Professional Documents

Culture Documents

Sample Checklist For Tower Crane

Uploaded by

Htun SoeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sample Checklist For Tower Crane

Uploaded by

Htun SoeCopyright:

Available Formats

SAMPLE CHECKLIST FOR TOWER CRANE

This checklist provides the basic requirements for safe operations of a tower crane. Tower crane users should consult

manufacturers, suppliers and owners on operations and safety requirements and address any concerns before using the

equipment. This checklist is non-exhaustive and users are recommended to make the necessary customisation to suit your work

processes and conditions at the workplace.

S/N Items Remarks

A. Tower Crane Approved For Use

1 Tower Crane is approved by MOM. Yes No

Tower Crane has a valid Lifting Machine (LM) certificate

2 Yes No

(issued less than 12 months ago).

B. General Requirements

Tower Crane is provided with markings of the Safe Working

3 Yes No

Load, serial number and LM number.

4 Safe access and egress are provided to the crane operator. Yes No

5 A load capacity chart is displayed in the operator cabin. Yes No

Operator crane cabin is provided with a locking mechanism

6 Yes No

so as to prevent unauthorised entry.

A safety bar is fitted across the operator’s cabin window

7 Yes No

where there is likelihood of the operator falling through it.

Fire extinguisher is fit for use and provided in the operator

8 Yes No

cabin.

An updated Operation and Maintenance log book is

9 Yes No

available in the operator cabin.

Manufacturer Operating Manual and Maintenance Manual

10 Yes No

are made available.

Tower crane is adequately grounded or protected against

11 Yes No

lightning.

C. Other visual checks

11 Load charts and other symbols are available and visible. Yes No

12 Hydraulic fluid level is sufficient. Yes No

13 Slewing oil level is sufficient. Yes No

14 All mounting bolts are in good condition. Yes No

15 Hydraulic system is free of leaks. Yes No

16 Boom sections are free of cracks or dents. Yes No

Main and auxiliary wire ropes are well lubricated and that

17 there are no visible defects such as broken wires, kinks, Yes No

excess wear, crushing etc.

Winches, pulleys and wire ropes are in good working

18 Yes No

condition.

Crane hook is provided with a safety catch to prevent

19 Yes No

displacement of the sling or load from the hook.

D. Safety and Operational Devices

20 Load radius indicator with warning alarm is installed. Yes No

21 Jib angle indicator is provided (For Luffing Jib Tower Crane). Yes No

Emergency stop button, which will terminate the operation of

22 the crane engine, is installed in the operator cabin and Yes No

correctly identified.

23 Effective braking mechanisms for the following is

Yes No

maintained:

(a) Hoisting Yes No

(b) Derricking Yes No

(c) Slewing Yes No

(d) Trolley Travelling Yes No

Hoisting Limiter to prevent over-hoisting of the hook block is

24 Yes No

functional.

Trolley Travelling limiter to prevent over-travelling of trolley is

25 Yes No

functional.

Limit switches to prevent over-derricking and over-lowering

26 Yes No

of jib (For Luffing Jib Tower Crane) is functional.

27 Slewing limiter to restrict slewing of crane is functional. Yes No

Overload Limiter to prevent overloading of crane is

28 Yes No

functional.

Load Moment Limiter to prevent over-turning moment is

29 Yes No

functional.

Anti-collision devices are tested to stop the tower crane’s

30 operation such that the crane-to-crane interference must be Yes No

maintained at not less than 3 metres.

Wind anemometer is installed and is in good working

31 Yes No

condition.

32 Adequate aircraft warning lights and/or chequered white and Yes No

red flags are provided.

E. Maintenance

Data logger for recording key operating parameters of the

32 Yes No

crane is functional.

Tower Crane has a regular maintenance programme that is

33 Yes No

in accordance with manufacturer’s specifications.

Maintenance work on the Tower Crane is carried out by

34 Yes No

Competent Persons.

You might also like

- Bar Cutting MachineDocument1 pageBar Cutting Machinesaurav roy100% (1)

- Bar Cutting Machine Inspection ChecklistDocument1 pageBar Cutting Machine Inspection ChecklistRicardo Dalisay100% (4)

- Permit To Excavate: Section - I Contact DetailsDocument1 pagePermit To Excavate: Section - I Contact DetailsBig Zaddy0% (1)

- Mobile Crane Monthly ChecklistDocument3 pagesMobile Crane Monthly ChecklistDAOUMY YOUNESSNo ratings yet

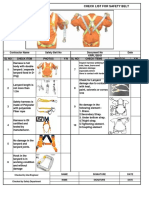

- Safety Checklist of Safety BeltDocument1 pageSafety Checklist of Safety BeltA S Yadav0% (1)

- Crane Carry - in InspectionDocument3 pagesCrane Carry - in InspectionAdhy Darmawan100% (1)

- Checklist For Equipment Inspection Air CompressorDocument1 pageChecklist For Equipment Inspection Air CompressorStephenNo ratings yet

- Checklist For Equipment Inspection Diesel GeneratorDocument1 pageChecklist For Equipment Inspection Diesel GeneratorKaif SiddiqueNo ratings yet

- 022 - HSSE - Full Body Harness Inspection ChecklistDocument1 page022 - HSSE - Full Body Harness Inspection ChecklistShashwat PandeyNo ratings yet

- Equipment Inspection Checklist NewDocument57 pagesEquipment Inspection Checklist Newakbar zulazmi100% (1)

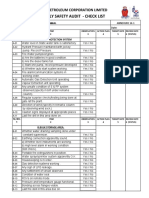

- Daily Safety ChecklistDocument4 pagesDaily Safety ChecklistKalyan ReddyNo ratings yet

- Inspection Checklist For Lifting Tools & TacklesDocument2 pagesInspection Checklist For Lifting Tools & Tacklesnil thaeu100% (1)

- 238 Preventive Check Sheet of Press Brake MachineDocument4 pages238 Preventive Check Sheet of Press Brake MachineAjay100% (2)

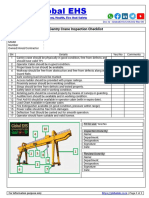

- Gantry Crane Safety Inspection Checklist Global EHSDocument1 pageGantry Crane Safety Inspection Checklist Global EHSloganathanNo ratings yet

- JAPL-F-TE-003-Generator Daily Inspection ChecklistDocument1 pageJAPL-F-TE-003-Generator Daily Inspection ChecklistAli Hassan100% (1)

- HSE-026.Pre-entry Hydra CraneDocument2 pagesHSE-026.Pre-entry Hydra CraneMithlesh Singh80% (5)

- 01 JTSPL WEEKLY CHECK LIST Crane F-15 PDFDocument5 pages01 JTSPL WEEKLY CHECK LIST Crane F-15 PDFsanjivan tawdeNo ratings yet

- Checklist For Equipment Inspection Bar Bending MachineDocument1 pageChecklist For Equipment Inspection Bar Bending MachineHung Hoang100% (3)

- Form 092 Excavator Safety Checklist 1Document2 pagesForm 092 Excavator Safety Checklist 1TANWIR AHEMADNo ratings yet

- Electrical Wiring DiagramDocument331 pagesElectrical Wiring DiagramkabibNo ratings yet

- Hira - Mobile CraneDocument4 pagesHira - Mobile CraneSantosh SinghNo ratings yet

- RPE Monthly Inspection ChecklistDocument2 pagesRPE Monthly Inspection ChecklistOussama Ouardani100% (2)

- Manlift Daily Inspection by OperatorDocument1 pageManlift Daily Inspection by OperatorNasrullah Khan Yousafzai100% (1)

- Bar Cutting Machine HSE ChecklistDocument2 pagesBar Cutting Machine HSE ChecklistMD Abdullah100% (1)

- Lifting Equipements Checklist-1Document59 pagesLifting Equipements Checklist-1areks3100% (1)

- Man Lift ChecklistDocument1 pageMan Lift Checklistpartha100% (1)

- New Mobile Crawler Crane ChecklistDocument2 pagesNew Mobile Crawler Crane ChecklistsunilNo ratings yet

- Dewatering PumpDocument1 pageDewatering PumpAbdus SamadNo ratings yet

- Doha Port Redevelopment - Combined Mina District & Seawater Diving Pool Check List For Drilling MachineDocument42 pagesDoha Port Redevelopment - Combined Mina District & Seawater Diving Pool Check List For Drilling MachineGia ArnelleNo ratings yet

- SWP-SF010A - 6 Daily Vibratory Roller Compactor Rev. ADocument1 pageSWP-SF010A - 6 Daily Vibratory Roller Compactor Rev. ACliffordNo ratings yet

- Crane InspectionDocument2 pagesCrane InspectionAdhy DarmawanNo ratings yet

- Tower Crane Daily Inspection FormDocument1 pageTower Crane Daily Inspection FormZainul Hazwan83% (6)

- 10 - Cherry Picker Inspection ChecklistDocument1 page10 - Cherry Picker Inspection Checklistsanjeev kumarNo ratings yet

- Fire Extinguisher ChecklistDocument1 pageFire Extinguisher ChecklistSafety Man ShopNo ratings yet

- Boom Placer Safety Inspection ChecklistDocument1 pageBoom Placer Safety Inspection ChecklistMyo LwinNo ratings yet

- Design of Tube Amplifiers in LT SpiceDocument33 pagesDesign of Tube Amplifiers in LT SpiceGaetanoCirillo100% (1)

- Jumping Compactor Inspection ChecklistDocument1 pageJumping Compactor Inspection Checklistarunjith rNo ratings yet

- Safety Inspection Checklist Abrasive Wheel Grinders Bench and PedestalDocument1 pageSafety Inspection Checklist Abrasive Wheel Grinders Bench and PedestalSanthosh Kumar100% (1)

- Cradle Inspection Weekly ChecklistDocument1 pageCradle Inspection Weekly ChecklistKARIM ABDELAZIZ100% (3)

- Checklist For Power Drill MachinDocument1 pageChecklist For Power Drill MachinLearn with Engr. Abdul Quyyaum ChaudharyNo ratings yet

- DRL - Project Check List For Metal Cutting Machine: .RPM .RPMDocument1 pageDRL - Project Check List For Metal Cutting Machine: .RPM .RPMSachin Hse Rohtak100% (1)

- Hazard Identification and Risk Assessment Form: Location Activities Hazard ControlsDocument6 pagesHazard Identification and Risk Assessment Form: Location Activities Hazard ControlsVikas SinghNo ratings yet

- Qusahwira Field Development Phase Ii Project Project No. 14395 Forklift ChecklistDocument1 pageQusahwira Field Development Phase Ii Project Project No. 14395 Forklift ChecklistJayaprakasan Koyadan KorothNo ratings yet

- Extension Cable ChecklistDocument1 pageExtension Cable ChecklistFandy Agita100% (2)

- 01 - Gas Cutting Set Inspection ChecklistDocument1 page01 - Gas Cutting Set Inspection Checklistsanjeev kumar100% (1)

- 3 Mobile Crane ChecklistDocument5 pages3 Mobile Crane ChecklistEriq100% (1)

- Hazard Identification Risk Assessment and Risk Control Hirarc Hiradc Office Hazard For Building SampleDocument10 pagesHazard Identification Risk Assessment and Risk Control Hirarc Hiradc Office Hazard For Building SampleAzaim Anaqi100% (3)

- Sample Checklist For Mobile CraneDocument2 pagesSample Checklist For Mobile CraneDan AlbertNo ratings yet

- Borang Hirarc KosongDocument2 pagesBorang Hirarc KosongAzaim Anaqi75% (4)

- Side Boom Crane Daily Inspection ChecklistDocument1 pageSide Boom Crane Daily Inspection ChecklistBorislav VulićNo ratings yet

- Meiller Kipper Rear Tipper VOLVO - 0026 - 0115 - 083 - 6X4 - en - RusDocument23 pagesMeiller Kipper Rear Tipper VOLVO - 0026 - 0115 - 083 - 6X4 - en - RusGora FedotovNo ratings yet

- TowerCrane ChecklistDocument1 pageTowerCrane ChecklistEleonor Maderazo100% (1)

- Crawler CraneDocument2 pagesCrawler CraneFarukBasyoriNo ratings yet

- Checklist For Equipment Inspection Winch Machine .Docx - Documentos de GoogleDocument1 pageChecklist For Equipment Inspection Winch Machine .Docx - Documentos de GoogleMarisabel Maidana100% (2)

- Check List (Pre Entry) For Portable Grinding MachineDocument4 pagesCheck List (Pre Entry) For Portable Grinding Machinealvhyan anandolaki100% (1)

- 019 Crane Check ListDocument1 page019 Crane Check ListMukesh Kumar100% (1)

- Lifting Tools & Tackles Inspection Checklist FormsDocument1 pageLifting Tools & Tackles Inspection Checklist FormsDas GobindaNo ratings yet

- Inspection Checklist of Drill Machine: Project Name: Date: Time: Checked byDocument1 pageInspection Checklist of Drill Machine: Project Name: Date: Time: Checked byRaza Muhammad Soomro0% (1)

- CBD15 Spare Parts ListDocument45 pagesCBD15 Spare Parts ListKINTOLOBONo ratings yet

- Cradle Check ListDocument1 pageCradle Check ListBineesh100% (3)

- Checklist of Gas Cutting SetDocument3 pagesChecklist of Gas Cutting SetSafety DeptNo ratings yet

- Man Basket Check ListDocument1 pageMan Basket Check Listlê ngọc tùng100% (1)

- CHANCADORESDocument25 pagesCHANCADORESYovany Hormazabal100% (1)

- Drill Machine - ChecklistDocument1 pageDrill Machine - ChecklistarkonamtfplNo ratings yet

- Daily Checklist Derrick Winch R.001Document2 pagesDaily Checklist Derrick Winch R.001angger aminda noorcipta joharNo ratings yet

- Please Write Yes or No in The Given Box and If Some Comments Write in Remarks ColumnDocument1 pagePlease Write Yes or No in The Given Box and If Some Comments Write in Remarks ColumnmurthyNo ratings yet

- 10 - Cherry Picker Inspection ChecklistDocument1 page10 - Cherry Picker Inspection Checklistsanjeev kumar100% (1)

- Potongan Baki 135000 132000 (98%) 88500 43500 2090 941 350 3381 2350 128000 (95%) 39500Document2 pagesPotongan Baki 135000 132000 (98%) 88500 43500 2090 941 350 3381 2350 128000 (95%) 39500Azaim AnaqiNo ratings yet

- Hse Flash: Site Rules For Use of Excavators For Lifting ActivitiesDocument1 pageHse Flash: Site Rules For Use of Excavators For Lifting ActivitiesAzaim AnaqiNo ratings yet

- Nilam Analisis 2016Document77 pagesNilam Analisis 2016Azaim AnaqiNo ratings yet

- (Malaysia) COUNTRY REPORT Present PDFDocument35 pages(Malaysia) COUNTRY REPORT Present PDFAzaim AnaqiNo ratings yet

- Sample Technical Writing Mechanism DescriptionDocument3 pagesSample Technical Writing Mechanism DescriptionAngelo De Oro67% (3)

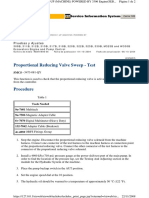

- Proportional Reducing Valve Sweep - Test: Pruebas y AjustesDocument2 pagesProportional Reducing Valve Sweep - Test: Pruebas y AjustesAugusto BellezaNo ratings yet

- NO Klasifikasi Code Number Nama Barang/Jasa: InventarisDocument28 pagesNO Klasifikasi Code Number Nama Barang/Jasa: InventarisRavita TrivegaNo ratings yet

- Documentation For: Technische Information Technical InformationDocument32 pagesDocumentation For: Technische Information Technical InformationLabinotMMorinaNo ratings yet

- Supply of 3 Pair, 5 Pair Telephone Cable, Jbs & Flexible Wire For Project Center Renovation WorkDocument2 pagesSupply of 3 Pair, 5 Pair Telephone Cable, Jbs & Flexible Wire For Project Center Renovation WorkkumarNo ratings yet

- Silver Streak and Blue Streak Repair Manual: All Rights Reserved, UJ BackusDocument20 pagesSilver Streak and Blue Streak Repair Manual: All Rights Reserved, UJ BackusRonNo ratings yet

- MA5800C SubracksDocument28 pagesMA5800C SubracksAlexander PischulinNo ratings yet

- Info Q50 TCM Jtdwa5681gbDocument8 pagesInfo Q50 TCM Jtdwa5681gbRoberto Garcia GodoyNo ratings yet

- USBOOSTERS - N Series Boosters - 07 2020 - 45 37064Document8 pagesUSBOOSTERS - N Series Boosters - 07 2020 - 45 37064AhmedNo ratings yet

- Tle ReportDocument30 pagesTle ReportEmyl FeguroNo ratings yet

- Whirlpool KAR-16 French Door Bottom Mount Refrigerator Service ManualDocument68 pagesWhirlpool KAR-16 French Door Bottom Mount Refrigerator Service ManualKeith Drake67% (3)

- Madcbb, Matdcbb, Masdcbb, & Mastdcbb: Owner'S ManualDocument24 pagesMadcbb, Matdcbb, Masdcbb, & Mastdcbb: Owner'S Manualvaishgoa56No ratings yet

- AWOS 3000 027 Maintenance Manual1 PDFDocument57 pagesAWOS 3000 027 Maintenance Manual1 PDFPham Van LinhNo ratings yet

- TV Parts TH50PZ85U PDFDocument29 pagesTV Parts TH50PZ85U PDFfmk1No ratings yet

- Cookery 12@maicaDocument6 pagesCookery 12@maicaleander santosNo ratings yet

- Pipe SealsDocument32 pagesPipe SealsSekhil DevNo ratings yet

- Forgotten Firearms of August CoendersDocument12 pagesForgotten Firearms of August CoendersRoddy PfeifferNo ratings yet

- Installation Manual SP-501: I. Accessory Parts II. Installation ProceduresDocument1 pageInstallation Manual SP-501: I. Accessory Parts II. Installation ProcedureshashemNo ratings yet

- AF305-30-11-13 100-250V 50/60Hz / DC: General InformationDocument3 pagesAF305-30-11-13 100-250V 50/60Hz / DC: General Informationel daniNo ratings yet

- Physic AssignmentDocument9 pagesPhysic AssignmentAlex jamesNo ratings yet

- Net Sure 701 DatasheetDocument2 pagesNet Sure 701 DatasheetGlenn NnelgNo ratings yet

- ABTED103157ENDocument8 pagesABTED103157ENfreddysh4330No ratings yet

- Sensor FloatDocument2 pagesSensor FloatAkram KheirNo ratings yet

- RT60580 - Rev02 - PRE-COURSE MATERIAL - SNUBBING THEORY EXERCISEDocument16 pagesRT60580 - Rev02 - PRE-COURSE MATERIAL - SNUBBING THEORY EXERCISEdaniel abiaNo ratings yet

- Mega TorqueDocument23 pagesMega TorquejouetNo ratings yet