Professional Documents

Culture Documents

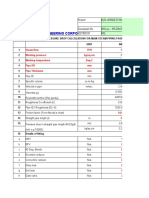

Cat - Dimension

Uploaded by

herysyam1980Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cat - Dimension

Uploaded by

herysyam1980Copyright:

Available Formats

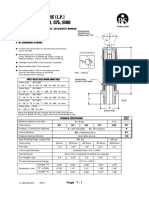

Dimensions

Dimensions, in inches (millimeters), are for reference only and are subject to change. Tube Stub

Ports

Female NPT Panel 0.39 (10.0) thick maximum with 2 lock nuts

Ports Panel 0.63 (16.0) thick maximum with 1 lock nut 0.84

Panel cutout 1.38 (35.0) dia (21.3)

3.00

(76.2)

2.13 2.16 0.75 VCR Ports

(54.0) (55.0)

(19.0)

dia dia

0.84

0.75 (21.3)

(19.0)

4.61 Mounting holes 5.00 3.70

(117) 10-32, 0.33 deep (127) (94.0)

(M5 0.8, 8.5 deep)

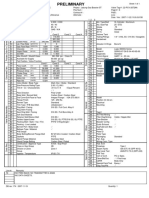

Ordering Information

Build a KPR series regulator ordering number by combining the designators in the sequence shown below.

4 5 6 7 8 9 10 11 12 13 14 15 16

KPR 1 F R F 4 1 2 A 2 0 0 0 0

4 Body Material 8 Ports 12 Handle, Mounting

1 = 316 SS 4 = 1/4 in. female NPT 2 = Knob

2 = Brass CW721R T = 1/4 in. 0.035 in. tube stub➀ 3 = 316 SS antitamper nut

4 = Alloy 400/R-405 V = 1/4 in. VCR gland, no nuts➀➁ 6 = Knob, panel mount

5 = Alloy C-276 X = 1/4 in. rotatable female VCR fitting➀ 7 = 316 SS antitamper nut, panel mount

A = 316 SS, ASTM G93-cleaned Y = 1/4 in. rotatable male VCR fitting➀

B = Brass, ASTM G93-cleaned ➀ Available only with 316 SS body material in A 13 Isolation and Relief Valves

C = 316 SS, SC-11–cleaned and F port configurations; does not contain a 0 = No valves

filter. Not available ASTM G93-cleaned.

➁ For use with VCR split-nuts, which can be For isolation and relief valve options,

5 Pressure Control Range ordered separately. See the Swagelok VCR see page 54.

C = 0 to 10 psig (0 to 0.68 bar) Metal Gasket Face Seal Fittings catalog,

MS-01-24.

D = 0 to 25 psig (0 to 1.7 bar) 14 Cylinder Connections

E = 0 to 50 psig (0 to 3.4 bar) 0 = No connections

9 Seat Material

F = 0 to 100 psig (0 to 6.8 bar) 1 = PCTFE For CGA cylinder connection options,

G = 0 to 250 psig (0 to 17.2 bar) 2 = PEEK see page 53.

J = 0 to 500 psig (0 to 34.4 bar)

10 Flow Coefficient (Cv) 15 Gauges

6 Maximum Inlet Pressure➀ 1 = 0.02 0 = No gauges

P = 3000 psig (206 bar)➁ 2 = 0.06 For inlet and outlet gauge options, see

R = 3600 psig (248 bar) 5 = 0.20 page 54.

➀ Substantially lower inlet pressures may 7 = 0.50

result in increased sensitivity when making

handle adjustments. Contact your authorized 16 Options

Swagelok representative for more information. 11 Sensing Mechanism, Vent 0 = No options

➁ Required and used only when ordering A = Alloy X-750 diaphragm, no vent H = Inboard helium leak test to a

regulators assembled with CGA cylinder

connection or inlet hose.

C = Alloy X-750 diaphragm, self vent➀ maximum leak rate of

E = Alloy X-750 diaphragm, captured 1 10–5 std cm3/s

vent 3 = 3 ft, 1/4 in. FM series metal flexible

7 Port Configuration

F = Alloy X-750 diaphragm, self and hose, 1/4 in. female NPT inlet

A, B, C, F, H, K, L

captured vent➀ 4 = 3 ft, 1/4 in. TH series PTFE-lined,

See Port Configurations, page 52.

H = Alloy C-276 diaphragm, no vent stainless steel braided hose,

➀ Available only with 316 SS and brass body 1/4 in. female NPT inlet

materials and 0.06 and 0.20 Cv.

For more information about hoses, see

page 56.

= CTO (Swagelok OFC)

= MTO (Swagelok OFC)

No highlight = MTO (Swagelok Ltd.)

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- A-630 B&G Field Adjustable, Pressure Independent Flow-Limiting Valves For Small Coils BrochureDocument2 pagesA-630 B&G Field Adjustable, Pressure Independent Flow-Limiting Valves For Small Coils Brochurekeith dietrichNo ratings yet

- 362Document2 pages362Ajay AsodariyaNo ratings yet

- Grinnell Mechanical Products Mechanical Outlet Coupling General Description Technical Data Installation / AssemblyDocument4 pagesGrinnell Mechanical Products Mechanical Outlet Coupling General Description Technical Data Installation / AssemblyСергей КолесниковNo ratings yet

- Pressure Reducing, Pilot Operated Spool Type: Common Cavity, Size 10Document2 pagesPressure Reducing, Pilot Operated Spool Type: Common Cavity, Size 10tecnicomanelNo ratings yet

- High Pressure Check Valves: SHCV SeriesDocument8 pagesHigh Pressure Check Valves: SHCV SeriesToty DzNo ratings yet

- Engine+Mechanical+System+L+1 0+LPGi+KAPPADocument124 pagesEngine+Mechanical+System+L+1 0+LPGi+KAPPAAnthonio LezcanoNo ratings yet

- RVP 16 - 300 P 9050063 enDocument5 pagesRVP 16 - 300 P 9050063 enMartin NelsonNo ratings yet

- Catalog 64 5000 Series Subatmospheric Pressure Regulator Tescom en 5351134Document4 pagesCatalog 64 5000 Series Subatmospheric Pressure Regulator Tescom en 5351134Titus PrizfelixNo ratings yet

- Circulating Fluidized Bed Boiler Design and OperationDocument9 pagesCirculating Fluidized Bed Boiler Design and OperationSanket BhaleraoNo ratings yet

- Differential Pressure Gauge Model D201: Max. Static Pressure 400 BarDocument2 pagesDifferential Pressure Gauge Model D201: Max. Static Pressure 400 BarYuri SeifaneNo ratings yet

- CE Series Slip-in Cartridge ValvesDocument6 pagesCE Series Slip-in Cartridge ValvesconimecNo ratings yet

- Datasheet Rah101Document4 pagesDatasheet Rah101Carlos AntunaNo ratings yet

- Torque Motor KiaDocument54 pagesTorque Motor KiaIvan Montaluisa67% (3)

- Catalogo Servo Motor AC Driver Policomp ComponentesDocument12 pagesCatalogo Servo Motor AC Driver Policomp ComponentesHI TEC SERVICE BAURUNo ratings yet

- CRF Coppie SerraggioDocument6 pagesCRF Coppie SerraggioFedericoFoxFossaluzzaNo ratings yet

- Pressure DropDocument36 pagesPressure DropdesignselvaNo ratings yet

- Bosch EP test values for diesel fuel injection equipmentDocument3 pagesBosch EP test values for diesel fuel injection equipmentTamer Moustafa100% (1)

- Affordable, Accurate Differential Pressure Transmitters for HVAC and Industrial ApplicationsDocument3 pagesAffordable, Accurate Differential Pressure Transmitters for HVAC and Industrial Applicationsugui81No ratings yet

- 400 Series Regulators for High Flow PurgingDocument3 pages400 Series Regulators for High Flow PurgingmiguesobeNo ratings yet

- 92 trx350+d SpecsDocument17 pages92 trx350+d SpecsJason ConerlyNo ratings yet

- Vco Type B Rev 6 (Ms-02-40)Document2 pagesVco Type B Rev 6 (Ms-02-40)herysyam1980No ratings yet

- Standard torque values for motorcycle fastenersDocument11 pagesStandard torque values for motorcycle fastenersfranco1234No ratings yet

- AAS 920 277C NovaSensor NPC 410 110117 Web PDF 3fo-1315849Document5 pagesAAS 920 277C NovaSensor NPC 410 110117 Web PDF 3fo-1315849ANo ratings yet

- 3105 e 11Document4 pages3105 e 11amarall04No ratings yet

- F-09772 1 StageDocument2 pagesF-09772 1 Stagedanielh776No ratings yet

- (°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )Document16 pages(°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )Elias EliasNo ratings yet

- MPSA56/MMBTA56/PZTA56 PNP General Purpose Amplifier: DescriptionDocument15 pagesMPSA56/MMBTA56/PZTA56 PNP General Purpose Amplifier: DescriptionloebazzzNo ratings yet

- Model: P255-Fully Stainless Steel Construction: Crimped-On-Ring Case Pressure GaugeDocument6 pagesModel: P255-Fully Stainless Steel Construction: Crimped-On-Ring Case Pressure GaugetaibkNo ratings yet

- PLL 1388Document12 pagesPLL 1388Taller PahrNo ratings yet

- S85 Technical Data: Capacitive Liquid Level SwitchDocument1 pageS85 Technical Data: Capacitive Liquid Level SwitchSyed Hamid AliNo ratings yet

- 9900 Series DatasheetDocument3 pages9900 Series DatasheetHans HongNo ratings yet

- Hydraulically Operated 4/2 and 4/3 Directional Control Valve Technical SpecsDocument2 pagesHydraulically Operated 4/2 and 4/3 Directional Control Valve Technical SpecsVito LaudicinaNo ratings yet

- 8.1.1 Design For Bearing On Concrete: ReferencesDocument10 pages8.1.1 Design For Bearing On Concrete: Referencessyed muhammad azeemNo ratings yet

- Lionn Auto SoftwaresDocument2 pagesLionn Auto SoftwaresLIONN ONESOLUTIONNo ratings yet

- Fuel System Specs and DiagnosticsDocument107 pagesFuel System Specs and DiagnosticsDery Lelana SaputraNo ratings yet

- Norgren Sizing Calculations Cylinder Sizing Calculations Force Pressure X Area of Piston (F PA)Document5 pagesNorgren Sizing Calculations Cylinder Sizing Calculations Force Pressure X Area of Piston (F PA)navneetNo ratings yet

- Digital Hour Meters & Counters GuideDocument30 pagesDigital Hour Meters & Counters Guidejeffv65No ratings yet

- BIS Safety Relief ValveDocument1 pageBIS Safety Relief ValveRahimNo ratings yet

- SERVICE DATA AND SPECIFICATIONS FOR AIR COMPRESSOR MODEL F9560W12Document14 pagesSERVICE DATA AND SPECIFICATIONS FOR AIR COMPRESSOR MODEL F9560W12anggieNo ratings yet

- Hermetic Silicon PhototransistorDocument5 pagesHermetic Silicon PhototransistorRahul SushruthNo ratings yet

- Dynisco PT130 PR 140 PT150 PT160 DatasheetDocument2 pagesDynisco PT130 PR 140 PT150 PT160 DatasheetFederico NahNo ratings yet

- High - Low Limiter: R User'S ManualDocument35 pagesHigh - Low Limiter: R User'S ManualMijail David Felix NarvaezNo ratings yet

- TMT401 EyhDocument28 pagesTMT401 EyhAlfredo UriarteNo ratings yet

- Hydraulics HFC-227ea - 04Document3 pagesHydraulics HFC-227ea - 04Mohammed ElmakNo ratings yet

- Compact Hydrostatic Steering UnitsDocument6 pagesCompact Hydrostatic Steering UnitsSam JacobNo ratings yet

- Pressure Reducing - Relieving Valve, Spool Type, Direct Acting, ModularDocument2 pagesPressure Reducing - Relieving Valve, Spool Type, Direct Acting, ModularRicham HamzeNo ratings yet

- 312 RegulatorDocument3 pages312 RegulatorMozzy GuNo ratings yet

- FT MedPressDocument12 pagesFT MedPressElinton SarmientoNo ratings yet

- AddPak Chemical Injector Technical DataDocument4 pagesAddPak Chemical Injector Technical Dataeka pramudia santosoNo ratings yet

- Taj 776811Document8 pagesTaj 776811balajiboss005No ratings yet

- Diaphragm Accumulator - AMW - 13.001 Rev.6Document8 pagesDiaphragm Accumulator - AMW - 13.001 Rev.6srikanthNo ratings yet

- Pump Sizing Calculation: Data FlowrateDocument4 pagesPump Sizing Calculation: Data FlowrateIoana PopescuNo ratings yet

- Veljan Flow Control ValveDocument2 pagesVeljan Flow Control ValveEdukondalu PentapatiNo ratings yet

- ds818Document3 pagesds818mmiranda.inmareproNo ratings yet

- Barksdale Valve 4 WayDocument2 pagesBarksdale Valve 4 WayDwiki RamadhaniNo ratings yet

- Barometric, Gage or Absolute Pressure Ranges: PX2700 SeriesDocument2 pagesBarometric, Gage or Absolute Pressure Ranges: PX2700 SeriesicsNo ratings yet

- A500 Spec SheetDocument2 pagesA500 Spec SheetMikku KattaNo ratings yet

- The Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationFrom EverandThe Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationNo ratings yet

- Pneumatic SymbolsDocument4 pagesPneumatic SymbolsBharathprabhuNo ratings yet

- Catalogo General 1 PDFDocument140 pagesCatalogo General 1 PDFZulemaNo ratings yet

- Seminar On Coupling PDFDocument0 pagesSeminar On Coupling PDFsgupta_615796100% (1)

- Heavy Duty Filtration Products: Filtration Solutions You Can Rely OnDocument39 pagesHeavy Duty Filtration Products: Filtration Solutions You Can Rely Onherysyam1980No ratings yet

- Flexible Coupling For Gas Turbine ApplicationsDocument10 pagesFlexible Coupling For Gas Turbine Applicationsherysyam1980No ratings yet

- Oxygen System Safety (MS-06-13)Document4 pagesOxygen System Safety (MS-06-13)herysyam1980No ratings yet

- J6 Series, MS-02-214 R1Document2 pagesJ6 Series, MS-02-214 R1herysyam1980No ratings yet

- Needle Valves 0,1,18,29&26 Series (ms-01-164) R2Document8 pagesNeedle Valves 0,1,18,29&26 Series (ms-01-164) R2herysyam1980No ratings yet

- Ameriflex High Performance Couplings: Installation InstructionsDocument37 pagesAmeriflex High Performance Couplings: Installation InstructionsHeryanto Syam100% (1)

- Valves GaugeDocument2 pagesValves GaugeAbu Bilal AbdillahNo ratings yet

- Needle Valves D Series (MS-01-42) Rev 3Document4 pagesNeedle Valves D Series (MS-01-42) Rev 3herysyam1980No ratings yet

- Needle Valves GU Series (MS-02-312-E) R1Document6 pagesNeedle Valves GU Series (MS-02-312-E) R1herysyam1980No ratings yet

- Flow Valves XS Series (MS-01-110) Rev 6Document4 pagesFlow Valves XS Series (MS-01-110) Rev 6herysyam1980No ratings yet

- Meetering Valves S, M, L &31 Series (MS-01-142) R3Document8 pagesMeetering Valves S, M, L &31 Series (MS-01-142) R3herysyam1980No ratings yet

- Blowdown Valves 6DB Series Rev 2 (MS-02-118)Document2 pagesBlowdown Valves 6DB Series Rev 2 (MS-02-118)herysyam1980No ratings yet

- Remote Mount Manifold (MS 02 330)Document2 pagesRemote Mount Manifold (MS 02 330)herysyam1980No ratings yet

- High Pressure (MS-02-160) R0Document6 pagesHigh Pressure (MS-02-160) R0herysyam1980No ratings yet

- Chek Valves C, CA, CH, CP & Cpa Series (Ms-01-176) r0Document14 pagesChek Valves C, CA, CH, CP & Cpa Series (Ms-01-176) r0herysyam1980No ratings yet

- Relief Maintenance Kits (MS-02-116-SCS) R1Document1 pageRelief Maintenance Kits (MS-02-116-SCS) R1herysyam1980No ratings yet

- Chek Valves CW Series (MS-02-89) R3Document2 pagesChek Valves CW Series (MS-02-89) R3herysyam1980No ratings yet

- Relief Valves R Series (MS-01-141) Rev 7Document8 pagesRelief Valves R Series (MS-01-141) Rev 7herysyam1980No ratings yet

- Afs Ball Valve Product CatalogDocument8 pagesAfs Ball Valve Product Catalogherysyam1980No ratings yet

- Maintenance Kits Rev3 (MS 02 115 E)Document2 pagesMaintenance Kits Rev3 (MS 02 115 E)herysyam1980No ratings yet

- Stainless Steel - Titanium Alloyed TubingDocument2 pagesStainless Steel - Titanium Alloyed Tubingtoxa0707No ratings yet

- Bellows Sealed Matering Valves BM Series (Ms-01-23) R3Document4 pagesBellows Sealed Matering Valves BM Series (Ms-01-23) R3herysyam1980No ratings yet

- Check Valves 50 Series (MS-01-98) R4Document2 pagesCheck Valves 50 Series (MS-01-98) R4herysyam1980No ratings yet

- Instalasin Jacketed Tubing (MS-CRD-ITUB)Document7 pagesInstalasin Jacketed Tubing (MS-CRD-ITUB)herysyam1980No ratings yet

- Afs Ball Valve Release NoteDocument2 pagesAfs Ball Valve Release Noteherysyam1980No ratings yet

- Stainless Steel Tubing Sizes and Specifications from SwagelokDocument2 pagesStainless Steel Tubing Sizes and Specifications from SwagelokmasimeriseNo ratings yet

- Jacketed Tubing (MS-02-188) R1Document6 pagesJacketed Tubing (MS-02-188) R1herysyam1980No ratings yet

- Albert Einstein - Wikipedia, The Free EncyclopediaDocument34 pagesAlbert Einstein - Wikipedia, The Free EncyclopediaalhanunNo ratings yet

- Robotics Process AutomationDocument21 pagesRobotics Process Automationbhaskarkiran.pNo ratings yet

- (Culture and History of The Ancient Near East 65) Leslie Anne Warden - Pottery and Economy in Old Kingdom Egypt-Brill Academic Publishers (2014)Document343 pages(Culture and History of The Ancient Near East 65) Leslie Anne Warden - Pottery and Economy in Old Kingdom Egypt-Brill Academic Publishers (2014)HugoBotello100% (1)

- Maam Approve Na Pls HuhuDocument28 pagesMaam Approve Na Pls HuhuErica Joy Escopete100% (1)

- Multicolor Fluorochrome Laser Chart PDFDocument1 pageMulticolor Fluorochrome Laser Chart PDFSathish KumarNo ratings yet

- Julia Henzler - Resume 2 27Document1 pageJulia Henzler - Resume 2 27api-491391730No ratings yet

- Ffective Riting Kills: Training & Discussion OnDocument37 pagesFfective Riting Kills: Training & Discussion OnKasi ReddyNo ratings yet

- Keto Food List for BodybuildingDocument8 pagesKeto Food List for Bodybuildingharris81No ratings yet

- DS-RTCD905 H6W4Document2 pagesDS-RTCD905 H6W4david fonsecaNo ratings yet

- AAPD Reference Manual - Pediatric Dentistry 2010-2011Document336 pagesAAPD Reference Manual - Pediatric Dentistry 2010-2011Tiara100% (1)

- COSMETOLOGY-9 Q1 W3 Mod2Document15 pagesCOSMETOLOGY-9 Q1 W3 Mod2Christian Elliot DuatinNo ratings yet

- Results and DiscussionsDocument13 pagesResults and DiscussionsEdpher Leo SindolNo ratings yet

- Haloalkanes and Haloarenes Notes GoodDocument21 pagesHaloalkanes and Haloarenes Notes GoodAnitesh DharamNo ratings yet

- Lab Practice # 01 An Introduction To MatlabDocument10 pagesLab Practice # 01 An Introduction To MatlabGhulam Abbas LashariNo ratings yet

- Integrated Marketing Communication PlanDocument5 pagesIntegrated Marketing Communication Planprojectwork185No ratings yet

- The Greatest Showman PDFDocument22 pagesThe Greatest Showman PDFMJ RecordNo ratings yet

- St. Augustine School of Nursing: Republic of The Philippines Department of Education SASN - Las PiñasDocument2 pagesSt. Augustine School of Nursing: Republic of The Philippines Department of Education SASN - Las PiñasCarl Joseph MasujerNo ratings yet

- Coaching, Mentoring & OnboardingDocument43 pagesCoaching, Mentoring & OnboardingosvehNo ratings yet

- Actor analysis explores decision-making in environmental governanceDocument48 pagesActor analysis explores decision-making in environmental governancerizkyNo ratings yet

- DP-10/DP-10T/DP-11/DP-15/DP-18 Digital Ultrasonic Diagnostic Imaging SystemDocument213 pagesDP-10/DP-10T/DP-11/DP-15/DP-18 Digital Ultrasonic Diagnostic Imaging SystemDaniel JuarezNo ratings yet

- Chapter 9: Operating SystemsDocument166 pagesChapter 9: Operating SystemsGazzzeeNo ratings yet

- Sapamine CSN Textile Softener: Technical Data SheetDocument5 pagesSapamine CSN Textile Softener: Technical Data SheetsaskoNo ratings yet

- Java syntax and data types tutorialDocument3 pagesJava syntax and data types tutorialpeter chan100% (1)

- T2-1 MS PDFDocument27 pagesT2-1 MS PDFManav NairNo ratings yet

- Kelley DavisDocument3 pagesKelley Davisapi-626701108No ratings yet

- Berkowitz Et Al (2010) - Skills For Psychological Recovery - Field Operations GuideDocument154 pagesBerkowitz Et Al (2010) - Skills For Psychological Recovery - Field Operations GuideRita CamiloNo ratings yet

- Re15209 03-95Document8 pagesRe15209 03-95Kaushik GhoshNo ratings yet

- Acer Aspire 4535 (Compal LA-4921P) PDFDocument57 pagesAcer Aspire 4535 (Compal LA-4921P) PDFMustafa AkanNo ratings yet

- Agile Spotify - Team - HomeworkDocument8 pagesAgile Spotify - Team - Homeworksp76rjm7dhNo ratings yet

- Knowledge Paper XDocument28 pagesKnowledge Paper XLaurențiu Cătălin NeagoeNo ratings yet