Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

8 viewsGate Valve Preservation PDF

Gate Valve Preservation PDF

Uploaded by

Ali AliCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Equipment Preservation Plan: Report No. 000-PR-R-002Document17 pagesEquipment Preservation Plan: Report No. 000-PR-R-002Richard BertoniNo ratings yet

- Physical Stock Taking ReportDocument2 pagesPhysical Stock Taking ReportvelNo ratings yet

- HSE Information Sheet Ageing Semi-Submersible Installations Offshore Information Sheet No 5 2007Document5 pagesHSE Information Sheet Ageing Semi-Submersible Installations Offshore Information Sheet No 5 2007Saeed JabbariNo ratings yet

- Mud Pump 12T1600 (47005005)Document8 pagesMud Pump 12T1600 (47005005)Ali AliNo ratings yet

- YouDocument1 pageYoufidanasNo ratings yet

- Master Tungsten Carbide Rotary Burrs PDFDocument12 pagesMaster Tungsten Carbide Rotary Burrs PDFFred AksoNo ratings yet

- Rehabilitation of Yanbu South Terminal Projects BI # 10-00567Document12 pagesRehabilitation of Yanbu South Terminal Projects BI # 10-00567qazi12No ratings yet

- UPDATED Bagging - Tagging (Ms. Jugno)Document26 pagesUPDATED Bagging - Tagging (Ms. Jugno)Krizia Daleene M. CorderoNo ratings yet

- Guidelines For Preservation of StoresDocument38 pagesGuidelines For Preservation of StoresAnonymous rYZyQQot55No ratings yet

- Annexure 6 - Storage and Preservation ProcedureDocument9 pagesAnnexure 6 - Storage and Preservation ProcedureAland FirozNo ratings yet

- HPCL Material Preservation GuidelinesDocument7 pagesHPCL Material Preservation GuidelinespaimpillyNo ratings yet

- Topside Painting and Corrosion Protection SpecificationDocument47 pagesTopside Painting and Corrosion Protection SpecificationRaimundo MirandaNo ratings yet

- Inspector Roles and Responsibilities Rev 01Document3 pagesInspector Roles and Responsibilities Rev 01sakthivelNo ratings yet

- Long Term Preservation ProcedureDocument2 pagesLong Term Preservation Procedureiyappan i.p.sNo ratings yet

- Installation/Operation Manual Pig Launcher: Franz Schuck GMBHDocument28 pagesInstallation/Operation Manual Pig Launcher: Franz Schuck GMBHWan Ah-LunNo ratings yet

- Material Handler Job Description ResumeDocument8 pagesMaterial Handler Job Description Resumefzdpofajd100% (2)

- Equipment Preservation Standard Specification - MCE EG016 CDocument4 pagesEquipment Preservation Standard Specification - MCE EG016 CSenol LimanNo ratings yet

- Pump Storage and PreservationDocument4 pagesPump Storage and PreservationazkNo ratings yet

- GRP Pipe Calculation: Ft/secDocument6 pagesGRP Pipe Calculation: Ft/secمعتصم منورNo ratings yet

- IB Steam Turbine PreservationDocument6 pagesIB Steam Turbine PreservationUdhayakumar VenkataramanNo ratings yet

- IQWQ-FT-BSPDS-00-120111 - 0 Packing SpecDocument27 pagesIQWQ-FT-BSPDS-00-120111 - 0 Packing Specjacksonbello34No ratings yet

- Nissar - Permit To Work - JGCDocument32 pagesNissar - Permit To Work - JGCDelta akathehuskyNo ratings yet

- 2-1328-PE-PACKING-01 RA Packing & Preservation ProcedureDocument8 pages2-1328-PE-PACKING-01 RA Packing & Preservation ProcedureDion BoedionoNo ratings yet

- 1030Document6 pages1030mgoethalsNo ratings yet

- Gas Over Oil Actuators GoDocument32 pagesGas Over Oil Actuators Goaugusto sebastianNo ratings yet

- (Rabigh) Geotechnical EvaluationDocument30 pages(Rabigh) Geotechnical Evaluationdeepak.dce.meNo ratings yet

- BurrDocument9 pagesBurrOmsri VinashaNo ratings yet

- Part - I - 220 - KV - LUNAWADA - EPCDocument115 pagesPart - I - 220 - KV - LUNAWADA - EPCKishore KrishnaNo ratings yet

- Machine Operator Job DescriptionDocument2 pagesMachine Operator Job DescriptionDũng TNNo ratings yet

- ROS-020 Edition 2015 Rev 00-2015 - Scaffold PDFDocument24 pagesROS-020 Edition 2015 Rev 00-2015 - Scaffold PDFFayaz MohammedNo ratings yet

- Erection Contractor's ScopeDocument4 pagesErection Contractor's ScopeasifaliabidNo ratings yet

- Needle Valve Quotation From SESCO PDFDocument2 pagesNeedle Valve Quotation From SESCO PDFAlaa RamadanNo ratings yet

- GRP Pipe Case History - Revised Shoiaba Eng Large DiaDocument4 pagesGRP Pipe Case History - Revised Shoiaba Eng Large DiaA.Subin DasNo ratings yet

- Qatar Traffic Manual Volume-1Document97 pagesQatar Traffic Manual Volume-1Nacho OrtolanoNo ratings yet

- Materials ManagementDocument17 pagesMaterials ManagementAkash SahaNo ratings yet

- FloGard MS6208Document1 pageFloGard MS6208engr.shahid041No ratings yet

- 5.2 Pre CommissioningDocument11 pages5.2 Pre Commissioninghwang2No ratings yet

- Cac Da C A PTSC M CDocument15 pagesCac Da C A PTSC M Ctaddeo100% (1)

- SOP For Filling Liquid Cylinder Using Pump Transfer Method Rev 1 PDFDocument9 pagesSOP For Filling Liquid Cylinder Using Pump Transfer Method Rev 1 PDFYASH ENGINEERING SOLUTIONSNo ratings yet

- MVR Part 1 - July - 2019 PDFDocument165 pagesMVR Part 1 - July - 2019 PDFHenry SugionoNo ratings yet

- SZ Sales ProgramDocument28 pagesSZ Sales ProgramrossifrancescoNo ratings yet

- Catalogo Industrias Ing0420Document16 pagesCatalogo Industrias Ing0420SameerKhanNo ratings yet

- Belzona 1111ps EnglDocument2 pagesBelzona 1111ps EnglNikolay GuerreroNo ratings yet

- Sample - Resume-IOCL FormatDocument5 pagesSample - Resume-IOCL FormatRajasekaran PrakasamNo ratings yet

- GS Ep PVV 107 enDocument38 pagesGS Ep PVV 107 ensenthil muruganNo ratings yet

- OvalIty CorrectionDocument1 pageOvalIty Correctionshah1980No ratings yet

- Chapter 2 Project Procurrement Planning and AnalysisDocument31 pagesChapter 2 Project Procurrement Planning and AnalysisMitku AssefaNo ratings yet

- Piping Support Types Purpose Design Codes Optimization Rules PDFDocument15 pagesPiping Support Types Purpose Design Codes Optimization Rules PDFMIlanNo ratings yet

- Injection Wellsite Packages PDFDocument4 pagesInjection Wellsite Packages PDFermusat100% (1)

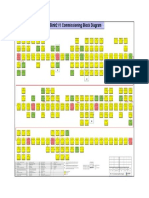

- Commissioning Sequence (20190320)Document1 pageCommissioning Sequence (20190320)Ba Giao NguyenNo ratings yet

- Praj Industries Investor Presentation February 2024 1Document32 pagesPraj Industries Investor Presentation February 2024 1Amit KumarNo ratings yet

- Axial Stop For Horizontal Cryogenic Pipes 2" - 80" NPS: Pipe Standard SupportsDocument3 pagesAxial Stop For Horizontal Cryogenic Pipes 2" - 80" NPS: Pipe Standard SupportsMainuddin Ali100% (1)

- Petro 1982Document385 pagesPetro 1982Ronaldo ArlandNo ratings yet

- Lap Joint Flange Vs Slip On FlangeDocument3 pagesLap Joint Flange Vs Slip On FlangeDarking1390No ratings yet

- CP HS 12Document8 pagesCP HS 12aliNo ratings yet

- Presentation of OGDCLDocument24 pagesPresentation of OGDCLMani JattNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1)Document45 pagesRas Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- Manual de Vaporizadores AmbientalesDocument9 pagesManual de Vaporizadores AmbientalesJose Luis Tadeo SabinoNo ratings yet

- WI-PC17 - Purging Process R0Document3 pagesWI-PC17 - Purging Process R0Fatin NajehahNo ratings yet

- Forming Head ProcedureDocument8 pagesForming Head ProcedureLuhur PrandikaNo ratings yet

- MS - Placing of ConcreteDocument4 pagesMS - Placing of ConcretephoenixsafetyconsultantNo ratings yet

- 000 00001 - Trac4 STD P - 01aDocument24 pages000 00001 - Trac4 STD P - 01aAli AliNo ratings yet

- 1 Hand Calculation ESP Design - HandoutDocument7 pages1 Hand Calculation ESP Design - HandoutAli AliNo ratings yet

- 3 Hand Calcualtion Answer GuideDocument3 pages3 Hand Calcualtion Answer GuideAli AliNo ratings yet

- 1 Hand Calculation ESP Design - HandoutDocument7 pages1 Hand Calculation ESP Design - HandoutAli AliNo ratings yet

- TRAC Series Annular Control SystemsDocument2 pagesTRAC Series Annular Control SystemsAli Ali100% (1)

- XMP Data Sheet PackerDocument2 pagesXMP Data Sheet PackerAli AliNo ratings yet

- 08 Co 178 Realiance Saf Val 2 LRDocument2 pages08 Co 178 Realiance Saf Val 2 LRAli AliNo ratings yet

- 12 VSDDocument34 pages12 VSDام فاطمة البطاطNo ratings yet

- Operator's Manual: Hydril K20-5000 Pulsation Dampener IAW PED 97/23/ECDocument16 pagesOperator's Manual: Hydril K20-5000 Pulsation Dampener IAW PED 97/23/ECAli Ali67% (3)

- Slickline Retrievable, Surface Controlled, Self-Equalizing, Flapper Valves With Working Pressures To 7,500 PsiDocument1 pageSlickline Retrievable, Surface Controlled, Self-Equalizing, Flapper Valves With Working Pressures To 7,500 PsiAli AliNo ratings yet

- 405.1 Gaslift Valve MechanicsDocument13 pages405.1 Gaslift Valve MechanicsAli AliNo ratings yet

- Perforating DEPTH Control: Depth Positioning Devices Perforation Depth Control Service Quality ProblemsDocument19 pagesPerforating DEPTH Control: Depth Positioning Devices Perforation Depth Control Service Quality ProblemsAli Ali100% (1)

- Shut-Down Drilling Rig Electrical DiagramDocument9 pagesShut-Down Drilling Rig Electrical DiagramAli AliNo ratings yet

- Mud Hog 1 1-Manual-Rev2Document19 pagesMud Hog 1 1-Manual-Rev2Ali Ali0% (1)

- Vendor Supplied Document: ContentsDocument3 pagesVendor Supplied Document: ContentsAli AliNo ratings yet

- Vendor Supplied Document: ContentsDocument15 pagesVendor Supplied Document: ContentsAli AliNo ratings yet

- Vendor Supplied Document: ContentsDocument23 pagesVendor Supplied Document: ContentsAli AliNo ratings yet

- Transfer Lubrication (47000461) PDFDocument8 pagesTransfer Lubrication (47000461) PDFAli AliNo ratings yet

- Earth System (47000227) PDFDocument5 pagesEarth System (47000227) PDFAli AliNo ratings yet

- Vendor Supplied Document: ContentsDocument20 pagesVendor Supplied Document: ContentsAli AliNo ratings yet

- Quantity Item BSC Part Number Description: TDS-11SA With PH-75 Pipe Handler and NOV Drive House A 3OM00252 ADocument1 pageQuantity Item BSC Part Number Description: TDS-11SA With PH-75 Pipe Handler and NOV Drive House A 3OM00252 AAli AliNo ratings yet

- 1500 - 2000 HP Rotary Table (47005010)Document7 pages1500 - 2000 HP Rotary Table (47005010)Ali AliNo ratings yet

- Power Tong Hydraulic System (50010907) PDFDocument1 pagePower Tong Hydraulic System (50010907) PDFAli AliNo ratings yet

- Titan Class Type "CH" Reset Relief Valve Operations & Maintenance ManualDocument21 pagesTitan Class Type "CH" Reset Relief Valve Operations & Maintenance ManualAli Ali100% (1)

Gate Valve Preservation PDF

Gate Valve Preservation PDF

Uploaded by

Ali Ali0 ratings0% found this document useful (0 votes)

8 views2 pagesOriginal Title

Gate Valve Preservation.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views2 pagesGate Valve Preservation PDF

Gate Valve Preservation PDF

Uploaded by

Ali AliCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Mud Gate Valve Preservation Procedure

The following procedure should be followed to reduce corrosive damage to the gate valves which can lead to

reduced valve life and failure of valve internals.

1. Monthly - Operate the valve by completely closing and opening the handwheel.

Figure 1 - Operating Handwheel

2. 3 Months - Grease all grease fittings on the valve with a Heavy Duty General Purpose Lithium Based

grease or equivalent.

Figure 2 - Lubrication of Grease Fittings

3. 6 Months - Perform internal & external valve preservation procedures.

a. External Paint Inspection and Touch-up.

• Inspect external surfaces for damaged paint and coat with paint as necessary.

b. Internal Valve Preservation Procedures

• Coat valve internals with spray on corrosion inhibitor from valve bore.

(CRC Industrial SP-400 Corrosion Inhibitor or Equivalent)

Figure 3 – Application of Corrosion Inhibitor Spray

4302 Profit / San Antonio, Texas 78219-2622

Tel: 210-304-5650 / Fax: 210-304-5641 / www.fot.com

Mud Gate Valve Preservation and Maintenance Schedule

Preservation Activity Schedule Date of Receipt Month 1 Month 2 Month 3 Month 4 Month 5 Month 6 Month 7 Month 8 Month 9 Month 10 Month 11 Month 12

1. Operate Handwheel

Every Month

2. Lubricate Grease Fittings

Every 3 Months

3 a. External Paint Inspection and

Touch-up Every 6 Months

3 b. Internal Inspection and

Preservation Procedures Every 6 Months

* White Boxes indicate that a preservation activity is required for the specified month.

4302 Profit / San Antonio, Texas 78219-2622

Tel: 210-304-5650 / Fax: 210-304-5641 / www.fot.com

You might also like

- Equipment Preservation Plan: Report No. 000-PR-R-002Document17 pagesEquipment Preservation Plan: Report No. 000-PR-R-002Richard BertoniNo ratings yet

- Physical Stock Taking ReportDocument2 pagesPhysical Stock Taking ReportvelNo ratings yet

- HSE Information Sheet Ageing Semi-Submersible Installations Offshore Information Sheet No 5 2007Document5 pagesHSE Information Sheet Ageing Semi-Submersible Installations Offshore Information Sheet No 5 2007Saeed JabbariNo ratings yet

- Mud Pump 12T1600 (47005005)Document8 pagesMud Pump 12T1600 (47005005)Ali AliNo ratings yet

- YouDocument1 pageYoufidanasNo ratings yet

- Master Tungsten Carbide Rotary Burrs PDFDocument12 pagesMaster Tungsten Carbide Rotary Burrs PDFFred AksoNo ratings yet

- Rehabilitation of Yanbu South Terminal Projects BI # 10-00567Document12 pagesRehabilitation of Yanbu South Terminal Projects BI # 10-00567qazi12No ratings yet

- UPDATED Bagging - Tagging (Ms. Jugno)Document26 pagesUPDATED Bagging - Tagging (Ms. Jugno)Krizia Daleene M. CorderoNo ratings yet

- Guidelines For Preservation of StoresDocument38 pagesGuidelines For Preservation of StoresAnonymous rYZyQQot55No ratings yet

- Annexure 6 - Storage and Preservation ProcedureDocument9 pagesAnnexure 6 - Storage and Preservation ProcedureAland FirozNo ratings yet

- HPCL Material Preservation GuidelinesDocument7 pagesHPCL Material Preservation GuidelinespaimpillyNo ratings yet

- Topside Painting and Corrosion Protection SpecificationDocument47 pagesTopside Painting and Corrosion Protection SpecificationRaimundo MirandaNo ratings yet

- Inspector Roles and Responsibilities Rev 01Document3 pagesInspector Roles and Responsibilities Rev 01sakthivelNo ratings yet

- Long Term Preservation ProcedureDocument2 pagesLong Term Preservation Procedureiyappan i.p.sNo ratings yet

- Installation/Operation Manual Pig Launcher: Franz Schuck GMBHDocument28 pagesInstallation/Operation Manual Pig Launcher: Franz Schuck GMBHWan Ah-LunNo ratings yet

- Material Handler Job Description ResumeDocument8 pagesMaterial Handler Job Description Resumefzdpofajd100% (2)

- Equipment Preservation Standard Specification - MCE EG016 CDocument4 pagesEquipment Preservation Standard Specification - MCE EG016 CSenol LimanNo ratings yet

- Pump Storage and PreservationDocument4 pagesPump Storage and PreservationazkNo ratings yet

- GRP Pipe Calculation: Ft/secDocument6 pagesGRP Pipe Calculation: Ft/secمعتصم منورNo ratings yet

- IB Steam Turbine PreservationDocument6 pagesIB Steam Turbine PreservationUdhayakumar VenkataramanNo ratings yet

- IQWQ-FT-BSPDS-00-120111 - 0 Packing SpecDocument27 pagesIQWQ-FT-BSPDS-00-120111 - 0 Packing Specjacksonbello34No ratings yet

- Nissar - Permit To Work - JGCDocument32 pagesNissar - Permit To Work - JGCDelta akathehuskyNo ratings yet

- 2-1328-PE-PACKING-01 RA Packing & Preservation ProcedureDocument8 pages2-1328-PE-PACKING-01 RA Packing & Preservation ProcedureDion BoedionoNo ratings yet

- 1030Document6 pages1030mgoethalsNo ratings yet

- Gas Over Oil Actuators GoDocument32 pagesGas Over Oil Actuators Goaugusto sebastianNo ratings yet

- (Rabigh) Geotechnical EvaluationDocument30 pages(Rabigh) Geotechnical Evaluationdeepak.dce.meNo ratings yet

- BurrDocument9 pagesBurrOmsri VinashaNo ratings yet

- Part - I - 220 - KV - LUNAWADA - EPCDocument115 pagesPart - I - 220 - KV - LUNAWADA - EPCKishore KrishnaNo ratings yet

- Machine Operator Job DescriptionDocument2 pagesMachine Operator Job DescriptionDũng TNNo ratings yet

- ROS-020 Edition 2015 Rev 00-2015 - Scaffold PDFDocument24 pagesROS-020 Edition 2015 Rev 00-2015 - Scaffold PDFFayaz MohammedNo ratings yet

- Erection Contractor's ScopeDocument4 pagesErection Contractor's ScopeasifaliabidNo ratings yet

- Needle Valve Quotation From SESCO PDFDocument2 pagesNeedle Valve Quotation From SESCO PDFAlaa RamadanNo ratings yet

- GRP Pipe Case History - Revised Shoiaba Eng Large DiaDocument4 pagesGRP Pipe Case History - Revised Shoiaba Eng Large DiaA.Subin DasNo ratings yet

- Qatar Traffic Manual Volume-1Document97 pagesQatar Traffic Manual Volume-1Nacho OrtolanoNo ratings yet

- Materials ManagementDocument17 pagesMaterials ManagementAkash SahaNo ratings yet

- FloGard MS6208Document1 pageFloGard MS6208engr.shahid041No ratings yet

- 5.2 Pre CommissioningDocument11 pages5.2 Pre Commissioninghwang2No ratings yet

- Cac Da C A PTSC M CDocument15 pagesCac Da C A PTSC M Ctaddeo100% (1)

- SOP For Filling Liquid Cylinder Using Pump Transfer Method Rev 1 PDFDocument9 pagesSOP For Filling Liquid Cylinder Using Pump Transfer Method Rev 1 PDFYASH ENGINEERING SOLUTIONSNo ratings yet

- MVR Part 1 - July - 2019 PDFDocument165 pagesMVR Part 1 - July - 2019 PDFHenry SugionoNo ratings yet

- SZ Sales ProgramDocument28 pagesSZ Sales ProgramrossifrancescoNo ratings yet

- Catalogo Industrias Ing0420Document16 pagesCatalogo Industrias Ing0420SameerKhanNo ratings yet

- Belzona 1111ps EnglDocument2 pagesBelzona 1111ps EnglNikolay GuerreroNo ratings yet

- Sample - Resume-IOCL FormatDocument5 pagesSample - Resume-IOCL FormatRajasekaran PrakasamNo ratings yet

- GS Ep PVV 107 enDocument38 pagesGS Ep PVV 107 ensenthil muruganNo ratings yet

- OvalIty CorrectionDocument1 pageOvalIty Correctionshah1980No ratings yet

- Chapter 2 Project Procurrement Planning and AnalysisDocument31 pagesChapter 2 Project Procurrement Planning and AnalysisMitku AssefaNo ratings yet

- Piping Support Types Purpose Design Codes Optimization Rules PDFDocument15 pagesPiping Support Types Purpose Design Codes Optimization Rules PDFMIlanNo ratings yet

- Injection Wellsite Packages PDFDocument4 pagesInjection Wellsite Packages PDFermusat100% (1)

- Commissioning Sequence (20190320)Document1 pageCommissioning Sequence (20190320)Ba Giao NguyenNo ratings yet

- Praj Industries Investor Presentation February 2024 1Document32 pagesPraj Industries Investor Presentation February 2024 1Amit KumarNo ratings yet

- Axial Stop For Horizontal Cryogenic Pipes 2" - 80" NPS: Pipe Standard SupportsDocument3 pagesAxial Stop For Horizontal Cryogenic Pipes 2" - 80" NPS: Pipe Standard SupportsMainuddin Ali100% (1)

- Petro 1982Document385 pagesPetro 1982Ronaldo ArlandNo ratings yet

- Lap Joint Flange Vs Slip On FlangeDocument3 pagesLap Joint Flange Vs Slip On FlangeDarking1390No ratings yet

- CP HS 12Document8 pagesCP HS 12aliNo ratings yet

- Presentation of OGDCLDocument24 pagesPresentation of OGDCLMani JattNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1)Document45 pagesRas Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- Manual de Vaporizadores AmbientalesDocument9 pagesManual de Vaporizadores AmbientalesJose Luis Tadeo SabinoNo ratings yet

- WI-PC17 - Purging Process R0Document3 pagesWI-PC17 - Purging Process R0Fatin NajehahNo ratings yet

- Forming Head ProcedureDocument8 pagesForming Head ProcedureLuhur PrandikaNo ratings yet

- MS - Placing of ConcreteDocument4 pagesMS - Placing of ConcretephoenixsafetyconsultantNo ratings yet

- 000 00001 - Trac4 STD P - 01aDocument24 pages000 00001 - Trac4 STD P - 01aAli AliNo ratings yet

- 1 Hand Calculation ESP Design - HandoutDocument7 pages1 Hand Calculation ESP Design - HandoutAli AliNo ratings yet

- 3 Hand Calcualtion Answer GuideDocument3 pages3 Hand Calcualtion Answer GuideAli AliNo ratings yet

- 1 Hand Calculation ESP Design - HandoutDocument7 pages1 Hand Calculation ESP Design - HandoutAli AliNo ratings yet

- TRAC Series Annular Control SystemsDocument2 pagesTRAC Series Annular Control SystemsAli Ali100% (1)

- XMP Data Sheet PackerDocument2 pagesXMP Data Sheet PackerAli AliNo ratings yet

- 08 Co 178 Realiance Saf Val 2 LRDocument2 pages08 Co 178 Realiance Saf Val 2 LRAli AliNo ratings yet

- 12 VSDDocument34 pages12 VSDام فاطمة البطاطNo ratings yet

- Operator's Manual: Hydril K20-5000 Pulsation Dampener IAW PED 97/23/ECDocument16 pagesOperator's Manual: Hydril K20-5000 Pulsation Dampener IAW PED 97/23/ECAli Ali67% (3)

- Slickline Retrievable, Surface Controlled, Self-Equalizing, Flapper Valves With Working Pressures To 7,500 PsiDocument1 pageSlickline Retrievable, Surface Controlled, Self-Equalizing, Flapper Valves With Working Pressures To 7,500 PsiAli AliNo ratings yet

- 405.1 Gaslift Valve MechanicsDocument13 pages405.1 Gaslift Valve MechanicsAli AliNo ratings yet

- Perforating DEPTH Control: Depth Positioning Devices Perforation Depth Control Service Quality ProblemsDocument19 pagesPerforating DEPTH Control: Depth Positioning Devices Perforation Depth Control Service Quality ProblemsAli Ali100% (1)

- Shut-Down Drilling Rig Electrical DiagramDocument9 pagesShut-Down Drilling Rig Electrical DiagramAli AliNo ratings yet

- Mud Hog 1 1-Manual-Rev2Document19 pagesMud Hog 1 1-Manual-Rev2Ali Ali0% (1)

- Vendor Supplied Document: ContentsDocument3 pagesVendor Supplied Document: ContentsAli AliNo ratings yet

- Vendor Supplied Document: ContentsDocument15 pagesVendor Supplied Document: ContentsAli AliNo ratings yet

- Vendor Supplied Document: ContentsDocument23 pagesVendor Supplied Document: ContentsAli AliNo ratings yet

- Transfer Lubrication (47000461) PDFDocument8 pagesTransfer Lubrication (47000461) PDFAli AliNo ratings yet

- Earth System (47000227) PDFDocument5 pagesEarth System (47000227) PDFAli AliNo ratings yet

- Vendor Supplied Document: ContentsDocument20 pagesVendor Supplied Document: ContentsAli AliNo ratings yet

- Quantity Item BSC Part Number Description: TDS-11SA With PH-75 Pipe Handler and NOV Drive House A 3OM00252 ADocument1 pageQuantity Item BSC Part Number Description: TDS-11SA With PH-75 Pipe Handler and NOV Drive House A 3OM00252 AAli AliNo ratings yet

- 1500 - 2000 HP Rotary Table (47005010)Document7 pages1500 - 2000 HP Rotary Table (47005010)Ali AliNo ratings yet

- Power Tong Hydraulic System (50010907) PDFDocument1 pagePower Tong Hydraulic System (50010907) PDFAli AliNo ratings yet

- Titan Class Type "CH" Reset Relief Valve Operations & Maintenance ManualDocument21 pagesTitan Class Type "CH" Reset Relief Valve Operations & Maintenance ManualAli Ali100% (1)