Professional Documents

Culture Documents

9.tech Data & Calculations

Uploaded by

hieu27Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9.tech Data & Calculations

Uploaded by

hieu27Copyright:

Available Formats

Tech.

Data & Calculations

Nguyen Cong Thuan/JPS DNV Vinashin Training/ 2007

Technical data and calculations

• An inspector is required to be able to carry out

simple calculations related to the coatings, like WFT

vs. DFT, volumes required for specific jobs,

spreading rates, consumptions, simple cost

calculations, solid content and thinning, etc.

• Participants will be given the various formulations

for calculation and required data during this course.

• They must however know where to find such

information on their own once the course has

finished

Nguyen Cong Thuan/JPS DNV Vinashin Training/ 2007

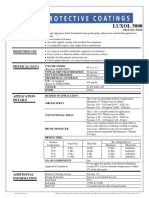

Technical Data

• Most of the product data we need

for carrying out inspections and for

carrying out necessary calculations

can be found in the Technical Data

Sheets (TDS) and/or in the Material

Safety Data Sheets (MSDS).

Nguyen Cong Thuan/JPS DNV Vinashin Training/ 2007

TDS for inspections & calculations

• Corresponding DFT & • Application Data

– Mixing ratio

WFT

– Induction time

– Minimum

– Pot life

– Maximum

– Thinner No.

– Typical

– Airless spray data

• Physical properties – Thinning

– Vol% solid

– Flash point

• Drying times

– At various temperatures

– VOC

• Surface preparation • Typical system

– Nos. coats

– On various substrates

– DFT

• Application

requirements • Pack size

– Ambient conditions

– Methods

Nguyen Cong Thuan/JPS DNV Vinashin Training/ 2007

MSDS for inspections &

calculations

Important sections: 9. Physical properties

1. Identification – Colour / Odour

– Where to contact for more info. – Flash point

– Density (Sp.G.)

2. Composition – Lower explosion limit

– Hazardous ingredients – Solubility

3. Hazard identification 10.Stability

– Warnings – Reactive?

4. First-aid measures 11.Toxicological

– What to do in an emergency – Danger to humans

5. Fire-fighting measures 12.Ecological

6. Accidental release – Environment

– Spillage 13.Disposal

7. Handling & storage – waste

8. Personal protection 14.Transport

– What PPE must be used 15.Regulation

16.Other

Nguyen Cong Thuan/JPS DNV Vinashin Training/ 2007

CALCULATIONS

• Can you calculate how high wet thickness to apply

of a product with 65% solid content that has been

diluted 15%, in order to achieve a dry film

thickness of 60 microns, and how much will the

total paint and thinner cost should when applying

two such coats on the outside of a cylindrical 8

meter high tank with diameter 12 meter, when the

loss is estimated to be 35% and the purchase price

is $8.25 for the paint and $2.90 for the thinner?

• You cannot? By the end of this course you should

be able to (might be included in the final

examination)

Nguyen Cong Thuan/JPS DNV Vinashin Training/ 2007

Calculations : Paint

Abbreviations

WFT = Wet Film Thickness

DFT = Dry Film Thickness

% VS = Percent Volume Solids

LF = Loss Factor

DV = Dead Volume

Nguyen Cong Thuan/JPS DNV Vinashin Training/ 2007

Wet Film calculations

• 1 litre covers 1 m2 in 1000 microns wet

• 1 litre covers 10 m2 in 100 microns wet

• RATIO: 1 : 1 : 1000

litre sq.meter wet film thickness

Meaning: Sq.m./ltr * WFT = 1000

Nguyen Cong Thuan/JPS DNV Vinashin Training/ 2007

Formula for determining the DFT

WFT x % VS

Formula: DFT = 100

Example:

WFT = 250 µm

% VS = 50 %

250 x 50

DFT = = 125 µm

100

Nguyen Cong Thuan/JPS DNV Vinashin Training/ 2007

Formula for determining the WFT

DFT x 100 %

Formula : WFT = % VS

Example:

DFT = 100 µm

% VS = 65 %

WFT = 100 x 100 % = 154 µm

65 %

Nguyen Cong Thuan/JPS DNV Vinashin Training/ 2007

Formula for determining the WFT after

thinning (Method 1)

Formula: WFT = DFT x (100 % + % thinner)

% VS

Example:

DFT = 100 µm

% VS = 65 %

Added thinner = 20 %

WFT = 100 x (100 % + 20 %) =185 µm

65 %

Nguyen Cong Thuan/JPS DNV Vinashin Training/ 2007

Formula for determining the WFT after

thinning (Method 2).

DFT = 100 microns

% VS = 65 %

Added thinner = 20 %

Volume of paint = 1 litre New % VS: 65 = 54 %

1,2

Volume of thinner = 0,2 litre

New volume = 1,2 litre

WFT = 100 % x 100 microns = 185 µm

54 %

Nguyen Cong Thuan/JPS DNV Vinashin Training/ 2007

Theoretical spreading rate

% VS x 10

Formula: = m2/litre

DFT

DFT = 100 microns

% VS = 65

10 = Factor

65 x 10

Spreading rate: = 6,5m2/litre

100

Nguyen Cong Thuan/JPS DNV Vinashin Training/ 2007

Consumption of paint, no loss (1 of 2)

To be painted: Tank, area of 500 m2

Paint DFT % VS

Epoxy mastic 200 microns 85 %

Polyurethane topcoat 50 “ 50 %

Area (m2) x DFT

Consumption = = litre

10 x % VS

Nguyen Cong Thuan/JPS DNV Vinashin Training/ 2007

Consumption of paint, no loss (1 of 2)

To be painted: Tank, area of 500 m2

Formula: Area, m2 x DFT

10 x % VS

Epoxy mastic 500 x 200 = 117,7 litre

10 x 85

500 x 50

Polyurethane topcoat = 50,0 litre

10 x 50

Nguyen Cong Thuan/JPS DNV Vinashin Training/ 2007

Consumption of Paint with loss

To be painted: Tank, area of 500 m2 , 40 % loss

40 % loss implies that only 60 % will remain on the surface.

The correction factor, Loss factor, will be 0.6

Formula: Area, m2 x DFT

10 x % VS x loss factor

500 x 200

Epoxy mastic 10 x 85 x 0,6 = 196 litre

Polyurethane topcoat 500 x 50 = 83 litre

10 x 50 x 0,6

Nguyen Cong Thuan/JPS DNV Vinashin Training/ 2007

You might also like

- Tech Data & CalculationsDocument13 pagesTech Data & Calculationsmaxwell marshall100% (1)

- Tech Data and Calculations PDFDocument10 pagesTech Data and Calculations PDFravi00098No ratings yet

- 7 CalculationDocument15 pages7 CalculationMohamed NouzerNo ratings yet

- 7 CalculationDocument15 pages7 Calculationislamfarag2No ratings yet

- Fertilizers AshutoshDocument6 pagesFertilizers AshutoshVidushi ShuklaNo ratings yet

- Microsoft Word - 13 Calculations FINAL 13-09Document12 pagesMicrosoft Word - 13 Calculations FINAL 13-09Djou KetataNo ratings yet

- Paint CalculationDocument5 pagesPaint CalculationEdy AlamNo ratings yet

- Review of Relative Density PrinciplesDocument35 pagesReview of Relative Density Principlesradi_ashraf100% (5)

- Calculations - Exercise 1 - Question Paper - 1Document1 pageCalculations - Exercise 1 - Question Paper - 1kellary liawNo ratings yet

- Unit 3 - Minimum Fluidization: Assignment: Module 2Document10 pagesUnit 3 - Minimum Fluidization: Assignment: Module 2shubhamNo ratings yet

- Relative Density of SandDocument29 pagesRelative Density of SandMd. Saiful Islam RonyNo ratings yet

- Mc-Dur 1077 FGDocument2 pagesMc-Dur 1077 FGTibelu'No ratings yet

- Drop Casting MethodDocument25 pagesDrop Casting MethodZoheir100% (4)

- Surfactants NDDocument46 pagesSurfactants NDJogender DhayalNo ratings yet

- 5 Good DERE Measurement PracticeDocument72 pages5 Good DERE Measurement PracticersuertoNo ratings yet

- Coating Application and TestingDocument22 pagesCoating Application and Testingsri ramadhaniNo ratings yet

- Fabrication of PS - Clay NanocompositesDocument19 pagesFabrication of PS - Clay NanocompositesNitin PurohitNo ratings yet

- Zinc Phosphate PrimerDocument2 pagesZinc Phosphate PrimertrinityallianceconsultancyNo ratings yet

- Bgas 3.2 Maths Exercise WFT Calculations WFT 100 X DFT VS: Page 1 of 5Document5 pagesBgas 3.2 Maths Exercise WFT Calculations WFT 100 X DFT VS: Page 1 of 5Bayu FalenNo ratings yet

- Lecture 3 - Vacuum Technologies Part 1Document44 pagesLecture 3 - Vacuum Technologies Part 1Clarissa Ariel SantosoNo ratings yet

- Deore Prashant Ashok Department of Pharmaceutics: Presented byDocument18 pagesDeore Prashant Ashok Department of Pharmaceutics: Presented byDeepakNo ratings yet

- t224 PDFDocument2 pagest224 PDFRodrigo Samuel Huanca PerezNo ratings yet

- Bio PractDocument3 pagesBio PractChloe TanNo ratings yet

- 2013 4M3 MembranesDocument73 pages2013 4M3 MembranesPa1 Kumar MNo ratings yet

- Pds Luxol 5000 VocDocument2 pagesPds Luxol 5000 VocmuthukumarNo ratings yet

- Nippon CR - Roadline PaintDocument2 pagesNippon CR - Roadline PaintRUMMNo ratings yet

- RobbiathaneDocument2 pagesRobbiathaneAnson FranklinNo ratings yet

- BGas Excercise Page 2Document1 pageBGas Excercise Page 2Bayu FalenNo ratings yet

- CIVE 205 - Spring2017 - Week10Document11 pagesCIVE 205 - Spring2017 - Week10haloNo ratings yet

- Nafufill: Corrosion Protection Coat and Bond CoatDocument2 pagesNafufill: Corrosion Protection Coat and Bond CoatRichard AmoahNo ratings yet

- Fluid Mechanics My Book PDFDocument38 pagesFluid Mechanics My Book PDFAniket BabutaNo ratings yet

- Module 5 Geotechnical Engineering BSRE 1st 23 24 1Document13 pagesModule 5 Geotechnical Engineering BSRE 1st 23 24 1calebjohnf0512No ratings yet

- FulltextDocument90 pagesFulltextjokonudiNo ratings yet

- Relative DensityDocument35 pagesRelative DensityJoseph Daguio JrNo ratings yet

- Paint CalculationDocument16 pagesPaint CalculationthandeshNo ratings yet

- Blend Times in Stirred Tanks Reacting Flows - Lecture 9: Instructor: André BakkerDocument39 pagesBlend Times in Stirred Tanks Reacting Flows - Lecture 9: Instructor: André BakkerBarış ErdoğanNo ratings yet

- Sam Classic FinishDocument2 pagesSam Classic FinishMo MosadNo ratings yet

- A Mu Check Program For Imrt: Ado Van Rensburg Pretoria Academic HospitalDocument27 pagesA Mu Check Program For Imrt: Ado Van Rensburg Pretoria Academic HospitalEdis ĐedovićNo ratings yet

- Epilux 218: Product DescriptionDocument2 pagesEpilux 218: Product DescriptionMoin AltafNo ratings yet

- Chemical Engineering 374: Fluid MechanicsDocument20 pagesChemical Engineering 374: Fluid Mechanicssathya prakashNo ratings yet

- Sigmacover 410Document5 pagesSigmacover 410panji akbarNo ratings yet

- PresentationsDocument35 pagesPresentationsNaveen KarunarathnaNo ratings yet

- ch5 DiffusionDocument26 pagesch5 DiffusionSaif AlbaddawiNo ratings yet

- Tutorial 5. Modeling Radiation and Natural ConvectionDocument54 pagesTutorial 5. Modeling Radiation and Natural Convectionwaleed yehiaNo ratings yet

- Touchwood NC Colour: Architectural CoatingsDocument2 pagesTouchwood NC Colour: Architectural CoatingsmuthukumarNo ratings yet

- Kumagai 2019Document8 pagesKumagai 2019Joao DumkeNo ratings yet

- Dissolution & DiffusionDocument3 pagesDissolution & Diffusionصيدلاني أزهراويNo ratings yet

- Zinc Chromate Primer PDFDocument2 pagesZinc Chromate Primer PDFWanda WibisanaNo ratings yet

- Certipur Certified Reference Material: Cadmium Standard Solution 1000 MG/L CDDocument1 pageCertipur Certified Reference Material: Cadmium Standard Solution 1000 MG/L CDArdhy LazuardyNo ratings yet

- Usepa Bioreactor Workshop FEBRUARY 27, 2003: Landfill & Waste Geotechnical StabilityDocument29 pagesUsepa Bioreactor Workshop FEBRUARY 27, 2003: Landfill & Waste Geotechnical StabilitymarcelodelfinNo ratings yet

- TOUNEKTI Dhiaeddine JEBNOUN Alaeddine: Planning A Very High Speed WDM Optical NetworkDocument17 pagesTOUNEKTI Dhiaeddine JEBNOUN Alaeddine: Planning A Very High Speed WDM Optical NetworkAla JebnounNo ratings yet

- University of Cambridge International Examinations General Certificate of Education Advanced Subsidiary Level and Advanced LevelDocument28 pagesUniversity of Cambridge International Examinations General Certificate of Education Advanced Subsidiary Level and Advanced LevelNoor ZahraNo ratings yet

- Srep 44236Document10 pagesSrep 44236Carol SantosNo ratings yet

- Particle Fluid Separation: Filtration: CHE 509: Introduction To Particle TechnologyDocument32 pagesParticle Fluid Separation: Filtration: CHE 509: Introduction To Particle TechnologyJane Eilyza AballaNo ratings yet

- DSA 2011 01590 - HEMPATHANE 55210 DatasheetDocument2 pagesDSA 2011 01590 - HEMPATHANE 55210 DatasheetMehedi HasanNo ratings yet

- The Science of Superhydrophobicity: Enhancing Outdoor Electrical InsulatorsFrom EverandThe Science of Superhydrophobicity: Enhancing Outdoor Electrical InsulatorsNo ratings yet

- Unit Processes in Pharmacy: Pharmaceutical MonographsFrom EverandUnit Processes in Pharmacy: Pharmaceutical MonographsRating: 4.5 out of 5 stars4.5/5 (4)

- QC 65-2015Document112 pagesQC 65-2015hieu27No ratings yet

- Bang Diem Thi TADocument2 pagesBang Diem Thi TAhieu27No ratings yet

- 111 2016 ND CPDocument12 pages111 2016 ND CPhieu27No ratings yet

- Red Wing Mens Coveralls Sizing ChartDocument1 pageRed Wing Mens Coveralls Sizing Charthieu27No ratings yet

- Garmin - Compare 2Document4 pagesGarmin - Compare 2hieu27No ratings yet

- Pps BrochureDocument12 pagesPps Brochurehieu27No ratings yet

- Part 7 Corrigenda-Aug18Document2 pagesPart 7 Corrigenda-Aug18hieu27No ratings yet

- U90M Part 1 E-Jan18Document10 pagesU90M Part 1 E-Jan18hieu27No ratings yet

- Garmin - CompareDocument9 pagesGarmin - Comparehieu27No ratings yet

- U90M Corrigenda-Aug18Document1 pageU90M Corrigenda-Aug18hieu27No ratings yet

- Part 7 Guide To Colors PDFDocument1 pagePart 7 Guide To Colors PDFhieu27No ratings yet

- Ve Sinh Lam Sach Cac KetDocument1 pageVe Sinh Lam Sach Cac Kethieu27No ratings yet

- Application PDFDocument85 pagesApplication PDFhieu27No ratings yet

- Survey After Construction 2018: Rules ForDocument11 pagesSurvey After Construction 2018: Rules Forhieu27No ratings yet

- Part 2 Corrigenda-July18Document1 pagePart 2 Corrigenda-July18hieu27No ratings yet

- 13.summary of StandardsDocument9 pages13.summary of Standardshieu27No ratings yet

- 4.surface Grades ISO 8501Document10 pages4.surface Grades ISO 8501truongphuong12No ratings yet

- Van An Toan Chai Gio Van Dong NhanhDocument1 pageVan An Toan Chai Gio Van Dong Nhanhhieu27No ratings yet

- 8.quality Control PDFDocument16 pages8.quality Control PDFhieu27No ratings yet

- Bi N B N Kióm Tra Inspection Report: Tçu H NG - 6.300TDocument2 pagesBi N B N Kióm Tra Inspection Report: Tçu H NG - 6.300Thieu27No ratings yet

- 1.corrosion (Vinashin) PDFDocument17 pages1.corrosion (Vinashin) PDFhieu27No ratings yet

- Stuffing Report - White Sugar - 23611-23 PAG 2 EVERGREENDocument6 pagesStuffing Report - White Sugar - 23611-23 PAG 2 EVERGREENEder FerreiraNo ratings yet

- Divinity Original Sin 2 Skill Book CombonationsDocument1 pageDivinity Original Sin 2 Skill Book Combonationsbeans54No ratings yet

- Dr. Fixit Primeseal PDFDocument2 pagesDr. Fixit Primeseal PDF41464147No ratings yet

- Jet Lube Grease CatalogDocument24 pagesJet Lube Grease CatalogKapil TiwariNo ratings yet

- Desalination: Gang Chen, Renxiao Liu, Ho Kyong Shon, Yanqiang Wang, Jianfeng Song, Xue-Mei Li, Tao HeDocument9 pagesDesalination: Gang Chen, Renxiao Liu, Ho Kyong Shon, Yanqiang Wang, Jianfeng Song, Xue-Mei Li, Tao Hemhafez1979No ratings yet

- Biodesulfurizare 1Document30 pagesBiodesulfurizare 1Stan Dragos-MihaiNo ratings yet

- Catalog For PH Meter PH-B200EMDocument1 pageCatalog For PH Meter PH-B200EMMohamed Shamnad محمد شمندNo ratings yet

- Chemistry: Crash Course For JEE Main 2020Document14 pagesChemistry: Crash Course For JEE Main 2020johnNo ratings yet

- SAES-N-100 PDF Download - Refractory Systems - PDFYAR - Engineering Notes, Documents & LecturesDocument6 pagesSAES-N-100 PDF Download - Refractory Systems - PDFYAR - Engineering Notes, Documents & LecturesZahidRafiqueNo ratings yet

- Pakistan International School, Jeddah Senior Girls Section Session 2019 - 2020 Chemistry Notes SSC 1Document28 pagesPakistan International School, Jeddah Senior Girls Section Session 2019 - 2020 Chemistry Notes SSC 1Umme AbdullahNo ratings yet

- Bahan Konstruski Dan Korosi - Pertemuan 14Document40 pagesBahan Konstruski Dan Korosi - Pertemuan 14AuliaMukadisNo ratings yet

- Fire - Hazard+explosion Hazard AssessmentDocument56 pagesFire - Hazard+explosion Hazard AssessmentSarla ShendeNo ratings yet

- COA of Calcium D Pantothente - RevisedDocument1 pageCOA of Calcium D Pantothente - RevisedJose.SuarezNo ratings yet

- Stereochemistry and StereoisomerDocument18 pagesStereochemistry and StereoisomerAyNo ratings yet

- Water Based Drilling FluidsDocument4 pagesWater Based Drilling FluidsHanyNo ratings yet

- DNA Replication WorksheetDocument2 pagesDNA Replication Worksheetfabyunaaa100% (1)

- M2 Science7aDocument2 pagesM2 Science7aSeb GanaraNo ratings yet

- Enhancement Activity/Outcome (Lesson 1) : No Answers YetDocument3 pagesEnhancement Activity/Outcome (Lesson 1) : No Answers YetWinxPink 17No ratings yet

- Resigen MSDSDocument11 pagesResigen MSDSrightchoice.rcps100% (1)

- Membrane TechnologyDocument26 pagesMembrane TechnologyRajan sigdel100% (3)

- CH 2015 PDFDocument19 pagesCH 2015 PDFBhawani Pratap Singh PanwarNo ratings yet

- Prudential Bank v. PanisDocument10 pagesPrudential Bank v. PanisAgent BlueNo ratings yet

- CHT302 - Ktu QbankDocument8 pagesCHT302 - Ktu Qbanknaagin12300No ratings yet

- Pidilite Roff VertifixDocument11 pagesPidilite Roff VertifixKaustubh SavanurNo ratings yet

- Caracksil Acrylic PasteDocument3 pagesCaracksil Acrylic PasteHaradhon DattaNo ratings yet

- Cd6405 Steaphine Binti Saiful Ahmad SavaranDocument24 pagesCd6405 Steaphine Binti Saiful Ahmad SavaranfadillaNo ratings yet

- Research Proposal-Kelsi GelleDocument5 pagesResearch Proposal-Kelsi Gelleapi-619041501No ratings yet

- Interpretasi Spektra Elektronik Senyawa Kompleks 1Document33 pagesInterpretasi Spektra Elektronik Senyawa Kompleks 1AsrelNo ratings yet

- Properties of BitumenDocument10 pagesProperties of Bitumenamanbhu1991100% (9)

- Operation AND Maintenance ManualDocument62 pagesOperation AND Maintenance ManualMohan BabuNo ratings yet