Professional Documents

Culture Documents

Saudi Aramco Test Report: Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 Elect

Uploaded by

karthi51289Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Test Report: Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 Elect

Uploaded by

karthi51289Copyright:

Available Formats

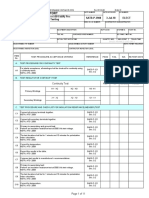

SAUDI ARAMCO ID/PIEU -3- July-2018 - REV. 2018.04.00 (Standards Cutoff -April 30, 2018) Rev. 2018.04.

00 30-Apr-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 ELECT-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

TEST PROCEDURE ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

A. Preparation for Test

Schedule Q

The personnel conducting the testing must be qualified to operate the test

A1 Att. IV

equipment and also familiar with the cable system and its components.

Sec. 7.3

At all ends from where the test equipment is to be connected, position a

guard or barricade the area to prevent unauthorized access to the SAES-P-107

A2

overhead system under test.(SAES-P-104, Sec. 3.1 and S A Pre- Sec. 3.1

Commissioning Form # P-041 & Form # P-042)

Check the DC high-potential test set for proper operation. Ensure that the

input voltage to the test set is regulated. Check test set and test leads at SAES-P-107

A3

testing voltage level (lead in place but not connected). (NEC 110.3 B Sec. 3.3

and Manufacurer's Instructions)

Check clearances at the overhead conductor ends meet the requirements Schedule Q

A4

of SAES-P-107, Sec. 10.5. Sec. 1.3

Use weather protection. (Contractor Schedule Q

A5

Method Statement) Sec. 3.1

Ground adjacent conductors and adjacent objects near the conductor

Schedule Q

A6 ends. Conductors not under test are to remain grounded at all ends.

Sec. 1.3

(NETA ATS, Sec. 7.3.3.2.2)

Remove all grounds from conductor to be "hi-potted". (NETA Schedule Q

A7

ATS, Sec. 7.3.3.2.2) Sec. 1.3

Determine temperature of test set at the time of test. (NETA Schedule Q

A8

ATS, Sec. 5.4.2.3) Sec. 1.3

Determine rate of rise on voltage applied at the time of testing. (NETA Schedule Q

A9

ATS, Sec. 5.4.2.3) Sec. 1.3

Hi-pot test After Mounting or Forming Terminations (SAES-P-104, Sec.

13.2-d) - Check that termination have creepage distance per SAES-P-

104, Sec 6.12 summarized in the table below:

Minimum Creepage Distance

Termination (in mm)

Voltage Rating Indoor Outdoor

(@ 25mm/kV L-L) (@ 40mm/kV L-L)

5 kV 125 200 SAES-P-107

A10

Sec. 3.1

6/10 kV 250 400

15 kV 375 600

Saudi Aramco: Company General Use

12/20 kV 500 800

35 kV 875 1,400

Saudi Aramco: Company General Use

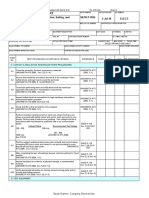

SAUDI ARAMCO ID/PIEU -3- July-2018 - REV. 2018.04.00 (Standards Cutoff -April 30, 2018) Rev. 2018.04.00 30-Apr-18

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE APPROVED QR NUMBER

Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 ELECT-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

TEST RESULTS ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

Hi-pot Test After Mounting or Forming Terminations - Check that

terminations are not connected to the equipment. ( Note: If conductors are SAES-P-107

A11

left connected to the equipment, the hi-pot shall not exceed the rating of Sec. 3.1

the equipment). (SAES-P-104, Sec. 13.2-d)

Hi-pot Test After Mounting or Forming Terminations - Check that there are

SAES-P-107

A12 sufficient clearances from enclosures and other adjacent objects. (SAES-

Sec. 3.1

P-104, Sec. 13.2-d)

The medium conductors shall be tested in accordance to the voltage level

listed below. (SAES-P-104, Sec. 13.2, Table 3)

DC High-Potential Field Test Voltages

Conductor Voltage Rating

After installation - before cable is placed SAES-P-107

A13 in regular service Sec. 3.1

5kV or 6/10kV 36 kV

15 kV or 12/20 kV 64 kV

35 kV 100 kV

Test voltages shall not exceed 80 percent of conductor manufacturer's

factory test value or the maximum test voltage in attachment 1, Table Schedule Q

A14

10.6. (SAES-P-104, Sec. 3.1 and S A Pre-Commissioning Form # P-041 Sec. 1.3

& Form # P-042)

Check the insulation resistance of the conductor using a 5000 volts dc

SAES-P-107

A15 megger tester. (SAES-P-104, Sec. 3.1 and S A Pre-Commissioning Form

Sec. 3.1

# P-041 & Form # P-042)

Perform DC High-potential testing in accordance with conductor and test

SAES-P-107

A16 instrument manufacturer recommendations. (NEC

Sec. 3.3

110.3 B)

Apply the test voltage slowly in a minimum of five equal increments until

maximum test voltage is reached, with no increment exceeding the

voltage rating of the conductor, and with each voltage step being held for SAES-P-107

A17

an equal interval of time long enough to allow the leakage current to reach Sec. 3.1

stability, approximately 1 to 2 minutes. (SAES-P-

104, Sec. 3.1, S A Pre-Commissioning Form # P-041 & Form # P-042)

Reading of leakage current and voltage shall be recorded at the end of

each minute prior to increasing to the next specified voltage level.

NOTE: A linear increase in leakage current is expected, and it should SAES-P-107

A18

stabilize or decrease from the initial value at each step. Sec. 3.1

(SAES-P-104, Sec. 13.6 and S A Pre-Commissioning Form # P-041 &

Form # P-042)

Plot test voltage versus leakage current on graph paper as the test

progresses. NOTE: Any excessive or non-linear increase in leakage

current can indicate imminent cable failure. Discontinue the test and, SAES-P-107

A19

consult the manufacturer for recommendations. (SAES- Sec. 3.1

P-104, Sec. 13.6 and S A Pre-Commissioning Form # P-041 & Form # P-

042)

Calculate the resistance of the cable at each step. Note: At any step

where the calculated leakage resistance decreases approximately 50% or

more of that of the next lower voltage, discontinue the test to prevent SAES-P-107

A20

conductor failure and to retain the conductor in a serviceable condition Sec. 3.3

until a replacement conductor is available. (NEC

110.3 B and Manufacurer's Instructions)

Saudi Aramco: Company General Use

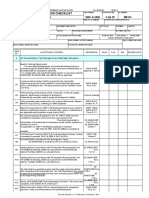

SAUDI ARAMCO ID/PIEU -3- July-2018 - REV. 2018.04.00 (Standards Cutoff -April 30, 2018) Rev. 2018.04.00 30-Apr-18

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE APPROVED QR NUMBER

Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 ELECT-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

TEST RESULTS ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

Upon satisfactory completion of test, connect conductors to equipment.

SAES-P-107

A21 Tighten connectors to manufacturer recommended torque levels. (NEC

Sec. 3.3

110.3 B and Manufacurer's Instructions)

The results of all tests performed on conductors rated 5 KV and above

shall be documented on the Saudi Aramco H. V. Cable Test Record Form SAES-P-107

A22

7823-ENG. (SAES-P-104, Sec. 13.6 and S A Pre-Commissioning Form # Sec. 3.1

041 & Form # P-042)

Appropriate records shall be made, as indicated in the test result form.

SAES-P-107

A23 (SAES-P-104, Sec. 13.6 and S A Pre-Commissioning Form # 041 & Form

Sec. 3.1

# P-042)

Insure that the input voltage to the test set is regulated. SAES-P-107

A24

(NEC 110.3 B and Manufacurer's Instructions) Sec. 3.3

Current- sensing circuits in test equipment shall measure only the leakage

current associated with the cable under test and shall not include internal SAES-P-107

A25

leakage of the test equipment. Sec. 3.3

(NEC 110.3 B and Manufacurer's Instructions)

Record wet-and dry-bulb temperatures or relative humidity and Schedule Q

A26

temperature. (NETA ATS, Sec. 5.4.2.3) Sec. 1.3

Test each section of conductor individually.

SAES-P-107

A27 (SAES-P-104, Sec. 3.1 and S A Pre-Commissioning Form # 041 & Form #

Sec. 3.1

P-042)

Individually test each conductor with all other conductors grounded.

SAES-P-107

A28 Ground all shields. (SAES-P-104, Sec. 3.1 and S A Pre-Commissioning

Sec. 3.1

Form # 041 & Form # P-042)

Termination shall be adequately corona-suppressed by guard ring, field

Schedule Q

A29 reduction sphere, or other suitable methods as necessary.

Sec. 1.3

(NETA ATS, Sec. 7.3.3.2.4)

Insure that the maximum test voltage does not exceed the limits for

terminations specified in ANSI/IEEE Standard 48, IEEE 386, S A Pre- Schedule Q

A30

Commissioning Form # 041 & Form # P-042, or manufacturer's Sec. 1.3

specifications.

Apply a dc high-potential test in at least five equal increments until

maximum test voltage is reached. No increment shall exceed the voltage

rating of the cable. Record dc leakage current at each step after a SAES-P-107

A31

constant stabilization time consistent with system charging current. Sec. 3.1

(SAES-P-104, Sec. 3.1 and S A Pre-Commissioning Form # P-041 &

Form # P-042)

Raise the conductor to the specified maximum test voltage and hold for 15

minutes on shielded cable and five minutes on no shielded cable. Record

SAES-P-107

A32 readings of leakage current at 30 seconds and one minute and at one

Sec. 3.1

minute intervals thereafter. (SAES-P-104, Sec. 3.1 and S A Pre-

Commissioning Form # P-041 & Form # P-042)

Reduce the conductor test potential to zero and measure residual voltage

SAES-P-107

A33 at discrete intervals. (SAES-P-104, Sec. 3.1 and S A Pre-Commissioning

Sec. 3.1

Form # P-041 & Form # P-042)

Apply grounds for a time period adequate to drain all insulation stored

SAES-P-107

A34 charge. (SAES-P-104, Sec. 3.1 and S A Pre-Commissioning Form # P-

Sec. 3.1

041 & Form # P-042)

B. TEST EQUIPMENT AND MATERIALS CRITERIA

Schedule Q

B1 Test shall be performed using a high-potential tester. Att. IV

Sec. 7.1

Schedule Q

B2 The test equipment calibration cycle shall not exceed twelve months. Att. IV

Sec. 7.1

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU -3- July-2018 - REV. 2018.04.00 (Standards Cutoff -April 30, 2018) Rev. 2018.04.00 30-Apr-18

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE APPROVED QR NUMBER

Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 ELECT-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

TEST RESULTS ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

Test Equipment Manufacturer: Serial Number:

Scale Range and accuracy: Calibration date:

Calibration Company and Technician: Calibration Expiration Date:

C. TEST RESULTS

Note: Use applicable MV Cable Test Report Forms (Attachments 1 to 6) for recording of test data.

ITEM

TEST RESULTS ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

The step voltage slope should be reasonably linear for the graphic plots of

Schedule Q

C1 leakage current versus step voltage at each increment. (NETA

Sec. 1.3

ATS, Sec. 5.4.1.5)

Perform a physical inspection of the overhead feeders to ensure any

Schedule Q

C2 damage to the poles, conductors at termination points, insulators,

Sec. 6.4

jumpers, cable supports, stays etc. prior to energization.

Capacitive and absorption current should decrease continually until

Schedule Q

C3 steady state leakage is approached for the graphic plots for leakage

Sec. 1.3

current versus time at the final test voltage. (NETA ATS, Sec. 5.4.1.5)

Test results are acceptable and in accordance with Saudi Aramco

Schedule Q

C4 Engineering Standards and contractual requirements. (NETA

Sec. 1.3

ATS, Sec. 5.4.1.5 & Sec. 7.3.3.3.2.4.2)

REMARKS:

REFERENCE DOCUMENTS:

1. Schedule G -- Material, Tools and Equipment (Pro Forma MP-IK-LS Contract), Contract Specific

2. Schedule Q -- Quality Requirements (Pro Forma Contract), Contract Specific

3. SAES-P-104 Wiring Methods and Materials 01 January 2018

4. SAES-P-107 Overhead Distribution Systems 19 October 2008

5. NFPA 70 National Electrical Code (NEC) 2014 Edition

6. Acceptance Testing Specifications for Electric Power Distribution Equipment and Systems- NETA (2009)

7. SA Pre- Commissioning Form # P-000 Testing Guide Lines, Issue Date (March 2006)

8. S A Pre-Commissioning Form # P-041 High Voltage Cables (5kV-15kV-35kV), Issue Date (March 2006) - supersedes S A Pre-Commissioning

Form # P-004 Medium Voltage Cables, Issue Date (10/97)

9. S A Pre-Commissioning Form # P-042 High Voltage Cables (69kV-115kV), Issue Date (March 2006) - supersedes S A Pre-Commissioning

Form # P-005 High Voltage Cables, Issue Date (10/97)

ATTACHMENT DOCUMENT: HI-POT TEST REPORT FOR MV CABLE

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products

or services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing

states

that the equipment, material, or services either meets appropriate designated standards or has been tested and found suitable for a specified

purpose.

4. Labeled - Equipment or materials to which has been attached a label, symbol, or other identifying mark of an approved qualified organization

concerned

with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the manufacturer

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU -3- July-2018 - REV. 2018.04.00 (Standards Cutoff -April 30, 2018) Rev. 2018.04.00 30-Apr-18

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE APPROVED QR NUMBER

Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 ELECT-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

TEST RESULTS ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

indicates compliance with appropriate standards or performance in a specified manner.

Contractor / Third-Party Saudi Aramco

Technician Performing Test* PMT Representative

Test Performed Successfully and Results are Acceptable: T&I Witnessed QC Record Reviewed Work Verified

Name, Title, Department,

Name, Initials and Date:

Company, Initials and Date:

QC Inspector PID Representative

Witnessed Test Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Implementation of Test and Analysis of Results Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU -3- July-2018 - REV. 2018.04.00 (Standards Cutoff -April 30, 2018) Rev. 2018.04.00 30-Apr-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 ELECT-

Attachment 1 - HI-POT TEST REPORT FOR MV CABLE

PROJECT DATA

B.I. or W.O. No. _________________________________________________________ DATE: ____________________________

PLANT NO:________________________________________________________________________________________________

LOCATION ________________________________________________________________________________________________

CABLE DATA

CIRCUIT # OR DESIGNATION _______________________________________________________________________________

CABLE SIZE:_______________________ CABLE LENGTH ___________________ RATED VOLTAGE: ___________

INSULATION AND JACKET TYPE: _______________________________________ INSULATION THICKNESS: ____________

MAX. LEAKAGE CURRENT AFTER 100% TEST VOLTAGE APPLIED: _______________________________________________

CABLE TEST VOLTAGE : ________________ NOTE: REDUCE THE CABLE TEST VOLTAGE LEVEL AND HOLD TIME ACCORDINGLY,

TEST HOLD TIME IN MINUTES:_____________ WHEN PERFORMING THE TEST WITH ELBOW CONNECTOR AND/OR EXISTING CABLE.

GENERAL TEST RECORD

CABLE ACCEPTABLE : _______________________________________ Not ACCEPTABLE: ____________________________

TEMPERATURE: ______________ % RELATIVE HUMIDITY: ___________________WEATHER CONDITIONS: _______________

REMARKS:________________________________________________________________________________________________

__________________________________________________________________________________________

RESISTANCE TEST

PHASE 1 TO GND PHASE 2 TO GND PHASE 3 TO GND (MEGGER)

TEST VOLTAGE

& HOLD TIME Leakage Cable Leakage Current Cable Leakage Cable

Current (μA) Resistance (μA) Resistance Current (μA) Resistance PHASE MΩ

Step 1 kV PH 1 - 2

Step 2 kV PH 2 - 3

Step 3 kV PH 3 - 1

Step 4 kV PH 1 - G

Step 5 kV PH 2 - G

15 SEC PH 3 - G

30 SEC

45 SEC POL. INDEX = 1 MINUTE

1 MIN 5 MINUTE

2 MIN

3 MIN

4 MIN

5 MIN

6 MIN

7 MIN

8 MIN

9 MIN

10 MIN

11 MIN

12 MIN POL. INDEX RESULTS

13 MIN If 1.25 - 2.0 good

14 MIN If below 1.0 failure

15 MIN If 1.0 - 1.25 marginal

NOTES: 1. READING AT END OF I MIN. DURATION PRIOR TO RAISING VOLTAGE TO NEXT STEP.

2. BETWEEN EACH STEP RAISE VOLTAGE UNIFORMLY.

3. STOP TEST IF CURRENT STEADILY INCREASES AT CONSTANT VOLTAGE.

4. ATTACH A SEPARATE GRAPH FOR PLOT OF TEST VOLTAGE VERSUS LEAKAGE CURRENT.

TESTED BY: CHECKED BY: WITNESSED BY:

Saudi Aramco: Company General Use

DATE: DATE: DATE:

Saudi Aramco: Company General Use

You might also like

- The ILLUSION of Money - How the USA and Canada Became BankruptDocument0 pagesThe ILLUSION of Money - How the USA and Canada Became BankruptJ.p. Baron100% (1)

- Cashology Reports Clean Credit in A Month ! Start Living Without The Anxiety of Crippling DebtDocument10 pagesCashology Reports Clean Credit in A Month ! Start Living Without The Anxiety of Crippling DebtCashology ReportsNo ratings yet

- "SIM Cloning": Submitted To: - Mr. Gurbakash PhonsaDocument6 pages"SIM Cloning": Submitted To: - Mr. Gurbakash PhonsagauravsanadhyaNo ratings yet

- Offshore Electrical Engineering ManualFrom EverandOffshore Electrical Engineering ManualRating: 4 out of 5 stars4/5 (9)

- The Trials of Rizal Bill: Learning ObjectivesDocument3 pagesThe Trials of Rizal Bill: Learning ObjectivesRammele Opemia NonNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistm4metzNo ratings yet

- Saudi Aramco Cable Testing ResultsDocument5 pagesSaudi Aramco Cable Testing Resultskarthi51289No ratings yet

- SAUDI ARAMCO INSPECTION CHECKLIST FOR PRESSURE VESSELSDocument2 pagesSAUDI ARAMCO INSPECTION CHECKLIST FOR PRESSURE VESSELSkarthi51289No ratings yet

- Saudi Aramco Transformer TestingDocument11 pagesSaudi Aramco Transformer Testingkarthi51289100% (1)

- Saudi Aramco Test Report: Laboratory Hood Test SATR-K-4005 15-Dec-09 HvacDocument4 pagesSaudi Aramco Test Report: Laboratory Hood Test SATR-K-4005 15-Dec-09 HvacWaleed MedhatNo ratings yet

- Saudi Aramco Test ReportDocument6 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Cable TestingDocument7 pagesSaudi Aramco Cable Testingkarthi51289No ratings yet

- SAIC-A-2015 Saudi Aramco Inspection ChecklistDocument8 pagesSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289No ratings yet

- MCQ NegoDocument20 pagesMCQ NegoMark Hiro NakagawaNo ratings yet

- Saudi Aramco Test ReportDocument10 pagesSaudi Aramco Test Reportkarthi51289100% (1)

- Saudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 24-Jul-18 CPDocument2 pagesSaudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 24-Jul-18 CPnadeem shaikhNo ratings yet

- Satr-P-3210 Rev 7 FinalDocument11 pagesSatr-P-3210 Rev 7 FinalzhangNo ratings yet

- Saudi Aramco Test Report: LV Cablebus Continuity and Insulation Resistance Testing SATR-P-3238 3-Jul-18 ElectDocument6 pagesSaudi Aramco Test Report: LV Cablebus Continuity and Insulation Resistance Testing SATR-P-3238 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco LV Panelboard TestingDocument4 pagesSaudi Aramco LV Panelboard TestingheikelNo ratings yet

- Saudi Aramco MV Cable Termination TestingDocument4 pagesSaudi Aramco MV Cable Termination TestingzhangNo ratings yet

- Saudi Aramco Test Report: SATR-P-3205 30-Apr-13 Elect-Low Voltage Power and Control Cable, Termination Torque TestingDocument7 pagesSaudi Aramco Test Report: SATR-P-3205 30-Apr-13 Elect-Low Voltage Power and Control Cable, Termination Torque TestingzhangNo ratings yet

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 InstDocument17 pagesSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 Instkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1Document6 pagesSaudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1sureshNo ratings yet

- Saudi Aramco Test Report: SATR-P-3210 3-Jul-18 Elect-Medium Voltage Power Cable, High-Potential Withstand TestingDocument10 pagesSaudi Aramco Test Report: SATR-P-3210 3-Jul-18 Elect-Medium Voltage Power Cable, High-Potential Withstand Testingkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Test Report: MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 ElectDocument5 pagesSaudi Aramco Test Report: MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 Electkarthi51289No ratings yet

- LV Controller Calibration Test ResultsDocument3 pagesLV Controller Calibration Test ResultsMa.socorro SaballaNo ratings yet

- Saudi Aramco Test Report: MV Cablebus Continuity and Insulation Resistance Testing SATR-P-3233 3-Jul-18 ElectDocument6 pagesSaudi Aramco Test Report: MV Cablebus Continuity and Insulation Resistance Testing SATR-P-3233 3-Jul-18 Electkarthi51289No ratings yet

- Satr-P-3912 Transformer InsulationDocument8 pagesSatr-P-3912 Transformer InsulationSurendren R100% (1)

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportMa.socorro SaballaNo ratings yet

- Saudi Aramco Test Report: Elect-LV Controlgear - ATS / MTS Calibration, Setting, and Functional Testing SATR-P-3824Document6 pagesSaudi Aramco Test Report: Elect-LV Controlgear - ATS / MTS Calibration, Setting, and Functional Testing SATR-P-3824Ma.socorro SaballaNo ratings yet

- Saudi Aramco Test Report: 3-Jul-18 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116Document5 pagesSaudi Aramco Test Report: 3-Jul-18 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116karthi51289No ratings yet

- Saudi Aramco Test Report: 30-Apr-13 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116Document5 pagesSaudi Aramco Test Report: 30-Apr-13 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116zhangNo ratings yet

- Satr-P-3208 Rev 8 FinalDocument7 pagesSatr-P-3208 Rev 8 FinalMohamed HaleemNo ratings yet

- Saudi Aramco Test Report: UPS Distribution System, Energized Bolted - Fault Test SATR-P-3112 3-Jul-18 ElectDocument3 pagesSaudi Aramco Test Report: UPS Distribution System, Energized Bolted - Fault Test SATR-P-3112 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Test Report: SATR-P-3117 3-Jul-18 Elect-DC Panelboards / CB'S, Pre-Commissioning & Functional TestingDocument6 pagesSaudi Aramco Test Report: SATR-P-3117 3-Jul-18 Elect-DC Panelboards / CB'S, Pre-Commissioning & Functional Testingkarthi51289No ratings yet

- Saudi Aramco Test Report: Switchyard - HV Mechanical Termination Torque Testing SATR-P-3901 3-Jul-18 ElectDocument8 pagesSaudi Aramco Test Report: Switchyard - HV Mechanical Termination Torque Testing SATR-P-3901 3-Jul-18 Electkarthi51289No ratings yet

- Satr-P-3206 LV Cable TerminationDocument5 pagesSatr-P-3206 LV Cable TerminationSurendren RNo ratings yet

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Satr P 3206Document6 pagesSatr P 3206munnaNo ratings yet

- Saudi Aramco Test Report: SATR-P-3105 Elect-UPS DC/AC Inverter, Pre-Commissioning & Functional TestingDocument9 pagesSaudi Aramco Test Report: SATR-P-3105 Elect-UPS DC/AC Inverter, Pre-Commissioning & Functional TestingehteshamNo ratings yet

- Saudi Aramco Test Report: UPS/DC Vented Ni-Cad Wet Cell, Jobsite Acceptance Test SATR-P-3102 ElectDocument7 pagesSaudi Aramco Test Report: UPS/DC Vented Ni-Cad Wet Cell, Jobsite Acceptance Test SATR-P-3102 ElectehteshamNo ratings yet

- SATR-P-3417 Rev 7 FinalDocument6 pagesSATR-P-3417 Rev 7 FinalzhangNo ratings yet

- Saudi Aramco Test Report: High Voltage Power Cable, Termination Torque Testing SATR-P-3213 3-Jul-18 ElectDocument5 pagesSaudi Aramco Test Report: High Voltage Power Cable, Termination Torque Testing SATR-P-3213 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 3-Jul-18 CPDocument2 pagesSaudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 3-Jul-18 CPkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Test Report: SATR-P-3407 3-Jul-18 Elect LV SCIM - Motor Insulation Resistance and Functional TestingDocument6 pagesSaudi Aramco Test Report: SATR-P-3407 3-Jul-18 Elect LV SCIM - Motor Insulation Resistance and Functional Testingkarthi51289No ratings yet

- Saudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 31-Mar-19 CPDocument2 pagesSaudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 31-Mar-19 CPAwais NaeemNo ratings yet

- Saudi Aramco Test Report: DC Rectifier Testing CP-SATR-X-3202Document8 pagesSaudi Aramco Test Report: DC Rectifier Testing CP-SATR-X-3202Yehia FelifelNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument12 pagesSaudi Aramco Test ReportehteshamNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-P-3851 Elect-LV Controlgear - Full Voltage Motor Controller Pre - CommissioningDocument3 pagesSaudi Aramco Inspection Checklist: SAIC-P-3851 Elect-LV Controlgear - Full Voltage Motor Controller Pre - CommissioningMa.socorro SaballaNo ratings yet

- Saudi Aramco Test Report: Medium Voltage Power Cable, Termination Torque Testing SATR-P-3209 3-Jul-18 ElectDocument4 pagesSaudi Aramco Test Report: Medium Voltage Power Cable, Termination Torque Testing SATR-P-3209 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Test Report: Overhead T&D - Capacitor Banks, Functional Testing SATR-P-3223 30-Apr-13 ElectDocument8 pagesSaudi Aramco Test Report: Overhead T&D - Capacitor Banks, Functional Testing SATR-P-3223 30-Apr-13 ElectzhangNo ratings yet

- SAIC-A-2025 Rev 6 Pre Test Pressure VesselDocument4 pagesSAIC-A-2025 Rev 6 Pre Test Pressure Vesselpookkoya thangal100% (1)

- Saudi Aramco Test Report: Building Drainage and Vent Piping Hydrotest SATR-S-4003 18-May-05 PlumbDocument2 pagesSaudi Aramco Test Report: Building Drainage and Vent Piping Hydrotest SATR-S-4003 18-May-05 PlumbNoor Mohamed AzeezNo ratings yet

- Saudi Aramco Test Report: Internal Tank Bottom Testing CP-SATR-X-3205Document8 pagesSaudi Aramco Test Report: Internal Tank Bottom Testing CP-SATR-X-3205Yehia FelifelNo ratings yet

- Saudi Aramco Test Report: External Tank Bottom Testing CP-SATR-X-3204Document8 pagesSaudi Aramco Test Report: External Tank Bottom Testing CP-SATR-X-3204Yehia FelifelNo ratings yet

- Saudi Aramco Test ReportDocument3 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Test Report: SATR-P-3103 Elect-UPS/DC Vented Lead-Acid Wet Cell, Jobsite Acceptance TestDocument9 pagesSaudi Aramco Test Report: SATR-P-3103 Elect-UPS/DC Vented Lead-Acid Wet Cell, Jobsite Acceptance TestehteshamNo ratings yet

- Saudi Aramco Test Report: DC Cable Holiday Testing 3-Jul-18 CP-SATR-X-3201Document3 pagesSaudi Aramco Test Report: DC Cable Holiday Testing 3-Jul-18 CP-SATR-X-3201karthi51289No ratings yet

- Saudi Aramco Test ReportDocument12 pagesSaudi Aramco Test ReportTahir MubeenNo ratings yet

- Saudi Aramco Test Report: LV Panelboard - Pre-Energized and Functional Testing SATR-P-3825 3-Jul-18 ElectDocument7 pagesSaudi Aramco Test Report: LV Panelboard - Pre-Energized and Functional Testing SATR-P-3825 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- SAUDI ARAMCO ID/PIEU INSPECTION CHECKLISTDocument4 pagesSAUDI ARAMCO ID/PIEU INSPECTION CHECKLISTkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 Civilkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 Civilkarthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 3-Jul-18 MechDocument1 pageSaudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 3-Jul-18 Mechkarthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 Mechkarthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saic A 2016Document1 pageSaic A 2016karthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 Mechkarthi51289100% (1)

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saic A 2016Document1 pageSaic A 2016karthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 MechDocument1 pageSaudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 Mechkarthi51289No ratings yet

- Overview of New Security Controls in ISO 27002 ENDocument15 pagesOverview of New Security Controls in ISO 27002 ENsotomiguelNo ratings yet

- Meghans LawDocument4 pagesMeghans LawNick MuhohoNo ratings yet

- Case Study of EBay IncDocument3 pagesCase Study of EBay IncyibungoNo ratings yet

- Green v. United States, 355 U.S. 184 (1957)Document27 pagesGreen v. United States, 355 U.S. 184 (1957)Scribd Government DocsNo ratings yet

- BAFE SP101 2017 Scheme Document Draft Consultation Version 1 - January 2017Document24 pagesBAFE SP101 2017 Scheme Document Draft Consultation Version 1 - January 2017orkhan manuchehriNo ratings yet

- Lesco 5-0-20 10feDocument1 pageLesco 5-0-20 10feCory HansonNo ratings yet

- Canoreco v. Torres GR 127249 2-27-1998Document10 pagesCanoreco v. Torres GR 127249 2-27-1998HjktdmhmNo ratings yet

- Comprehensive car insurance cover noteDocument2 pagesComprehensive car insurance cover noteSupernau Admin KuchingNo ratings yet

- Industrial Worker - Issue #1760, November 2013Document16 pagesIndustrial Worker - Issue #1760, November 2013Industrial WorkerNo ratings yet

- Foreign CapitalDocument15 pagesForeign Capitaldranita@yahoo.comNo ratings yet

- Profibus DP Master Protocol APIDocument336 pagesProfibus DP Master Protocol APImail87523100% (2)

- The Geography of Religion: Chapter 8 Lecture OutlineDocument25 pagesThe Geography of Religion: Chapter 8 Lecture OutlinedixitbhattaNo ratings yet

- SKF FYJ 509 SpecificationDocument4 pagesSKF FYJ 509 SpecificationgulieionutNo ratings yet

- 03 Arabay Vs CFIDocument3 pages03 Arabay Vs CFIJustin Andre Siguan100% (1)

- Shurts v. Shurts, Ariz. Ct. App. (2015)Document6 pagesShurts v. Shurts, Ariz. Ct. App. (2015)Scribd Government DocsNo ratings yet

- Advantages and Disadvantages of DemocracyDocument2 pagesAdvantages and Disadvantages of Democracybharath alurNo ratings yet

- Davao Del Sur - MunDocument41 pagesDavao Del Sur - MunireneNo ratings yet

- Salmeron V Enterprise RecoveryDocument23 pagesSalmeron V Enterprise RecoveryKirk HartleyNo ratings yet

- 10 Demerits of Caste System in IndiaDocument7 pages10 Demerits of Caste System in Indiarabiya altafNo ratings yet

- Soal Siklus AkuntansiDocument6 pagesSoal Siklus Akuntansidery dulitaNo ratings yet

- 2.110 Cost or Price ReasonablenessDocument4 pages2.110 Cost or Price ReasonablenessferryNo ratings yet

- Chapter Three: Valuation of Financial Instruments & Cost of CapitalDocument68 pagesChapter Three: Valuation of Financial Instruments & Cost of CapitalAbrahamNo ratings yet

- Vanguard 18hp - Engine # 3564470373F1Document61 pagesVanguard 18hp - Engine # 3564470373F1Matias Alfredo Contreras KöbrichNo ratings yet

- The Color of OrangeDocument3 pagesThe Color of Orangeben_faganNo ratings yet

- Patrick Caronan Vs Richard CaronanDocument8 pagesPatrick Caronan Vs Richard CaronanJosh CabreraNo ratings yet