Professional Documents

Culture Documents

A320 CBT Fuel System: Table of Content

Uploaded by

Aman VermaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A320 CBT Fuel System: Table of Content

Uploaded by

Aman VermaCopyright:

Available Formats

Ref: C-OL-AC4012ING

A320 CBT Page: 1/8

FUEL SYSTEM Rev: 1

Date: 22.01.2019

TABLE OF CONTENT

LEGAL CAUTION ..........................................................................................................................................................2

FUEL SYSTEM .................................................................................................................................................................2

ENGINE FUEL FEED ..............................................................................................................................................................2

INTERTANK TRANSFER VALVES ..........................................................................................................................................2

SUCTION FEED .....................................................................................................................................................................2

APU FUEL FEED ....................................................................................................................................................................2

FUEL RECIRCULATION SYSTEM ..........................................................................................................................................3

FUEL SYSTEM CONTROLS AND INDICATIONS ..................................................................................................................3

REFUELING AND DEFUELING .............................................................................................................................................4

FUEL QUANTITY INDICATION AND FUEL LEVEL SENSING ...............................................................................................4

FUEL TANK INERTING SYSTEM .............................................................................................................................................5

ECAM FUEL PAGE ...............................................................................................................................................................5

WARNING AND CAUTIONS ...............................................................................................................................................6

SUMMARY OF WARNINGS AND CAUTIONS ..............................................................................................................8

Copyrights © 2007 by Flyco Training Solutions

Ref: C-OL-AC4012ING

A320 CBT Page: 2/8

FUEL SYSTEM Rev: 1

Date: 22.01.2019

LEGAL CAUTION

The material contained in this training program is based on the information obtained from

current national, international and company regulations and it is to be used for training

purposes only. At the time of designing this program contained then current information.

In the event of conflict between data provided herein and that in publications issued by

the authority, the authority shall take precedence.

2

FUEL SYSTEM

ENGINE FUEL FEED

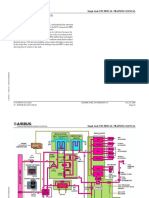

The engine fuel feed system uses these primary components to supply fuel to the engines:

the tank pumps, the inter-tank transfer valves crossfeed valve, the engine low pressure

fuel valves, and suction feed.

3

INTERTANK TRANSFER VALVES

Two inter-tank transfer valves are installed in each wing to allow fuel transfer from the

outer to the inner wing tank.

4

When the inner tank fuel quantity reduces to a low fuel level, that is about 750 kilograms,

the transfer valves automatically open and let the fuel be transferred from the outer to

inner tanks by gravity.

5

If at least one transfer valve is open in one wing tank, the OUTER TANK FUEL TRANSFER

message appears on the MEMO display

6

Once open, the transfer valves remain open until they automatically close at the next

refueling operation.

7

When an engine fire pushbutton is pushed or the engine master switch is set to OFF, the

respective low pressure valve closes to stop fuel flow to the engine.

8

SUCTION FEED

The engine fuel feed also incorporates suction feeds. When the inner tank pumps fail, the

suction feed allows an engine to be fed by gravity from its corresponding inner tank

bypassing the tank pumps.

9

The center tank is not fitted with a suction line. Thus, gravity feeding is not possible from

the center tank.

10

APU FUEL FEED

The APU fuel feed system supplies fuel to the APU from the left side of the fuel manifold

as long as the tank pumps are operative.

Copyrights © 2007 by Flyco Training Solutions

Ref: C-OL-AC4012ING

A320 CBT Page: 3/8

FUEL SYSTEM Rev: 1

Date: 22.01.2019

11

When fuel feed pressure is low due to loss of tank pumps or loss of normal AC electrical

supply, a special fuel pump supplies fuel for an APU startup.

12

FUEL RECIRCULATION SYSTEM

Some of the fuel supplied to the engine burner is divided to the IDG oil cooler which heats

the fuel and cools the oil. This ensures IDG cooling when the engine runs at low speed or

the IDG operates on high electrical load.

13

The heated fuel then goes to the fuel return valve which is controlled by the FADEC. In

the return valve, the heated fuel is mixed with the cold fuel from the low pressure pump

before it is directed to the outer wing tank.

14

During the fuel recirculation, if the outer tank is already full, the fuel overflows to the inner

tank through a spill pipe.

15

If the center wing tank is supplying the engine, the fuel recirculation may cause the wing

tanks to overfill. To prevent this, the center tank pumps should be stopped so that wing

tanks feed the engine.

16

If the fuel system is operating in automatic mode, the center pump is automatically

turned off when the inner tank is full. The wing tank pumps supply the engine until

approximately 500 kg of fuel is used. Then the center tank pump resumes operation.

17

If the fuel system is in the manual mode, the center pump does not turn off automatically

when the inner tank is full. Therefore, you must manually switch the center tank off to

prevent overflow of the wing tanks on ground.

18

FUEL SYSTEM CONTROLS AND INDICATIONS

The fuel panel is located on the overhead panel.

19

When the output pressure of the wing tank pump is low, amber FAULT light illuminates on

the respective wing tank pump switch. The FAULT light is inhibited when the switch is in

the OFF position

20

When the mode selector switch lights are extinguished, the automatic mode is selected

and control of center tank pumps is automatic.

21

With the mode selector switch in the AUTO position, if the slats are retracted, the center

tank pumps run automatically before or after the engine start sequence.

22

At engine start, regardless of slat position, the center tank pumps run for two minutes to

verify operation.

Copyrights © 2007 by Flyco Training Solutions

Ref: C-OL-AC4012ING

A320 CBT Page: 4/8

FUEL SYSTEM Rev: 1

Date: 22.01.2019

23

Five minutes after the center tank low level is reached, the pumps turn off automatically.

25

When center tank contains more than 250 kilograms of fuel and the left or right wing tank

contains less than 5000 kilograms, amber the FAULT light illuminates on the mode selector

switch.

27

When at least one center tank pump is energized, the CENTER TANK FEEDING message

appears on MEMO display.

28

With the mode selector switch in the AUTO mode, until approximately 500 kilograms of

the fuel has been used in an inner tank, the associated center tank pump stops and the

OFF light remains illuminated on the pump switch.

29

The crossfeed switch controls and indicates the crossfeed valve position.

32

When the valve is fully open, the OPEN light illuminates green on the switch.

33

REFUELING AND DEFUELING

The aircraft fueling and defueling system consists of one or two refueling couplings under

each wing.

34

Fuel from the refuel coupling goes into refueling line. Then it flows through the refuel

valves into the fuel tanks.

35

Refueling starts with the outer tanks. When an outer tank is full, the fuel overflows into the

inner tank through a spill pipe

36

If the fuel quantity selected from the refuel panel exceeds the wing tank capacity, the

center tank is refueled simultaneously.

37

A defuel transfer valve allows the tank pumps to transfer fuel from one tank to another. It

is also used for defueling through the refuel coupling.

38

When the door of the refuel control panel is open, the REFUELING message appears on

the MEMO display.

39

The refuel valves selectors control the operation of respective refuel valve.

40

FUEL QUANTITY INDICATION AND FUEL LEVEL SENSING

Fuel quantity indication computer incorporates two subsystems: the Fuel Quantity

Indication System and the Fuel Level Sensing Control Units.

41

Copyrights © 2007 by Flyco Training Solutions

Ref: C-OL-AC4012ING

A320 CBT Page: 5/8

FUEL SYSTEM Rev: 1

Date: 22.01.2019

The fuel quantity indication system supplies all fuel information, including total fuel mass,

and quantity and temperature of fuel in each individual tank to the ECAM and controls

automatic refueling.

42

Fuel probes measure the fuel level and fuel temperature in each tank.

43

The fuel quantity indication system also receives aircraft attitude data to improve the

accuracy of the fuel quantity computation

44

The fuel level sensing control unit produces fuel level and fuel temperature signals which

are used to operate the appropriate valves for refueling, defueling, the center tank-to-

wing tank fuel transfer system, and control the IDG cooling recirculation system.

45

The fuel level sensing is independent of fuel quantity indicating system.

46

FUEL TANK INERTING SYSTEM

The purpose of fuel tank inerting system is to provide protection against fuel tank fire and

explosion.

47

The system is used only for the center tank which has a high flammability exposure.

48

The fuel tank inerting system reduces the flammability by using oxygen depleted air to

displace the ambient air in the center tank.

49

ECAM FUEL PAGE

The fuel used indication displays in green and automatically resets upon engine start on

the ground.

50

When the fuel indicating system is not accurate, amber lines appears over the last two

digits.

51

When the inner tank level is at low level state, the fuel on board indication is half-boxed

in amber, if both the center tank pumps are: failed or switched OFF, or both transfer

valves in either wing fail to open.

52

When the difference between the fuel quantities in the two wings is greater than 1500 kg,

the indications of the wing inner and outer tanks, with the highest fuel level pulses in

green. Now let’s look at a degraded fuel indications.

53

On the upper ECAM display, if you see the fuel on board indication with two dashes over

the last two digits, it means that the fuel quantity indication is operating in a degraded

mode. In this case, you must call the FUEL page on the ECAM lower display to determine

which tank is affected.

54

Copyrights © 2007 by Flyco Training Solutions

Ref: C-OL-AC4012ING

A320 CBT Page: 6/8

FUEL SYSTEM Rev: 1

Date: 22.01.2019

The fuel temperature is displayed in green when the associated temperature sensor is

wet.

55

If a high or low limit is exceeded, the associated indication becomes amber.

56

WARNING AND CAUTIONS

While operating, if a center tank pump output pressure drops to less than normal, both

master caution lights come on, a single chime sounds, the ECAM shows the CENTER TANK

PUMP LOW PRESSURE caution message with the affected pump number and the FUEL

page appears on the lower display unit. In addition to the central system cautions, the

amber FAULT light illuminates on the associated center tank pump switch.

57

When you receive a center tank pump low pressure caution and if there is no fuel leak,

set the crossfeed valve switch to ON. Turn off the affected center tank pump. To prevent

a possible fuel imbalance, you may turn off crossfeed valve when the center tank is

empty. If a fuel imbalance occurs, apply the fuel imbalance procedure as required.

58

If low output pressure is detected in both the center tank pumps, both master caution

lights come on, a single chime sounds, the ECAM shows the CENTER TANK PUMPS LOW

PRESSURE caution message and the FUEL page appears on the lower display unit. In

addition to the central system cautions, the amber FAULT lights illuminate on both center

tank pump switches.

59

When both center tank pump pressures are low, set the mode selector switch to manual.

Turn both center tank pumps off. The center tank fuel is not usable for the rest of the

flight.

60

When the left or right wing tank pumps low pressure caution is generated with the center

tank empty, ensure that no fuel leak exists. If you are above the flight level 150, select the

crossfeed valve to ON. Set the engine mode selector to IGNITION to start continuous

relight. This provides protection against a possible flame-out due to fuel supply surging.

Switch off the affected wing tank pumps.

61

Note that with both wing tank pumps off, only gravity feeding is possible from the

affected wing tank. Thus apply the gravity fuel procedure if the fuel is required from this

wing tank.

62

The AUTO FEED FAULT caution is generated for two cases: a large difference in fuel

quantity between the center tank and the wing tanks on either side or an

uncommanded operation of the center tank pumps.

63

If the center tank contains more than 250 kilograms of fuel while the left or right wing tank

has less than 5000 kilograms, the AUTO FEED FAULT caution activates. Both master

caution lights come on, a single chime sounds, the ECAM displays the AUTO FEED FAULT

Copyrights © 2007 by Flyco Training Solutions

Ref: C-OL-AC4012ING

A320 CBT Page: 7/8

FUEL SYSTEM Rev: 1

Date: 22.01.2019

caution message and the FUEL page appears on the lower display unit. An amber FAULT

light illuminates on the mode select switch.

64

Set the mode select switch to manual. The center tank pumps will run and feed the

engines. For aircraft equipped with CFM engines only: On the ground, if the center tank

is not empty at slat extension, the center tank pumps should be switched OFF manually

to prevent a possible wing tank overflow due to the IDG fuel recirculation.

65

If the center tank pumps do not stop after slat extension or the center tank low level is

reached, the auto feed fault caution activates again. Both the master caution lights

come on, a single chime sounds, the ECAM shows the AUTO FEED FAULT caution message

and the FUEL page is displayed on the lower display unit. Switch off the center tank

pumps to clear the caution.

66

When a low level is detected in both wing inner tanks with the remaining flight time is

about 30 minutes, both master caution lights come on, a single chime sounds, the ECAM

indicates the left and right wing tanks low level caution message and the FUEL page is

shown on the lower display unit.

67

With the center tank not empty, set the mode select switch to MANUAL. Ensure all pump

switches are ON and the cross feed valve switch is off.

68

When the fuel temperature in the outer or inner tank exceeds the high limit, both master

caution lights come on and a single chime sounds.

69

If the fuel temperature in left or right outer tank is above 55 °C on ground or above 60 °C

in flight, the ECAM shows the OUTER TANK HIGH TEMPERATURE caution message for the

affected tank.

70

Likewise, when the fuel temperature in an inner tank is above 45 °C on ground or above

54 °C in flight, the left or right INNER TANK HIGH TEMPERATURE caution message shows on

the ECAM upper display. In both cases, the FUEL page is called on the lower display unit.

71

When a fuel high temperature caution shows on the ECAM, wait 2 minutes while the fuel

temperature measurement is updated. This is required to ensure that the caution is not

a false indication due to radio wave interference from the communication equipment.

72

After 2 minutes, if the ECAM still shows the caution, it is usually due to high temperature

of fuel returning from the IDG cooling recirculation system

73

Turn off the galley to reduce the electrical load on the IDG, which in turn, will reduce the

fuel temperature used for the cooling.

74

Copyrights © 2007 by Flyco Training Solutions

Ref: C-OL-AC4012ING

A320 CBT Page: 8/8

FUEL SYSTEM Rev: 1

Date: 22.01.2019

If you are on the ground, and the fuel temperature reaches 60° C in outer tank or 54° C

in inner tank, delay the takeoff. Turn off the engine master switch on the affected side.

75

If you are in the air, adjust the thrust lever to increase fuel flow on the affected side. This

helps decrease the temperature of the fuel returning to the outer tank.

76

In case, the fuel temperature reaches 65° C in outer tank or 57° C in inner tank and if the

opposite generator is available, turn off the IDG on the affected side. You may also use

APU generator to disconnect the affected IDG.

77

Likewise, when the APU low pressure fuel valve is not in the commanded position, both

master caution lights come on, a single chime sounds, the ECAM upper display shows

the APU low pressure valve fault caution message and the FUEL page appears in the

lower display unit. No crew action is required for this caution as well.

78

SUMMARY OF WARNINGS AND CAUTIONS

This part summarizes warnings and cautions associated with the system.

End of course.

Copyrights © 2007 by Flyco Training Solutions

You might also like

- 1.troubleshoot Engine Crank But Cant StartDocument3 pages1.troubleshoot Engine Crank But Cant StartsyahrilNo ratings yet

- Heui Fuel System c9 EngineDocument25 pagesHeui Fuel System c9 Enginebabaisandip91% (53)

- A320 Neo Leap 1a Ata - 28Document43 pagesA320 Neo Leap 1a Ata - 28basid911No ratings yet

- c15 and c18 Engines For Caterpillar Built Engines Fuel SystemDocument10 pagesc15 and c18 Engines For Caterpillar Built Engines Fuel SystemDiegoD'AmbrosioNo ratings yet

- Cat C 6.4 Fuel SystemDocument13 pagesCat C 6.4 Fuel Systemali83% (6)

- Bosch K-Jet (CIS)Document14 pagesBosch K-Jet (CIS)gjm126No ratings yet

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)No ratings yet

- Vol. 1 Auxiliary Power UnitDocument22 pagesVol. 1 Auxiliary Power UnitRicardo GarciaNo ratings yet

- PMDG 737Ngx Groundwork: Fuel System Lesson IntroductionDocument9 pagesPMDG 737Ngx Groundwork: Fuel System Lesson IntroductionJoãoPaulodeAlmeidaNo ratings yet

- Tr7-8fi ManualDocument82 pagesTr7-8fi ManualClint CooperNo ratings yet

- A319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 28 Fuel SystemDocument354 pagesA319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 28 Fuel SystemAhmedHamdyElsaidy100% (7)

- Naval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsFrom EverandNaval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsNo ratings yet

- Mayo College: Dining Hall at AjmerDocument79 pagesMayo College: Dining Hall at AjmerFaquruddinNo ratings yet

- MathematicsDocument10 pagesMathematicsAman Verma100% (1)

- VW Transporter T4 Workshop Manual Diesel 2000-2004From EverandVW Transporter T4 Workshop Manual Diesel 2000-2004Rating: 5 out of 5 stars5/5 (5)

- 28 FUEL (Metric Units)Document324 pages28 FUEL (Metric Units)fourj747100% (3)

- Ata 73Document61 pagesAta 73Jorge Ignacio Lara CeballosNo ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Fuel System: Systems OperationDocument7 pagesFuel System: Systems OperationbejoythomasNo ratings yet

- AW139 Fuel System ChapterDocument72 pagesAW139 Fuel System ChapterŞükrü ÇarkçiNo ratings yet

- SsangYong Action Service ManualDocument2,172 pagesSsangYong Action Service ManualHector Garin91% (103)

- Water Standard Specification Index As On Dec 2015Document10 pagesWater Standard Specification Index As On Dec 2015afp15060% (1)

- Falcon 7X EnginesDocument45 pagesFalcon 7X EnginesDavidMontoya100% (2)

- C-18 Caterpillar Engine For PM200 Cold Planer P1M00001-UP (MACHINE) POWERED BY C-18 Engine (KEBP0335 - 04) - Product StructureDocument4 pagesC-18 Caterpillar Engine For PM200 Cold Planer P1M00001-UP (MACHINE) POWERED BY C-18 Engine (KEBP0335 - 04) - Product Structurebasem elhosanyNo ratings yet

- Stoke's LawDocument15 pagesStoke's LawPratik YadavNo ratings yet

- A320 - ATA71 To 80-CFM56-5 - B1-B2 - Iss-03 - May 2016 PDFDocument388 pagesA320 - ATA71 To 80-CFM56-5 - B1-B2 - Iss-03 - May 2016 PDFKamalVirk100% (3)

- EMBRAER 135/145: For Training Purposes OnlyDocument31 pagesEMBRAER 135/145: For Training Purposes OnlyIludiran KolaNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- B NG-FuelDocument0 pagesB NG-FuelManish MishraNo ratings yet

- Fuel - APU - Engine TrainingDocument288 pagesFuel - APU - Engine TrainingBianco Yep100% (2)

- TFE 731 Chap 73Document34 pagesTFE 731 Chap 73Egor85100% (2)

- Ata 28 FuelDocument210 pagesAta 28 FuelAminur PahlawanNo ratings yet

- Interglobe Aviation LTD: Igo/Ops/Form/Trg/16 Page 1 of 8 Effective: 01-APRIL-2018Document8 pagesInterglobe Aviation LTD: Igo/Ops/Form/Trg/16 Page 1 of 8 Effective: 01-APRIL-2018Aman VermaNo ratings yet

- Commercial ATP GuideDocument23 pagesCommercial ATP GuidejpzemogNo ratings yet

- MRTT 3Document4 pagesMRTT 3Jeremy TohNo ratings yet

- Boeing 767 300 FuelDocument14 pagesBoeing 767 300 FuelWorawat Wongratanamajcha100% (1)

- General-Purpose Steam Turbines (Amendments/Supplements To Api 611)Document27 pagesGeneral-Purpose Steam Turbines (Amendments/Supplements To Api 611)BiswasNo ratings yet

- Fuel System: Smcs - 1250Document25 pagesFuel System: Smcs - 1250GiovaniBalzaniNo ratings yet

- AEM Series 2 EMS Setup Notes - 02v02 Firmware UpdatesDocument24 pagesAEM Series 2 EMS Setup Notes - 02v02 Firmware UpdatesAmaury RichardNo ratings yet

- CH 3 Gas Refrigeration CycleDocument20 pagesCH 3 Gas Refrigeration CycleMeleseNo ratings yet

- A320 CBT Navigation: Table of ContentDocument40 pagesA320 CBT Navigation: Table of ContentAman VermaNo ratings yet

- Ferhat ErdalDocument22 pagesFerhat ErdalsaifoaNo ratings yet

- CFM56 Fuel System Training ManualDocument184 pagesCFM56 Fuel System Training ManualCassiano CapellassiNo ratings yet

- Power Plant (CFM56)Document21 pagesPower Plant (CFM56)Jefferson CuNo ratings yet

- Aman Verma Bank StatementDocument4 pagesAman Verma Bank StatementAman VermaNo ratings yet

- Aman Verma Bank StatementDocument4 pagesAman Verma Bank StatementAman VermaNo ratings yet

- PP10CC 00 3mav MR Abc 001Document9 pagesPP10CC 00 3mav MR Abc 001anbesivam87No ratings yet

- Jeep+2.5 TD PDFDocument38 pagesJeep+2.5 TD PDFMiguel ChaconNo ratings yet

- Dash8 200 300 Fuel PDFDocument13 pagesDash8 200 300 Fuel PDFCarina Ramo LakaNo ratings yet

- Generator Fuel System GuideDocument4 pagesGenerator Fuel System GuidebejoythomasNo ratings yet

- vnx.su transit 1976-1986 Часть2 PDFDocument543 pagesvnx.su transit 1976-1986 Часть2 PDFscodavnxNo ratings yet

- System Description Section 20: 737 Flight Crew Operations ManualDocument5 pagesSystem Description Section 20: 737 Flight Crew Operations ManualWilliam XavierNo ratings yet

- Fire ProtectionDocument12 pagesFire ProtectionJefferson CuNo ratings yet

- Fuel Return ValveDocument2 pagesFuel Return ValvePédro GONZALEZNo ratings yet

- Fuel System JTEC ChryslerDocument56 pagesFuel System JTEC ChryslerkeiwerkasNo ratings yet

- ML B 300 b350mm609Document5 pagesML B 300 b350mm609Alejandro BenavidesNo ratings yet

- 28.26.00006 07-JUL-2023 05-SEP-2023 Open A318, A319, A320, A321 28-00 UpdateDocument17 pages28.26.00006 07-JUL-2023 05-SEP-2023 Open A318, A319, A320, A321 28-00 UpdateYaser SahiboleNo ratings yet

- Power Is Intermittently Low or Power Cutout Is Intermittent 320DDocument4 pagesPower Is Intermittently Low or Power Cutout Is Intermittent 320DfalahNo ratings yet

- Aircraft Maintenance Manual: Print Date: 2021-03-25Document8 pagesAircraft Maintenance Manual: Print Date: 2021-03-25CHIMONo ratings yet

- Перекачка и заправка топливомDocument28 pagesПерекачка и заправка топливом6rg2x2y8ssNo ratings yet

- Zaude ModrnDocument47 pagesZaude ModrnZewdeneh AsemieNo ratings yet

- 73-00Document4 pages73-00Sergio LópezNo ratings yet

- GloriasDocument4 pagesGloriastimNo ratings yet

- Ec480d Fuel SystemDocument6 pagesEc480d Fuel SystemVinod SekharNo ratings yet

- Gic 2022 - 6Document5 pagesGic 2022 - 6Prajwal PatidarNo ratings yet

- Breaks and PneumaticsDocument20 pagesBreaks and PneumaticsRodrigo Hernández AbarzúaNo ratings yet

- 240 L4-2.3L Sohc Vin 88 B230F (1987) PDFDocument121 pages240 L4-2.3L Sohc Vin 88 B230F (1987) PDFbeep boopNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- LetterDocument1 pageLetterAman VermaNo ratings yet

- Private Car Package Policy: Certificate of Insurance Cum Policy ScheduleDocument2 pagesPrivate Car Package Policy: Certificate of Insurance Cum Policy ScheduleAman VermaNo ratings yet

- Salient Features GMC 2020-21 PDFDocument4 pagesSalient Features GMC 2020-21 PDFAman VermaNo ratings yet

- Salient Features GMC 2020-21 PDFDocument4 pagesSalient Features GMC 2020-21 PDFAman VermaNo ratings yet

- Phill RTDocument2 pagesPhill RTAman VermaNo ratings yet

- 2010-2011 - Annexuare - To - Directors - Report PDFDocument6 pages2010-2011 - Annexuare - To - Directors - Report PDFAman VermaNo ratings yet

- IGA Employee RecordsDocument20 pagesIGA Employee RecordsAman VermaNo ratings yet

- EnglishDocument9 pagesEnglishAman VermaNo ratings yet

- Log Book Last 3 PagesDocument7 pagesLog Book Last 3 PagesAman VermaNo ratings yet

- 2 3rd MasterDocument1 page2 3rd MasterAman VermaNo ratings yet

- Guidance Note On TDS On Property, Payment Procedure & Points To RememberDocument6 pagesGuidance Note On TDS On Property, Payment Procedure & Points To RememberAman VermaNo ratings yet

- Indigo CHP Approval RequirementsDocument8 pagesIndigo CHP Approval RequirementsAman VermaNo ratings yet

- 1421843580461Document9 pages1421843580461Aman VermaNo ratings yet

- 1407041121026Document2 pages1407041121026Aman VermaNo ratings yet

- IGA3976Document1 pageIGA3976Aman VermaNo ratings yet

- How to Orchestrate Music and SituationsDocument1 pageHow to Orchestrate Music and SituationsAman VermaNo ratings yet

- BecomingDocument3 pagesBecomingAman VermaNo ratings yet

- PhysicsDocument9 pagesPhysicsAman VermaNo ratings yet

- Private & Confidential 2 Sept 2016: Letter of Undertaking For Sim Assessment TATA SIA Airlines LTDDocument1 pagePrivate & Confidential 2 Sept 2016: Letter of Undertaking For Sim Assessment TATA SIA Airlines LTDAman VermaNo ratings yet

- JO967 - 2015 11 02 VnaDocument13 pagesJO967 - 2015 11 02 VnaAman VermaNo ratings yet

- 1421843580461Document9 pages1421843580461Aman VermaNo ratings yet

- Revised - JuneDocument9 pagesRevised - JuneAman VermaNo ratings yet

- 1428566869356Document8 pages1428566869356Aman VermaNo ratings yet

- Log Book Last 3 PagesDocument7 pagesLog Book Last 3 PagesAman VermaNo ratings yet

- VXA 700 Owner ManualDocument68 pagesVXA 700 Owner ManualjohnNo ratings yet

- CZ-RTC4 - Service ManualDocument68 pagesCZ-RTC4 - Service ManualAnonymous 31Airw50% (2)

- Objective and Scope and Importance of Mineral Beneficiation With Special Reference To IndiaDocument4 pagesObjective and Scope and Importance of Mineral Beneficiation With Special Reference To IndiaVidya Sagar100% (1)

- The Design, Development and Future of Electric Vehicle: Prof. Eric ChengDocument18 pagesThe Design, Development and Future of Electric Vehicle: Prof. Eric ChengDeepak ChaurasiaNo ratings yet

- Master Plan 2021Document172 pagesMaster Plan 2021Rajnish MishraNo ratings yet

- National Science Olympiad: SyllabusDocument4 pagesNational Science Olympiad: SyllabusawaninderNo ratings yet

- Amcor 2016Document69 pagesAmcor 2016Romulo AlvesNo ratings yet

- DC Components Co., LTD.: Rectifier SpecialistsDocument3 pagesDC Components Co., LTD.: Rectifier SpecialistsPICVIONo ratings yet

- 1Document26 pages1Maribel Bihag AlcantaraNo ratings yet

- ECU Mount-On-Engine Vibration StudyDocument6 pagesECU Mount-On-Engine Vibration StudyElroy LeeNo ratings yet

- RAIS PDA AppDocument8 pagesRAIS PDA Appzaw lin ooNo ratings yet

- Chemical Reactions: Physical Vs Chemical ChangesDocument7 pagesChemical Reactions: Physical Vs Chemical ChangesIfra HassanNo ratings yet

- 2013 Renault ZOE PresskitDocument34 pages2013 Renault ZOE PresskitDidelisNo ratings yet

- U3 Oxidation and Reduction PPT WatermarkDocument45 pagesU3 Oxidation and Reduction PPT Watermarkapi-125934329No ratings yet

- 018 10Document3 pages018 10ilkerkozturkNo ratings yet

- Table 4E4A - Current Carrying Capacity in AmpereDocument1 pageTable 4E4A - Current Carrying Capacity in AmperesalvuNo ratings yet

- Ptmail - m1021 - Ss - Ev Ultimate Market Intelligence ReportDocument23 pagesPtmail - m1021 - Ss - Ev Ultimate Market Intelligence ReportPIYUSH GOPALNo ratings yet

- IGBC Annual Review 2011-2012Document28 pagesIGBC Annual Review 2011-2012Sourav SenNo ratings yet

- Rectification ProcessDocument5 pagesRectification ProcessDilnaz TegispayNo ratings yet

- rt8205b Datasheet-06Document28 pagesrt8205b Datasheet-06André Hipnotista100% (1)

- India's Former President APJ Abdul Kalam on Leadership, Knowledge and Managing FailureDocument14 pagesIndia's Former President APJ Abdul Kalam on Leadership, Knowledge and Managing FailureHarsh TiwariNo ratings yet

- DPDC MaintenanceDocument5 pagesDPDC MaintenanceArfana Akter BanogirNo ratings yet

- JCM Hybrid Controller User ManualDocument13 pagesJCM Hybrid Controller User ManualMtvc LbNo ratings yet

- High Efficiency Battery Charger Using DC-DC ConverterDocument4 pagesHigh Efficiency Battery Charger Using DC-DC ConvertersanilNo ratings yet