Professional Documents

Culture Documents

A Simple and Efficient Ozone Generator PDF

A Simple and Efficient Ozone Generator PDF

Uploaded by

Marcelo IpolitoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Simple and Efficient Ozone Generator PDF

A Simple and Efficient Ozone Generator PDF

Uploaded by

Marcelo IpolitoCopyright:

Available Formats

In the Laboratory

edited by

Cost-Effective Teacher Harold H. Harris

University of Missouri—St. Louis

St. Louis, MO 63121

A Simple and Efficient Ozone Generator

Debra J. Sponholtz, Michael A. Walters, Jimmy Tung, and Joseph J. BelBruno*

Department of Chemistry, Dartmouth College, Hanover, NH 03755; *jjbchem@Dartmouth.edu

Ozonolysis in the educational laboratory has been prima- 0.33 cm3 s{1 (20 cm3 min{1) through a silent electric discharge.

rily a tool used in structure determination (1–3). Instrumental In their experiment, ozone was produced at a rate of approxi-

methods of analysis have effectively eliminated the need for mately 2 µmol min{1.

these oxidation reactions and removed ozonolysis from the

classroom. However, oxidation is still an important topic in The Apparatus

introductory courses and ozonolysis can play an important

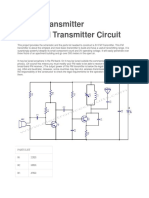

role in describing this concept. Typically, however, the pre- A schematic design of an ozone generator suitable for

parative uses of ozone imply use of a commercial apparatus. lab scale investigations using a corona discharge has been

Commercial ozone generators are often unwieldy in size and reported in the literature (5, 16 ). The device we developed

inefficient in their production of ozone. On the other hand, is simpler in construction and readily assembled from com-

most of the ozone generators reported in this Journal, with a ponents commonly found in any laboratory. It is based on

single exception (4 ), are for small-scale production of deriva- the published schematic but, rather than being custom

tives for structural determination and are unsuitable for glassblown, is constructed of standard West condensers. Two

the safe generation of the quantities of ozone needed for an condensers, each with one ground glass joint removed and

oxidation reaction (6–13). We report herein the construction the end sealed, are connected in series with Tygon tubing and

of an inexpensive, efficient, and compact ozonolysis apparatus suspended in a custom-made PVC container. This container

that is a convenient alternative to the more expensive gen- is constructed from 11.5-cm o.d., 10-cm i.d. pipe. It is sealed

erators currently on the market. with an o-ring to a bottom flange and has a removable press-

Ozone is produced in a silent electrical discharge within fit top (Fig. 1). The length of each condenser is approximately

which electrons with sufficient kinetic energy split the O=O 20 cm. The innermost cavity of each condenser, which is

bond upon impact (14 ). In general, when an alternating normally used to condense solvent vapor, is filled with electro-

current voltage is applied to a sample of oxygen, ozone lyte. One electrode of the discharge, a 0.25-inch copper tube,

production doubles as the frequency of the current is doubled. is inserted into the solution in this inner cavity and subse-

The amount of ozone generated varies exponentially with the quently connected to the power source. The other electrode

applied voltage. The half-life of ozone is more than 5000 s of the discharge, which is constructed from copper mesh, is

at temperatures less than 100 °C and tends to increase with inserted into the electrolyte solution surrounding the entire

decreasing ozone concentration. Mudd and co-workers (15) condenser assembly. The copper mesh may be electrically

were able to generate ozone by passing O2 at a flow rate of grounded or connected to the power source as necessary and,

typically, a 0.3 M CaCl2 solution is used as the electrolyte.

When generating ozone at temperatures below 20 °C, a

stainless steel dewar is substituted for the PVC container and

Power Supply

electrolyte solutions of 4.5 M MgCl2 or 6.5 M CaCl2 are

O2 O2 + O3 used owing to the lower freezing points of these solutions.

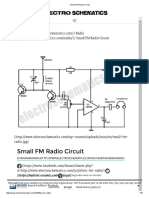

The power supply, shown in Figure 2, consists of a step-up

transformer for the line voltage and a set of contact points

operated by a second transformer. The power supply output

is limited to less than 0.5 A and, on average, is approximately

20 kV at an unregulated frequency near 60 Hz.

PVC Housing

Electrolyte Levels

Electrode

Gas Flow

Copper Mesh Electrode

Ends Sealed

Figure 1. Schematic diagram of the ozone generation cell. Figure 2. Power supply schematic diagram.

1712 Journal of Chemical Education • Vol. 76 No. 12 December 1999 • JChemEd.chem.wisc.edu

In the Laboratory

Ozone is produced by passing zero grade oxygen, 99.8% 3-(2-Oxopropyl)-1,3-oxazolidin-2-one (2)

purity, through the cooling jacket of the condenser. The maxi- Chromatography of the crude product (EtOAc) yielded

mum concentration of ozone obtained with the feed oxygen the desired compound quantitatively. 1H NMR (CDCl3, 300

and discharge near room temperature was approximately 4% MHz) δ 4.40 (dd, 2H, J = 8.06 Hz), 4.11 (s, 2H), 3.66 (dd,

v/v at a flow rate of 0.33 mL s{1. A marginal increase in ozone 2H, J = 8.06 Hz), 2.18 (s, 3H); 13C NMR (CDCl3, 75 MHz)

concentration was measured when the discharge temperature δ 202.3, 158.8, 62.1, 53.1, 44.9, 26.8; TLC R f 0.19 (75%

was cooled to {20 °C. Decreasing the feed gas temperature EtOAc/hexanes).

further by passing it through a pentane/liquid nitrogen slurry

bath (approximately {150 °C) at a flow rate of up to approxi- Safety Warnings

mately 25 mL s{1 resulted in concentrations up to 10% v/v

of ozone in oxygen. CAUTION: Ozone is a highly reactive and toxic gas. It

Photometric detection at 254 nm allowed the determi- rapidly, and sometimes violently, reacts with organic molecules.

nation of ozone concentration in the effluent stream. (The Chronic exposure and exposure to high concentrations may

O3 absorption coefficient at 254 nm is 134 ± 2 atm{1 cm{1 at cause respiratory difficulties and eye irritation. The apparatus

273 K and 123 ± 2 atm{1 cm{1 at 298 K [17–24 ].) Alterna- described in this report should only be operated with proper

tively, a titrimetric technique that involves bubbling the ventilation, preferably in a fume hood. Generation of ozone

effluent gas through an aqueous solution of potassium iodide requires a high-voltage discharge. Care should be taken to

may also be used to determine ozone concentration (25). physically and electrically isolate the high-voltage components

Advantages of this ozone generating system are that it of this apparatus from any nearby solvents.

does not require expensive, high-purity oxygen and that it

can be constructed from common glassware. The power Note

source involves only three electrical components and the 1. The following electrical components are suitable for power sup-

specifications of those components are not critical to the ply construction: EG&G, Inc. Step-up transformer (Model TR-153),

operation of the device.1 The simplicity of design and effi- Allied Electronics 120V Repeat Cycle Timer (Model 519-4005) and

ciency of ozone production offered by this apparatus should 10 kΩ current limiting resistor. However, any similar components will

make it ideal for use in advanced laboratory settings. The be acceptable.

preparation of 3-(2-oxopropyl)-1,3-oxazolidin-2-one (2) is

illustrative of the use of the apparatus described above. Many Literature Cited

other olefinic substrates could be oxidized in like fashion. 1. Gross, R. A. Jr. J. Chem. Educ. 1996, 73, 1019.

In this case, the starting material is obtained by N-alkyla- 2. Sharefkin, J. G.; Ribner, A. J. Chem. Educ. 1960, 37, 296.

tion of the sodium salt of 2-oxazolidinone. The procedure 3. Rhoads, C. M.; Farquar, G. R.; Wood, W. F. J. Chem. Educ. 1997,

features the use of triethylamine for ozonide decomposition, 74, 1220.

offering the benefit of easy workup and purification of the 4. Dardin, V. J. J. Chem. Educ. 1966, 43, 439.

5. Rubin, M. B. J. Chem. Educ. 1964, 41, 388.

desired carbonyl product. 6. Whaley, T. P. J. Chem. Educ. 1957, 34, 94.

7. Andrews, A. C.; Mickel, B. L.; Klassen, K. C. J. Chem. Educ.

General Procedure for Ozonolysis 1955, 32, 154.

8. Bonner, W. A. J. Chem. Educ. 1953, 30, 452.

O O O O 9. Ransford, J. E. J. Chem. Educ. 1951, 28, 477.

1. O3 O 10. Uhrig, K. J. Chem. Educ. 1945, 22, 582.

N 2. TEA N 11. Lisk, G. M. J. Chem. Educ. 1931, 8, 2429.

12. Lisk, G. M. J. Chem. Educ. 1932, 9, 2099.

1 2 13. Maxwell, M. J. Chem. Educ. 1928, 5, 1493.

14. Yagi, S.; Tanaka, M. J. Phys. D Appl. Phys. 1979, 12, 1509.

A 50-mL pear-shaped flask was charged with 0.342 g 15. Mudd, J. B.; Leavitt, R.; Ongun, A.; McManus, T. T. Atmos.

(1.55 mmol) of methallyl oxazolidinone (1) and 35 mL of Environ. 1969, 3, 669.

freshly distilled (CaH2) CH2Cl2. The solution was cooled to 16. Holtzclaw, H. F.; Robinson, W. R.; Nebergall, W. H. General

{78 °C and O3 was bubbled through it. To effect addition of Chemistry; 7th ed.; D.C. Heath: Lexington, MA, 1980; p 225.

ozone, the exit port of the ozone generator was connected 17. Inn, E. C. Y.; Tanaka, Y. J. Opt. Soc. Am. 1953, 43, 870.

with Tygon tubing to a piece of glass tubing that terminated 18. Hearn, A. G. Proc. Phys. Soc., London 1961, 78, 932.

19. DeMore, W. B.; Raper, O. J. Phys. Chem. 1964, 68, 412.

in a glass frit. Ozone was delivered to the reaction solution 20. Griggs, M. J. Chem. Phys. 1968, 49, 857.

using this fritted tube, the fritted end being submerged in 21. Becker, K. H.; Schurath, U.; Seitz, H. Int. J. Chem. Kinet. 1974,

the solvent. After approximately 30 min the solution was blue, 6, 725.

indicating the presence of excess ozone. The ozone delivery 22. Clyne, M. A. A.; Coxom, J. A. Proc. R. Soc. 1968, A303, 207.

tube was removed from the reaction and the flask was placed 23. Simons, J. W.; Paur, R. J.; Webster, H. A.; Bair, E. J. J. Chem.

under a slightly positive pressure of N2 on an inert atmosphere Phys. 1973, 59, 1203.

24. Okabe, H. Photochemistry of Small Molecules; Wiley: New York,

line. Triethylamine (TEA) was added (0.41 mL, 3.09 mmol) and 1978; pp 237–246.

the solution was gradually warmed to room temperature and 25. Mudd, J. B.; Leavitt, R.; Ongun, A.; McManus, T. T. Atmos.

stirred overnight (26 ). The reaction was washed with brine Environ. 1969, 3, 669.

and dried (MgSO4), and the solvent was removed in vacuo. 26. Hon, Y. S; Lin, S.W.; Chen, Y. J. Synth. Commun. 1993, 23, 1543.

JChemEd.chem.wisc.edu • Vol. 76 No. 12 December 1999 • Journal of Chemical Education 1713

You might also like

- Presented By-Dr - Siddhartha Ghelani P.G Teacher-Dr - Hemina DesaiDocument61 pagesPresented By-Dr - Siddhartha Ghelani P.G Teacher-Dr - Hemina DesaiSiddhartha GhelaniNo ratings yet

- 6280Document13 pages6280sanbarunNo ratings yet

- PSA Nitrogen PlantsDocument4 pagesPSA Nitrogen PlantsIdo Aprilian TariganNo ratings yet

- Samples Layher Scaffold Comparisons WeightDocument9 pagesSamples Layher Scaffold Comparisons WeightKhaws KmsNo ratings yet

- Aop-2310 Eda V1 eDocument30 pagesAop-2310 Eda V1 eden mas paratate leo ego100% (2)

- 433MHz Transmitter DetailsDocument7 pages433MHz Transmitter DetailskaushikrejaNo ratings yet

- Ozone TheraphyDocument42 pagesOzone Theraphyanakedya13100% (1)

- IS Codes For Public Health EngineeringDocument4 pagesIS Codes For Public Health EngineeringRaghavan ARNo ratings yet

- Expandable Graphic EqualiserDocument6 pagesExpandable Graphic EqualiserCarlos TigseNo ratings yet

- MF 5400 Product GuideDocument143 pagesMF 5400 Product GuideAnonymous dYYLURMNo ratings yet

- TE13 & TE17 3-SpeedDocument166 pagesTE13 & TE17 3-SpeedAnonymous dYYLURM100% (2)

- Actua DorDocument4 pagesActua DorAnonymous dYYLURMNo ratings yet

- ELECTRONIC SCALE USER MANUAL Rev 6Document33 pagesELECTRONIC SCALE USER MANUAL Rev 6Iyad Abu-Firas100% (2)

- Scale Remover PresentationDocument18 pagesScale Remover PresentationRaja Pathamuthu.G100% (1)

- Guidelines For Sewage Works Design WSA-MOEDocument28 pagesGuidelines For Sewage Works Design WSA-MOEMichał KisielewskiNo ratings yet

- MInitransceiver SSB 80mDocument8 pagesMInitransceiver SSB 80mag1tatorNo ratings yet

- 6684-EQS-101-CA-0001 - 000 - 03 - Contractor's Scope of Work - Static EquiDocument15 pages6684-EQS-101-CA-0001 - 000 - 03 - Contractor's Scope of Work - Static EquiAvinash ShuklaNo ratings yet

- Chapter 4 Metal Oxide Semiconductor FET (MOSFET)Document47 pagesChapter 4 Metal Oxide Semiconductor FET (MOSFET)redhataNo ratings yet

- Define BP Role & BP Role Category in SAP S4 Hana - SAP TutorialDocument9 pagesDefine BP Role & BP Role Category in SAP S4 Hana - SAP TutorialGowrikishore Kishore100% (1)

- Solar Irrigation-Detailed Project Report PDFDocument17 pagesSolar Irrigation-Detailed Project Report PDFJimmy ValentineNo ratings yet

- Circuit Diagram of RC Transmitter and ReceiverDocument6 pagesCircuit Diagram of RC Transmitter and ReceivernicoletabytaxNo ratings yet

- Deodorants and AntiperspirantsDocument38 pagesDeodorants and AntiperspirantsSonam Madan100% (1)

- Slewing Bearing Slewing Ring Slewing Gear Swing CircleDocument19 pagesSlewing Bearing Slewing Ring Slewing Gear Swing Circlezczc32z5No ratings yet

- TZ000002 Principles of Ozone GenerationDocument17 pagesTZ000002 Principles of Ozone GenerationmohsenNo ratings yet

- Trickling FiltersDocument16 pagesTrickling FiltersGunnar AgarwalNo ratings yet

- Dr. Katz'S Aktivoxigen Ozonator: Specifically Designed To Rapidly Ozonate Liquids & OilsDocument16 pagesDr. Katz'S Aktivoxigen Ozonator: Specifically Designed To Rapidly Ozonate Liquids & Oilstyber100100% (3)

- Small Radio Transmitter CircuitDocument2 pagesSmall Radio Transmitter Circuitrik206No ratings yet

- 3V FM Transmitter 3V FM Transmitter CircuitDocument4 pages3V FM Transmitter 3V FM Transmitter Circuitpeter.gomes20087216No ratings yet

- Eela Audio SRM Users ManualDocument14 pagesEela Audio SRM Users ManualJose Carlos SoaresNo ratings yet

- FM Radio ReceiverDocument3 pagesFM Radio ReceiverRajatNo ratings yet

- (Tutorial Chemistry Texts) James R. Hanson-Organic Synthetic Methods-Royal Society of Chemistry (2002) PDFDocument184 pages(Tutorial Chemistry Texts) James R. Hanson-Organic Synthetic Methods-Royal Society of Chemistry (2002) PDFViên ViênNo ratings yet

- Ozone Washing: By-Vipul Verma Amit Kumar BFT-6Document12 pagesOzone Washing: By-Vipul Verma Amit Kumar BFT-6Amethia Apparelz100% (1)

- FM TransmitterDocument15 pagesFM TransmitterMuhammad Aiman AmranNo ratings yet

- Respi Anaphy Day 1Document128 pagesRespi Anaphy Day 1Tracy Megan RusillonNo ratings yet

- 2 George Wise Science and TechnologyDocument19 pages2 George Wise Science and TechnologyChetan OswalNo ratings yet

- The Art and Mystery of The Gentle CraftDocument75 pagesThe Art and Mystery of The Gentle Craftlaurabow0% (1)

- Silver Hydrogen Peroxide - Dairy DisinfectantDocument2 pagesSilver Hydrogen Peroxide - Dairy DisinfectantSilver Hydrogen PeroxideNo ratings yet

- Small FM Radio Circuit PDFDocument10 pagesSmall FM Radio Circuit PDFSantosh Kumar0% (1)

- Ozone DecompositionDocument13 pagesOzone DecompositionLad SlasNo ratings yet

- Factors Affecting Wet Scrubber PerformanceDocument4 pagesFactors Affecting Wet Scrubber PerformanceZee KayNo ratings yet

- Removal of Iron From GroundwaterDocument3 pagesRemoval of Iron From GroundwaterRishya Prava ChatterjeeNo ratings yet

- Swimming Pool Ozone SystemDocument21 pagesSwimming Pool Ozone SystemPragnesh MehtaNo ratings yet

- 45-860MHz Radio Receiver Based On UV916-tunerDocument7 pages45-860MHz Radio Receiver Based On UV916-tunerSutharsan Kumar KrishnamoorthyNo ratings yet

- Class E AmplifiersDocument28 pagesClass E AmplifiersBharath Reddy100% (1)

- Handbook of Fuel CellsDocument6 pagesHandbook of Fuel CellsgarysandelinNo ratings yet

- Code of Practice For Selection, Laying of Moist Fuel Gas Lines IPSS:1-06-014-17Document11 pagesCode of Practice For Selection, Laying of Moist Fuel Gas Lines IPSS:1-06-014-17Sarbendu PaulNo ratings yet

- Rust Removal Using ElectrolysisDocument4 pagesRust Removal Using Electrolysisbvd1940No ratings yet

- Project Standards and Specifications Dryers Systems Rev01Document18 pagesProject Standards and Specifications Dryers Systems Rev01Christian CleofasNo ratings yet

- Electrical Circuit Project Design PackageDocument5 pagesElectrical Circuit Project Design Packageapi-242278621No ratings yet

- UBE Air Drying MembranesDocument8 pagesUBE Air Drying Membranesharry_chem100% (1)

- Reverse Osmosis and Ultra Filtration Class LectureDocument7 pagesReverse Osmosis and Ultra Filtration Class Lecturenabil100% (1)

- Aqua SILENCERDocument28 pagesAqua SILENCERAnandu Pm100% (5)

- Portable Ozone GeneratorsDocument11 pagesPortable Ozone GeneratorsglobalrevolutionNo ratings yet

- Daf Equipment and Ozone EquipmentDocument6 pagesDaf Equipment and Ozone EquipmentAnonymous Tj3ApePIrNo ratings yet

- HHODocument5 pagesHHOdan_todoran100% (1)

- Application of ElectrostaticsDocument7 pagesApplication of ElectrostaticsrasajatiNo ratings yet

- Advanced Waste Water TreatmentDocument1 pageAdvanced Waste Water TreatmentMoises FriasNo ratings yet

- Aqua SilencerDocument14 pagesAqua Silencermd inam ul hasan safwan100% (1)

- Thermal Powertech Corporation India Limited: I) IntroductionDocument9 pagesThermal Powertech Corporation India Limited: I) Introductionkannagi1980% (1)

- Measurement of Insulation Resistance IR Part 1Document5 pagesMeasurement of Insulation Resistance IR Part 1hafizg100% (1)

- KOBELCO Welding Handbook 2009Document202 pagesKOBELCO Welding Handbook 2009shamsabbasNo ratings yet

- OZONEDocument8 pagesOZONEAlexiss Chavez-De la MoraNo ratings yet

- Use of Electrically Excited Oxygen For The Low Temperature Decomposition of Organic SubstancesDocument4 pagesUse of Electrically Excited Oxygen For The Low Temperature Decomposition of Organic SubstancesMee CoolNo ratings yet

- Functionalization-Mediated Physicochemical Properties of inDocument6 pagesFunctionalization-Mediated Physicochemical Properties of inNguyen Cong TuNo ratings yet

- Apr 2011 2 4 104 107 PDFDocument4 pagesApr 2011 2 4 104 107 PDFDavid GonzalezNo ratings yet

- Effect of Generating Heat On Ozone Generation in DDocument5 pagesEffect of Generating Heat On Ozone Generation in DFeyza KaragözNo ratings yet

- Vanadio NMRDocument7 pagesVanadio NMRsergioodin4851No ratings yet

- Rodriguez 2002Document9 pagesRodriguez 2002Andres FragosoNo ratings yet

- Asteman Influence of Water Vapor and Flow Rate On The High-Temperature OxidatioDocument16 pagesAsteman Influence of Water Vapor and Flow Rate On The High-Temperature OxidatioAbigail GuerreroNo ratings yet

- New Techniques for the Study of Electrodes and Their ReactionsFrom EverandNew Techniques for the Study of Electrodes and Their ReactionsNo ratings yet

- ABB Control PP30012HS DatasheetDocument1 pageABB Control PP30012HS DatasheetAnonymous dYYLURMNo ratings yet

- Celda de Carga Viga A La FlexionDocument1 pageCelda de Carga Viga A La FlexionAnonymous dYYLURMNo ratings yet

- Daa Lab ManualDocument12 pagesDaa Lab Manualshom1123550% (2)

- ENO Systems&2D PDFDocument41 pagesENO Systems&2D PDFMehdi EzadiNo ratings yet

- Vane Gaz Honeywell PDFDocument16 pagesVane Gaz Honeywell PDFCezaryCezasNo ratings yet

- Geovista Data LoggerDocument1 pageGeovista Data LoggerShahzad KhanNo ratings yet

- ELG3311: Assignment 2: Problem 5-22Document10 pagesELG3311: Assignment 2: Problem 5-22Babasrinivas GuduruNo ratings yet

- Energies: Battery Thermal Management Systems: Current Status and Design Approach of Cooling TechnologiesDocument32 pagesEnergies: Battery Thermal Management Systems: Current Status and Design Approach of Cooling TechnologiesAnjali prajapatiNo ratings yet

- Modeling Decision Processes: Decision Support Systems in The 21 Century, 2 by George M. MarakasDocument19 pagesModeling Decision Processes: Decision Support Systems in The 21 Century, 2 by George M. MarakasVũ ThảoNo ratings yet

- Kaspersky Presales Paper EDR and KATADocument21 pagesKaspersky Presales Paper EDR and KATAatherNo ratings yet

- Breathing System FiltersDocument4 pagesBreathing System FiltersNiyi ArunaNo ratings yet

- Final CP-I RecordDocument29 pagesFinal CP-I RecordAmbikapathy RajendranNo ratings yet

- Explorations Chapter 1Document7 pagesExplorations Chapter 1isothermNo ratings yet

- Acid Base Imbalance PDFDocument32 pagesAcid Base Imbalance PDFdr.Bobi Ahmad Sahid, S.KepNo ratings yet

- Operator's Manual GPS Navigator GP-150Document104 pagesOperator's Manual GPS Navigator GP-150evbulgakovNo ratings yet

- CHEM 341 Physical Chemistry Final Exam: Do Not Open This Exam Until Told To Do SoDocument10 pagesCHEM 341 Physical Chemistry Final Exam: Do Not Open This Exam Until Told To Do SoOmarNo ratings yet

- OMD Pourstop ChartDocument1 pageOMD Pourstop ChartKriszel TorrelizaNo ratings yet

- Assignment 1 - SolutionDocument3 pagesAssignment 1 - Solutionkanwalmann29No ratings yet

- Effect of Silica Fume On The Properties of Concrete: (Ijerat)Document5 pagesEffect of Silica Fume On The Properties of Concrete: (Ijerat)Ohnmar OmNo ratings yet

- Senior Trans ResumeDocument5 pagesSenior Trans Resumeapi-244822888No ratings yet

- Rehman HPDocument887 pagesRehman HPbala_thiNo ratings yet

- Mathematics 8300/1H: Higher Tier Paper 1 Non-CalculatorDocument31 pagesMathematics 8300/1H: Higher Tier Paper 1 Non-Calculatorgreg heffleyNo ratings yet

- Students NotesDocument268 pagesStudents Notes1balamanianNo ratings yet

- FM24C04D Ds EngDocument28 pagesFM24C04D Ds EngJuan Daniel Angeles AnguloNo ratings yet