Professional Documents

Culture Documents

CHAPTER V: BALANCING (Continuation)

Uploaded by

Patrick Paul PalacolOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CHAPTER V: BALANCING (Continuation)

Uploaded by

Patrick Paul PalacolCopyright:

Available Formats

CHAPTER V: BALANCING (continuation) of the machine.

Fan and blower housing,

fan duct work or other large surface areas

NOISE CONTROL TECHNIQUES of machine tend to create a “loud

A. Controlling noise at the source speaker” affect with very little applied

B. Controlling noise in its path energy. If this is the case, the noise may

C. Controlling noise at the receiver be reduced by stiffening these areas or by

applying damping materials.

CONTROLLING NOISE AT THE SOURCE

Forms of Damping Materials:

- Correcting mechanical problems is one

obvious way of reducing noise at the - These are usually asphalt, latex or epoxy

source. materials.

- There are additional steps which can be o Brush-on

taken. Some of these are outlined below: o Spray-on

o Trowl-on

1. Substitute of machine or components.

Damping can be achieved by cementing:

a) Substitute nylon, plastic or

sintered gears for steel gears. o Flexible sheets of rubber

b) Use V-belt drives in place of gear o Glass fiber

drives. o Leaded vinyl

c) Use larger, lower RPM machines o Other materials directly to the vibrating

in place of smaller highspeed surface

machines.

d) Use hydraulic presses in place of Factors in selecting the most appropriate damping

stamping presses. materials:

e) Substitute rotating shears for o Water and chemical resistance

square shears.

o Fire resistance

f) Use step dies in place of single

o Cost

operation dies.

2. Substitution of processes.

a) Substitute compression riveting CONTROLLING NOISE IN ITS PATH

in place of impact riveting. - if reducing the noise level at the source is

b) Use welding instead of riveting. not practical or feasible, the next possible

c) Substitute hot working for cold solution is to stop the noise in its path to

working. prevent it from reaching the listener.

3. In cases where excessive noise is the Three ways of Controlling Noise in its Path:

result of air or fluid flow turbulence in

a) sound absorption materials

duct work or piping, install silencers,

b) acoustic barriers and enclosures

mufflers, baffels, etc. Avoid sharp changes

c) vibration insulation

in flow direction.

4. Vibration Damping: many machinery

noise problems are the result of noise

radiated from vibration of the skin surface

SOUND ABSORBTION MATERIALS b) Is a complete enclosure necessary or will

a partial enclosure or barrier serve the

- sound absorption materials are usually

purpose?

lightweight, porous materials that do not

c) Are provisions needed for ventilating

block the sound but offer flow resistance,

enclosed machinery?

thus converting sound energy into heat.

d) Will the barrier or enclosure restrict the

Common sound absorption materials used: movement of material to and from the

machine?

o glass fiber e) Once enclosed, will the machines be

o mineral wool readily accessible for service and repair?

o fiber board Can the machine be removed from

o open-cell plastic foams enclosure if replacement becomes

o carpet and draperies necessary?

- to control noise radiated directly from a Application of partial enclosure and barriers:

source requires a barrier or acoustic a) A partial enclosure or barrier may be all

enclosure. that’s needed to protect workers near the

machine.

b) A sound barrier may not be effective in a

ACOUSTIC BARRIERS AND ENCLOSURE small enclosed area because of the

presence of reflected sound.

- Materials used for acoustic enclosures

and sound barriers are usually heavy and

dense to block the passage of sound

energy. VIBRATION ISOLATION

- The basic type of enclosure relies on the - Structure-borne vibration and noise is

mass or weight of the materials used in its controlled by vibration isolation.

construction for its effectiveness.

- The more massive the barrier, the better Structure-borne vibration – often result in

it will resist the passage of sound. excessive noise at location far from the machine

responsible.

Materials widely used for sound barriers and

enclosure: - Vibration isolation involves the use of

resilient materials such as rubber, cork,

o Masonry block felt or fiberglass pads; coil springs; flexible

o Brick joints in piping or conduit; which prevent

o Sheet lead the vibration from being transmitted into

o Ordinary gypsum board the structure.

Factors must be considered in installation of an

acoustic enclosure or barrier:

CONTROLLING NOISE AT THE RECEIVER

a) How mush noise reduction is required

- If the two techniques are not possible,

and what are the major noise

the only remaining solution is to control

frequencies? These facts must be known

the noise at the receiver or listener.

in order to select the proper enclosure

- This involves the use of personal hearing

material.

protection devices such as ear muffs or

ear plugs.

You might also like

- Noise Reduction: Enhancing Clarity, Advanced Techniques for Noise Reduction in Computer VisionFrom EverandNoise Reduction: Enhancing Clarity, Advanced Techniques for Noise Reduction in Computer VisionNo ratings yet

- Building Services IV Module 05Document26 pagesBuilding Services IV Module 05hardik MajethiyaNo ratings yet

- Noise Control in OC, UG & MPPDocument83 pagesNoise Control in OC, UG & MPPSubhamoy GhoshNo ratings yet

- Chapter 4.5 Noise and Vibration PDFDocument31 pagesChapter 4.5 Noise and Vibration PDFMinho OnionsNo ratings yet

- Materials Today: Proceedings: Margus Villau, Hans Rämmal, Jüri LavrentjevDocument7 pagesMaterials Today: Proceedings: Margus Villau, Hans Rämmal, Jüri LavrentjevSERGIO LUCIANO TINOCO TUPAYACHINo ratings yet

- Top 10 Noise Control Solutions 2015 EmailDocument12 pagesTop 10 Noise Control Solutions 2015 EmailRodrigo MottaNo ratings yet

- Design Process To Evaluate Potential of Wind Noise at Façade Elements - UnlockedDocument6 pagesDesign Process To Evaluate Potential of Wind Noise at Façade Elements - UnlockedPabloNo ratings yet

- Noise Reduction in AircraftDocument2 pagesNoise Reduction in AircraftjoereisNo ratings yet

- Facade Sound Isolation: A Few Questions: To Cite This VersionDocument7 pagesFacade Sound Isolation: A Few Questions: To Cite This VersionbatteekhNo ratings yet

- Chapter-1: Downloaded FromDocument22 pagesChapter-1: Downloaded Fromsai ramanaNo ratings yet

- Noise ControlDocument14 pagesNoise ControlDon JoviNo ratings yet

- Noise HandbookDocument6 pagesNoise HandbookkarthiksugamNo ratings yet

- Acoustical Design: by Ar. Sarthak KauraDocument34 pagesAcoustical Design: by Ar. Sarthak KauraPaapu DeviNo ratings yet

- Examples of Noisy Equipment/Processes Examples of Substitutes Noisy Equipment/machineryDocument6 pagesExamples of Noisy Equipment/Processes Examples of Substitutes Noisy Equipment/machineryubabNo ratings yet

- Architectural Acoustics Lecture - O8Document20 pagesArchitectural Acoustics Lecture - O8r tasnimNo ratings yet

- THX Architectural SuggestionsDocument10 pagesTHX Architectural SuggestionsrobiwaNo ratings yet

- Chapter FourDocument10 pagesChapter FourMilat KifluNo ratings yet

- Raincheck BrochureDocument4 pagesRaincheck BrochureNandini SNo ratings yet

- BTN 1999-006 Noise Barriers V2.2 June 2006Document3 pagesBTN 1999-006 Noise Barriers V2.2 June 2006aeroforce1007No ratings yet

- Guideline For Control of Occupational NoiseDocument2 pagesGuideline For Control of Occupational NoiseAlexandra johnNo ratings yet

- Noise Control EngineeringDocument12 pagesNoise Control EngineeringArindam Bhowmick100% (1)

- Properties of Transparent Sound-Absorbing Panels For Use in Noise BarriersDocument8 pagesProperties of Transparent Sound-Absorbing Panels For Use in Noise BarriersSantiago de CompostelaNo ratings yet

- Bridge Technical Note 2018 - 007 Noise Attenuation Walls June 2018Document3 pagesBridge Technical Note 2018 - 007 Noise Attenuation Walls June 2018Thong NguyenNo ratings yet

- Noise and Noise Reduction: Soil & Waste Systems in BuildingsDocument17 pagesNoise and Noise Reduction: Soil & Waste Systems in BuildingsCatherine DaphneNo ratings yet

- Noise Control in Ug Mines - 116mn0584Document32 pagesNoise Control in Ug Mines - 116mn0584Tandin WangchukNo ratings yet

- Product Information MAURER Noise Protection GUfDocument2 pagesProduct Information MAURER Noise Protection GUfRenato BastosNo ratings yet

- The Design of Active Crossovers by Douglas Self - Appointedd PDFDocument33 pagesThe Design of Active Crossovers by Douglas Self - Appointedd PDFBrandy ThomasNo ratings yet

- BS-IV Acoustics - Module 4 & 5 - 03-11-23Document50 pagesBS-IV Acoustics - Module 4 & 5 - 03-11-231DC20AT025 Ganesh AkshayNo ratings yet

- Enclosure Dimensions:: Guidelines For Building EnclosuresDocument2 pagesEnclosure Dimensions:: Guidelines For Building EnclosuresAbraham AvNo ratings yet

- Convention Paper: Sound Field Characterisation and Absorption Measurement of Wideband AbsorbersDocument10 pagesConvention Paper: Sound Field Characterisation and Absorption Measurement of Wideband AbsorbersJulian ForondaNo ratings yet

- PD H2 118S Plans 150318Document24 pagesPD H2 118S Plans 150318nigelchaparadza82No ratings yet

- A Comparative Study On The Effect of Air Gap On Sound Transmission Loss Provided by Double Glazed PanelsDocument5 pagesA Comparative Study On The Effect of Air Gap On Sound Transmission Loss Provided by Double Glazed Panelssparesh121No ratings yet

- Xiaolong - Experimental Investigation On The Enhancement of Plenum Window Noise Reduction Using Solid ScatterersDocument15 pagesXiaolong - Experimental Investigation On The Enhancement of Plenum Window Noise Reduction Using Solid ScatterersmoniqhahaNo ratings yet

- 6B 7 Evironmental Management Plan For Pipelines - RC200612Document2 pages6B 7 Evironmental Management Plan For Pipelines - RC200612Rupesh .pNo ratings yet

- SimmonsDocument12 pagesSimmonsGürelBaltalıNo ratings yet

- STUDENTS Lecture 4 (Chapter 3)Document19 pagesSTUDENTS Lecture 4 (Chapter 3)Sirine AjourNo ratings yet

- Nitoflor DissipativeDocument4 pagesNitoflor DissipativeVincent JavateNo ratings yet

- 2-Way Trapezoidal 10" Reflex Enclosure: Cabinet Design ForDocument3 pages2-Way Trapezoidal 10" Reflex Enclosure: Cabinet Design ForferdinandNo ratings yet

- Owens CorningDocument2 pagesOwens CorningGiải Pháp Cơ ĐiệnNo ratings yet

- AssignmentDocument10 pagesAssignmentswarna raviNo ratings yet

- Vibration Isolation For Noise Control in Residential Condensing UnitsDocument7 pagesVibration Isolation For Noise Control in Residential Condensing Unitsshank100No ratings yet

- Transformers Are Never SilentDocument4 pagesTransformers Are Never SilentEngr. AbdullahNo ratings yet

- Building AcousticsDocument4 pagesBuilding AcousticsarnautoiuNo ratings yet

- Viscoelastic and Acoustic Characterization of Polyurethane-Based Acoustic Absorber Panels For Underwater ApplicationsDocument9 pagesViscoelastic and Acoustic Characterization of Polyurethane-Based Acoustic Absorber Panels For Underwater ApplicationsIvan FelisNo ratings yet

- FaneBR18XS ReflexEnclosure111019Document10 pagesFaneBR18XS ReflexEnclosure111019Sanjaya Leelananda RajathewaNo ratings yet

- Sound Absorbing Materials and ConstructionsDocument60 pagesSound Absorbing Materials and Constructionsss100% (1)

- Noise ControlDocument33 pagesNoise ControlAditha Varma RajaNo ratings yet

- Using Acoustic Liner For Fan Noise Reduction in Mo PDFDocument6 pagesUsing Acoustic Liner For Fan Noise Reduction in Mo PDFNaveen Suresh KumarNo ratings yet

- A Comparison Between The Performance of DifferentDocument8 pagesA Comparison Between The Performance of DifferentVan Luong BuiNo ratings yet

- A Note On A Circular Panel Sound Absorber With An Elastic Boundary ConditionDocument8 pagesA Note On A Circular Panel Sound Absorber With An Elastic Boundary ConditionShakila PathiranaNo ratings yet

- Mining GeologyDocument10 pagesMining GeologyRMRE UETNo ratings yet

- Flexible and Transparent W-Band Absorber Fabricated by EHD Printing TechnologyDocument5 pagesFlexible and Transparent W-Band Absorber Fabricated by EHD Printing Technologyreza mirzakhaniNo ratings yet

- Challenging The Need For Insulation: Issued May 2021Document9 pagesChallenging The Need For Insulation: Issued May 2021yrdna nawaiteosNo ratings yet

- Applied Acoustics: M.P. Peiró-Torres, M.J. Parrilla Navarro, M. Ferri, J.M. Bravo, J.V. Sánchez-Pérez, J. RedondoDocument10 pagesApplied Acoustics: M.P. Peiró-Torres, M.J. Parrilla Navarro, M. Ferri, J.M. Bravo, J.V. Sánchez-Pérez, J. RedondoJeanOscorimaCelisNo ratings yet

- 200litre Cabinet For 1 X 18" Driver: Project - 200 Litre - 18" Reflex EnclosureDocument3 pages200litre Cabinet For 1 X 18" Driver: Project - 200 Litre - 18" Reflex EnclosurebetoNo ratings yet

- Determination of Insertion Loss of Acoustic BarrieDocument6 pagesDetermination of Insertion Loss of Acoustic BarrieDaniel MoraNo ratings yet

- Research Paper On Noise Control in Ic EngineDocument6 pagesResearch Paper On Noise Control in Ic Enginegz7veyrh100% (1)

- Acoustics (SART) Flashcards - QuizletDocument14 pagesAcoustics (SART) Flashcards - QuizletrjeepanaderoNo ratings yet

- Professional Deck Builder ArticleDocument2 pagesProfessional Deck Builder Articleyash24No ratings yet

- Balancing 2Document6 pagesBalancing 2Patrick Paul PalacolNo ratings yet

- Reviewer On Safety PrelimsDocument1 pageReviewer On Safety PrelimsPatrick Paul PalacolNo ratings yet

- CAD Shortcut KeysDocument1 pageCAD Shortcut KeysPatrick Paul PalacolNo ratings yet

- Reviewer On Safety PrelimsDocument1 pageReviewer On Safety PrelimsPatrick Paul PalacolNo ratings yet

- Assignment ME LabDocument2 pagesAssignment ME LabPatrick Paul PalacolNo ratings yet

- Ial's Electrical Resistance Changes With TemperatureDocument1 pageIal's Electrical Resistance Changes With TemperaturePatrick Paul PalacolNo ratings yet

- Assignment ME LabDocument2 pagesAssignment ME LabPatrick Paul PalacolNo ratings yet

- Cstps Modofied-131230103858Document66 pagesCstps Modofied-131230103858Santoshkumar GuptaNo ratings yet

- Hot Stamping 642-8Document2 pagesHot Stamping 642-8wulfgang66No ratings yet

- ForensicEngineeringMay262015 LoadTestingDocument10 pagesForensicEngineeringMay262015 LoadTestingEli MatucadNo ratings yet

- 400 Series: Rear AxleDocument23 pages400 Series: Rear AxleMrAlbert2009No ratings yet

- Kinematics of Projectile MotionDocument23 pagesKinematics of Projectile MotiontgimranNo ratings yet

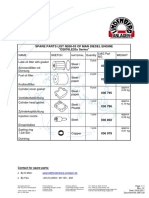

- Spare Parts List N200-03 of Man Diesel Engine "D2876LE20x Series"Document1 pageSpare Parts List N200-03 of Man Diesel Engine "D2876LE20x Series"Jezrell JaravataNo ratings yet

- Som QuestionDocument5 pagesSom QuestionjayakumarNo ratings yet

- Hyster S40CPDocument247 pagesHyster S40CPAlessandro de Oliveira100% (1)

- Std. O-Ring TolerancesDocument5 pagesStd. O-Ring TolerancesBharatNo ratings yet

- Dispositivo Disparo Diluvio VK800Document4 pagesDispositivo Disparo Diluvio VK800David EnríquezNo ratings yet

- AAPL Capability StatementDocument41 pagesAAPL Capability StatementjsmnjasminesNo ratings yet

- TDMS G1 ProjectDocument5 pagesTDMS G1 ProjectSneha Girish ShirsatNo ratings yet

- Manual Operación y Mantenimiento BI652203-00-EnDocument394 pagesManual Operación y Mantenimiento BI652203-00-Enjlparedesy100% (1)

- Maintenance Instruction ManualDocument44 pagesMaintenance Instruction ManualmohammedalathwaryNo ratings yet

- Module 5: Design of Deep Foundations Lecture 20: Introduction (Section 20.1: Introduction) Objectives in This Section You Will Learn The FollowingDocument12 pagesModule 5: Design of Deep Foundations Lecture 20: Introduction (Section 20.1: Introduction) Objectives in This Section You Will Learn The FollowingmaizansofiaNo ratings yet

- Biju CVDocument5 pagesBiju CVMercatoR GamingNo ratings yet

- mtm-2017-11-549 ANISOTROPY OF THE MECHANICAL PROPERTIES OF HOT ROLLED STEEL COILS FOR WELDED PIPESDocument4 pagesmtm-2017-11-549 ANISOTROPY OF THE MECHANICAL PROPERTIES OF HOT ROLLED STEEL COILS FOR WELDED PIPESZerina ČustovićNo ratings yet

- Welding Procedure Specification PresentasiDocument3 pagesWelding Procedure Specification PresentasiHASIM HASIMNo ratings yet

- Design Guide For Overhead CranesDocument3 pagesDesign Guide For Overhead CranesralluinNo ratings yet

- Principle Stresses Calc.Document19 pagesPrinciple Stresses Calc.Abdallah AL-AbbadiNo ratings yet

- Govt - Polytechnic, Beed. 2021-22: CertificateDocument9 pagesGovt - Polytechnic, Beed. 2021-22: CertificateUttareshwarNo ratings yet

- Wolouf CatalogueDocument3 pagesWolouf CatalogueJawad AbusamhaNo ratings yet

- Physical Ageing in Amorphous Polymers and Other MaterialsDocument249 pagesPhysical Ageing in Amorphous Polymers and Other Materialswc_11111No ratings yet

- Wind Speed in Sri Lanka PDFDocument15 pagesWind Speed in Sri Lanka PDFsandrock92100% (1)

- State-Space Linear Systems: ExercisesDocument9 pagesState-Space Linear Systems: ExercisesYoshua Diaz0% (1)

- ASTM D2105 Longitudinal Tensile FiberglassDocument6 pagesASTM D2105 Longitudinal Tensile FiberglassAngyMartinezNo ratings yet

- Submersible Sewage Ejector Pump: Pump Installation and Service ManualDocument8 pagesSubmersible Sewage Ejector Pump: Pump Installation and Service Manualallen_worstNo ratings yet

- Estimating Design Parameters in Propane Refrigerant Systems - Pumps & SystemsDocument6 pagesEstimating Design Parameters in Propane Refrigerant Systems - Pumps & Systemsm.shehreyar.khanNo ratings yet

- MAK205 HW3 Ans PDFDocument6 pagesMAK205 HW3 Ans PDFUlises Alexander Oliver BetanzNo ratings yet

- Scientific: ResearchDocument15 pagesScientific: ResearchEugene OwiNo ratings yet