Professional Documents

Culture Documents

Job Follow Up System: Organizational Unit: Forum

Uploaded by

Shahid Razzaq0 ratings0% found this document useful (0 votes)

33 views32 pages1. The document is an overdue actions report from an inspection job follow up system listing 17 actions and recommendations related to inspections of pipelines and equipment that are in progress with target completion dates ranging from 2011 to 2020.

2. Many of the actions involve planned inspections, preparation of job requests to replace anodes or pipelines, or coating and repair work on pipelines to address corrosion or thickness loss issues.

3. Several of the actions have been in progress for many years with completion percentages of 0% indicating they have remained overdue.

Original Description:

Original Title

Group Wise JFS

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. The document is an overdue actions report from an inspection job follow up system listing 17 actions and recommendations related to inspections of pipelines and equipment that are in progress with target completion dates ranging from 2011 to 2020.

2. Many of the actions involve planned inspections, preparation of job requests to replace anodes or pipelines, or coating and repair work on pipelines to address corrosion or thickness loss issues.

3. Several of the actions have been in progress for many years with completion percentages of 0% indicating they have remained overdue.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

33 views32 pagesJob Follow Up System: Organizational Unit: Forum

Uploaded by

Shahid Razzaq1. The document is an overdue actions report from an inspection job follow up system listing 17 actions and recommendations related to inspections of pipelines and equipment that are in progress with target completion dates ranging from 2011 to 2020.

2. Many of the actions involve planned inspections, preparation of job requests to replace anodes or pipelines, or coating and repair work on pipelines to address corrosion or thickness loss issues.

3. Several of the actions have been in progress for many years with completion percentages of 0% indicating they have remained overdue.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 32

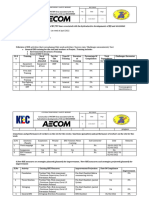

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

1 Scope for repair of main header to be Job will be executed once handed over to Medium 02-04-2012 - 07-06-2012 - 02- In Progress

0%

finalized after inspection of main header. Inspection. Reminder sent to DM-Urea on 01-2020

20.10.14.

2 CTP # 7. Connection to be checked and Job will be executed once handed over to Medium 31-07-2012 - 30-11-2012 - 30- In Progress

0%

repaired. Inspection 12-2019

3 Anodes 120, 123, 133 and 143 to be JR to be prepared Medium 31-01-2013 - 31-03-2013 - 31- In Progress

0%

planned for replacement (identified as 12-2019

irreparable).

4 As anodes connected with AJB 10/1 are JR to be prepared Medium 31-01-2013 - 31-03-2013 - 31- In Progress

0%

inaccessible and no repair work can be 12-2019

performed, plan the replacement of these

Anodes with new ones

5 1.This internal inspection was carried out on Internal inspection of S-502 is planned in Feb Medium 06-03-2012 - 06-03-2017 - 31- In Progress

70%

M/s Force recommendations (4-5 years). - 2019. Observations related to SCC will be 12-2019

Next internal inspection shall be carried out taken in the same opportunity.

after 5-6 years interval to confirm that SCC

mitigation actions taken this year have

yielded desired results i.e. no significant SCC

is detected in the next inspection.

6 2.Non-intrusive inspection such as acoustic Internal inspection of S-502 is planned in Feb Medium 06-03-2012 - 06-03-2017 - 31- In Progress

70%

emission can be considered after next - 2019. In case no significant SCC or other 12-2019

internal inspection. That too in case no corrosion is detected in the planned

significant SCC or other corrosion is inspection, further techniques will be

detected in the next inspection. As non engaged.

intrusive inspection methods applied from

outside the sphere are not yet been widely

used by the industry because they are less

sensitive than MT.

7 02 Anodes identified as irreparable (Anode JR to be prepared Medium 31-01-2013 - 31-03-2013 - 31- In Progress

0%

# 171 and 78) to be planned for 12-2019

replacement

Production Server Data Page 1 of 32 RPT-JFS-005

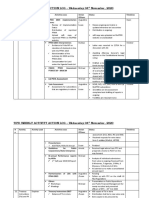

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

8 Inspection of pipelines to be carried out on Medium 27-07-2011 - 31-03-2015 - 31- In Progress

0%

damaged locations against any thickness 12-2019

loss,corrosion etc.

9 Re-coating / wrapping to be carried out at Medium 03-08-2011 - 31-03-2015 - 31- In Progress

0%

above locations after removal of old 12-2019

coating &proper surface preparation.

10 Holiday detection test to be done after Medium 03-08-2011 - 31-03-2015 - 31- In Progress

0%

coating and before back filling/surface 12-2019

restoration.

11 Reinforcement of line portion with reduced Medium 03-08-2011 - 31-03-2015 - 31- In Progress

0%

thickness (if any) to be carried out followed 12-2019

byDPT.

12 Insulation at marked locations to be Medium 27-07-2011 - 31-03-2015 - 31- In Progress

0%

removed for inspection of metallic pipeline 12-2019

underside.

13 Thickness to be monitored at above Medium 03-08-2011 - 31-03-2015 - 31- In Progress

0%

locations after removal of coating. 12-2019

14 Re-coating / wrapping to be carried out at Medium 03-08-2011 - 31-03-2015 - 31- In Progress

0%

above locations after removal of old 12-2019

coating &proper surface preparation.

15 Thickness to be monitored at above Medium 03-08-2011 - 31-03-2015 - 31- In Progress

0%

locations after removal of coating. 12-2019

16 Holiday detection test to be done after Medium 03-08-2011 - 31-03-2015 - 31- In Progress

0%

coating and before back filling/surface 12-2019

restoration.

17 Reinforcement of line portion with reduced Medium 03-08-2011 - 31-03-2015 - 31- In Progress

0%

thickness (if any) to be carried out followed 12-2019

byDPT.

18 Prior to any paint job, inspection is required Medium 26-09-2011 - 31-03-2015 - 31- In Progress

0%

for the surface preparation. 12-2019

Production Server Data Page 2 of 32 RPT-JFS-005

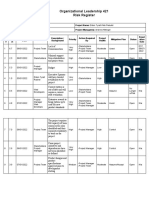

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

19 Insulation of the NPS 4" LS pipeline to Medium 22-12-2011 - 01-04-2015 - 31- In Progress

0%

removed so that the soundbase metal is 12-2019

exposed. In order to restore the pipeline to

its intendedoperating condition, the sleeve

to be installed by welding on soundbase

metal after thickness monitoring.

20 Power brush cleaning of Channel head and Medium 15-02-2012 - 01-04-2015 - 31- In Progress

0%

cover. Epoxy painting tobe carried out after 12-2019

cleaning for corrosion protection.

21 Reactor to be inspected in next available Medium 17-08-2012 - 01-04-2015 - 31- In Progress

0%

opportunity. 12-2019

22 Replacement of Anodes (160, 162) with new Medium 12-07-2013 - 02-04-2015 - 31- In Progress

0%

ones to be carried out. 12-2019

23 Holiday detection test to be done after Medium 08-03-2011 - 31-03-2015 - 31- In Progress

0%

coating and before back filling/surface 12-2019

restoration.

24 Repair of partition plate to be carried out. Medium 15-02-2012 - 01-04-2015 - 31- In Progress

0%

12-2019

25 All fittings were found above retiring Medium 06-03-2012 - 01-04-2015 - 31- In Progress

0%

thickness. Fittings with thickness below 12-2019

nominal are to be kept under observation.

26 Vessel to be inspected after a service life of Medium 01-02-2012 - 01-04-2015 - 31- In Progress

0%

05 years. 12-2019

27 Vessel to be inspected after a service life of Medium 01-02-2013 - 01-04-2015 - 31- In Progress

0%

05 years. 12-2019

28 Remaining recommendations of 1st Medium 07-03-2013 - 01-04-2015 - 31- In Progress

0%

inspection report to be carried out. 12-2019

29 Eddy Current testing to be performed in Medium 31-03-2013 - 01-04-2015 - 31- In Progress

0%

next turnaround. 12-2019

Production Server Data Page 3 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

30 01 Anodes identified as irreparable (Anode Medium 12-07-2013 - 02-04-2015 - 31- In Progress

0%

# 171) to be planned forreplacement 12-2019

31 A new shaft from OEM to be procured for Medium 10-10-2013 - 02-04-2015 - 31- In Progress

0%

contingency and checking mechanical 12-2019

properties.

32 Backfill carried out in front of Anode Medium 24-10-2013 - 02-04-2015 - 31- In Progress

0%

junction box. (Obs. #2) 12-2019

33 PSP values at FH # 35, 34 &30 to be kept Medium 24-10-2013 - 02-04-2015 - 31- In Progress

0%

under observation. (Obs. # 1) 12-2019

34 Reinforcement of line portion with reduced Medium 08-03-2011 - 31-03-2015 - 31- In Progress

0%

thickness (if any) to be carried out followed 12-2019

byDPT.

35 PSP values at FH # 35 to be kept under Medium 12-07-2013 - 02-04-2015 - 31- In Progress

0%

observation. (Obs. # 01) 12-2019

36 Anode # 119 (Total 01) to be rectified Medium 24-10-2013 - 02-04-2015 - 31- In Progress

0%

against no current flow. 12-2019

37 Anodes 107,139,120, 123, 133 and 143 to be Medium 24-10-2013 - 02-04-2015 - 31- In Progress

0%

planned for replacement (identified as 12-2019

irreparable).

38 Furnace tubes to be checked thru peep Medium 25-03-2013 - 02-04-2015 - 31- In Progress

0%

holes during the next startup opportunity. 12-2019

Any red hot bank will be an evidence of

blockage.

39 UT, Thickness measurement and hardness at Medium 25-03-2013 - 02-04-2015 - 31- In Progress

0%

the most sagged portions of the tube to be 12-2019

performed in the 5th tube bank in the

upcoming emergency shutdown.

40 FH # 28 Grounding to be checked and Medium 24-10-2013 - 02-04-2015 - 31- In Progress

0%

rectification to be carried out properly 12-2019

Production Server Data Page 4 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

41 Anode # 184 to be checked against Medium 24-10-2013 - 02-04-2015 - 31- In Progress

0%

probable cable connection damage and 12-2019

fault to be rectified.

42 Re-coating / wrapping to be carried out at Medium 08-03-2011 - 31-03-2015 - 31- In Progress

0%

above locations after removal of old 12-2019

coating &proper surface preparation.

43 Based on the corrosion rate to avoid any Medium 02-02-2011 - 29-01-2016 - 31- In Progress

0%

potential leakage, above mentioned fittings 12-2019

are recommended to be replaced.

44 Audit of damaged insulation of carbon steel Medium 22-12-2011 - 01-04-2015 - 31- In Progress

0%

& low alloy piping(Temperature range -12 to 12-2019

175 deg C) and piping under

intermittentservice to be carried out. On

basis of audit following procedure will

beadopted for the damaged insulation

piping:a. Insulation removal and cleaning of

pipeline.b. Inspection of pipeline and

thickness monitoring, if applicable.c. Repair

/ maintenance of pipeline, if required.d. Re-

insulation of pipeline.

45 In order to investigate and mitigate the Medium 04-01-2012 - 01-04-2015 - 31- In Progress

0%

threat of CUI onDe-aerator (V-603), removal 12-2019

of 30% of complete insulationof De-aerator

to be carried out including

damagedinsulation area. Visual inspection

and thicknessmonitoring to be carried out

on the cleaned area afterinsulation

removal.

46 Replacement / repair maintenance of Medium 27-02-2012 - 01-04-2015 - 31- In Progress

0%

fittings (08 ea) mentioned above on priority. 12-2019

Selected fittings to be monitored again next

year.

Production Server Data Page 5 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

47 Selected fittings to be monitored again next Medium 06-03-2012 - 01-04-2015 - 31- In Progress

0%

year. 12-2019

48 Excavation as per indications of DCVG Medium 20-12-2012 - 01-04-2015 - 31- In Progress

0%

survey (Jan, 2009) to be carriedout. 12-2019

49 Repair of above mentioned locations to be Medium 04-10-2012 - 01-04-2015 - 31- In Progress

0%

carried out. The line to be inspectedby 12-2019

inspection after the insulation is removed.

50 Cracks in acid injection lines to be removed Medium 07-03-2013 - 01-04-2015 - 31- In Progress

0%

by grinding / welding followed byDPT. 12-2019

51 Vibration Analysis of E-302 A to be Medium 31-03-2013 - 01-04-2015 - 31- In Progress

0%

performed for presence of any flow 12-2019

induced vibrations. If flow induced

vibrations were observed then eddy current

testing to be performed in the exchanger

tubes in next turnaround.

52 Thickness to be monitored at above Medium 08-03-2011 - 31-03-2015 - 31- In Progress

0%

locations after removal of coating. 12-2019

53 The decision for the repair/ replacement of Medium 26-09-2011 - 31-03-2015 - 31- In Progress

0%

any part will be taken after the cleaning & 12-2019

inspection.

54 Remaining coating defects indicated in Medium 23-01-2012 - 01-04-2015 - 31- In Progress

0%

DCVG survey to beinvestigated and 12-2019

repaired if required.

55 The Benfield circuit to be monitored again Medium 01-01-1900 - 01-04-2015 - 31- In Progress

0%

this year. 12-2019

56 Selected fittings to be monitored again this Medium 01-01-1900 - 01-04-2015 - 31- In Progress

0%

year. 12-2019

57 Sand filters to be inspected maximum at an Medium 24-12-2012 - 01-04-2015 - 31- In Progress

0%

interval of 02 years. 12-2019

Production Server Data Page 6 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

58 DPT of cracks at partition plate to be Medium 31-03-2013 - 01-04-2015 - 31- In Progress

0%

performed in next available opportunity. 12-2019

59 Boiler to be inspected in next available Medium 31-03-2013 - 01-04-2015 - 31- In Progress

0%

opportunity. 12-2019

60 Anode # 11 and 19 (Total 02 each) to be Medium 12-07-2013 - 02-04-2015 - 31- In Progress

0%

checked against probable 12-2019

cableconnection damage and fault to be

rectified.

61 19 Anodes (71, 76, 54, 34, 35, 36, 37, 29, 31, Medium 12-07-2013 - 02-04-2015 - 31- In Progress

0%

33, 18, 2, 23 6, 9, 11, 11Aand 11B) as 12-2019

identified in observation # 2 to be rectified

against nocurrent flow.

62 Low PSP value in Observation 2 to be kept Medium 12-07-2013 - 02-04-2015 - 31- In Progress

0%

under observation 12-2019

63 Inspection of scrapper will be carried out Medium 26-09-2011 - 31-03-2015 - 31- In Progress

0%

after proper cleaning and removal of 12-2019

deposits (corrosion/paint & Urea).

Operations, to ensure timely inspection after

cleaning of every part.

64 Long Range Ultrasonic Testing (LRUT) of HDD Medium 23-01-2012 - 01-04-2015 - 31- In Progress

0%

section will be carriedout to gather the 12-2019

baseline data after one year of service. Test

to berepeated after a period of 02 years to

carry out trending and effect ofmoisture

accumulation on pipeline.

65 To gather baseline data for future Medium 23-01-2012 - 01-04-2015 - 31- In Progress

0%

reference, LRUT of the selectedportions on 12-2019

NG line is planned in 2012.

66 The Benfield circuit to be monitored again Medium 01-01-1900 - 01-04-2015 - 31- In Progress

0%

this year. 12-2019

Production Server Data Page 7 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

67 Long Range Ultra Sonic Inspection (LRUT) of Medium 08-09-2011 - 31-03-2015 - 31- In Progress

0%

the selected portions ofthe line to be 12-2019

carried out in order to assess threat of

internalcorrosion.

68 Scope for repair, if any, and frequency of Medium 04-11-2012 - 01-04-2015 - 31- In Progress

0%

inspection will be finalized after inspection. 12-2019

69 Selected thickness monitoring to be done Medium 24-05-2012 - 01-04-2015 - 31- In Progress

0%

after 2 years of service. 12-2019

70 During the past few turnarounds, the Medium 31-03-2013 - 01-04-2015 - 31- In Progress

0%

refractory had been repeatedly found 12-2019

dislodged at overhead locations and trend

seems to be rising e.g., refractory directly

above E-201 coil was replaced in TA-2011

due to occurrence of large hot spots

(above 5000C). In view of this, following

actions are recommended;a.

Thermography of the overhead refractory

locations to be performed (already

planned in June & Dec 2013).b. Refractory

repairs of overhead areas to be planned

accordingly in TA-2014.

71 Bulging measurements to be performed in Medium 25-03-2013 - 02-04-2015 - 31- In Progress

0%

TA-2014 for trending. 12-2019

72 01 most sagged tube to be removed for Medium 25-03-2013 - 02-04-2015 - 31- In Progress

0%

micro structural evaluation in TA-2014. 12-2019

Production Server Data Page 8 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

73 Re-coating/wrapping to be carried out at Medium 23-09-2013 - 02-04-2015 - 31- In Progress

0%

above locations with following steps:a. 12-2019

Removal of old coating & proper surface

preparation (Careful power brush cleaning)

and thickness monitoring.b. Reinforcement

of line portion with reduced thickness (if

any) to be carried out followed by DPT.c.

Holiday detection test to be done after

coating and before back filling/surface

restoration.

74 Urea solution recovery tank to be inspected Medium 01-01-1900 - 30-06-2016 - 01- In Progress

0%

during next turnaround 01-2020

75 Shell to be pulled for inspection of tube Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

bundle in next turnaround. 01-2020

76 Ammonia Knock out drum to be inspected Medium 02-09-2015 - 30-06-2016 - 01- In Progress

0%

after 5 years. 01-2020

77 Steam drum of auxiliary boiler to be Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

inspected in next turnaround. 01-2020

78 Combustion chamber of B-602 to be Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

inspected during next turnaround. 01-2020

79 Column to be inspected in next TA. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

80 Bent weir plate as per observation no. 5 to Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

be kept under observation during next 01-2020

inspection.

81 Vessel to be inspected in next TA. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

Production Server Data Page 9 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

82 Cleaning and painting of test posts to be Only excavation of Test post # 7 is pending Medium 13-04-2015 - 31-03-2016 - 01- In Progress

80%

carried out against external corrosion. Test due to high water table and same will be 01-2020

posts locks to be repaired. Additionally, executed by March 2016.

excavation of the test post no. 7 to be

carried out to verify the connection.

83 PSP values at FH # 35 to be restored to Medium 30-04-2015 - 30-10-2015 - 01- In Progress

0%

recommended limits. (Obs. #1) 01-2020

84 Malfunctioning anode # 05, 07 of east side Medium 14-02-2015 - 01-06-2015 - 01- In Progress

0%

ground bed and Anode # 03, 05 of west 01-2020

side ground bed to be repaired.

85 Low PSP value at V-602 Near opt cabin to Medium 11-02-2015 - 01-06-2015 - 01- In Progress

0%

be kept under observation (as per Obs. 01-2020

#01)

86 De-aerator to be inspected during next Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

turnaround. 01-2020

87 Top dish head blind nozzles to be opened Medium 06-03-2013 - 02-04-2015 - 31- In Progress

0%

and offered for inspection. 12-2019

88 Steps for reducing leakage rate (observed Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

during water fill test) to be finalized. 01-2020

Correspondence is already underway with

SAIPEM for the probable use of thicker hold

downgrid plate (around 20-25mm) in order

to exert more down-force onto the ferrules

for propersealing/ elimination of solution

bypassing.

89 Excavation to be carried out at FH # 15 and Medium 12-04-2014 - 02-04-2015 - 31- In Progress

0%

condition of coating / wrapping to be 12-2019

checked. (Ref Obs. # 1)

90 Grounding of FH¿s # 30, 31, 33, 34, 35, 76 to Medium 11-02-2015 - 01-06-2015 - 01- In Progress

0%

be removed by providing coat wrap on the 01-2020

fault locations.

Production Server Data Page 10 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

91 Urea distillation tower to be inspected in Medium 09-02-2015 - 31-10-2017 - 01- In Progress

0%

next turnaround opportunity. 01-2020

92 3rd & 4th Beds to be inspected in next T/A. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

93 UT Inspection of all tube to tubesheet welds Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

to be planned for next turnaround. 01-2020

94 Grounding of FH¿s # 60, 62 to be removed Medium 02-05-2015 - 02-11-2015 - 01- In Progress

0%

by providing coat wrap on the fault 01-2020

locations.

95 Thickness monitoring of HP Loop circuit to Medium 11-06-2014 - 02-04-2015 - 31- In Progress

0%

be performed in two years on-stream to 12-2019

monitor against any aggravation in

thickness reduction.

96 Vessel to be inspected in next Turnaround. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

97 Exchanger to be inspected and repairs to Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

be performed in next available opportunity. 01-2020

98 Vessel to be inspected in next Turnaround. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

99 Anodes # 03,11, 19 (Total 03) to be rectified Medium 30-04-2015 - 30-10-2015 - 01- In Progress

0%

against nil current flow. (Obs. #2) 01-2020

100 Ampere meter to be rectified at TR #01 (Ref: Medium 02-05-2015 - 02-11-2015 - 01- In Progress

0%

Obs. #04) 01-2020

101 Full length Eddy Current Testing of tubes in Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

outer periphery to be planned for next 01-2020

turnaround.Tubes with defects of 40% or

more to be plugged.

102 Flue gas duct of auxiliary boiler to be Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

inspected in next Turnaround. 01-2020

Production Server Data Page 11 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

103 Internal Inspection and repair of hot spot Medium 02-09-2014 - 02-04-2015 - 31- In Progress

0%

locations indicated in thermography report. 12-2019

104 V-401 to be inspected during the next Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

turnaround. 01-2020

105 Survey to be repeated after 3 years Medium 13-04-2015 - 01-10-2015 - 01- In Progress

0%

frequency. 01-2020

106 Replica metallography of 1st row non- Medium 16-07-2014 - 01-06-2015 - 31- In Progress

0%

leaking tubes (to be performed after coil 12-2019

removal).

107 Following reliability work of urea reactor is Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

short listed. However, the actual priority of 01-2020

jobscope to be finalized prior to next

inspection / maintenance opportunity.a.

Rehabilitation of welds of 1994 relined

segment.b. Replacement of Support ribs

with new approved design. The priority is to

remove thesesupports from 1992 & 1994

relined segments.c. Replacement of

interruption strips with circular corner design.

Currently, 1994 relinedsegment and bottom

segments have square shaped interruption

strips.d. Segregation of relined segments of

1994 / 1995. Communication paths of weep

holesto be verified by unit.e. Relining of Shell

course no. 31 & Bottom dome.f.

Replacement / Repair of Ammonia and

Carbon dioxide inlet pipe subject to

condition.

108 Tank to be inspected in next turnaround Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

opportunity. 01-2020

Production Server Data Page 12 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

109 Material availability to be ensured for the Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

replacement of low thickness trays (as 01-2020

found duringprevious inspections). However,

replacement is subject to results of

inspection findings.

110 Probable cable connection damage Medium 12-04-2014 - 02-04-2015 - 31- In Progress

0%

(during new foundations construction) to be 12-2019

checked and fault to be rectified at base of

V-250 K.O Drum.

111 Bulging in 1M nozzle to be kept under Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

observation. 01-2020

112 18 Anodes (71, 76, 54, 34, 35, 36, 37, 29, 31, Medium 24-10-2013 - 02-04-2015 - 31- In Progress

0%

33, 18, 2, 6, 9, 11, 11A and 11B) as identified 12-2019

in observation # 2 to be rectified against no

current flow.

113 Equipment to be inspected in next Turn Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

around opportunity. 01-2020

114 Need of RFT and bundle inspection to be Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

evaluated before next turnaround. 01-2020

115 H-Scan on catalyst tubes to be performed in Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

next turnaround. 01-2020

116 Low PSP value at FH #22, V-1001, SS #6 West Medium 12-04-2014 - 02-04-2015 - 31- In Progress

0%

side planning car parking shed to be kept 12-2019

under observation (as per Obs. #01)

117 PSP values at FH # 15 to be restored to Medium 30-04-2015 - 30-10-2015 - 01- In Progress

0%

recommended limits. (Obs. #1) 01-2020

118 The internal surfaces of the sight glass and Medium 06-03-2013 - 02-04-2015 - 31- In Progress

0%

its seating area to be offered forinspection 12-2019

once the sight glass is removed.

Production Server Data Page 13 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

119 Blow down vent stack to be inspected Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

during next turn around. 01-2020

120 Vessel to be inspected in next TA. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

121 (IR#1127)Rec.#2 Anode # 184 to be Medium 04-05-2016 - 30-11-2017 - 01- In Progress

0%

checked against probable cable 01-2020

connection damage and

122 18 Anodes (172, 71, 76, 54, 34, 35, 36, 37, 29, Medium 12-04-2014 - 02-04-2015 - 31- In Progress

0%

31, 33, 18, 2, 6, 9, 11, 11A and 11B) to be 12-2019

rectified for nil current flow (as per Obs. #02)

123 Bed no. 2 & 3 to be inspected in next Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

turnaround. 01-2020

124 Comprehensive rehabilitation plan needs to Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

be prepared for ensuring vessel integrity 01-2020

prior tonext Turnaround.

125 Repeated corrosion phenomenon at Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

previously repaired areas to be kept under 01-2020

observation.Belzona application to be

considered in next opportunity based upon

Inspection findings.

126 Ammonia Accumulator to be inspected Medium 02-09-2015 - 30-06-2016 - 01- In Progress

0%

after 5 years. 01-2020

127 Anodes #119,121, 126,132 (Total 04) to be Medium 11-02-2015 - 01-06-2015 - 01- In Progress

0%

rectified against nil current flow. 01-2020

128 Replacement of Urea stripper vapor outlet Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

line to be planned in next turnaround. 01-2020

Detailedscope shall be provided by

Inspection.

129 Vessel to be inspected in next turn around. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

Production Server Data Page 14 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

130 Low pressure inert washing tower is to be Medium 09-02-2015 - 31-10-2017 - 01- In Progress

0%

inspected during the next turnaround 01-2020

opportunity.

131 The flash drum is to be inspected after 5 Medium 02-09-2015 - 30-06-2016 - 01- In Progress

0%

years. 01-2020

132 Economizer of auxiliary boiler to be Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

inspected in next Turnaround. 01-2020

133 Tank to be inspected after a service life of Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

seven years. 01-2020

134 Temperature monitoring of the hot spot to Medium 16-04-2015 - 16-07-2015 - 01- In Progress

0%

be performed to check for any 01-2020

aggravation.

135 Locations marked on the isometric may be Medium 02-10-2015 - 31-03-2016 - 01- In Progress

0%

traced after removal of insulation, to 01-2020

pinpoint the exact welds and the repairs

made to address the recurrent leakages

stemming from them. Visual inspection of

these repairs may be carried out for

verification and subsequently tagged on

the external cover of the insulation for ease

of identification at a later stage.

136 Exchanger to be inspected and repairs to Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

be performed in next available opportunity. 01-2020

137 Super heaters are to be inspected during Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

next turnaround. 01-2020

138 Natural gas pre heater to be inspected Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

during the next turnaround. 01-2020

139 Low PSP value at V-602 Near opt cabin to Medium 01-01-1900 - 02-11-2015 - 01- In Progress

0%

be kept under observation (as per Obs. 01-2020

#01)

Production Server Data Page 15 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

140 (IR#1127)Rec.#3 Ammeter to be rectified at Medium 04-05-2016 - 30-11-2017 - 01- In Progress

0%

TR #01. (Ref: Obs. #04) 01-2020

141 Grounding of FH¿s #29, 30, 31, 33, 34, 35 to Medium 12-04-2014 - 02-04-2015 - 31- In Progress

0%

be removed by providing coat wrap on the 12-2019

fault locations.

142 Equipment to be inspected in next Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

turnaround opportunity. 01-2020

143 Ammonia Separator to be inspected after 5 Medium 02-09-2015 - 30-06-2016 - 01- In Progress

0%

years interval. 01-2020

144 Super heater of auxiliary boiler to be Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

inspected in next Turnaround. 01-2020

145 (IR#1127)Rec.#1 PSP values measured Medium 04-05-2016 - 30-11-2017 - 01- In Progress

0%

below the recommended limit are to be 01-2020

restored. (Ref: Obs. # 01)

146 (IR# 1128)Rec.#3 Anodes # (107, 139, 120, Medium 04-05-2016 - 30-11-2017 - 01- In Progress

0%

123, 133 & 143) to be planned for 01-2020

replacement (identified as irreparable).

(Ref: Obs. # 04)

147 Anode identified as irreparable (Anode # Medium 12-04-2014 - 02-04-2015 - 31- In Progress

0%

78 & 171) to be planned for replacement 12-2019

148 Anodes #107, 139, 120, 123, 133 and 143 to Medium 11-02-2015 - 01-06-2015 - 01- In Progress

0%

be replaced (identified as irreparable). 01-2020

149 Backfilling needs carrying out in front of Medium 11-02-2015 - 01-06-2015 - 01- In Progress

0%

Anode junction box. 01-2020

150 Vessel to be inspected in next TA. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

151 Air duct of boiler to be inspected in next Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

Turnaround. 01-2020

Production Server Data Page 16 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

152 MPI of complete shell welds seams and Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

nozzles to be carried out in next inspection. 01-2020

153 Equipment to be inspected in next TA Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

154 The pitted area in the bottom of the vessel Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

to be kept under observation. 01-2020

155 Backfilling needs carrying out in front of Medium 30-04-2015 - 30-10-2015 - 01- In Progress

0%

Anode junction boxes. 01-2020

156 Grounding of FH¿s # 30, 33, 34, 35, 76 to be Medium 30-04-2015 - 30-10-2015 - 01- In Progress

0%

removed by providing coat wrap on the 01-2020

fault locations.

157 As per our past experience on titanium Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

stripper, restoration of damaged tube ends 01-2020

(due tosolution bypassing) by machining in

next turnaround to be looked into.

158 Re-coating / wrapping to be carried out at Medium 21-04-2015 - 29-01-2016 - 01- In Progress

0%

above locations with following steps:a. 01-2020

Excavation around the line of at least 350

mm depth. Removal of old coating, visual

inspection, proper surface preparation

(Careful power brush cleaning) and

thickness monitoring.b. Reinforcement of

line portion with reduced thickness (if any)

to be carried out followed by DPT.c. Holiday

detection test to be done after coating and

before back filling/surface restoration.

159 PSP values at FH # 35 to be restored to Medium 11-02-2015 - 01-06-2015 - 01- In Progress

0%

recommended limits. (Obs. #1) 01-2020

Production Server Data Page 17 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

160 Option of blowing to remove any left-over Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

blockage may be considered in case 01-2020

repetitivesagging will be observed in

replaced tubes.

161 Sagging data to be measured in next Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

available opportunity. 01-2020

162 Interconnecting nozzles to be replaced in Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

next Turnaround owing severe internal 01-2020

thicknessloss.

163 Hardness and Radiographic testing of the Medium 01-01-1900 - 31-03-2016 - 01- In Progress

0%

weld rehabilitated in the chassis plate of the 01-2020

P & H crane # 43944 is to be undertaken in

accordance to its WPS. Arrangements for

undertaking these NDT¿s are also to be

made.

164 Reduce the load of T/R in 18 area as per Medium 14-02-2015 - 01-06-2015 - 01- In Progress

0%

external audit report. Inspection will re- 01-2020

check PSP of all test posts after the activity.

165 Cracks visible in painting, requires cleaning Medium 01-10-2012 - 02-04-2015 - 31- In Progress

0%

and re-inspection. (Ref. obs #15) 12-2019

166 Blow down vent stack to be inspected Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

during next turnaround. 01-2020

167 Urea waste water tank to be inspected Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

during the next turnaround. 01-2020

168 Vessel to be inspected in next TA. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

169 Air duct of auxiliary boiler to be inspected in Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

next Turnaround. 01-2020

170 Anodes #119,121, 126,132 (Total 04) to be Medium 30-04-2015 - 30-10-2015 - 01- In Progress

0%

rectified against nil current flow. 01-2020

Production Server Data Page 18 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

171 (IR#1118) 6.Thickness of epoxy paint is to be Medium 03-11-2016 - 31-03-2017 - 01- In Progress

0%

measured. It should equal 300 microns in 01-2020

total

172 Sand filters to be inspected maximum at an Medium 22-04-2014 - 02-04-2015 - 31- In Progress

0%

interval of 03 years. 12-2019

173 Grounding of FH¿s # 4, 7, and 3 to be Medium 11-02-2015 - 01-06-2015 - 01- In Progress

0%

removed by providing coat wrap on the 01-2020

fault locations.

174 Anodes # 11, 14, 17, 19 (Total 04) to be Medium 11-02-2015 - 01-06-2015 - 01- In Progress

0%

rectified against nil current flow. (Obs. #2) 01-2020

175 Distributor tray of 1MF manway to be Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

replaced in next T/A. 01-2020

176 Option of tubes' life assessment to be Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

evaluated before next turnaround. 01-2020

177 Steam drum of the boiler is to be inspected Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

during next turnaround. 01-2020

178 Cracks # 01 and # 02 in the ring bearing Medium 01-01-1900 - 31-03-2016 - 01- In Progress

0%

(turn table) of crane # 43943 are pending 01-2020

removal and repair. Arrangements for the

accessibility to and inspection of the

bearings¿ inner race may also be

considered to ensure the reliability of such a

vital component.

179 (IR#1121) 2. Thickness monitoring of Medium 15-04-2016 - 31-12-2017 - 01- In Progress

0%

complete circuit to be carried out in 2017. 01-2020

180 Anodes #119, 126 (Total 02) to be rectified Medium 12-04-2014 - 02-04-2015 - 31- In Progress

0%

against nil current flow. 12-2019

181 Tank to be inspected in next turnaround Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

opportunity. 01-2020

Production Server Data Page 19 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

182 Vessel to be inspected in next turnaround. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

183 Vessel to be inspected in next TA. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

184 All locations to be excavated for inspection Medium 13-04-2015 - 31-03-2016 - 01- In Progress

0%

/ repair of external coating. Defects in Mari 01-2020

gas battery limit to be prioritized.

185 (IR# 1128)Rec.#2 Anodes # (107, 119, 120, Medium 04-05-2016 - 30-11-2017 - 01- In Progress

0%

121, 123, 126, 128, 132, 133, 139, 142, 143) to 01-2020

be rectified against nil current flow. (Ref:

Obs. # 02)

186 Anode # 184 to be checked against Medium 12-04-2014 - 02-04-2015 - 31- In Progress

0%

probable cable connection damage and 12-2019

fault to be rectified (Ref: Obs. #02

187 Malfunctioning anode #03, 05, 07 of ground Medium 15-04-2014 - 02-04-2015 - 31- In Progress

0%

bed to be repaired. 12-2019

188 Blow down vent stack to be inspected Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

during next turnaround. 01-2020

189 MPD to be inspected in next turnaround. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

190 Equipment to be inspected in next TA. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

191 Exchanger to be inspected and repairs to Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

be performed in next available opportunity. 01-2020

192 Startup furnace to be inspected in next Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

available opportunity. 01-2020

193 De-super heater of auxiliary boiler to be Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

inspected in next Turnaround. 01-2020

Production Server Data Page 20 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

194 Anodes #107, 139, 120, 123, 133 and 143 to Medium 12-04-2014 - 02-04-2015 - 31- In Progress

0%

be replaced (identified as irreparable). 12-2019

195 Equipment to be inspected in next Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

Turnaround Opportunity. 01-2020

196 De-super heater to be inspected in next Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

turnaround. 01-2020

197 Complete Eddy Current Testing of Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

exchanger to be planned for next 01-2020

turnaround.

198 Tubes external indentation due to baffle Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

hammering and striking of sharp corners of 01-2020

stiffenersto be kept under observation.

Additionally, soft material (Aluminum and

Teflon) to bearranged for inserting stiffeners

in next turnaround opportunity.

199 Exchanger to be inspected in next Turn Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

around opportunity. 01-2020

200 An audit for such observations to be carried Medium 24-07-2015 - 24-01-2016 - 01- In Progress

0%

out on similar piping near PD pumps. 01-2020

201 Anode # 160 /162 to be replaced. (Ref: Medium 12-04-2014 - 02-04-2015 - 31- In Progress

0%

Obs. #02) 12-2019

202 PSP values at FH # 35 to be restored to Medium 12-04-2014 - 02-04-2015 - 31- In Progress

0%

recommended limits. (Obs. #1) 12-2019

203 Anode identified as irreparable (Anode # Medium 11-02-2015 - 01-06-2015 - 01- In Progress

0%

78 & 171) to be planned for replacement 01-2020

204 Ammonia let down vessel to be inspected Medium 02-09-2015 - 30-06-2016 - 01- In Progress

0%

after 5 years. 01-2020

Production Server Data Page 21 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

205 SAIPEM has suggested the use of liquid Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

Teflon in conjunction with Teflon gaskets at 01-2020

all thetube-ferrule interfaces during the next

available opportunity. This option /

recommendation isto be evaluated with

regards to the suitable method of liquid

Teflon application, itseffectiveness, type of

product to be used and the curing time

involved etc.

206 RT of mid height joints of all bulged tubes to Medium 03-03-2014 - 02-04-2015 - 31- In Progress

0%

be performed in upcoming Turnaround for 12-2019

integrity assessment of the welds.

207 Equipment to be inspected in next Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

Turnaround opportunity. 01-2020

208 ECT of tube bundle to be repeated in next Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

turnaround. 01-2020

209 Grounding of FH¿s # 60, 62 to be removed Medium 11-02-2015 - 01-06-2015 - 01- In Progress

0%

by providing coat wrap on the fault 01-2020

locations

210 07 Anodes (78, 65, 54, 29, 31, 33, 18) to be Medium 11-02-2015 - 01-06-2015 - 01- In Progress

0%

rectified for nil current flow (as per Obs. #02) 01-2020

211 Random thickness of shell and nozzles to be Medium 06-03-2013 - 02-04-2015 - 31- In Progress

0%

carried out 12-2019

212 Inlet nozzle and shell area near Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

impingement plate to be kept under 01-2020

observation.

213 Vessel to be inspected during next turn Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

around. 01-2020

214 Vessel to be inspected in next Turnaround. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

Production Server Data Page 22 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

215 Anodes #107, 139, 120, 123, 133 and 143 to Medium 30-04-2015 - 30-10-2015 - 01- In Progress

0%

be replaced (identified as irreparable). 01-2020

216 Internal epoxy painting of the shell to be Medium 16-07-2015 - 16-01-2016 - 01- In Progress

0%

carried out after thorough cleaningand 01-2020

repair.

217 Degassifier to be inspected in next TA. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

218 Acid injection lines to be removed and Medium 06-03-2013 - 02-04-2015 - 31- In Progress

0%

offered for inspection. 12-2019

219 Option of blowing to remove any left-over Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

blockage may be considered in case 01-2020

repetitivesagging will be observed in

replaced tubes.

220 E-208A to be inspected in suitable Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

opportunity. 01-2020

221 This vessel is to be inspected after 5 years. Medium 02-09-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

222 (IR#1119) 3. All fittings are to be monitored Medium 11-05-2016 - 31-12-2018 - 01- In Progress

0%

after an interval of 03 years. 01-2020

223 01 Anodes identified as irreparable (Anode Medium 24-10-2013 - 02-04-2015 - 31- In Progress

0%

# 171 and ) to be planned for replacement 12-2019

224 (IR# 1128)Rec.#1 PSP value at FH # 15 to be Medium 04-05-2016 - 30-11-2017 - 01- In Progress

0%

restored to recommended limits. (Ref: Obs. 01-2020

# 01)

225 Vessel to be inspected in next Turn around Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

opportunity. 01-2020

226 Manway sealing surface to be kept under Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

observation. 01-2020

Production Server Data Page 23 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

227 Vessel to be inspected in next turnaround Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

opportunity. 01-2020

228 Vessel to be inspected after 5 years of Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

service. 01-2020

229 Rubber lining of the vessel to be completely Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

rehabilitated after removal of old lining. 01-2020

(Recommendation since TA-2005). Base

metal to be cleaned and inspected before

installationof new lining to check for any

corrosion damage.

230 Carbamate Separator to be inspected in Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

next turnaround. 01-2020

231 Vessel to be inspected in next TA. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

232 Corrosion deposits observed on the metallic Medium 15-12-2015 - 31-12-2016 - 01- In Progress

0%

plates to be cleaned followed by inspection 01-2020

and repainting as per specification.

233 Vessel to be inspected in next TA. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

234 Combustion Chamber of auxiliary boiler to Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

be inspected in next Turnaround. 01-2020

235 Inspection of mixing tee to be carried out in Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

next Turnaround. 01-2020

236 Hardness on weld joint of tube no. 19C & Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

16E to be kept under observation. 01-2020

237 The 05 welds of Section III (P & H Crane # Medium 01-01-1900 - 31-03-2016 - 01- In Progress

0%

43944) which were found to have 01-2020

contained defects like undercuts and

pinholes are to be repaired and

subsequently inspected.

Production Server Data Page 24 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

238 Anode # 160 /162 to be replaced. (Ref: Medium 11-02-2015 - 01-06-2015 - 01- In Progress

0%

Obs. #02) 01-2020

239 Vessel to be inspected in next turnaround. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

240 Vessel to be inspected in next TA. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

241 Low PSP value at FH # 22,T-902, SS6 West Medium 24-10-2013 - 02-04-2015 - 31- In Progress

0%

side planning car parking shed to be kept 12-2019

under observation

242 Economizer to be inspected during the next Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

turnaround. 01-2020

243 When the header is offline, metallography, Medium 02-10-2015 - 31-03-2016 - 01- In Progress

0%

hardness testing and PMI should be 01-2020

performed at its problematic sections to

assist in ascertaining the root cause of these

leakages.

244 Vessel to be inspected in next turnaround. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

245 Supports inside Mari gas battery limited to Medium 13-04-2015 - 31-03-2016 - 01- In Progress

0%

be removed for inspection and repair work 01-2020

against external corrosion. Additionally,

coat wrap at NG line entrance point to be

exposed for inspection.

246 The remaining 03 defected lacings Medium 01-01-1900 - 31-03-2016 - 01- In Progress

0%

comprising the Section II (P & H Crane # 01-2020

43944) are to be replaced and

subsequently tested through VT, MPI (before

load test) and DPT (before and after load

test).

Production Server Data Page 25 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

247 Extensive ongoing thickness monitoring Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

program outside turnaround and 01-2020

radiography of jointsduring turnaround to

be continued.

248 The equipment to be inspected during next Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

turnaround. 01-2020

249 Gas outlet side of Product Gas Cooler to be Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

inspected in next turnaround. 01-2020

250 Flue gas duct of auxiliary boiler to be Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

inspected at next Turnaround. 01-2020

251 Corrosion of the gasket seating surface to Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

be inspected in next Turnaround for 01-2020

anyaggravation.

252 Holiday detection to be performed at the Medium 06-03-2013 - 02-04-2015 - 31- In Progress

0%

bottom portion of vessel after drying ofthe 12-2019

vessel.

253 Auxiliary Super heater to be inspected in Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

next turnaround. 01-2020

254 V-425 to be inspected in the next Medium 02-09-2015 - 30-06-2016 - 01- In Progress

0%

turnaround. 01-2020

255 Vessel to be inspected in next Turnaround. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

256 Anode identified as irreparable (Anode # Medium 01-01-1900 - 02-11-2015 - 01- In Progress

0%

78 & 171) to be planned for replacement 01-2020

257 For ruling out any in-adequacy in gas flow Medium 03-03-2014 - 02-04-2015 - 31- In Progress

0%

pattern, temperature profile of the tube 12-2019

banks at one and three turn valve openings

to be performed at Plant-I start-up furnace.

Production Server Data Page 26 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

258 Inspection/ DPT of drum welds on available Medium 16-07-2014 - 02-04-2015 - 31- In Progress

0%

opportunities till the completion of 12-2019

recommendation # 2 above.

259 PSP values at FH # 62 to be restored to Medium 11-02-2015 - 01-06-2015 - 01- In Progress

0%

recommended limits. (Obs. #1) 01-2020

260 Scope of repair/replacement to be finalized Medium 16-12-2014 - 02-04-2015 - N/A In Progress

0%

after inspection.

261 Exchanger to be inspected and repairs to Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

be performed in next available opportunity. 01-2020

262 ECT of tubes to be repeated in next Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

turnaround. 01-2020

263 All repaired locations on process side and Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

corrosion near seal welds to be kept 01-2020

underobservation.

264 Medium pressure absorber to be inspected Medium 09-02-2015 - 31-10-2017 - 01- In Progress

0%

during next turnaround. 01-2020

265 Primary reformer to be inspected in next Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

turnaround. 01-2020

266 Solution Inlet nozzle (sacrificial) liner to be Medium 09-02-2015 - 31-10-2017 - 01- In Progress

0%

kept available. However, a possible 01-2020

switching ofliner material from titanium to

zirconium to be explored with SAIPEM for

better protectionagainst erosion.

267 Temporary fasteners, nuts, studs, tie-rods Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

etc. of titanium material were generally 01-2020

observed tobe worn-out. Their replacement

(where possible) with the suitable material

to be looked into.

Production Server Data Page 27 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Inspection Action Reporting

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

268 Grounding of FH¿s # 4, 5, 7, and 3 to be Medium 30-04-2015 - 30-10-2015 - 01- In Progress

0%

removed by providing coat wrap on the 01-2020

fault locations.

269 Anode # 184 to be checked against Medium 02-05-2015 - 02-11-2015 - 01- In Progress

0%

probable cable connection damage and 01-2020

fault to be rectified (Ref: Obs. #02)

270 07 Anodes (78, 65,68, 54, 29, 31, 33, 18) to Medium 01-01-1900 - 02-11-2015 - 01- In Progress

0%

be rectified for nil current flow (as per Obs. 01-2020

#02)

271 Backfilling needs carrying out in front of Medium 12-04-2014 - 02-04-2015 - 31- In Progress

0%

Anode junction box. (Obs. #2) 12-2019

272 Anode # 160,184,158 to be checked Medium 11-02-2015 - 01-06-2015 - 01- In Progress

0%

against probable cable connection 01-2020

damage and fault to be rectified (Ref: Obs.

#02)

273 Bulging data to be taken for trend analysis. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

274 Accumulator to be inspected during next Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

turnaround. 01-2020

275 UT Inspection of all tube to tubesheet welds Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

to be planned for next turnaround. 01-2020

276 Evaluation for the possibility of ToFD Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

examination on 2nd circumferential weld 01-2020

seam of Bed no.4 to be carried out prior to

next turnaround.

277 Vessel to be inspected in next TA. Medium 09-02-2015 - 30-06-2016 - 01- In Progress

0%

01-2020

Production Server Data Page 28 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Plant Reliability Task Force

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

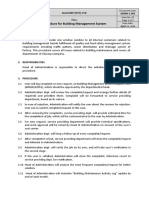

1 For inspection and critical structure repairs Vendors with such expertise related to civil High N/A - N/A - 12-12-2019 In Progress

60%

expertiseshould be identified and hired from structures have been contacted.

market.

2 Provision of sleeves to be done with proper A survey of coat wrap of piping has been High N/A - N/A - 12-12-2019 In Progress

40%

insulation afterdigging the line till healthy carried out. Remedial actions are to follow

portion in all over the plant. now.

3 Develop mechanism to check the CUI in all High N/A - N/A - 29-01-2019 In Progress

0%

critical plantpiping.

4 Piping segments with two phase flow and High N/A - N/A - 29-01-2019 In Progress

0%

high velocities tobe identified and included

in inspection plan.

5 Dead ends (for corrosive services in High N/A - N/A - 29-01-2019 In Progress

0%

particular) andInjection/mixing points to be

identified and included ininspection plan.

6 Piping segments with harsh operating High N/A - N/A - 29-01-2019 In Progress

0%

conditions to beidentified and included in

inspection plan.

7 Audit of paint damage on piping to be High N/A - N/A - 29-01-2019 In Progress

0%

carried out for properrepair

8 Painting of piping to be carried out only High N/A - N/A - 29-01-2019 In Progress

0%

after propersurface cleaning and

inspection of base pipe. Awarenesssession

on this observation to be made part of

trainingmodule.

9 In order to have idea of equipment’s High N/A - N/A - 29-01-2019 In Progress

0%

external condition it isrecommended to

remove insulation of Back End 2nd

chillerCold insulation in TA and carry out

inspection. (Based onobservation further

line of action may be defined)

Production Server Data Page 29 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Plant Reliability Task Force

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

10 External inspection of the vessels to be High N/A - N/A - 29-01-2019 In Progress

0%

included in pressurevessel inspection plan

including inspection of externalcoating /

insulation, piping connections, skirt,

foundation andassociated structure.

11 Inspection of conveyor belts structure to be High N/A - N/A - 29-01-2019 In Progress

0%

included ininspection plan.

12 Structure on corrosive service should be High N/A - N/A - 29-01-2019 In Progress

0%

inspected / auditedfor their reliability and

mechanical integrity as per

definedfrequency may be 10 or 15 years.

13 All davits at the plant to be inspected and High N/A - N/A - 29-01-2019 In Progress

0%

their design to beimproved.

14 Enlist piping which has vibration problems High N/A - N/A - 29-01-2019 In Progress

0%

especiallythose adjacent to reciprocating

machines and their healthto be checked.

15 Review supports with the pad especially on High N/A - N/A - 29-01-2019 In Progress

0%

the lineshaving high vibrations.

16 Fresh review of PMP on the basis of current High N/A - N/A - 29-01-2019 In Progress

0%

observations isrequired to include missing

jobs, update equipmentsreplaces,

frequency based on experience and

actionassigned to correct agency.

17 Material availability status to be update by High N/A - N/A - 29-01-2019 In Progress

0%

P&S on quarterlybasis for reliable planning

of jobs through concerned.

18 Target date should be marked in all High N/A - N/A - 29-01-2019 In Progress

0%

recommendations

Production Server Data Page 30 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Plant Reliability Task Force

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

19 There should be a written closing note to High N/A - N/A - 29-01-2019 In Progress

0%

close assignedaction signed by in-charge of

the executing unit with theconsent of

initiating unit. System similar to SR closing

note tobe followed.

20 The recommended approach is to High N/A - N/A - 29-01-2019 In Progress

0%

conclude reports afterRCA so that actions

are realistic.

21 Actions assigned in reports to be mutually High N/A - N/A - 29-01-2019 In Progress

0%

agreed andreviewed by all concerned.

22 Any action which is against SOP or unusual High N/A - N/A - N/A In Progress

0%

without givingconsideration of

consequential outcome should

beinvestigated and RCA to be done.

Accordingly report to beissued.

23 All units to develop training modules and High N/A - N/A - 29-01-2019 In Progress

0%

separate “on-thejob”and customize training

subjects.

24 Training module should cover all subjects/ High N/A - N/A - 29-01-2019 In Progress

0%

activitiesrelated to functions of a unit.

Practical demonstration/handsontraining of

small job activities to be carried out

atdepartmental level before assigning

independent jobswherever applicable.

25 Shutdown opportunities to be used to train High N/A - N/A - 29-01-2019 In Progress

0%

people on all suchactivities. Include in

training manual of unit’s.

26 Training plans to be developed on the basis High N/A - N/A - 29-01-2019 In Progress

0%

of individualstraining needs and

observations in performance appraisal.

Include in training manua

Production Server Data Page 31 of 32 RPT-JFS-005

Fauji Fertilizer Company Limited Date / Time

Job Follow Up System 06-April-2020 11:51:28AM

OverDue Actions Report

Organizational Unit: Inspection (MM)

Forum: Plant Reliability Task Force

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

27 Level of junior management up to DE may High N/A - N/A - 29-01-2019 In Progress

0%

be fixed to ensurecompletion of five basic

mandatory training programs

beforepromotion to DE level. Same to be

included in trainingmanual.

28 RCA should be made part of basic High N/A - N/A - 29-01-2019 In Progress

0%

mandatory training for allEngineers. Include

this in working procedure of unit’s.

29 Coils bulging assessment to be carried out High N/A - N/A - 29-01-2019 In Progress

0%

for replacement ifrequired. Also its thermal

expansion support to be clean asper TMP

plan.

Forum: Sub SOC (M)

Sr. No Action / Recommendation Detailed Status / Remarks Priority (%) Assign / Target / Update Status

Date

1 Vibration problem of Lube oil Pumps P-309 Very High 12-10-2017 - 31-12-2017 - N/A In Progress

0%

A/B to be studied in detail.

Production Server Data Page 32 of 32 RPT-JFS-005

You might also like

- Testing and Commissioning Procedure For Leak Detection SystemDocument24 pagesTesting and Commissioning Procedure For Leak Detection SystemWinNo ratings yet

- HSE Monthly Report Mei 2020Document19 pagesHSE Monthly Report Mei 2020Rendi SeptiansyahNo ratings yet

- Ppe Training NTTFDocument47 pagesPpe Training NTTFAkshatha M100% (1)

- Revised Establishment Report Form v3 1Document5 pagesRevised Establishment Report Form v3 1Sai GuyoNo ratings yet

- Procedure For Environmental Impacts & AspectsDocument6 pagesProcedure For Environmental Impacts & AspectsMohammed AffrozeNo ratings yet

- Qa Capa Person Grid Capa Details Search PDFDocument11 pagesQa Capa Person Grid Capa Details Search PDFPharmacistNo ratings yet

- Directory Search by Company NameDocument57 pagesDirectory Search by Company NameShahid RazzaqNo ratings yet

- 26-1208-01 Evolution of Silicon-Based Technology in CoatingsDocument10 pages26-1208-01 Evolution of Silicon-Based Technology in Coatingskreci1No ratings yet

- Dep 31.38.01.13-Compilation of Bill of Material For Piping IsometricsDocument12 pagesDep 31.38.01.13-Compilation of Bill of Material For Piping Isometricssudeep9666No ratings yet

- Construction WRM-10 - Safety SlideDocument5 pagesConstruction WRM-10 - Safety SlideRajesh SutharNo ratings yet

- BS 7910Document8 pagesBS 7910Shahid RazzaqNo ratings yet

- Testing and Commissioning of FM200 SystemDocument29 pagesTesting and Commissioning of FM200 SystemWinNo ratings yet

- 2020-06-14 K-4101 BCL Overhaul Job ReportDocument33 pages2020-06-14 K-4101 BCL Overhaul Job ReportShahid RazzaqNo ratings yet

- Oral Case Presentation Benchmarks - : Identifying Information & Chief ConcernDocument9 pagesOral Case Presentation Benchmarks - : Identifying Information & Chief ConcernManisanthosh KumarNo ratings yet

- Three-Quater Face Schematics PDFDocument20 pagesThree-Quater Face Schematics PDFSchiteanu ClaudiuNo ratings yet

- Dep 31.38.01.13-Compilation of Bill of Material For Piping IsometricsDocument12 pagesDep 31.38.01.13-Compilation of Bill of Material For Piping Isometricssudeep9666No ratings yet

- Supervision Procedure: Oml100 (Fso Unity)Document8 pagesSupervision Procedure: Oml100 (Fso Unity)Ezemeh Nigeria100% (1)

- Airbnb 2018 PDFDocument8 pagesAirbnb 2018 PDFyodhisaputraNo ratings yet

- Soalan Biologi Kertas 2 Tingkatan 4Document14 pagesSoalan Biologi Kertas 2 Tingkatan 4azszah100% (17)

- Equipment, Flowline, Instrument Electrical & Structural NumberingDocument22 pagesEquipment, Flowline, Instrument Electrical & Structural NumberingNBTC Tubes & PipesNo ratings yet

- 1st Week Report April 2022Document4 pages1st Week Report April 2022Ramesh PandianNo ratings yet

- XVFC Work Order Monitoring Format NewDocument2 pagesXVFC Work Order Monitoring Format Newకొల్లి రాఘవేణిNo ratings yet

- SE Conference AgendaDocument2 pagesSE Conference AgendaShreya SinghNo ratings yet

- QMS MisDocument5 pagesQMS Miskumar QANo ratings yet

- Administration of Engineering StandardsDocument12 pagesAdministration of Engineering StandardsNBTC Tubes & PipesNo ratings yet

- AC Uninterruptibale Power System (UPS) SuppliesDocument29 pagesAC Uninterruptibale Power System (UPS) SuppliesNBTC Tubes & PipesNo ratings yet

- Amended Report Requirements For March 2020Document5 pagesAmended Report Requirements For March 2020Dann MarrNo ratings yet

- 2020 Third Quarter DMEA Tool For Districts 2Document7 pages2020 Third Quarter DMEA Tool For Districts 2Shannara ElliseNo ratings yet

- Annual Performance Review Form 2023 For GOVINDAM GUPTA: 1.1 Inventory ManagementDocument13 pagesAnnual Performance Review Form 2023 For GOVINDAM GUPTA: 1.1 Inventory ManagementGovindam GuptaNo ratings yet

- Engineering Unit Desk ManualDocument16 pagesEngineering Unit Desk ManualAimee GozonNo ratings yet

- DPC - Compilation of Circular-Rules-OrderDocument17 pagesDPC - Compilation of Circular-Rules-OrderKumud Kishor100% (2)

- MPR March 2022Document1 pageMPR March 2022Susmita BhattacharyaNo ratings yet

- Sample A3 ReportDocument1 pageSample A3 ReportManel VazquezNo ratings yet

- 3262-Article Text-8756-1-10-2022010289686060Document6 pages3262-Article Text-8756-1-10-2022010289686060rinditNo ratings yet

- DFPS Arif 2010-2020Document7 pagesDFPS Arif 2010-2020Ivan HerreraNo ratings yet

- Equipment Noise SpecificationDocument18 pagesEquipment Noise SpecificationNBTC Tubes & PipesNo ratings yet

- Rapid Project Spot Inspection Report: AttendeeDocument9 pagesRapid Project Spot Inspection Report: AttendeeAtuk SafizNo ratings yet

- SP 1242Document17 pagesSP 1242Drilling Engineering ChannelNo ratings yet

- (012821) (020421) Krakatau Steel (B) - Global CompetitionDocument6 pages(012821) (020421) Krakatau Steel (B) - Global CompetitionYani RahmaNo ratings yet

- 20200617-KCC Container Work PlanDocument2 pages20200617-KCC Container Work PlanShafaizal MohammedNo ratings yet

- Tipd Weekly Activity Action Log 04 11 2020Document5 pagesTipd Weekly Activity Action Log 04 11 2020Andrew MuhumuzaNo ratings yet

- Internal Safety Audit - 2020: Job Not Completed Even Target Date Over: 1Document24 pagesInternal Safety Audit - 2020: Job Not Completed Even Target Date Over: 1ravitejatalatamNo ratings yet

- Internal Safety Audit - 2020: Job Not Completed Even Target Date Over: 1Document24 pagesInternal Safety Audit - 2020: Job Not Completed Even Target Date Over: 1ravitejatalatamNo ratings yet

- Quality Improvement PlanDocument8 pagesQuality Improvement Plansaleemadamu1414No ratings yet

- MOM Status PM05 ESGRM03Document3 pagesMOM Status PM05 ESGRM03Debanjali Roy SenguptaNo ratings yet