Professional Documents

Culture Documents

WS46-02 - Tubing 3.5

Uploaded by

Carlos PerdomoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WS46-02 - Tubing 3.5

Uploaded by

Carlos PerdomoCopyright:

Available Formats

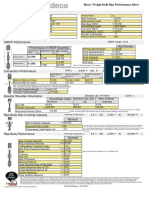

Size and Weight: 3.500'' 9.30 ppf 0.

254'' wall

Grade: N-80

Tubing Performance Sheet Range: 2

Tool Joint: 4.500'' x 2.992'' EUE (8 RD)

Pipe Body: Tubular Assembly:

Nominal 87.5% Premium

100% RBW RBW 80% RBW Approximate Length (ft): 31.0

OD (in): 3.500 3.437 3.398 Nominal Weight (lbs/ft): 9.30

Wall Thickness (in): 0.254 0.222 0.203

Nominal ID (in): 2.992 2.992 2.992 Material Grade: N-80

Tensile Strength (lbs): 207,215 179,540 163,178 Compression Strength (lbs): Not Reported

Torsional Strength (ft-lbs): 15,089 13,039 11,833 Max Bending (degress/100 ft): Not Reported

Burst Capacity (psi): 10,160 10,160 9,289 Drift Size (in): 2.867

Collapse Capacity (psi): 10,535 8,595 7,396

Fluid Capacity (gal/ft): 0.3652

Fluid Capacity (bbls/ft): 0.0087

Notes: Body properties are calculated based on uniform OD and wall thickness.

Burst capacity for Nominal (100% RBW) based on 87.5% RBW per API.

Casing and Tubing are ordered to API 5CT wall thickness tolerance specification at 87.5% RBW.

Connection: EUE (8 RD)

Connection OD (in): 4.500 Threads per Inch: 8 Maximum MUT (ft-lbs): 4,000

Connection ID (in): 2.992 Make-Up Loss (in): N/A Optimum MUT (ft-lbs): 3,200

Special Clearance OD (in): 4.180 Internal Pressure Rating (psi): 10,160 Minimum MUT (ft-lbs): 2,400

Connection Torsional Strength (ft-lbs): Not Reported

Connection Tensile Strength (lbs): 207,200

The technical information contained herein, including the product performance sheet and other attached documents, has been extracted from information available from the manufacturer and is for reference only and not a recommendation. The user is fully responsible for the accuracy and suitability of use of the technical

information. Workstrings International cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various

inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable operation limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices,

and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.workstringsinternational.com 20-Sep-21

Download the Workstrings International Pipe Specification App on the App Store℠ or Google Play™ WS46-02

You might also like

- Cast Iron: Physical and Engineering PropertiesFrom EverandCast Iron: Physical and Engineering PropertiesRating: 5 out of 5 stars5/5 (1)

- TBPSDocument1 pageTBPSElvis E Prado PNo ratings yet

- Performance Sheet Tubing: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Tubing: Pipe Body: Tubular Assemblykm1790No ratings yet

- Tubing 3.500" 9.30 LB/FT: Pipe Grade: N80 / Range: 2 Tool Joint: 4.500'' X 2.992'' EUE (8 RD)Document1 pageTubing 3.500" 9.30 LB/FT: Pipe Grade: N80 / Range: 2 Tool Joint: 4.500'' X 2.992'' EUE (8 RD)Êfrên Rôdrîgûêz TôrrêsNo ratings yet

- 2,7,8, DP Aoh Condiciones TecnicasDocument3 pages2,7,8, DP Aoh Condiciones TecnicasFernando EncisoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument3 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyAboozar FathinejadNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyjohangomezruizNo ratings yet

- HWDP Performance Sheet: Pipe Body: Tubular AssemblyDocument1 pageHWDP Performance Sheet: Pipe Body: Tubular AssemblyKevin MuellerNo ratings yet

- WS43-11 LSPSDocument1 pageWS43-11 LSPSAbelardo Castro EstupiñanNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- DPPS PDFDocument2 pagesDPPS PDFPablo SantisNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument3 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblySamuel PerezNo ratings yet

- WS41-53 DPPSDocument3 pagesWS41-53 DPPSRocard NgomaNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument3 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJosh SabimanNo ratings yet

- Drill Collar 4.75 NC38 - SpiralDocument1 pageDrill Collar 4.75 NC38 - SpiralFernando OlaveoNo ratings yet

- 5948 DCPSDocument1 page5948 DCPSGarcia MarinNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument3 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyFranklynMartinezNo ratings yet

- 7.625 OD 0.625 Wall V-150 MaXit807 (9.750 X 6.250 TJ)Document3 pages7.625 OD 0.625 Wall V-150 MaXit807 (9.750 X 6.250 TJ)Abelardo Castro EstupiñanNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarNaman ShahNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- 7.625 OD 0.688 Wall V-150 MaXit807 (9.750 X 6.125 TJ)Document3 pages7.625 OD 0.688 Wall V-150 MaXit807 (9.750 X 6.125 TJ)Abelardo Castro EstupiñanNo ratings yet

- DPPS PDFDocument2 pagesDPPS PDFStowartNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- HWDPDocument15 pagesHWDPjinyuan74No ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarsimmsbopNo ratings yet

- Heavy Weight Drill Pipe PerformanceDocument3 pagesHeavy Weight Drill Pipe PerformanceHomero NavarroNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarsimmsbopNo ratings yet

- 2-7/8'' EUE 8RD - 3.668'' X 2.441'': Tubing Specification & Performance Data SheetDocument1 page2-7/8'' EUE 8RD - 3.668'' X 2.441'': Tubing Specification & Performance Data SheetKabir PantNo ratings yet

- Especificaciones Tecnicas DP 5.5 FH R2 PDFDocument1 pageEspecificaciones Tecnicas DP 5.5 FH R2 PDFDiego Fabian Ruiz VacaflorNo ratings yet

- 6.625 HWDPDocument23 pages6.625 HWDPözgüncNo ratings yet

- Performance Sheet Drill CollarDocument2 pagesPerformance Sheet Drill CollarAboozar FathinejadNo ratings yet

- HWDP Configuration: Performance of HWDP AssemblyDocument3 pagesHWDP Configuration: Performance of HWDP AssemblyMamani Vargas WiljhoNo ratings yet

- Drill-Pipe Performance SheetDocument8 pagesDrill-Pipe Performance SheetrahulNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarashadNo ratings yet

- Technical Data Sheet TMK UP FMT 3.5 X 9.2 N80Document1 pageTechnical Data Sheet TMK UP FMT 3.5 X 9.2 N80earlangga rmpNo ratings yet

- Workstring International MaXit 807 Completion Landing StringDocument2 pagesWorkstring International MaXit 807 Completion Landing StringzhiqianxuNo ratings yet

- Drillpipe 3.500 G 105 2.438 ID 15.5ppf NC38Document1 pageDrillpipe 3.500 G 105 2.438 ID 15.5ppf NC38german131418No ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 80 % Inspection ClassLuis Manuel García GuillénNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.500)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.500)Luis Alberto García CórdovaNo ratings yet

- Geometry and Performance: Pipe Data (In)Document1 pageGeometry and Performance: Pipe Data (In)Diego Fabian Ruiz VacaflorNo ratings yet

- No. 27Document3 pagesNo. 27UPGM Ingenieria petroleraNo ratings yet

- Especificaciones de Tuberia Pesada HW 5 1/2 F.HDocument1 pageEspecificaciones de Tuberia Pesada HW 5 1/2 F.HAlberto Cárdenas100% (1)

- WS38-16 DPPS PDFDocument1 pageWS38-16 DPPS PDFJohnsNo ratings yet

- Drill pipe performance and safety advisoryDocument3 pagesDrill pipe performance and safety advisoryLuis Alberto García CórdovaNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument7 pagesDrill Pipe Configuration: 80 % Inspection ClassWaleedm MariaNo ratings yet

- 5.5 HWDPDocument3 pages5.5 HWDPözgüncNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 80 % Inspection Classalekz89No ratings yet

- DC 6.5in 120ksi 90.61ppf NC46 R2 SpiralDocument2 pagesDC 6.5in 120ksi 90.61ppf NC46 R2 SpiralKevin MuellerNo ratings yet

- Datasheet 312 EU-x-1330-x-S135-x-R2-31.5-ft - 478-x-2916-x-TSDS38-x-135-ksi-SMYS - 1412-Box-12-Pin - HB-Box - 60-70-MUT - 1.0-FF-and-1.15-FF - TSC-DP-Web-Site-1Document2 pagesDatasheet 312 EU-x-1330-x-S135-x-R2-31.5-ft - 478-x-2916-x-TSDS38-x-135-ksi-SMYS - 1412-Box-12-Pin - HB-Box - 60-70-MUT - 1.0-FF-and-1.15-FF - TSC-DP-Web-Site-1oscarNo ratings yet

- DesktopDocument9 pagesDesktop唐辉No ratings yet

- For Reference Only: Drill Pipe Performance Characteristics ©Document3 pagesFor Reference Only: Drill Pipe Performance Characteristics ©alekz89100% (1)

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarsimmsbopNo ratings yet

- Drillpipe-3.500-110KSI-225-ID-NC38Document1 pageDrillpipe-3.500-110KSI-225-ID-NC38Lucas Paul Perez HernandezNo ratings yet

- 3-1/2'', 13.30#, 0.368'', S135, EU, R2: Delta377 - 4.750'' X 2.563''Document5 pages3-1/2'', 13.30#, 0.368'', S135, EU, R2: Delta377 - 4.750'' X 2.563''Jcchcc JcchccNo ratings yet

- No. 3Document1 pageNo. 3Luis Alberto García CórdovaNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarabelardoNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarsimmsbopNo ratings yet

- Comparativo Varillas de Bombeo-EmeraldDocument10 pagesComparativo Varillas de Bombeo-EmeraldCarlos PerdomoNo ratings yet

- Hydra Jar Operation Manual 6-80Document31 pagesHydra Jar Operation Manual 6-80Carlos PerdomoNo ratings yet

- Wild Well Control Technical Data Book 2011Document77 pagesWild Well Control Technical Data Book 2011manuelperdomotNo ratings yet

- DRILCO Handbook 2001Document99 pagesDRILCO Handbook 2001Carlos Perdomo100% (2)

- S K MondalDocument17 pagesS K MondalTapas Swain100% (1)

- Groupreport SingaporeDocument21 pagesGroupreport SingaporeRogerine RoyNo ratings yet

- VSK SeparatorDocument1 pageVSK SeparatorthatmonoNo ratings yet

- Evapco O&M InstructionDocument52 pagesEvapco O&M InstructionYutt WattNo ratings yet

- ELEC9712 - Lec3 - Insulation Materials and HV TestingDocument64 pagesELEC9712 - Lec3 - Insulation Materials and HV TestingAhmed ElsayedNo ratings yet

- Understanding Architectural Details 3 Sample PDFDocument23 pagesUnderstanding Architectural Details 3 Sample PDFolu67% (9)

- J Heat Transfer 1978 Vol 100 N3Document185 pagesJ Heat Transfer 1978 Vol 100 N3getsweetNo ratings yet

- Method Statement - Drainage & SewerageDocument8 pagesMethod Statement - Drainage & Seweragedanes hereNo ratings yet

- Hot-Dip Galvanized Rebar Performance & Condition Epoxy-Coated RebarDocument4 pagesHot-Dip Galvanized Rebar Performance & Condition Epoxy-Coated RebarJoaquin RiccitelliNo ratings yet

- Classical free electron theory and its limitationsDocument17 pagesClassical free electron theory and its limitationsSaketNo ratings yet

- Brochure - Luffa Cylindrica Fiber As An Additive in Concrete MIxtureDocument2 pagesBrochure - Luffa Cylindrica Fiber As An Additive in Concrete MIxtureRhizyl Jhane EstrellaNo ratings yet

- ME2151-1 Cooling Rate EffectDocument17 pagesME2151-1 Cooling Rate EffectAngelique PorterNo ratings yet

- Clinker Microscopy Training ICC Eng 2023Document8 pagesClinker Microscopy Training ICC Eng 2023ICC Independent Cement ConsultantsNo ratings yet

- LG Inverter SCAC CatalogDocument20 pagesLG Inverter SCAC Catalogsk luko100% (1)

- Construction and Building Materials: Ali N. AL-Gemeel, Yan ZhugeDocument9 pagesConstruction and Building Materials: Ali N. AL-Gemeel, Yan ZhugeManisha ShewaleNo ratings yet

- Door Hinge DesignDocument17 pagesDoor Hinge DesignAlikhan ShambulovNo ratings yet

- 4500MB - CH 2 - Parr - Stirred Reactors and Pressure Vessels Catalog v15 Literature PDFDocument45 pages4500MB - CH 2 - Parr - Stirred Reactors and Pressure Vessels Catalog v15 Literature PDFglaubersgNo ratings yet

- European Recommendations For Sandwich Panels: Part I: DesignDocument62 pagesEuropean Recommendations For Sandwich Panels: Part I: DesignSilvo ŠtihNo ratings yet

- Bathnagar Et Al 2016Document13 pagesBathnagar Et Al 2016Marcelo CifuentesNo ratings yet

- Rheomix 131: Page 1 of 2Document2 pagesRheomix 131: Page 1 of 2Ankita Baban Gavade100% (1)

- S123 2003 Minimum Specification For Bovine Livestock Units Reinforced TanksDocument29 pagesS123 2003 Minimum Specification For Bovine Livestock Units Reinforced TanksDoug WeirNo ratings yet

- Constitutive Law PolycarbonateDocument10 pagesConstitutive Law PolycarbonateajaykumarKBSNo ratings yet

- SaudiAramco ladder designDocument1 pageSaudiAramco ladder designDomie Neil Bucag SalasNo ratings yet

- PAVEMENT DESIGN REPORT (Tura Dalu CS)Document28 pagesPAVEMENT DESIGN REPORT (Tura Dalu CS)Navarun VashisthNo ratings yet

- Standard Specification For Storage TanksDocument22 pagesStandard Specification For Storage TanksJITENDER KUMAR75% (4)

- Ib Tutorial 4 (12 13) Sem 2Document5 pagesIb Tutorial 4 (12 13) Sem 2omarnasriNo ratings yet

- Joining Processes Explained: Welding, Brazing and SolderingDocument20 pagesJoining Processes Explained: Welding, Brazing and SolderingarunNo ratings yet

- Marylebone Construction UpdateDocument2 pagesMarylebone Construction UpdatePedro SousaNo ratings yet

- VRF PDHM Series Outdoor Unit Type GMV-PDHM: Air Conditioning and HeatpumpsDocument2 pagesVRF PDHM Series Outdoor Unit Type GMV-PDHM: Air Conditioning and HeatpumpsAflredo FloresNo ratings yet