Professional Documents

Culture Documents

Unit IV Joining Process

Uploaded by

arun0 ratings0% found this document useful (0 votes)

12 views20 pagesThe document discusses different joining processes used to join metal parts. It describes permanent joining processes like welding which fuse metals by heating them to melting point. Semi-permanent processes like nuts and bolts join parts at room temperature. It then focuses on welding, brazing and soldering processes. Welding involves heating metals to melting point to fuse them. Brazing uses filler alloys above 450°C without melting the base metals. Soldering uses filler alloys below 450°C for electrical applications.

Original Description:

Original Title

unit-iv-joining-process

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses different joining processes used to join metal parts. It describes permanent joining processes like welding which fuse metals by heating them to melting point. Semi-permanent processes like nuts and bolts join parts at room temperature. It then focuses on welding, brazing and soldering processes. Welding involves heating metals to melting point to fuse them. Brazing uses filler alloys above 450°C without melting the base metals. Soldering uses filler alloys below 450°C for electrical applications.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views20 pagesUnit IV Joining Process

Uploaded by

arunThe document discusses different joining processes used to join metal parts. It describes permanent joining processes like welding which fuse metals by heating them to melting point. Semi-permanent processes like nuts and bolts join parts at room temperature. It then focuses on welding, brazing and soldering processes. Welding involves heating metals to melting point to fuse them. Brazing uses filler alloys above 450°C without melting the base metals. Soldering uses filler alloys below 450°C for electrical applications.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 20

Joining Processes

"Our Attitude Decides Our Altitudes"

Introduction

• Joining process is where two or more pieces of parts are

joined together to produce a single product of required

shape and size.

• The joining process can be classified as

a. Permanent joining process

It is done by fusing the metal together. The metal

"Our Attitude Decides Our Altitudes"

is heated to its melting state and then it is fused to

become one unit.

Ex. Welding, soldering and brazing

b. Semi – permanent or temporary joining process

In this the metal is not heated. Process is carried

out at room temperature. Temporary joining process can

be done using nuts, bolts, screws and adhesives.

Welding Process

• Simple definition of welding -

"joining metals through heating them to a

molten state and fusing them together.“

• Technical definition of Welding -

“a localized coalescence of metals, wherein coalescence is

"Our Attitude Decides Our Altitudes"

obtained by heating to suitable temperature, with or

without the application of pressure and with or without the

use of filler material. This filler material has the melting

point same as the base material.”

It is also know as a metallurgical joining process of two

metal pieces, to produce a single piece of product.

Welding Terminologies

• Base Metal – Work pieces that are needed to be joined

• Weld Bead - A weld bead is a weld deposit produced by a

single pass of the welding processes. It is also known as bead

• Puddle – The molten base metal at the joint during the

welding operation

"Our Attitude Decides Our Altitudes"

• Weld pass – Movement of weld torch from one end of the

joint to the other end.

• Tack Weld – it is the temporary joint done before welding to

keep the work pieces to be welded in place during welding.

The joints are done at the ends of the work piece.

Classification of Welding Process

The welding process can be

classified based on the source of

energy to heat the metal and the

"Our Attitude Decides Our Altitudes"

state of metal at the joint.

• Pressure Welding

• Fusion Welding

Pressure Welding

• The surfaces of the joint to be welded is heated to a

plastic state and forced together with external pressure to

finish the joint.

• Depends on the application of pressures and temperature

"Our Attitude Decides Our Altitudes"

• ISO – 857 defines “Welding in which sufficient outer force

is applied to cause more or less plastic deformation of

both the facing surfaces, generally without the addition of

filler metal. Usually, but not necessarily, the facing

surfaces are heated in order to permit or to facilitate

bonding”

"Our Attitude Decides Our Altitudes"

Fusion Welding

• Heating in to molten state and allowed to

solidify to form joint with or without the

addition of filler material.

• The process is carried out with out the

"Our Attitude Decides Our Altitudes"

application of pressure.

• ISO – 857 defines “Welding without application

of outer force in which the facing surface must

be melted. Usually, but not necessarily, molten

filler metal is added”.

"Our Attitude Decides Our Altitudes"

Advantages

• It is a high temperature process where the base

metals are heated above their melting temp.

• Strength of the joint obtained in welding is much

stronger than the parent metal

"Our Attitude Decides Our Altitudes"

• Welding produces stronger joints.Hence this

process is used for fabrication and structural

applications

Disadvantages

• Requires certain finishing operations like

grinding , filing etc

• Since welding is carried out at high temp,

"Our Attitude Decides Our Altitudes"

the metal adjacent to the weld portion

called the heat affected zone which is

affected to a large extent

Applications

It can be employed in industry as a tool for,

Fabrication of automobile cars , Air- craft,

Refrigerators, Pressure vessels , Furnaces etc

"Our Attitude Decides Our Altitudes"

Repair and maintenance work

Joining broken parts

Rebuilding worn out components etc

Brazing

• it is a method of joining two similar or dissimilar metals using a

special fusible alloy called as “Spelters”.which is non ferrous

metal or alloy

• The base metals do not melt; they are heated above 450 deg

C but below their melting temperatures of base metal.

"Our Attitude Decides Our Altitudes"

• Some diffusion of the filler metal with base metal takes place.

• There are two types of spelters used:

• Copper and Copper base alloys

• Silver and silver base alloys

Butt Joint

When two metals are positioned in a head-to-head

arrangement for brazing, it will result in a Butt joint.

Lap Joints

Lap joint is the type of joint that have a larger surface area

because it is formed by overlapping of two metals.

"Our Attitude Decides Our Altitudes"

Butt-Lap Joint

It is a combination of both butt and lap type of joint and offers

the advantages of both. Butt-lap joint give the profitable

features of single thickness as well as of maximum strength

Advantages

• Dissimilar metals and parts having thin

sections can be joined easily.

• Brazing may avoid the metallurgical

"Our Attitude Decides Our Altitudes"

damage to the base metals.

• Strong joint can be obtained by brazing.

• It is economical and quick process

• Less heating is required than for welding.

Soldering

• Soldering is a method of uniting two thin metal pieces

using a dissimilar metal or an alloy by application of

heat.

• The alloy is called as solder.

• Two types of solder are:

"Our Attitude Decides Our Altitudes"

• Soft solder

• Hard solder

• Usually the base metal is heated upto around 350 deg

C.

• Soldering is usually used for electrical & electronic

works and some low end sheet metal work.

Soft soldering is characterized by having a melting point of the

filler metal below approximately 400 °C (752 °F). Soft solder

filler metals are typically alloys (often containing lead) that have

liquidius temperatures below 350°C. Soft soldering can be done

with a heated iron whereas the other methods require a higher

temperature to melt the solder than can be achieved with a heated

iron.

"Our Attitude Decides Our Altitudes"

Hard soldering use higher temperatures, typically requiring a

flame or carbon arc torch to achieve the melting of the filler.

Hard soldering, as used by jewelers, machinists and in some

plumbing applications, requires the use of a torch or other high

temperature source and is much stronger than soft soldering.

ADVANTAGES

• It is simple and economical process

• Since it done at relatively low temperature, no metallurgical

damage to the base metal.

• The soft soldered joints can easily be dismantled by simple heating

• Operator fatigue is less compared to welding process.

"Our Attitude Decides Our Altitudes"

• DISADVANTAGES

• 1. The process is limited to minimum thickness (3mm)

• 2. Skilled operator is required.

• 3. Strength of joint when compared to welding is low.

Difference between Soldering and Brazing

Sl no Brazing Soldering

1 Melting point of the filler Melting point of the filler material

material is about 600 degree. is below 450 degree.

2 Dissimilar metals can be Only similar metals can be joined.

"Our Attitude Decides Our Altitudes"

joined easily.

3 Good surface finish. Does not yield a good surface

finish

4 Stronger joints. Less stronger joint.

5 It is used for production of It is used for electrical and

heat exchangers and electronic applications.

radiators.

Difference between Welding , Brazing and

Soldering

Sl no Parameter welding brazing soldering

1 Temperature Very high, about Melting point of the Melting point of

more than 5000 filler metal is above the filler metal is

degree c 600 degree c below 450 degree

"Our Attitude Decides Our Altitudes"

2 Type of metal Only similar metals Dissimilar metals Only similar

to be joined metals

3 Surface finish moderate good poor

4 strength Very high high weak

You might also like

- Fabrication (Metal Joining) : Ravishankar M D 17EME14 Elements of Mechanical EngineeringDocument18 pagesFabrication (Metal Joining) : Ravishankar M D 17EME14 Elements of Mechanical EngineeringSatish HSNo ratings yet

- Metal - Brazing and Soldering - ProcessesDocument8 pagesMetal - Brazing and Soldering - Processeshisham_eyes100% (1)

- Metal JoiningDocument20 pagesMetal JoiningnehasjacobNo ratings yet

- Brazing & Soldering: by Ashrav GuptaDocument22 pagesBrazing & Soldering: by Ashrav GuptaAshrav GuptaNo ratings yet

- Welding Class 1Document73 pagesWelding Class 1omkardashetwarNo ratings yet

- Experiment No. 5: 1. SolderingDocument4 pagesExperiment No. 5: 1. SolderingArun kumar rouniyarNo ratings yet

- Differences Between WeldingDocument2 pagesDifferences Between WeldingBeing Ban100% (3)

- Aircraft Materials, Construction and RepairDocument34 pagesAircraft Materials, Construction and RepairMark Jovince CardenasNo ratings yet

- Chrome PlatingDocument16 pagesChrome PlatingAliNo ratings yet

- Soldering, Brazing and Welding BasicsDocument7 pagesSoldering, Brazing and Welding BasicsJerin CyriacNo ratings yet

- Smaw WeldingDocument66 pagesSmaw WeldingAbdullah AbdullahNo ratings yet

- Shielded Metal Arc Welding: by L D PoyyaraDocument65 pagesShielded Metal Arc Welding: by L D PoyyaraAshish PatelNo ratings yet

- Welding 1Document61 pagesWelding 1عبدالرحمن سيدNo ratings yet

- Joining of MetalsDocument25 pagesJoining of MetalsSaba SaqerNo ratings yet

- Arc Welding in DetailDocument34 pagesArc Welding in DetailSohen PatelNo ratings yet

- Heat TreatmentDocument19 pagesHeat TreatmentRaja Sekhar Benarjee Yalla100% (3)

- Arcwelding 170804063548Document72 pagesArcwelding 170804063548Izzat TammamNo ratings yet

- Forging and ForgeabilityDocument3 pagesForging and ForgeabilityjestinNo ratings yet

- Soldering and Brazing PDFDocument4 pagesSoldering and Brazing PDFnaresh naikNo ratings yet

- Introduction To WeldingDocument153 pagesIntroduction To WeldingNyanda MalashiNo ratings yet

- Unit 5 Welding ProcessDocument57 pagesUnit 5 Welding Processmahammad kamaluddeenNo ratings yet

- Types: - Plastic Welding or Pressure WeldingDocument23 pagesTypes: - Plastic Welding or Pressure WeldinglpusatishNo ratings yet

- 9-Haz, Welding Defecs, Causes and RemdiesDocument24 pages9-Haz, Welding Defecs, Causes and RemdiesRamu Amara100% (1)

- ForgingDocument26 pagesForgingamarparimiNo ratings yet

- Forging Processes: Satya Amarnadh ParimiDocument26 pagesForging Processes: Satya Amarnadh ParimiamarparimiNo ratings yet

- Manufacturing Processes (Welding (BENG) HandoutDocument67 pagesManufacturing Processes (Welding (BENG) HandoutbananaNo ratings yet

- BrazingDocument16 pagesBrazingbalamurugan_me100% (3)

- Course Title: Metal Forming (Pr-603) Lecture Note: Instructor In-Charge: Dr. Raj BallavDocument21 pagesCourse Title: Metal Forming (Pr-603) Lecture Note: Instructor In-Charge: Dr. Raj BallavDinesh Killada50% (2)

- Fabrication: Ar. Mehardeep Kaur Assistant Professor Shri Vaishnav Institute of Architecture IndoreDocument22 pagesFabrication: Ar. Mehardeep Kaur Assistant Professor Shri Vaishnav Institute of Architecture IndoreSwapnil ShrivastavaNo ratings yet

- Welding Class 2Document22 pagesWelding Class 2omkardashetwarNo ratings yet

- Soldering & Brazing: Unit-IvDocument15 pagesSoldering & Brazing: Unit-IvRamu AmaraNo ratings yet

- M2 MET204 IMP TOPICS - Ktunotes - inDocument76 pagesM2 MET204 IMP TOPICS - Ktunotes - inmachaviseNo ratings yet

- Name 215 Ship Construction and Welding TechnologyDocument27 pagesName 215 Ship Construction and Welding TechnologySakib RafeeNo ratings yet

- OBJECTIVEDocument3 pagesOBJECTIVEGautam Singh RajputNo ratings yet

- Sonargaon University Shop 160 Welding - 2: Prepared by Zayed AhmedDocument19 pagesSonargaon University Shop 160 Welding - 2: Prepared by Zayed Ahmedদুর্জয় দুর্বারNo ratings yet

- Presentation Topic:: Soldering and BrazingDocument27 pagesPresentation Topic:: Soldering and BrazingSarath ChandraNo ratings yet

- 8.metal Joining Processes and EquipmentDocument30 pages8.metal Joining Processes and EquipmentGRAHAM KUNDAI DENGEZANo ratings yet

- PRT (IC141) - Lecture 12-13 WeldingDocument38 pagesPRT (IC141) - Lecture 12-13 WeldingGaurav MeenaNo ratings yet

- Welding LectureDocument101 pagesWelding Lecturesumit sengarNo ratings yet

- Forging Presentation (Autosaved)Document12 pagesForging Presentation (Autosaved)Dead IceingNo ratings yet

- F Arcwelding 131118222251 Phpapp02Document42 pagesF Arcwelding 131118222251 Phpapp02hassan aliNo ratings yet

- Welding ProcessDocument25 pagesWelding ProcessMayankNo ratings yet

- Soldering, Brazing & WeldingDocument52 pagesSoldering, Brazing & WeldingChandrakantha K100% (1)

- Spacetec Certification Readiness Course: Materials and Processes I & IiDocument68 pagesSpacetec Certification Readiness Course: Materials and Processes I & IiB.SATHISH KUMARNo ratings yet

- 9) Soldering WeldingDocument23 pages9) Soldering WeldingArchanaNo ratings yet

- WELDINGDocument36 pagesWELDINGSOURABH GANGWARNo ratings yet

- Welding Basics, Techniques & Safety-2020Document86 pagesWelding Basics, Techniques & Safety-2020Tayyaba RahimNo ratings yet

- Welding Processes UNIT-IIIDocument186 pagesWelding Processes UNIT-IIIAasif ProchaNo ratings yet

- Eme Mod2@Azdocuments - inDocument31 pagesEme Mod2@Azdocuments - inPratham BalikaiNo ratings yet

- Unit 6 (Metal Processing)Document33 pagesUnit 6 (Metal Processing)Syfull musicNo ratings yet

- Soldering, Brazing and Braze Welding: Ag Metals I Welding Principles & ApplicationsDocument51 pagesSoldering, Brazing and Braze Welding: Ag Metals I Welding Principles & ApplicationsAd Man GeTigNo ratings yet

- Solid State Welding Is A Welding Process, inDocument24 pagesSolid State Welding Is A Welding Process, inPRABHJOT SINGHNo ratings yet

- Inspection Techniques: Lecture Delivered By: Jawed Ahsan Pak Arab Fertilizer (PVT.) LTDDocument66 pagesInspection Techniques: Lecture Delivered By: Jawed Ahsan Pak Arab Fertilizer (PVT.) LTDMajid Sattar100% (1)

- Welding SRMDocument24 pagesWelding SRMcfcshakerNo ratings yet

- Soldering March IntakeDocument49 pagesSoldering March IntakeoriverbmwasotemwasoteNo ratings yet

- TO Welding: P.Suresh Kumar Me - I YearDocument25 pagesTO Welding: P.Suresh Kumar Me - I YearsureshpadmaNo ratings yet

- Welding Technology Lecture Notes by DR - Behzad PDFDocument354 pagesWelding Technology Lecture Notes by DR - Behzad PDFAnonymous L9LWVE100% (7)

- Machining ProcessDocument16 pagesMachining ProcessPoonam MargajNo ratings yet

- Alagappa University: Annexure - IDocument1 pageAlagappa University: Annexure - IThirumal KumarNo ratings yet

- UntitledDocument1 pageUntitledarunNo ratings yet

- Computer Virus HistoryDocument3 pagesComputer Virus HistoryarunNo ratings yet

- VersionDocument30 pagesVersionarunNo ratings yet

- When Was The First Computer InventedDocument13 pagesWhen Was The First Computer InventedVishal GuptaNo ratings yet

- RP 3210 Gold BrochureDocument2 pagesRP 3210 Gold BrochurearunNo ratings yet

- Intel Core I9 Comparison ChartDocument1 pageIntel Core I9 Comparison ChartRaulMorenoPerezNo ratings yet

- Electric WeldingDocument19 pagesElectric WeldingAnonymous e3XZzQNo ratings yet

- Running Projects in NPD (New Product Development) Area CTQ (Critical To Quality)Document5 pagesRunning Projects in NPD (New Product Development) Area CTQ (Critical To Quality)Mohammad AdilNo ratings yet

- PT B, CH 1, Sec 1: 5.6 Scantling of GlazingDocument6 pagesPT B, CH 1, Sec 1: 5.6 Scantling of GlazingHamada AttiaNo ratings yet

- ChE 134 Attrition Mill - GuanlaoDocument1 pageChE 134 Attrition Mill - GuanlaoJelor Gallego100% (1)

- Synthesis of Dibenzalacetone: Tobias Langenegger Tobiasla@student - Ethz.ch 05-918-362 D-Biol (Chem.)Document6 pagesSynthesis of Dibenzalacetone: Tobias Langenegger Tobiasla@student - Ethz.ch 05-918-362 D-Biol (Chem.)Júlio Gabriel Queiroz dos SantosNo ratings yet

- Simulating Foam Glass Production in A Tunnel Furnace Powered With MicrowavesDocument5 pagesSimulating Foam Glass Production in A Tunnel Furnace Powered With MicrowavesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Junkshop DirectoryDocument2 pagesJunkshop DirectoryAlexis Escarrilla100% (2)

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationDocument2 pagesQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovNo ratings yet

- Science Course III: Enhanced Oil Recovery: Starter PackDocument15 pagesScience Course III: Enhanced Oil Recovery: Starter PackJames SampurnaNo ratings yet

- Overcord R12: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageOvercord R12: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- Fosroc Conbextra BB80: Constructive SolutionsDocument4 pagesFosroc Conbextra BB80: Constructive SolutionsVincent JavateNo ratings yet

- Lighting & MirrorsDocument172 pagesLighting & MirrorsemmataylorcityNo ratings yet

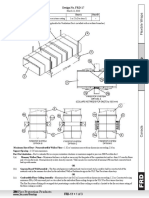

- FRD17Document3 pagesFRD17Raul FloresNo ratings yet

- Cov Fast Stainless Steel Cat - 3rd Ed - Jun 09Document116 pagesCov Fast Stainless Steel Cat - 3rd Ed - Jun 09jaffliangNo ratings yet

- Chapter 2-IBSDocument20 pagesChapter 2-IBSmohamadzameer78% (9)

- Dupont Oasis 120TWT561 Datasheet 1Document2 pagesDupont Oasis 120TWT561 Datasheet 1kamlesh vaishnavNo ratings yet

- Assignment On: Floating FoundationDocument10 pagesAssignment On: Floating FoundationShaibal Ahmed100% (1)

- VOC Compliant Resin Technology For Decorative Coatings Full TextDocument10 pagesVOC Compliant Resin Technology For Decorative Coatings Full TextcockeiserNo ratings yet

- Heat Treatment Processes Powerpoint PresentationDocument14 pagesHeat Treatment Processes Powerpoint PresentationDaniel Dowding100% (1)

- Composite InsulatorsDocument8 pagesComposite InsulatorsJosue Espinoza YachachinNo ratings yet

- Volume 2 Issue 10 - October 2013Document406 pagesVolume 2 Issue 10 - October 2013Tatiana Monroy MoraNo ratings yet

- Certifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itDocument2 pagesCertifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itMohamed Raafat100% (1)

- Appendixes: Appendix Particle Size - 1 - A - AluminumDocument19 pagesAppendixes: Appendix Particle Size - 1 - A - AluminumIbrahim HeaderNo ratings yet

- Generation of Electricity Using Nitinol: S K Haaris G Madhu Murali Siran2Document3 pagesGeneration of Electricity Using Nitinol: S K Haaris G Madhu Murali Siran2Deepak BhopeNo ratings yet

- USP 401 Fats and OilsDocument13 pagesUSP 401 Fats and OilsChandrajeet U. SagarNo ratings yet

- Procedure For AluminizingDocument4 pagesProcedure For AluminizingCorrosion FactoryNo ratings yet

- Lab Manual - ChemistryDocument10 pagesLab Manual - Chemistryananya.audition.mailNo ratings yet

- Stretch Conductive Fabric: 49OO - Technical DatasheetDocument1 pageStretch Conductive Fabric: 49OO - Technical DatasheetAdrian PramantaNo ratings yet

- Effect of Sunlight Ultraviolet Exposure On The Corrosion of Fusion Bonded Epoxy (FBE) Coated Steel Rebars in ConcreteDocument40 pagesEffect of Sunlight Ultraviolet Exposure On The Corrosion of Fusion Bonded Epoxy (FBE) Coated Steel Rebars in ConcretenagarajuNo ratings yet

- Gypsum Products ....Document111 pagesGypsum Products ....Dr.Sathyabhama A.VNo ratings yet