Professional Documents

Culture Documents

Variable Valve Timing & Acoustic Control Induction Systems: Section 8

Variable Valve Timing & Acoustic Control Induction Systems: Section 8

Uploaded by

sungjoo75Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Variable Valve Timing & Acoustic Control Induction Systems: Section 8

Variable Valve Timing & Acoustic Control Induction Systems: Section 8

Uploaded by

sungjoo75Copyright:

Available Formats

Section 8

Variable Valve Timing & Acoustic Control Induction Systems

ECM

Crankshaft Position Sensor Camshaft

Target Valve Timing Timing Oil

Control Valve

Mass Air Flow Meter

Feedback

Throttle Position Sensor

Engine Coolant Temp. Sensor Correction

VVT Sensor Actual Valve Timing

T852f286

Lesson Objectives 1. Familiarity with the VVT-i systems and ACIS systems operation

Engine Control Systems I - Course 852

Section 8

Variable Valve Timing & Acoustic Control Induction Systems

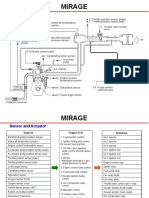

VVT-i System

Throttle Position Sensor

Camshaft Timing Oil Control

VVT Sensor

Camshaft Timing Oil Control

VVT Sensor

Engine Coolant Temp. Sensor

ECM

Crankshaft Position Sensor

Mass Air

Flow Meter

ECM

Crankshaft Position Sensor Camshaft

Target Valve Timing Timing Oil

Control Valve

Mass Air Flow Meter

Feedback

Throttle Position Sensor

Duty Control

Engine Coolant Temp. Sensor Correction

VVT Sensor Actual Valve Timing

Fig. 8-01

T852f285/T852f286

Variable Valve Without variable valve timing, engine valve timing is a compromise

Timing between the needs to produce maximum torque (horsepower) at low to

Systems medium speeds, idle stability, fuel economy, low emissions, and maxi-

mum horsepower output. Continuously adjusting when the valves open

and close, called variable valve timing, yields significant improvements

in all these areas. The ECM, according to driving conditions such as the

engine speed and load, will advance or retard the camshaft, changing

when the valves open and close. This system is called the Variable Valve

Timing-intelligent (V V T-i) system.

Engine Control Systems I - Course 852 8-1

Section 8

VVT-i Range

The G signal represents

the movement of the

Controllable Controllable

camshaft in degrees in Range of VVT-i Range of VVT-i Most Advanced

relation to the crankshaft. Advanced Side

Most Delayed Angle Position Angle Position

G2

NE Signal

Crankshaft Angle 0 120 240 360

#6 TDC #2 TDC #4 TDC #1 TDC

Controllable Range of VVT-i

G2 Signal

NE Signal

Crankshaft Angle 360 480 600 720

#1 TDC #5 TDC #3 TDC #6 TDC

Fig. 8-02

Phase Relationship Between G2 and NE Signal T852f287

Components of V V T-i uses the crankshaft position sensor and Variable Valve Timing

V V T-i (V V T ) sensors (camshaft position sensor) to measure the amount of

camshaft movement. This feedback is necessary for the ECM to know

how much and which direction to move the camshaft, and for diagnosis.

A continuously variable valve timing mechanism, called a controller or

actuator, is used to adjust the camshaft from the starting stage to the

high speed traveling state.

A camshaft timing Oil Control Valve (OCV), controlled by the ECM,

directs engine oil pressure to the advance or retard side of the V V T-i

controller.

Effect of Continuous Smooth Idle - At idle rpm, valve overlap is eliminated by retarding the

Valve Timing camshaft. With the intake valve opening after the exhaust valve has

Changes closed, there is no blow back of exhaust gases to the intake side. Now,

combustion is more stable because of the clean air/fuel mixture. This

allows the engine idle smoothly at a lower rpm and fuel consumption is

reduced.

Torque Improvement in Low to Medium Speed Range - In the low to

medium speed range with a heavy load, the camshaft is advanced

increasing the valve overlap. This has two effects. First, the exhaust

gases help pull in the intake mixture. Second, by closing the intake

valve early, the air/fuel mixture taken into the cylinder is not discharged.

8-2 TOYOTA Technical Training

Variable Valve Timing & Acoustic Control Induction Systems

This improves volumetric efficiency and increases torque (and therefore

horsepower) in the low and midrange rpm range. The driver notices a

more powerful acceleration.

EGR Effect - V V T-i eliminates the need for an EGR valve. As a result of

increasing the valve overlap in which the exhaust and intake valves are

both open, the exhaust gas is able to flow to the intake side. Diluting the

air/fuel mixture with exhaust gases reduces the combustion temperature

and the production of NOx. Also, some of the unburned air/fuel mixture

present in the exhaust gas will be burned.

Better Fuel Economy - A V V T-i equipped engine is more efficient and

provides better fuel economy from a variety of factors. Without V V T-i, the

engine would have to be larger and heavier to produce the same horse-

power. Smaller pistons, connecting rods, and crankshaft reduce friction

and mechanical losses. A lighter engine improves vehicle fuel economy.

Improved fuel consumption is also realized because of the further reduc-

tion in the intake stroke resistance. In the medium-load operation range,

when the valve overlap is increased, the vacuum (negative pressure) in

the intake manifold is reduced. Now, it takes less energy to move the pis-

ton downward on the intake stroke. With the pumping loss reduced dur-

ing the intake stroke, more energy is available to propel the vehicle.

At idle, with no valve overlap, the idle speed is lower improving fuel econ-

omy.

Improved Emission Control Performance - In the light-medium load

operation range, V V T-i increases the valve overlap creating an internal

EGR effect. By opening the intake valve earlier in the exhaust stroke at a

lower RPM allows the exhaust gases to push into the intake manifold

mixing with the fresh air. The return of exhaust gas into the cylinder low-

ers the combustion temperature, resulting in NOx reduction. Essentially,

V V T-i will increase the valve overlap to obtain the same EGR effect as an

engine equipped with an EGR valve. In other words, when an EGR valve

on an EGR equipped engine opens is when V V T-i will increase the valve

overlap.

Another benefit is that HCs are also reduced. Some of the unburned

air/fuel mixture from the previous cycle returns to the cylinder for combustion.

Finally, C02 is reduced because of the decrease in fuel consumption.

Engine Control Systems I - Course 852 8-3

Section 8

Oil Control Valve

(OCV)

To Timing Pulley

(Advanced Side) Coil

(Retard Side)

Drain Drain

Spring

Spool Valve Plunger

Oil Pressure

Variable Angle (50º)

Exhaust Valve

Intake Valve

Valve Lift

Crankshaft Angle

Valve Timing

Fig. 8-03

T852f288/T852f289

Operation The Camshaft Timing Oil Control Valve (OCV), controlled by the ECM,

Camshaft Timing directs engine oil pressure to the advance or retard side of the V V T-i

Oil Control Valve controller. The spool valve position is determined by the magnetic field

strength opposing the spring. As the ECM increases the pulsewidth

(duty ratio), the magnetic field moves the spool valve overcoming spring

pressure and directing more oil to the advance side. To retard the tim-

ing, the ECM decreases the pulsewidth, and spring pressure moves the

spool valve towards the retard position. When the desired camshaft

angle is achieved, the ECM will generate a pulsewidth signal to move

the spool valve to hold position. In the hold position, the oil is trapped

in the controller maintaining the desired angle. When the engine is

stopped, the spring pushes the spool valve to the most retarded state.

8-4 TOYOTA Technical Training

Variable Valve Timing & Acoustic Control Induction Systems

VVT-i Controller Assembly

Timing Pulley

VVT Tube

Piston

Intake Camshaft

Inner Gear

Outer Gear

Exhaust Camshaft

Scissors Gear

Fig. 8-04

T852f290

V V T-i Controller

The helical splines force the camshaft to

advance or retard in relation to the timing

pulley. Helical Spline

(Inner Gear) Helical Spline

Outer Gear

Timing Pulley

Intake Camshaft

Piston

Inner Gear

Piston Fig. 8-05

T852f291/T852f292

VVT-i Controller This V V T-i controller comprises of an outer gear driven by the timing

(Helical Type) belt, an inner gear affixed to the camshaft, and a movable piston that is

Operation placed between the outer gear and inner gear. As the piston moves later-

ally (axially), the helical splines on the piston and inner gear force the

camshaft to move in relation to the timing gear.

Engine Control Systems I - Course 852 8-5

Section 8

Advance

By the command of the Piston Camshaft Timing

ECM, when the OCV is Oil Control Valve

in the position shown,

hydraulic pressure is

applied from the left side

of the piston, which

causes the piston to

move to the right.

Because of the twist in

the helical splines on the

inside diameter of the

piston, the intake

camshaft rotates in the Intake

advance direction in Camshaft

relation to the camshaft Drain

timing pulley.

Oil Pressure

Timing Pulley

Fig. 8-06

T852f293

Retard

When the OCV is in the

position shown, the Piston

piston moves to the left

and rotates the camshaft

in the retard direction.

Drain

Oil Pressure

Fig. 8-07

T852f294

8-6 TOYOTA Technical Training

Variable Valve Timing & Acoustic Control Induction Systems

Hold

To hold to the desired

position, the OCV shuts

off the oil passages to

maintain the hydraulic

pressure at both sides of

the piston, thus

maintaining that position.

Fig. 8-08

T852f295

VVT-i Actuator (Vane Type) Housing

(Fixed on driven gear)

Vane Seal

Lock Pin

Housing

Side Vane

Exhaust Camshaft Portion

VVT-i Controllers

(Fixed on

intake

camshaft)

Hydraulic

Pressure

Driven Gear

Intake Camshafts

Exhaust Camshaft

Fig. 8-09

T852f296/T852f297

VVT-i Actuator This controller consists of a housing driven by the exhaust camshaft and

(Vane Type) a vane fixed to the intake camshaft. Oil pressure is directed to either side

Operation of the vane causing the camshaft to rotate in relation to the driven gear.

Engine Control Systems I - Course 852 8-7

Section 8

VVT-i Operation

Camshaft Timing

Operation Oil Control Valve

Drive Signal

Description

VVT-I Controller When the camshaft timing oil

control valve is positioned as

illustrated at left by the

Advance

advance signal from the

ECM, the resultant oil pres-

ECM sure is applied to the timing

Rotating

Direction Duty Ratio advance side vane chamber

to rotate the camshaft in the

Oil timing advance direction.

Pressure

Vane (Fixed on When the camshaft timing oil

intake camshaft)

control valve is positioned as

illustrated at left by the

Retard

retard signal from the ECM,

the resultant oil pressure is

ECM applied to the timing retard

Rotating

Direction Duty Ratio side vane chamber to rotate

the camshaft in the timing

Oil retard direction.

Pressure

The ECM calculates the tar-

get timing angle according to

Vane (Fixed on the traveling state to perform

intake camshaft)

control as described above.

After setting at the target

timing, the camshaft timing

Hold

oil control valve is in the neu-

ECM tral position unless the travel-

ing state changes. This

Duty Ratio adjusts the valve timing at

the desired target position

Oil and prevents the engine oil

Pressure

from running out when it is

unnecessary.

Fig. 8-10

T852f298/T852f299

T852f300/T852f301

T852f302/T852f303

8-8 TOYOTA Technical Training

Variable Valve Timing & Acoustic Control Induction Systems

Variable Valve Timing with

Lift - intelligent (VVTL-i)

Camshaft Position Sensor

Oil Control Valve (Variable Valve Timing and Lift)

Engine Coolant Temp Sensor Throttle Position

Sensor

ECM

Oil Control Valve

(Variable Valve Timing) Mass Air Flow

Meter

Crankshaft Position Sensor

Fig. 8-11

T852f304

VVTL-i

Oil Control Valve (Variable

Low and Medium Lift or High Lift Valve Timing and Lift)

Crankshaft Position Sensor Oil Control Valve

Target Value Timing (Variable Valve Timing

Mass Air Flow Meter

Feedback

Duty Control

Throttle Position

Engine Coolant Temp. Sensor Correction

Camshaft Position Sensor Actual Valve Timing

Fig. 8-12

T852f305

Variable Valve Based on the V V T-i system, the Variable Valve Timing with Lift - intelli-

Timing Lift- gent (VVTL-i) system has adopted a cam changeover mechanism that

intelligence changes the amount of lift and duration of the intake and exhaust valves

System while the engine is operating at high speeds. In addition to achieving

higher engine speeds and higher outputs, this system enables the valve

timing to be optimally set, resulting in improved fuel economy.

Engine Control Systems I - Course 852 8-9

Section 8

When the engine is operating in the low-to-mid-speed range, the

low/medium-speed cam lobes of the camshafts operate to move the two

valves via the rocker arms. Then, when the engine is operating in the

high-speed range, the signals from the sensors cause the ECM to

change the hydraulic passage of the oil control valve, thus changing to

the high-speed cam lobes. Now, the lift and the duration of the intake

and exhaust valves increases, allowing a greater volume of the air/fuel

mixture to enter the cylinder, and a greater volume of the exhaust gases

to leave the cylinder. As a result, the engine produces more power over

a wider RPM range.

The construction and the operation of the valve timing control are basi-

cally the same as in the V V T-i system.

Camshaft Lobes

Low and Medium

Speed Cam Exhaust Camshaft

Intake Camshaft

High Speed Cam

Fig. 8-13

T852f306

8-10 TOYOTA Technical Training

Variable Valve Timing & Acoustic Control Induction Systems

Rocker Arm Needle Roller

Assembly (Integrated with Rocker Arm)

Rocker Arm Pad Rocker Arm

Rocker Shaft

Adjusting Shim

A

Rocker Arm Pin

Valve

Fig. 8-14

T852f307

Construction The main components of the rocker arm assembly are the rocker arm,

rocker arm pad, rocker arm pin, and the rocker shaft. This assembly is

used for both the intake and exhaust camshafts, with each connected to

its respective rocker arm shaft. Both the intake and exhaust camshafts

contain low and medium-speed cams and high-speed cams.

Rocker Arm

High Speed Cam

Assembly (Cams)

Low and Medium

Speed Cam

Rocker Arm Pad

Adjusting Shim

Rocker Arm Pin

Fig. 8-15

A of View

T852f308

Engine Control Systems I - Course 852 8-11

Section 8

Operation When the engine coolant temperature is higher than 60°C (140°F) and

the engine speed is higher than 6000 RPM, this system switches from

the low/medium speed cams to the high-speed cams.

Low/Medium Speed Operation High Speed Cam

When the engine is operating in the low-to

mid-speed range (below 6000 RPM), the

low and medium-speed cam pushes the

needle roller of the rocker arm down to

operate the two valves. At this time, the Low and Medium

high-speed cam is also pushing down on Speed Cam

the rocker arm pad, but because the rocker

arm pad moves freely, this movement does Rocker

not cause the rocker arm and the valves to Arm Pad

move.

Rocker Arm Pin

Low and Medium

Speed Cam

High Speed Cam Moves Freely

A of View

Needle Roller

Fig. 8-16

T852f309/T852f310

A

8-12 TOYOTA Technical Training

Variable Valve Timing & Acoustic Control Induction Systems

High Speed

When the engine

reaches a high speed

(over 6000 RPM), oil

pressure from the OCV

pushes the rocker arm

Rocker Arm Pad

pin out to lock the

bottom of the rocker arm

pad. Now, the high-

speed cam operates the

A

two valves via the rocker

arm pad and the rocker

arm. Because the high-

speed cam has a greater

cam lift and duration than

the low/medium-speed

cam, the intake and

exhaust valves are open

a longer period of time.

Hydraulic Pressure Locked

A of View

Fig. 8-17

T852f311/T852f312

Oil Control Valve

Spool valve position is controlled by the

duty ratio signal from the ECM. When

high speed operation is needed, oil

pressure is directed to the high-speed Cam Changeover Connector

cam side of the cam changeover Mechanism

(Rocker Arm Type)

mechanism.

Spool Valve

Sleeve

Drain Oil Plunger Fig. 8-18

Spring Coil

Pressure T852f313

Engine Control Systems I - Course 852 8-13

Section 8

Low and Medium Speed Oil Flow

The oil control valve is open on the drain

side so that the oil pressure will not be

applied to the cam changeover mechanism.

LOW HIGH LOW HIGH LOW HIGH LOW HIGH

ECM

OCV Oil Control

HIGH LOW HIGH LOW HIGH LOW HIGH LOW Valve “OFF”

Oil Pressure Drain

Changeover Mechanism

Fig. 8-19

T852f314

High Speed

The oil control valve closes on the drain side

in order to apply the oil pressure to the high-

speed cam of the cam changeover

mechanism.

LOW HIGH LOW HIGH LOW HIGH LOW HIGH

ECM

Oil Control

OCV Valve “ON”

HIGH LOW HIGH LOW HIGH LOW HIGH LOW

Oil Pressure Fig. 8-20

T852f315

Oil Pressure When the engine is operating in the low-to-mid-speed range, the oil con-

Control trol valve is open on the drain side so that the oil pressure will not be

applied to the cam changeover mechanism. Then, when the engine

reaches a high speed, the oil control valve closes on the drain side in

order to apply the oil pressure to the high-speed cam of the cam changeover

mechanism.

8-14 TOYOTA Technical Training

Variable Valve Timing & Acoustic Control Induction Systems

Acoustic

Control Induction

System (ACIS)

Throttle valve

Intake Air Valve Vacuum

Tank

Engine Speed

ECM

Throttle Valve

Opening Angle

Throttle Valve

Fig. 8-21

T852f316

Acoustic The Acoustic Control Induction System (ACIS) improves the torque in the

Control Induction whole RPM range, especially that in the low-speed range, by changing the

System intake manifold length in stages. The intake manifold length is varied in

(ACIS) stages by optimum control of the intake air control valve(s). The air flow

in the intake pipe pulsates due to opening and closing of the engine

intake valves. When an intake valve is closed, the air near the valve is

compressed by the inertia force. This compressed air pushes off the

intake valve at high speed toward the intake chamber. If the intake mani-

fold length and intake chamber shape are set to cause the compressed air

pressure to return to an engine intake valve during the intake stroke, the

intake air volume is increased improving volumetric efficiency. This is

called the intake inertia effect. This improves torque and horsepower.

The ACIS changes the intake manifold length in stages according to the

pulsating flow cycle that varies with the engine speed and throttle valve

opening.

Engine Control Systems I - Course 852 8-15

Section 8

The ACIS is tuned for each type of engine. Vacuum stored in the vacu-

um chamber is applied to the intake control valve through the VSV. The

VSV is switched on and off by the ECM. The intake control valve is

switched according to engine speed and load.

There are two-stage and three-stage ACIS systems. The three-stage uses

two VSVs.

2-Stage V-6 ACIS

Intake Air Control Valve

From Air Cleaner

Actuators

(for ACIS)

Fig. 8-22

T852f317

8-16 TOYOTA Technical Training

Variable Valve Timing & Acoustic Control Induction Systems

2JZ-FE ACIS

① VSV turned ON

No. 4 to No. 6

Air Control Valve

For Cylinders

Closing air control valve has the same

effect as lengthening the intake manifold. (closed)

No. 1 to No. 3

For Cylinders

Throttle Valve

➁ VSV turned OFF

Opening air control valve has the same Air Control Valve

effect as shortening the intake manifold. (open)

Fig. 8-23

T852f318/T852f319

1MZ-FE 2-Stage ACIS VSV Chart

1MZ-FE 2 Stage ACIS VSV chart. 2JZ-FE 2 Stage ACIS VSV chart.

Fig. 8-24

T852f320

Engine Control Systems I - Course 852 8-17

Section 8

1MZ-FE 3-Stage ACIS Torque Improvement

Effect of ACIS

3-Stage ACIS System for greater control

In Long Intake Manifold State

In Middle Intake Manifold State

In Short Intake

Manifold State

Close

Closed

Long Intake Manifold

Close

Open Actuator

Throttle Valve

Middle Intake Manifold

Actuator

VSV

Open

Open

To Throttle Body

Short Intake Manifold

Throttle Opening ECM

Engine RPM

Vacuum Tank

Fig. 8-25

Intake Manifold Length T852f321/T852f324

Intake Chamber T852f322/T852f325

T852f323/T852f326

ACIS VSV

To Actuator

From Vacuum Tank

Atmosphere

Fig. 8-26

T852f327

8-18 TOYOTA Technical Training

You might also like

- 2AZ-FE Engine ControlDocument347 pages2AZ-FE Engine ControlIsmael Cutipa Lopez100% (6)

- NAS1169Document2 pagesNAS1169Yong-il Kim0% (1)

- 2ZR-FE Engine Control-System DiDocument1 page2ZR-FE Engine Control-System DiEddie Tai100% (1)

- Patrol Y61 2.8 TD Ecu System Operation DiagramDocument9 pagesPatrol Y61 2.8 TD Ecu System Operation Diagramvali_nedelea100% (1)

- Foundation ItalianDocument72 pagesFoundation Italianohmysuperfly_666100% (2)

- Control System in AutomobilesDocument30 pagesControl System in AutomobilesSudhakar Ramasamy100% (1)

- Servicemanual Peugeot Euro 4 PDFDocument16 pagesServicemanual Peugeot Euro 4 PDFsky100% (2)

- Two Can Play That Game - . .Document73 pagesTwo Can Play That Game - . .exeter555100% (3)

- Canopy - Glass ThicknessDocument1 pageCanopy - Glass ThicknessSHANIL051No ratings yet

- SampleSynastry PDFDocument2 pagesSampleSynastry PDFAlcioneNo ratings yet

- DRS PDFDocument460 pagesDRS PDFCao Lan100% (3)

- VVT-i (Variable Valve Timing-Intelligent) System: GS430/300 - NEW FEATURES 41Document5 pagesVVT-i (Variable Valve Timing-Intelligent) System: GS430/300 - NEW FEATURES 41Luqman AzamNo ratings yet

- DTC P0010 Camshaft Position "A" Actuator Circuit (Bank 1)Document1 pageDTC P0010 Camshaft Position "A" Actuator Circuit (Bank 1)Clodoaldo BiassioNo ratings yet

- ETCS-i (Electronic Throttle Control System-Intelligent) : GeneralDocument14 pagesETCS-i (Electronic Throttle Control System-Intelligent) : GeneralSajjad KhaliqNo ratings yet

- Sistema de Control de Acelerador Motor 2ZR-FEDocument12 pagesSistema de Control de Acelerador Motor 2ZR-FESamuel GarzaNo ratings yet

- 14 Electrical Section-N900 Series JMCDocument23 pages14 Electrical Section-N900 Series JMCRusonegro100% (1)

- Dual VVTiDocument19 pagesDual VVTigalih septyanNo ratings yet

- DTC P0010 Camshaft Position "A" Actuator Circuit (Bank 1) : DescriptionDocument10 pagesDTC P0010 Camshaft Position "A" Actuator Circuit (Bank 1) : Descriptionsharon truck trailerNo ratings yet

- Error Code FD50NT ControllerDocument86 pagesError Code FD50NT ControllerDeni Moch IchsanNo ratings yet

- 3grfse 1pdf PDFDocument42 pages3grfse 1pdf PDFzerospace100% (4)

- General: Jengine Control SystemDocument16 pagesGeneral: Jengine Control SystemVictor HenNo ratings yet

- Materia-2006 Engine (1) - 005Document1 pageMateria-2006 Engine (1) - 005Ty ToyNo ratings yet

- Week 3-4 Gasoline Engine Sensors and ActuatorsDocument74 pagesWeek 3-4 Gasoline Engine Sensors and Actuatorsعمر محمد عبدالرحمن عليNo ratings yet

- Yaris 1ar - Fe - Engine - Control PDFDocument36 pagesYaris 1ar - Fe - Engine - Control PDFCristhian CamposNo ratings yet

- VVTIEhDocument5 pagesVVTIEhBilal AmirNo ratings yet

- Engince Control CircuitsDocument12 pagesEngince Control Circuitsferas alkassmNo ratings yet

- Material Curso Rav4 SENATI (001-050)Document50 pagesMaterial Curso Rav4 SENATI (001-050)Edwuar Brando Escobedo ArteagaNo ratings yet

- Sensor CatalogueDocument72 pagesSensor Cataloguefurious man67% (3)

- Common Rail D. - Engine - 2 PDFDocument38 pagesCommon Rail D. - Engine - 2 PDFEdi Susianto100% (1)

- 13 Ecu-BoschDocument22 pages13 Ecu-BoschThiên ThanhNo ratings yet

- Dokumen - Tips - 1gr Fe Engine Control System Es81 Toyota FJ Cruiser Repaires82 1gr Fe Engine PDFDocument2 pagesDokumen - Tips - 1gr Fe Engine Control System Es81 Toyota FJ Cruiser Repaires82 1gr Fe Engine PDFAnh Ngô HoàngNo ratings yet

- Engine Data ListDocument45 pagesEngine Data ListKada Ben youcefNo ratings yet

- Electronic Control System: Click The Volvo-Logo in The Lower Right Corner To Return To This Menu Main MenuDocument26 pagesElectronic Control System: Click The Volvo-Logo in The Lower Right Corner To Return To This Menu Main MenuPower MobileNo ratings yet

- Denso - Ecd IIDocument26 pagesDenso - Ecd IIMohamed Yousif Hamad100% (3)

- Denso - Ecd IIDocument26 pagesDenso - Ecd IIVASEK100% (4)

- PLC Pak Dheka Kajian Desain Retrofit Governor Control System Di PLTU Nii Tanasa Unit 1Document20 pagesPLC Pak Dheka Kajian Desain Retrofit Governor Control System Di PLTU Nii Tanasa Unit 1Yassar atha100% (1)

- 10 Emission ControlDocument13 pages10 Emission Controldmitry esaulkovNo ratings yet

- Engine Data ListDocument23 pagesEngine Data ListIsaias Daniel Reyes VelasquezNo ratings yet

- Single Part Installation PositionDocument4 pagesSingle Part Installation PositionAbe Rezal AbeNo ratings yet

- DTC P0010 Camshaft Position "A" Actuator Circuit (Bank 1)Document6 pagesDTC P0010 Camshaft Position "A" Actuator Circuit (Bank 1)jeremih alhegnNo ratings yet

- SH450HD 3BDocument28 pagesSH450HD 3BsuriantoNo ratings yet

- Camshaft Position A ActuatorDocument6 pagesCamshaft Position A ActuatorDannyDDannyDNo ratings yet

- VVT-i (Variable Valve Timing-Intelligent) System: GeneralDocument4 pagesVVT-i (Variable Valve Timing-Intelligent) System: GeneralLuqman AzamNo ratings yet

- Combination Meter 1. GeneralDocument12 pagesCombination Meter 1. GeneralRoma KuzmychNo ratings yet

- D20Dtf Engine InformationDocument16 pagesD20Dtf Engine InformationFrancisco Alejandro TelloNo ratings yet

- Hybrid Regenerative Braking Systems PDFDocument97 pagesHybrid Regenerative Braking Systems PDFCRISTIANO PRUSCHNo ratings yet

- Block Diagram of Feedback Control System For Robotic ArmDocument3 pagesBlock Diagram of Feedback Control System For Robotic ArmMohammad SubhanNo ratings yet

- 20 RT-flex MechanicalDocument43 pages20 RT-flex MechanicalGannavarapu KrishnaNo ratings yet

- DTC P0045/34 Turbo/Super Charger Boost Control Solenoid Circuit / OpenDocument4 pagesDTC P0045/34 Turbo/Super Charger Boost Control Solenoid Circuit / OpenYani Yani0% (1)

- 5 Examples of Process ControlDocument3 pages5 Examples of Process ControlMohammad SubhanNo ratings yet

- Engine Control SystemDocument12 pagesEngine Control SystemPopescu IonNo ratings yet

- WML 201Document42 pagesWML 201Mayk OzNo ratings yet

- 0 - Various Information-AbbrevationsDocument2 pages0 - Various Information-AbbrevationsioanNo ratings yet

- ForewordDocument9 pagesForewordLchJmesNo ratings yet

- Nissan Diagnostico de Iacv y AacvDocument7 pagesNissan Diagnostico de Iacv y AacvJose Luis Velasquez RomeroNo ratings yet

- Extended Warranty 1000+ Covered ComponentsDocument3 pagesExtended Warranty 1000+ Covered ComponentsPuneet BajpaiNo ratings yet

- OcvDocument4 pagesOcvIsmail SetiawanNo ratings yet

- Engine Data Display Table: Parameter Unit ValueDocument45 pagesEngine Data Display Table: Parameter Unit ValuedavidNo ratings yet

- ControllerDocument66 pagesControllercristian faundesNo ratings yet

- 4M4 Gr13E PDFDocument36 pages4M4 Gr13E PDFcristian garciaNo ratings yet

- System Injection MIRAGEDocument22 pagesSystem Injection MIRAGEAzinaro OttoNo ratings yet

- 330d Service TrainingDocument38 pages330d Service Trainingtmeany196% (52)

- Digital Power Electronics and ApplicationsFrom EverandDigital Power Electronics and ApplicationsRating: 3.5 out of 5 stars3.5/5 (3)

- Engine Misfire DiagnosisDocument13 pagesEngine Misfire Diagnosissungjoo75No ratings yet

- Catalytic Converter Diagnosis: Section 8Document13 pagesCatalytic Converter Diagnosis: Section 8sungjoo75No ratings yet

- Technical Reference & Specifications: Diagnostic TesterDocument17 pagesTechnical Reference & Specifications: Diagnostic Testersungjoo75No ratings yet

- On-Board Diagnostic Systems: Section 2Document56 pagesOn-Board Diagnostic Systems: Section 2sungjoo75No ratings yet

- Circuit Inspection: Appendix ADocument14 pagesCircuit Inspection: Appendix Asungjoo75No ratings yet

- Introduction To Engine Control System Processes and Diagnostic ToolsDocument27 pagesIntroduction To Engine Control System Processes and Diagnostic Toolssungjoo75No ratings yet

- O2 and A/F Sensor Diagnosis: Section 7Document44 pagesO2 and A/F Sensor Diagnosis: Section 7sungjoo75No ratings yet

- Addition PDFDocument3 pagesAddition PDFsungjoo75No ratings yet

- EVAP Canister Component Locations: Late Type EVAP ComponentsDocument10 pagesEVAP Canister Component Locations: Late Type EVAP Componentssungjoo75No ratings yet

- Idle Air Control Systems: Section 6Document20 pagesIdle Air Control Systems: Section 6sungjoo75No ratings yet

- Evaporative Systems Diagnosis: Section 5Document40 pagesEvaporative Systems Diagnosis: Section 5sungjoo75No ratings yet

- Turbocharging & Supercharging Systems: Section 9Document26 pagesTurbocharging & Supercharging Systems: Section 9sungjoo75No ratings yet

- Caliper TrainingDocument24 pagesCaliper Trainingsungjoo75No ratings yet

- Air Conditioning System: PrecautionDocument94 pagesAir Conditioning System: Precautionsungjoo75No ratings yet

- Fuel System Diagnosis: Section 6Document7 pagesFuel System Diagnosis: Section 6sungjoo75No ratings yet

- American Wire Gauge 1Document3 pagesAmerican Wire Gauge 1sungjoo75No ratings yet

- Probability Test PDFDocument4 pagesProbability Test PDFSithmi HimashaNo ratings yet

- Bolted Joint AnalysisDocument19 pagesBolted Joint AnalysisSyed MajeedNo ratings yet

- Effects of Rabindra Sangeet On People's MindDocument27 pagesEffects of Rabindra Sangeet On People's MindshovowNo ratings yet

- Gender and Religion Representations in First Cycle Primary School English Language Text Books: A Multicultural PerspectiveDocument23 pagesGender and Religion Representations in First Cycle Primary School English Language Text Books: A Multicultural PerspectiveBoru IfaNo ratings yet

- Research PaperDocument2 pagesResearch Paperapi-208339428No ratings yet

- Awarded Solar Projects (As of 2014 07-31)Document7 pagesAwarded Solar Projects (As of 2014 07-31)midas33No ratings yet

- GTS NX 2019 (v2.1) Release NotesDocument15 pagesGTS NX 2019 (v2.1) Release Notesyin hoe ongNo ratings yet

- Communication & Personality Essay TitlesDocument4 pagesCommunication & Personality Essay TitlesPaulo RobillotiNo ratings yet

- Paper - FinalDocument4 pagesPaper - Finalapi-204058740No ratings yet

- Submitted By: Timothy Domingo Arvin Emata Kaer Mercado Gerald Bengco Mikko BermudoDocument11 pagesSubmitted By: Timothy Domingo Arvin Emata Kaer Mercado Gerald Bengco Mikko BermudoKaren ManaloNo ratings yet

- The Wick: The Magazine of Hartwick College - Summer 2012Document52 pagesThe Wick: The Magazine of Hartwick College - Summer 2012Stephanie BrunettaNo ratings yet

- 04 KahleDocument19 pages04 KahleZagi BanjalucanNo ratings yet

- Madagascar eMBeD DiagnosticDocument46 pagesMadagascar eMBeD DiagnosticLILIAN OTIENONo ratings yet

- MineSight and PythonDocument10 pagesMineSight and PythonRicardo Contreras BNo ratings yet

- IV. Lecture Notes: Social Justice: 2.2 The Hypothetical SocietyDocument17 pagesIV. Lecture Notes: Social Justice: 2.2 The Hypothetical SocietyBoram LeeNo ratings yet

- Golden Software Grapher v13.x - User's Guide (Grapher13FullGuide-eBook)Document941 pagesGolden Software Grapher v13.x - User's Guide (Grapher13FullGuide-eBook)Pepiño100% (1)

- 3795-210-S10-E99-0002-Rev.3 PLC Io Mapping List Including Time Synchronize SDocument7 pages3795-210-S10-E99-0002-Rev.3 PLC Io Mapping List Including Time Synchronize SFomaa ElsayedNo ratings yet

- Reading in The Philippine History NotesDocument3 pagesReading in The Philippine History NotesAngilyn LumabasNo ratings yet

- Unified Problem Solving - KAIZEN: Select Current Week Below WK 22 WK 23 WK 24 WK 25Document21 pagesUnified Problem Solving - KAIZEN: Select Current Week Below WK 22 WK 23 WK 24 WK 25Binde PonleNo ratings yet

- Operations Manual: IM30AE Non-Directional Overcurrent RelayDocument16 pagesOperations Manual: IM30AE Non-Directional Overcurrent RelaycrcruzpNo ratings yet

- Video Conferencing Room Solutions VA200 Series: Key FeaturesDocument3 pagesVideo Conferencing Room Solutions VA200 Series: Key FeaturesRo JackNo ratings yet

- Direct Current Circuits (QB)Document48 pagesDirect Current Circuits (QB)Mohammed Aftab AhmedNo ratings yet

- GGU RETAIN - Man e PDFDocument146 pagesGGU RETAIN - Man e PDFRyszard TęczaNo ratings yet

- Kaempferia Rotunda VNDocument3 pagesKaempferia Rotunda VNVietHoangNo ratings yet