Professional Documents

Culture Documents

5.500 HWDP With HT55 (7.125 X 4.000 TJ) Spiral

5.500 HWDP With HT55 (7.125 X 4.000 TJ) Spiral

Uploaded by

Alberto CárdenasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5.500 HWDP With HT55 (7.125 X 4.000 TJ) Spiral

5.500 HWDP With HT55 (7.125 X 4.000 TJ) Spiral

Uploaded by

Alberto CárdenasCopyright:

Available Formats

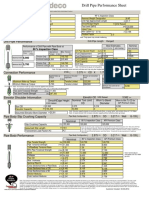

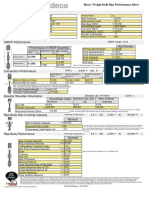

Heavy Weight Drill Pipe Performance Characteristics Pipe Size and Weight: 5.500" X 4.

000" Spiral Heavy Weight

Workstrings International® 2011 Version 1.0 Pipe Grade: 55ksi Standard Heavy Weight

Range: 2

Tool Joint: 7.125" X 4.000" HT55

Pipe Body

New New

(Nominal) (Nominal)

OD (in) 5.500 Cross Sectional Area of Pipe Body (in2) 11.192

Wall Thickness (in) 0.750 Cross Sectional Area of OD (in2) 23.758

ID (in) 4.000 Cross Sectional Area of ID (in2) 12.566

Calculated Plain End Weight (lbs/ft) 38.048 38.048 Section Modulus (in3) 11.764

Polar Section Modulus (in3) 23.528

Tensile Strength (lbs) 615,600

Torsional Strength (ft-lbs) 62,200

80% Torsional Strength (ft-lbs) 49,760

Burst Pressure (psi) 13,125

Collapse Pressure (psi) 12,955

Tool Joint 120,000 psi Material Yield Strength Drill Pipe Assembly with Grant Prideco

HT55 HT55 HI TORQUE Connection

OD (in) 7.125

ID (in) 4.000

Pin Tong Length (in) 24.0 Adjusted Weight (lbs/ft) 55.24

Box Tong Length (in) 24.0 Approximate Length (ft) 31.00

Torsional Strength (ft-lbs) 77,500 Fluid Displacement (gal/ft) 0.844

Max Recommended Make-up Torque (ft-lbs) 46,500 Fluid Capacity (gal/ft) 0.653

Min Recommended Make-up Torque (ft-lbs) 33,800 Fluid Capacity (bls/ft) 0.01555

Tensile Strength (lbs) 1,244,500 Drift Size (in) 3.750

Tool Joint/Drill Pipe Torsional Ratio (New Pipe) 1.25

Balance OD (in) 6.935

Note: Minimum make-up is based on shoulder separation caused by bending

The technical information contained herein, including the product performance sheet and other attached documents, has been extracted from information available from the manufacturer and is for reference only and not a recommendation. The user is fully responsible for the accuracy

and suitability of use of the technical information. Workstrings International cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall

thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable operation limits. It is the responsibility of the customer and the end

user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box ID’s, tool joint ID refers to the pin ID. Per

Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

JCT 03-21-2011

You might also like

- HWDPDocument15 pagesHWDPjinyuan74No ratings yet

- Drill Collar, 6.625 API Reg (8.000 X 2.813) 100,000 (Psi PDFDocument1 pageDrill Collar, 6.625 API Reg (8.000 X 2.813) 100,000 (Psi PDFИнженер Луис А. ГарсиаNo ratings yet

- Preservatin of Spare and EquipmentsDocument38 pagesPreservatin of Spare and EquipmentsSamNo ratings yet

- Especificaciones de Tuberia Pesada HW 5 1/2 F.HDocument1 pageEspecificaciones de Tuberia Pesada HW 5 1/2 F.HAlberto Cárdenas100% (1)

- HWDP 6.625in 55ksi 73.59ppf 6.625FH R2 110ksi TJDocument1 pageHWDP 6.625in 55ksi 73.59ppf 6.625FH R2 110ksi TJKevin MuellerNo ratings yet

- Ejemplo FichaDocument1 pageEjemplo FichaYesid Cruz Yesid CruzNo ratings yet

- Drill Collar, 4.5 IF (6.500 X 2.813) 110,000 (Psi)Document1 pageDrill Collar, 4.5 IF (6.500 X 2.813) 110,000 (Psi)juan moralesNo ratings yet

- Drill Pipe PerformanceDocument3 pagesDrill Pipe PerformanceJohn Jairo Simanca CastilloNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.500)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.500)Luis Alberto García CórdovaNo ratings yet

- 3.500 HWDP With HT38 (4.875 X 2.250 TJ) Tri-SpiralDocument1 page3.500 HWDP With HT38 (4.875 X 2.250 TJ) Tri-SpiralLuis A G. C.No ratings yet

- No. 3Document1 pageNo. 3Luis Alberto García CórdovaNo ratings yet

- Drill Pipe Performance Characteristics SheetDocument1 pageDrill Pipe Performance Characteristics SheetDheeraj KapoorNo ratings yet

- HW 3.5 DatasheetDocument1 pageHW 3.5 DatasheetDaniel NavarroNo ratings yet

- 4.000 HWDP With XT39 (4.875 X 2.5625 TJ) ConventionalDocument1 page4.000 HWDP With XT39 (4.875 X 2.5625 TJ) Conventionalsurendra kumarNo ratings yet

- For Reference Only: Drill Pipe Performance Characteristics ©Document3 pagesFor Reference Only: Drill Pipe Performance Characteristics ©alekz89100% (1)

- Archer DP 5.875 Inch XT 57 SpecsDocument3 pagesArcher DP 5.875 Inch XT 57 SpecsMamani Vargas Wiljho100% (1)

- Drill Pipe Performance Characteristics SheetDocument1 pageDrill Pipe Performance Characteristics SheetJeremias UtreraNo ratings yet

- DC 4.75 DatasheetDocument1 pageDC 4.75 DatasheetDaniel NavarroNo ratings yet

- 3.5 In. 15.50# EU X-95 R2 XT39 (5.0 X 2.6875) - 10P.15BDocument3 pages3.5 In. 15.50# EU X-95 R2 XT39 (5.0 X 2.6875) - 10P.15BIng. Luis A. García CórdovaNo ratings yet

- Drillpipe 3.500 110KSI 225 ID NC38Document1 pageDrillpipe 3.500 110KSI 225 ID NC38Lucas Paul Perez HernandezNo ratings yet

- Drillpipe 3.500 G 105 2.438 ID 15.5ppf NC38Document1 pageDrillpipe 3.500 G 105 2.438 ID 15.5ppf NC38german131418No ratings yet

- DC 6.5in 120ksi 90.61ppf NC46 R2 SpiralDocument2 pagesDC 6.5in 120ksi 90.61ppf NC46 R2 SpiralKevin MuellerNo ratings yet

- Drill-Pipe PipeBody at 80%, 5.875in, 0.361wall, IEUDocument9 pagesDrill-Pipe PipeBody at 80%, 5.875in, 0.361wall, IEUFernando Ruiz ArroyoNo ratings yet

- Drill-Pipe Performance SheetDocument8 pagesDrill-Pipe Performance SheetrahulNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 80 % Inspection ClassLuis Manuel García GuillénNo ratings yet

- HWDP Configuration: Performance of HWDP AssemblyDocument3 pagesHWDP Configuration: Performance of HWDP AssemblyMamani Vargas WiljhoNo ratings yet

- 5.5 Drill Pipe W Cet54 ConnectionsDocument1 page5.5 Drill Pipe W Cet54 Connectionsfarhad iqbalNo ratings yet

- 3,5 in Drill Pipe Performance Data SS 105Document1 page3,5 in Drill Pipe Performance Data SS 105mustafaNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 80 % Inspection Classalekz89No ratings yet

- HeavyWeight 3.5 25.58lbs NC-38 PDFDocument3 pagesHeavyWeight 3.5 25.58lbs NC-38 PDFHomero NavarroNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 80 % Inspection Classalekz89No ratings yet

- WS46-02 - Tubing 3.5Document1 pageWS46-02 - Tubing 3.5Carlos PerdomoNo ratings yet

- HWDP Performance Sheet: Pipe Body: Tubular AssemblyDocument1 pageHWDP Performance Sheet: Pipe Body: Tubular AssemblyKevin MuellerNo ratings yet

- 5-1/2" Ht-55 HWDP Performance Data SheetDocument1 page5-1/2" Ht-55 HWDP Performance Data SheetJanderson Sanchez CastañedaNo ratings yet

- Technical Data Sheet TMK UP FMT 3.5 X 9.2 N80Document1 pageTechnical Data Sheet TMK UP FMT 3.5 X 9.2 N80earlangga rmpNo ratings yet

- 5.5 Inch 24.70 VX54 6625 4000 2 (Landing String)Document2 pages5.5 Inch 24.70 VX54 6625 4000 2 (Landing String)humberto Nascimento100% (1)

- Drill Pipe Performance Characteristics SheetDocument1 pageDrill Pipe Performance Characteristics SheetGaona industrial PetroleroNo ratings yet

- 3.5 Drill Pipe W Nc38 ConnectionsDocument1 page3.5 Drill Pipe W Nc38 ConnectionsMohamed FikryNo ratings yet

- 4in DP 14# IU S135T XTF39 (5.00 x2.5625)Document7 pages4in DP 14# IU S135T XTF39 (5.00 x2.5625)Pavin PiromNo ratings yet

- Api Tubular Strengths: 561242111.xls Mitchell Engineering ProgramsDocument2 pagesApi Tubular Strengths: 561242111.xls Mitchell Engineering ProgramsMohamad TayeaNo ratings yet

- DrillPipe, 80%, 2.875 OD, 0.362 Wall, EU, G-105.. XT26 (3.375 X 1.750)Document3 pagesDrillPipe, 80%, 2.875 OD, 0.362 Wall, EU, G-105.. XT26 (3.375 X 1.750)Luis Alberto García CórdovaNo ratings yet

- Datasheet - 5 IEU X 1950 X S135 X R2 31.5 FT - 658 X 312 X TSDS50 X 135 Ksi SMYS - 14 Box 11 Pin - HB Box - 60 70 MUT - 1.0 FF and 1.15 FF - TSC DP Web Site 1Document2 pagesDatasheet - 5 IEU X 1950 X S135 X R2 31.5 FT - 658 X 312 X TSDS50 X 135 Ksi SMYS - 14 Box 11 Pin - HB Box - 60 70 MUT - 1.0 FF and 1.15 FF - TSC DP Web Site 1oscar0% (1)

- No. 27Document3 pagesNo. 27UPGM Ingenieria petroleraNo ratings yet

- METRIC - 5.500 HWDP With 5.5FH DSTJ (7.000 X 3.500 TJ) Integral ConventionalDocument1 pageMETRIC - 5.500 HWDP With 5.5FH DSTJ (7.000 X 3.500 TJ) Integral Conventionalarun sidhuNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarPopovici AlexandruNo ratings yet

- Floor Slab DesignDocument1 pageFloor Slab DesignPre SheetNo ratings yet

- API Tube StrengthDocument2 pagesAPI Tube Strengthmarshiel_rasNo ratings yet

- 4 DP VX-39 Dogis Pipe. Drift ID. With Int. Coated PipeDocument3 pages4 DP VX-39 Dogis Pipe. Drift ID. With Int. Coated Pipeyatinbhat100% (1)

- 6.625 HWDPDocument23 pages6.625 HWDPözgüncNo ratings yet

- Pile E2 On WallDocument4 pagesPile E2 On WallSiew Kok HongNo ratings yet

- 5.5 HWDPDocument3 pages5.5 HWDPözgüncNo ratings yet

- STAAD Foundation%2Document10 pagesSTAAD Foundation%2sinambeladavidNo ratings yet

- Ejemplo Ketle HTRIDocument6 pagesEjemplo Ketle HTRICami Vander MeyNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarabelardoNo ratings yet

- Deviated Well Kill Sheet 6.125 SECTION 08-Sep-2020.Document7 pagesDeviated Well Kill Sheet 6.125 SECTION 08-Sep-2020.yousef nNo ratings yet

- LateralDocument2 pagesLateralDeddy TambunanNo ratings yet

- 5.5英寸短钻杆 HT55质量文件包裹模板Document17 pages5.5英寸短钻杆 HT55质量文件包裹模板zhaibo666No ratings yet

- 4.0 Drill Pipe W XT39 ConnectionsDocument1 page4.0 Drill Pipe W XT39 ConnectionsDugas DeivyNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument7 pagesDrill Pipe Configuration: 80 % Inspection ClassWaleedm MariaNo ratings yet

- Toughened Glass Suspension Insulator Clevis - Tongue Type Ball Socket TypeDocument1 pageToughened Glass Suspension Insulator Clevis - Tongue Type Ball Socket TypePedro M LoNo ratings yet

- Yp022020012.repair Pipa Dan Plate - HciDocument1 pageYp022020012.repair Pipa Dan Plate - Hcifaishal hafizhNo ratings yet

- Optimization of Plastics Injection Molding ProcessDocument11 pagesOptimization of Plastics Injection Molding Processfaishal hafizhNo ratings yet

- CB 9 Wo 22030002Document1 pageCB 9 Wo 22030002faishal hafizhNo ratings yet

- Arfan 2020 IOP Conf. Ser. Earth Environ. Sci. 448 012034Document12 pagesArfan 2020 IOP Conf. Ser. Earth Environ. Sci. 448 012034faishal hafizhNo ratings yet

- Challenge Test Ejector BotolDocument1 pageChallenge Test Ejector Botolfaishal hafizhNo ratings yet

- Scan Attendence List Pengukuran PreformDocument1 pageScan Attendence List Pengukuran Preformfaishal hafizhNo ratings yet

- SALARY SamsungDocument1 pageSALARY Samsungfaishal hafizhNo ratings yet

- Boxplot Over Fixed Range UploadDocument5 pagesBoxplot Over Fixed Range Uploadfaishal hafizhNo ratings yet

- Analisis Penggunaan Bit For ChevronDocument15 pagesAnalisis Penggunaan Bit For Chevronfaishal hafizhNo ratings yet

- Report By: Mohit Goyal M SatyamDocument48 pagesReport By: Mohit Goyal M Satyamfaishal hafizhNo ratings yet

- PIN Automatic Overfill Prevention SystemDocument4 pagesPIN Automatic Overfill Prevention Systemfaishal hafizhNo ratings yet

- SALARY SamsungDocument1 pageSALARY Samsungfaishal hafizhNo ratings yet

- Stiffness Ratio B / BDocument9 pagesStiffness Ratio B / BRobin LeeNo ratings yet

- (Doi 10.2118 - 28774-Ms) Agawani, Mamdouh Rahman, S.S. Maidla, E.E. - (Society of Petroleum Engineers SPE Asia Pacific Oil and Gas Conference - Melbourne, Australia (1994!11!07) ) SPE Asia Pacific ODocument9 pages(Doi 10.2118 - 28774-Ms) Agawani, Mamdouh Rahman, S.S. Maidla, E.E. - (Society of Petroleum Engineers SPE Asia Pacific Oil and Gas Conference - Melbourne, Australia (1994!11!07) ) SPE Asia Pacific Ofaishal hafizhNo ratings yet

- Predicting Bottomhole Assembly Performance: J.S. Williamson, A. LubinskiDocument13 pagesPredicting Bottomhole Assembly Performance: J.S. Williamson, A. Lubinskifaishal hafizhNo ratings yet

- A Review of Cuttings Transport in Directional-Well DrillingDocument3 pagesA Review of Cuttings Transport in Directional-Well Drillingfaishal hafizhNo ratings yet

- Presentation 2Document7 pagesPresentation 2faishal hafizhNo ratings yet

- Internet CafeDocument23 pagesInternet CafeAnonymous D5bMfFrH100% (2)

- Lesson 6 - Laws Affecting Elderly CareDocument13 pagesLesson 6 - Laws Affecting Elderly CareHanz Alecz Q. DasmariñasNo ratings yet

- APC Silcon 60-80kW 208/480V UPS Installation GuideDocument94 pagesAPC Silcon 60-80kW 208/480V UPS Installation GuideHector GuizzardNo ratings yet

- Nle Notes MCNDocument33 pagesNle Notes MCNjosephmary09No ratings yet

- Daddy Wasn't There, Abandonment PoemDocument2 pagesDaddy Wasn't There, Abandonment Poemonejako12No ratings yet

- Evolution of Dentition in Cattle LifeDocument7 pagesEvolution of Dentition in Cattle LifeDragos MisteryoNo ratings yet

- Crown Light CommissioningDocument41 pagesCrown Light CommissioningAli AKNo ratings yet

- 2018-08-01 PowerDocument148 pages2018-08-01 Powerbar catalinNo ratings yet

- GearDocument103 pagesGearyeop03No ratings yet

- Jurnal Ilmu Kehutanan: Pendugaan Simpanan Karbon Pada Kawasan Rehabilitasi Pesisir Selatan Pulau JawaDocument13 pagesJurnal Ilmu Kehutanan: Pendugaan Simpanan Karbon Pada Kawasan Rehabilitasi Pesisir Selatan Pulau JawaSwandi Lamrotua SimamoraeNo ratings yet

- Drug Study ZiprasidoneDocument2 pagesDrug Study ZiprasidoneArnzz Agbulos100% (1)

- 312 Lec Cu7Document1 page312 Lec Cu7Carl SantosNo ratings yet

- Dosage Chapter 1 PDFDocument4 pagesDosage Chapter 1 PDFLena EmataNo ratings yet

- Vikram Tea Case StudyDocument2 pagesVikram Tea Case StudyAlberto Del RioNo ratings yet

- C+F-Overview of Supraventriculer Tachycardia in Dogs and CatsDocument11 pagesC+F-Overview of Supraventriculer Tachycardia in Dogs and Catstaner_soysurenNo ratings yet

- Minor Decision EventsDocument19 pagesMinor Decision EventsAeneas WoodNo ratings yet

- The Indian Weekender 1st February 2019Document32 pagesThe Indian Weekender 1st February 2019Indian WeekenderNo ratings yet

- Nelspruit Boxing Club Membership Application, Idemnity (3) 2Document5 pagesNelspruit Boxing Club Membership Application, Idemnity (3) 2hanno hymanNo ratings yet

- Pavlov SkinnerDocument2 pagesPavlov SkinnerLADJAHALI, FARISHA TIMPAHANNo ratings yet

- Operations in HospitalDocument99 pagesOperations in HospitalFranco Angelo Ifurung GonzalesNo ratings yet

- Chapter 23 Hedging With Financial DerivativesDocument15 pagesChapter 23 Hedging With Financial DerivativesJBNo ratings yet

- Occidental Mindoro-sec-Agri Fishery ArtsDocument4 pagesOccidental Mindoro-sec-Agri Fishery ArtsPRC BoardNo ratings yet

- Life of Pi Study QuestionsDocument11 pagesLife of Pi Study QuestionsMaddie Amsterdam100% (1)

- HP Bleed Valve FaultDocument9 pagesHP Bleed Valve FaultSuman BajracharyaNo ratings yet

- Population DynamicsDocument23 pagesPopulation DynamicsKurth Michael Ibarra100% (1)

- HPSP and GME Update COL Maurer May 2020 PDFDocument27 pagesHPSP and GME Update COL Maurer May 2020 PDFHema LaughsalotNo ratings yet

- Survey On Maggi NoodlesDocument18 pagesSurvey On Maggi NoodlesSiddhesh SawantNo ratings yet

- Embryology of Cleft Lip & Cleft PalateDocument76 pagesEmbryology of Cleft Lip & Cleft PalateDR NASIM100% (1)

- GSG MP40 - 9x19 - America PDFDocument20 pagesGSG MP40 - 9x19 - America PDFeric100% (1)