramirez Resumeapi-530840537No ratings yet

- Queen of All Saints Case StudyDocument2 pagesQueen of All Saints Case StudyOaga GutierrezNo ratings yet

- Job AnalysisDocument27 pagesJob AnalysisNiaz AhmedNo ratings yet

- 1.meaning and Relevance of HistoryDocument37 pages1.meaning and Relevance of HistorySunshine C GanteNo ratings yet

- Bosch Sistem Digital Traducere Simultana Integrus PDFDocument16 pagesBosch Sistem Digital Traducere Simultana Integrus PDFIoan TrifuNo ratings yet

- Implementing Odoo ERP for Business AppsDocument8 pagesImplementing Odoo ERP for Business AppsSohail HamidNo ratings yet

- Methods For Teaching PDFDocument114 pagesMethods For Teaching PDFPutra Bhungsu100% (2)

- Case Study: Walmart Inc. Takes On: Subject: Retail Management StategyDocument8 pagesCase Study: Walmart Inc. Takes On: Subject: Retail Management StategyAkhil ChaudharyNo ratings yet

- Home Theater Magazine March 2006Document123 pagesHome Theater Magazine March 2006linhbeoNo ratings yet

- Research On The Evolution of Innovation Behavior oDocument27 pagesResearch On The Evolution of Innovation Behavior oWafaa AlkafaweenNo ratings yet

- Arsenio Santos Memorial Elementary SchoolDocument5 pagesArsenio Santos Memorial Elementary SchoolCel Rellores SalazarNo ratings yet

- Save The Environment To Save Life: By: Adithiyan RajanDocument2 pagesSave The Environment To Save Life: By: Adithiyan RajanAlanlovely Arazaampong AmosNo ratings yet

- BA 2 Chapter 2 Personnel Program PoliciesDocument4 pagesBA 2 Chapter 2 Personnel Program PoliciesClara DupitasNo ratings yet

- Globalization Über Alles: Framing The 1956 Suez Crisis Within America's Economic ProjectDocument25 pagesGlobalization Über Alles: Framing The 1956 Suez Crisis Within America's Economic ProjectStefan JokićNo ratings yet

- Teachers and Students Perception of Multigrade Teaching in Eastern Bhutan and The Way Forward StrategyDocument7 pagesTeachers and Students Perception of Multigrade Teaching in Eastern Bhutan and The Way Forward Strategyyash agarwalNo ratings yet

- Nature and Scope of Salary Taxation in IndiaDocument36 pagesNature and Scope of Salary Taxation in IndiamaheshNo ratings yet

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Algorithms to Live By: The Computer Science of Human DecisionsFrom EverandAlgorithms to Live By: The Computer Science of Human DecisionsRating: 4.5 out of 5 stars4.5/5 (722)

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityFrom EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityRating: 5 out of 5 stars5/5 (1)

- Generative AI: The Insights You Need from Harvard Business ReviewFrom EverandGenerative AI: The Insights You Need from Harvard Business ReviewRating: 4.5 out of 5 stars4.5/5 (2)

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessFrom EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessNo ratings yet

- Cyber War: The Next Threat to National Security and What to Do About ItFrom EverandCyber War: The Next Threat to National Security and What to Do About ItRating: 3.5 out of 5 stars3.5/5 (66)

- Chaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyFrom EverandChaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyRating: 3.5 out of 5 stars3.5/5 (111)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveFrom EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveNo ratings yet

- Digital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyFrom EverandDigital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyRating: 4 out of 5 stars4/5 (51)

- The E-Myth Revisited: Why Most Small Businesses Don't Work andFrom EverandThe E-Myth Revisited: Why Most Small Businesses Don't Work andRating: 4.5 out of 5 stars4.5/5 (709)

- CompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideFrom EverandCompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideRating: 5 out of 5 stars5/5 (2)

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldFrom EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldRating: 4.5 out of 5 stars4.5/5 (55)

- The Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumFrom EverandThe Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumRating: 3 out of 5 stars3/5 (12)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyFrom EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNo ratings yet

- The Future of Geography: How the Competition in Space Will Change Our WorldFrom EverandThe Future of Geography: How the Competition in Space Will Change Our WorldRating: 4.5 out of 5 stars4.5/5 (4)

- Chip War: The Quest to Dominate the World's Most Critical TechnologyFrom EverandChip War: The Quest to Dominate the World's Most Critical TechnologyRating: 4.5 out of 5 stars4.5/5 (227)

- Reality+: Virtual Worlds and the Problems of PhilosophyFrom EverandReality+: Virtual Worlds and the Problems of PhilosophyRating: 4 out of 5 stars4/5 (24)

- Artificial Intelligence: The Insights You Need from Harvard Business ReviewFrom EverandArtificial Intelligence: The Insights You Need from Harvard Business ReviewRating: 4.5 out of 5 stars4.5/5 (104)

- Machine Learning: The Ultimate Beginner's Guide to Learn Machine Learning, Artificial Intelligence & Neural Networks Step by StepFrom EverandMachine Learning: The Ultimate Beginner's Guide to Learn Machine Learning, Artificial Intelligence & Neural Networks Step by StepRating: 4.5 out of 5 stars4.5/5 (19)

- Mini Farming: Self-Sufficiency on 1/4 AcreFrom EverandMini Farming: Self-Sufficiency on 1/4 AcreRating: 4 out of 5 stars4/5 (76)