Professional Documents

Culture Documents

Basf Master Seal 635 PDF

Basf Master Seal 635 PDF

Uploaded by

hemantrulzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Basf Master Seal 635 PDF

Basf Master Seal 635 PDF

Uploaded by

hemantrulzCopyright:

Available Formats

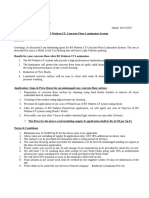

MasterSeal® M 635

Flexible and elastic single component polyurethane waterproofing membrane

DESCRIPTION substrates is MasterSeal P 640. Refer to PDS

MasterSeal M 635 is a single component, liquid for application guidelines.

applied polyurethane based, elastomeric coating for Before the surface application, all detail areas

roof waterproofing. and any singular points like wall-floor

connections, chimneys, joints, substrate cracks,

RECOMMENDED USES penetrations, corners, etc., must be treated. For

• Applicable for outdoor use this apply one layer of MasterSeal M 635, then

• Can be applied on concrete and cement mortar. place a correct cut stripe of geotextile mat

• Waterproofing of roofs, balconies and terraces. (110g/m²) into the wet material. Press in to fully

Contact the Technical Service of your local soak without leaving air pockets. Then fully

BASF Construction Chemicals office regarding saturate the geotextile mat by applying additional

any application required not mentioned here.

MasterSeal M 635. All lap joints in the mat

FEATURES AND BENEFITS

reinforcement should be minimum 50 mm.

• High elasticity and flexibility

• Excellent adhesion to concrete and mortar. Fully (b) Mixing

bonded system. (c) Application

• Tar free Homogenize MasterSeal M 635 with mechanical

• Root resistant stirring before use. Pour the MasterSeal M 635

• Easy to apply. onto the primed substrate and spread with a

• Excellent crack bridging capacity even at low roller or brush at a maximum consumption of 0.9

temperatures. kg/m² per layer.

• Monolithic – no laps, welds or seams. Working within the recommended over coating

• High water vapor permeability - low risk of times, apply a second layer of MasterSeal M

blistering. 635 at a maximum consumption of 0.9 kg/m².

• Resistant to standing water

For demanding applications, apply a third layer

APPLICATION METHOD of MasterSeal M 635.

(a) Surface Preparation For details like wall-floor connections, 90˚

All substrates (new and old) must be structurally angles, chimneys, pipes, waterspouts (siphon),

etc. it is recommended to reinforce with a

sound, dry and free of laitance and loose particles.

geotextile mat (110g/m²)

Clean of oil, grease, paint stains and other adhesion

impairing contaminants. Profile mechanically the Do not apply MasterSeal M 635 over 0.6mm dry

surface by shot blasting, high-pressure water jetting film thickness per layer ( corresponds to 0.9

kg/m² consumption)

or other suitable mechanical preparation method.

After surface preparation, the pull off value of the Top Coat:

substrate should exceed 1 N/mm2 (check with an MasterSeal M 635 does not have sufficient UV

approved pull-off tester). Temperature of the and weather resistance to be used in exposed

substrate should be minimum +5 ºC and maximum applications without protection. In exposed

+35 ºC. The residual moisture content of the applications, apply one or two coats of MasterSeal

substrate must not exceed 4% (check with e.g. CM TC 640. Refer to PDS for application guidelines.

MasterSeal TC 640 can be broad- casted with dry

device). The temperature of the substrate must be at

least 3 K above the current dew point temperature. silica sand to provide a hard wearing, slip resistant

finish.

Primer: Suitable primer for using MasterSeal M

635 on concrete or cementitious mortar

MasterSeal® M 635

COVERAGE STORAGE /SHELF LIFE

Normally approx. 1.2 to 2.0 kg per m² are required in Store in cool and dry warehouse conditions

two - three coats, depending on chosen application between 15 - 25 °C. Do not expose to direct

method. These consumptions are theoretical and sunlight. Shelf life in these conditions is 9 months

can vary according to the absorption and roughness in unopened original containers.

of the support. It is essential to carry out

WATCH POINTS

representative trials on site to evaluate the exact

This product conforms to the EU directive

consumption. Higher consumptions (for detailing’s

2004/42/EG (Deco-Paint directive) and contains

with geo textile fabric) are possible. less than the maxi- mum allowable VOC limit

(Stage 2, 2010)

For best performance

The product must not be applied when the According to the EU directive 2004/42, the

maximum allowable VOC content for the Product

temperature is below +10 ºC or above 30 ºC. Do not Category IIA / j is 500 g/l (Limit: Stage 2, 2010).

mix solvents, sand or other products that could The VOC content for MasterSeal M 635 is < 500

affect the products properties must not be added. Do g/l (for the ready to use product).

not apply in more than 0,6 mm thickness per layer. It

HANDLING / PRECAUTIONS

is recommended to use a reinforcement mat for In its cured state, MasterSeal M 635 is

junctions and profile changes. physiologically non-hazardous. The following

protective measures should be taken when

FINISHING AND CLEANING working with this material:

While still wet clean with solvent (e.g. Cleaner 40 Wear safety gloves, goggles and protective

or sol- vent naphtha). Once cured it can only be clothing. Avoid contact with the skin and eyes. In

removed mechanically. case of eye contact, seek medical attention. Avoid

inhalation of fumes. When working with the

PACKAGING product, do not eat, smoke or work near a naked

flame. For additional references to safety hazard

MasterSeal M 635 is available in 25 kg and 6 kg

warnings, regulations regarding transport and

pails waste management, please refer to the relevant

Material Safety Data Sheet. The regulations of the

COLOUR local trade association and/or other authorities

White, red and grey regarding safety and hygiene of workers handling

polyurethanes and isocyanates must be observed.

TDS Ref. No. : M’Seal M635/02/0418

The technical information and application advice given in this BASF Construction Chemicals publication are based

STATEMENT OF on the present state of our best scientific and practical knowledge. As the information herein is of a general nature,

RESPONSIBILITY no assumption can be made as to a product's suitability for a particular use or application and no warranty as to its

(Disclaimer) accuracy, reliability or completeness either expressed or implied is given other than those required by law. The

user is responsible for checking the suitability of products for their intended use.

® = registered trademark of BASF group in many countries

Field service where provided does not constitute supervisory responsibility. Suggestions made by BASF

NOTE Construction Chemicals either orally or in writing may be followed, modified or rejected by the owner, engineer or

contractor since they, and not BASF Construction Chemicals, are responsible for carrying out procedures

appropriate to a specific application.

BASF India Limited

Construction Chemicals Division

Plot.No.12,TTC Area

Thane Belapur Road,Turbhe

Navi Mumbai - 400705,India

Tel: +91 22 67127600, Fax: +91 22 67917358

E-mail: construction-india@basf.com , www.master-builders-solutions.basf.in

MasterSeal® M 635

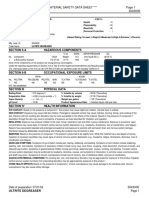

Technical data*

Properties Standard Data Unit

Chemical base - Polyurethane -

Mixing ratio A:B single component -

Working time at 20 °C - 40 min

Re-coating interval / at 20 °C min. 12 h

Open to pedestrian traffic - max. 48 h

Rain safe at 20 °C 4 d

Fully cured at 20 °C - 7 d

Substrate and ambient temperatures min. 8 °C

-

max. 35 °C

Permissible relative humidity - max. 80 %

Technical data after curing*

Properties Standard Data Unit

Service temperatures min. - 20 °C

max. 80 °C

Shore-A-hardness ASTM D 2240 65±5 -

Crack bridging ASTM C1305 up to 2 mm

Elongation at break ASTM D412 / >400 %

DIN 52455

Tensile strength ASTM D412 / >4 N/mm²

DIN 52455

Water vapor permeability ISO 9932:91 >30 g/m²/24h

Hydrolysis (5% KOH, 7days cycle) In house No significant

change

Resistance to root penetration UNE 53420 Resistant

Adhesion to concrete ASTM D 903 >2 N/mm²

* The above figures are intended as a guide only and should not be used as a basis for specification.

The technical information and application advice given in this BASF Construction Chemicals publication are based

STATEMENT OF on the present state of our best scientific and practical knowledge. As the information herein is of a general nature,

RESPONSIBILITY no assumption can be made as to a product's suitability for a particular use or application and no warranty as to its

(Disclaimer) accuracy, reliability or completeness either expressed or implied is given other than those required by law. The

user is responsible for checking the suitability of products for their intended use.

® = registered trademark of BASF group in many countries

Field service where provided does not constitute supervisory responsibility. Suggestions made by BASF

NOTE Construction Chemicals either orally or in writing may be followed, modified or rejected by the owner, engineer or

contractor since they, and not BASF Construction Chemicals, are responsible for carrying out procedures

appropriate to a specific application.

BASF India Limited

Construction Chemicals Division

Plot.No.12,TTC Area

Thane Belapur Road,Turbhe

Navi Mumbai - 400705,India

Tel: +91 22 67127600, Fax: +91 22 67917358

E-mail: construction-india@basf.com , www.master-builders-solutions.basf.in

You might also like

- Apex Shade CardDocument7 pagesApex Shade Cardvermavikki97No ratings yet

- Chartek 7 Application Manual (Rev10) 2017-05-19Document64 pagesChartek 7 Application Manual (Rev10) 2017-05-19suriya100% (6)

- Method Statement For Foundation WaterProofingDocument9 pagesMethod Statement For Foundation WaterProofingMuhammad Sami ParvezNo ratings yet

- MasterProtect 300Document3 pagesMasterProtect 300Gavriel NgNo ratings yet

- RHOPLEX™ MC-1834P: Cement Mortar ModifierDocument6 pagesRHOPLEX™ MC-1834P: Cement Mortar Modifierhemantrulz100% (1)

- M-120 Material Data Sheets For Structural Steel Edition 5Document47 pagesM-120 Material Data Sheets For Structural Steel Edition 5vlong3003100% (3)

- 2131 Roswan QD HB Rev (1409)Document2 pages2131 Roswan QD HB Rev (1409)Trịnh Minh KhoaNo ratings yet

- BASF MasterSeal M 790 TdsDocument9 pagesBASF MasterSeal M 790 TdsAmar WadoodNo ratings yet

- Masterseal TC 254 - TdsDocument2 pagesMasterseal TC 254 - TdsHanyNo ratings yet

- Basf Masterseal 640 TdsDocument2 pagesBasf Masterseal 640 TdsJassi Singh0% (1)

- MasterProtect 300 Asean v3-0415Document2 pagesMasterProtect 300 Asean v3-0415Muhammad Fadhil ImansyahNo ratings yet

- Basf Masterprotect 2020Document2 pagesBasf Masterprotect 2020SHAIK ASIMUDDIN100% (1)

- Basf Masterseal m808 TdsDocument8 pagesBasf Masterseal m808 TdsOkan KalendarNo ratings yet

- 1 - Masterseal-M-262-TdsDocument2 pages1 - Masterseal-M-262-TdsPaul ManiquisNo ratings yet

- MasterProtect 300FC - 1Document2 pagesMasterProtect 300FC - 1Mohand EliassNo ratings yet

- Basf Masterseal P 640 Tds 2Document3 pagesBasf Masterseal P 640 Tds 2Bashir SolimanNo ratings yet

- Sikaseal - 105Document3 pagesSikaseal - 105Nader ToutounjiNo ratings yet

- MBCC Masterseal 345 Tds v4Document2 pagesMBCC Masterseal 345 Tds v4shashikantNo ratings yet

- Mastertop P 651 TdsDocument2 pagesMastertop P 651 Tdsmuhammednaar32No ratings yet

- Masterseal 588: Description Packaging and ColorsDocument2 pagesMasterseal 588: Description Packaging and ColorsmariaNo ratings yet

- Mastertop 1324 v1Document3 pagesMastertop 1324 v1mahmoodawadhNo ratings yet

- Masterseal TC 257 TdsDocument2 pagesMasterseal TC 257 TdsfirozembrayilNo ratings yet

- Masterseal - 551Document2 pagesMasterseal - 551Sathish KumarNo ratings yet

- Masterseal 550Document4 pagesMasterseal 550Haresh BhavnaniNo ratings yet

- MasterSeal 550Document2 pagesMasterSeal 550Muhammad Abdul Wajid RaiNo ratings yet

- MasterSeal - 551 v4Document2 pagesMasterSeal - 551 v4piyu114No ratings yet

- Radiant Barrier Coating: For Energy Conservation and Light ReflectionDocument2 pagesRadiant Barrier Coating: For Energy Conservation and Light ReflectionEsaNo ratings yet

- Basf Masterseal 550 Waterproof Wall CoatingDocument3 pagesBasf Masterseal 550 Waterproof Wall Coatingmeja.gamerNo ratings yet

- Masterseal 345 TdsDocument2 pagesMasterseal 345 TdsMarko BlagojevicNo ratings yet

- Masterflow 400 TdsDocument3 pagesMasterflow 400 TdsverNo ratings yet

- Masterseal 550 TdsDocument3 pagesMasterseal 550 TdsMohammed EssamNo ratings yet

- 14 - TDS - Concresive 2020Document2 pages14 - TDS - Concresive 2020aahtagoNo ratings yet

- MasterProtect 300 v2Document2 pagesMasterProtect 300 v2Zainal AbidhynNo ratings yet

- Polycoat RTLDocument2 pagesPolycoat RTLniaz05288No ratings yet

- MasterSeal 380 TDSDocument2 pagesMasterSeal 380 TDSEngTamerNo ratings yet

- Masterseal 540Document2 pagesMasterseal 540Nguyen Chi Thanh100% (1)

- Manual Everbuild Evercryl One Coat 15341Document3 pagesManual Everbuild Evercryl One Coat 15341scribd2162No ratings yet

- Masterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingDocument3 pagesMasterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingEngTamerNo ratings yet

- Masterflex 700 GGDocument3 pagesMasterflex 700 GGHaresh BhavnaniNo ratings yet

- Masterbrace® Lam (Formerly Known As Mbrace® Laminate)Document2 pagesMasterbrace® Lam (Formerly Known As Mbrace® Laminate)KY PengNo ratings yet

- Sikarep® Microcrete-4: Product Data SheetDocument2 pagesSikarep® Microcrete-4: Product Data Sheetsidharthsud28No ratings yet

- Starproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingDocument1 pageStarproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingYASHICA VAITTIANATHANNo ratings yet

- Masterseal 540: Flexible, Polymer Cement Waterproofing SlurryDocument2 pagesMasterseal 540: Flexible, Polymer Cement Waterproofing SlurryRicky Reung100% (1)

- Masterprotect 1813: Amine-Cured, Pitch Free EpoxyDocument2 pagesMasterprotect 1813: Amine-Cured, Pitch Free EpoxyGavriel Ng100% (1)

- Protectosil CIT PDFDocument3 pagesProtectosil CIT PDFFrancois-No ratings yet

- Masterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingDocument3 pagesMasterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingEngTamerNo ratings yet

- Mbrace Laminate LM, MM, HM TDSDocument3 pagesMbrace Laminate LM, MM, HM TDSDoug WeirNo ratings yet

- SikaMonoTop 620MY en MY (11 2018) 1 1Document3 pagesSikaMonoTop 620MY en MY (11 2018) 1 1chanqiming51No ratings yet

- Masterseal Traffic 1330 TdsDocument3 pagesMasterseal Traffic 1330 TdsSolomon AhimbisibweNo ratings yet

- Masterseal M 635: Flexible and Elastic Single Component Polyurethane Waterproofing MembraneDocument3 pagesMasterseal M 635: Flexible and Elastic Single Component Polyurethane Waterproofing MembraneMadhu RaiNo ratings yet

- Polycoat Rbe FR: Rubberized Bitumen EmulsionDocument2 pagesPolycoat Rbe FR: Rubberized Bitumen EmulsionAbidNo ratings yet

- Basf Masteremaco S 488 TdsDocument3 pagesBasf Masteremaco S 488 TdsArindamBhattacharjee100% (2)

- Sikasil® Wet Areas: Product Data SheetDocument3 pagesSikasil® Wet Areas: Product Data SheetMostafa BatanyNo ratings yet

- Sikafill®-300 Thermic: Product Data SheetDocument4 pagesSikafill®-300 Thermic: Product Data Sheetmaga2292No ratings yet

- BASF MasterSeal M 800Document4 pagesBASF MasterSeal M 800Mohiuddin Muhin100% (2)

- Eng Masterrheobuild 850 TdsDocument4 pagesEng Masterrheobuild 850 TdsaghamshahidNo ratings yet

- Masterseal 380Document2 pagesMasterseal 380Francois-No ratings yet

- Flexoplast®: Product Data SheetDocument2 pagesFlexoplast®: Product Data SheetRoyete M Silfani PattyNo ratings yet

- TDS - Mastertop 1332Document2 pagesTDS - Mastertop 1332Venkata RaoNo ratings yet

- Antistatic SLEDocument51 pagesAntistatic SLEhodido2006No ratings yet

- X-Shield SF PrimerDocument2 pagesX-Shield SF Primernader enanyNo ratings yet

- Basf MasterEmaco S 488Document3 pagesBasf MasterEmaco S 488abdul majeedNo ratings yet

- MasterSeal 610Document2 pagesMasterSeal 610Gavriel NgNo ratings yet

- Masterflow: Epoxy Based, High Strength GroutDocument3 pagesMasterflow: Epoxy Based, High Strength GroutAydın VarolNo ratings yet

- BASF Masterseal 540 PDFDocument2 pagesBASF Masterseal 540 PDFJM Subion100% (1)

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- TDS BS Futura PCX 106 - Nepal (Low PC) NepalDocument2 pagesTDS BS Futura PCX 106 - Nepal (Low PC) NepalhemantrulzNo ratings yet

- Technotrade Associates Quotation Hisab/QT #TA/115: Terms and ConditionsDocument1 pageTechnotrade Associates Quotation Hisab/QT #TA/115: Terms and ConditionshemantrulzNo ratings yet

- Technical Data For Bs-17 3P: Smart Chemistry For ConcreteDocument2 pagesTechnical Data For Bs-17 3P: Smart Chemistry For ConcretehemantrulzNo ratings yet

- Description of BS-17 3PR (Retention SN)Document2 pagesDescription of BS-17 3PR (Retention SN)hemantrulzNo ratings yet

- MC Injekt2033 PDFDocument2 pagesMC Injekt2033 PDFhemantrulzNo ratings yet

- Triethoxy Caprylylsilane: Treatment-11SDocument2 pagesTriethoxy Caprylylsilane: Treatment-11ShemantrulzNo ratings yet

- Technical Specifications Civil: Dr. Ram Manohar Lohia State Academy For Administration and ManagementDocument43 pagesTechnical Specifications Civil: Dr. Ram Manohar Lohia State Academy For Administration and ManagementhemantrulzNo ratings yet

- COMPANY PROFILE-BuildcareDocument7 pagesCOMPANY PROFILE-BuildcarehemantrulzNo ratings yet

- Delivery Challan# INV-17Document2 pagesDelivery Challan# INV-17hemantrulzNo ratings yet

- Mel-Drain: Rolled Matrix Drainage SystemsDocument2 pagesMel-Drain: Rolled Matrix Drainage SystemshemantrulzNo ratings yet

- Efflock™ Admixture System: Division 04 - MasonryDocument2 pagesEfflock™ Admixture System: Division 04 - MasonryhemantrulzNo ratings yet

- Plasticizer Formulation Selector Guide: Technical TipDocument4 pagesPlasticizer Formulation Selector Guide: Technical TiphemantrulzNo ratings yet

- Over Smooth or Granulated Bur/Modbit SPF: Spray Polurethane Foam & CoatingDocument9 pagesOver Smooth or Granulated Bur/Modbit SPF: Spray Polurethane Foam & CoatinghemantrulzNo ratings yet

- MC-Entöler: Cleaning Agent For Oil ContaminationDocument2 pagesMC-Entöler: Cleaning Agent For Oil ContaminationhemantrulzNo ratings yet

- Quotation - WP: Rob & Joe TradersDocument2 pagesQuotation - WP: Rob & Joe TradershemantrulzNo ratings yet

- Quotation - WP: Rob & Joe TradersDocument2 pagesQuotation - WP: Rob & Joe TradershemantrulzNo ratings yet

- Ultrite Degreaser: Heavy-Duty Concrete Degreaser and StripperDocument2 pagesUltrite Degreaser: Heavy-Duty Concrete Degreaser and StripperhemantrulzNo ratings yet

- PCMM Acting For and On Behalf of The President of India Invites E-Tenders Against Tender No 34194077Document4 pagesPCMM Acting For and On Behalf of The President of India Invites E-Tenders Against Tender No 34194077hemantrulzNo ratings yet

- Vandex Super TDS PDFDocument2 pagesVandex Super TDS PDFhemantrulzNo ratings yet

- Mr. Satyanarain Chauhan (Adult, Male) : Travel Date Flight No. From/Terminal To/Terminal Dep - Time Arr - Time AirlineDocument2 pagesMr. Satyanarain Chauhan (Adult, Male) : Travel Date Flight No. From/Terminal To/Terminal Dep - Time Arr - Time AirlinehemantrulzNo ratings yet

- BS Wahren CF Lamination Quote To Siddha Group Kolkatta-1 PDFDocument2 pagesBS Wahren CF Lamination Quote To Siddha Group Kolkatta-1 PDFhemantrulzNo ratings yet

- TDS BS Wahren CF May 2017Document2 pagesTDS BS Wahren CF May 2017hemantrulzNo ratings yet

- Material Safety Data Sheet: Proseal TCDocument2 pagesMaterial Safety Data Sheet: Proseal TChemantrulzNo ratings yet

- Deck-O-Grip - MsdsDocument2 pagesDeck-O-Grip - MsdshemantrulzNo ratings yet

- TDS BS MoistureZeroDocument3 pagesTDS BS MoistureZerohemantrulzNo ratings yet

- TDS Brushbond IndiaDocument2 pagesTDS Brushbond IndiahemantrulzNo ratings yet

- Ultrite Degreaser MsdsDocument2 pagesUltrite Degreaser MsdshemantrulzNo ratings yet

- BOQ Water Proofing With BASF RangeDocument1 pageBOQ Water Proofing With BASF Rangehemantrulz0% (1)

- Lead Generation Strategy Tackle Box: Catch High-Quality Leads Using LinkedinDocument23 pagesLead Generation Strategy Tackle Box: Catch High-Quality Leads Using LinkedinhemantrulzNo ratings yet

- Rule 1113. Architectural CoatingsDocument24 pagesRule 1113. Architectural CoatingsPrakash BaskaranNo ratings yet

- PFD, Pfmea & CPDocument482 pagesPFD, Pfmea & CPnadi gobinda0% (1)

- 7) PPG Amercoat 385 - Pds - AiDocument4 pages7) PPG Amercoat 385 - Pds - AididbeauNo ratings yet

- 100 GPP GCX 00074 001 - Method Statement For Painting WorksDocument90 pages100 GPP GCX 00074 001 - Method Statement For Painting WorksEko Prastyo96100% (1)

- Plasguard 5309 PDFDocument3 pagesPlasguard 5309 PDFNageswara Rao BavisettyNo ratings yet

- PaintsDocument22 pagesPaintsPriyanka BasuNo ratings yet

- A2-30 Applied Finishes For Flat RoofsDocument23 pagesA2-30 Applied Finishes For Flat RoofsJacky TiongNo ratings yet

- In Plant Training Report - Sanjay SureshDocument13 pagesIn Plant Training Report - Sanjay SureshAshutosh Prakash Mishra0% (2)

- TDS Kemikote High BuildDocument2 pagesTDS Kemikote High BuildKusal Hettiarachchi100% (1)

- UNIQDocument6 pagesUNIQkylegazeNo ratings yet

- Amended Order - MM EnterprisesDocument16 pagesAmended Order - MM EnterprisesSaranNo ratings yet

- Paint Specification Especificación de Pintura: Primary Sulfide ProjectDocument21 pagesPaint Specification Especificación de Pintura: Primary Sulfide ProjectEsteban Rios PitaNo ratings yet

- Sonneborn NP2Document4 pagesSonneborn NP2Edward FlynnNo ratings yet

- Pentadur 5540 (F6A)Document3 pagesPentadur 5540 (F6A)SiDdu Kalashetti0% (1)

- Surface Preparation and Protective CoatingDocument19 pagesSurface Preparation and Protective CoatingnitinNo ratings yet

- Dulux 1 Step Prep Water Based Primer Sealer UndercoatDocument5 pagesDulux 1 Step Prep Water Based Primer Sealer UndercoatPeter SivilayNo ratings yet

- TDs - Emaco R101Document3 pagesTDs - Emaco R101Venkata RaoNo ratings yet

- 09 Samss 030Document8 pages09 Samss 030Kalanithi KasirajanNo ratings yet

- Trenton Wax TapeDocument12 pagesTrenton Wax TapearunkumarNo ratings yet

- Paint Inspection ServicesDocument27 pagesPaint Inspection ServicesJAVID TAJHIZ MAHAN100% (1)

- Dow Corning 813 Silicone Sealant: Glazing and Construction SealantDocument2 pagesDow Corning 813 Silicone Sealant: Glazing and Construction SealantcandyamNo ratings yet

- Renderoc HB40 TDS.2018Document5 pagesRenderoc HB40 TDS.2018Joan FosterNo ratings yet

- Truss DesignDocument111 pagesTruss DesignSuhas NatuNo ratings yet

- Hempel YachtPro CatalogueDocument64 pagesHempel YachtPro Cataloguelilitipantaxi_lt100% (1)

- Va242 17 R 0513 007Document33 pagesVa242 17 R 0513 007nanusha nNo ratings yet