Professional Documents

Culture Documents

CAMPUS® Datasheet: CELANEX LW2333R - PBT - (GB+GF) 50 Ticona

Uploaded by

Angerer0 ratings0% found this document useful (0 votes)

67 views2 pagesOriginal Title

CELANEX PBT (GB+GF)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

67 views2 pagesCAMPUS® Datasheet: CELANEX LW2333R - PBT - (GB+GF) 50 Ticona

Uploaded by

AngererCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

CAMPUS® Datasheet

CELANEX LW2333R - PBT-(GB+GF)50

Ticona

Rheological properties Value Unit Test Standard

Molding shrinkage, parallel 0.1 % ISO 294-4, 2577

Molding shrinkage, normal 0.4 % ISO 294-4, 2577

Mechanical properties Value Unit Test Standard

Tensile Modulus 4100 MPa ISO 527-1/-2

Stress at break 40 MPa ISO 527-1/-2

Strain at break 3 % ISO 527-1/-2

Charpy impact strength, +23°C 22 kJ/m² ISO 179/1eU

Charpy impact strength, -30°C 54 kJ/m² ISO 179/1eU

Charpy notched impact strength, +23°C 7 kJ/m² ISO 179/1eA

Charpy notched impact strength, -30°C 3.1 kJ/m² ISO 179/1eA

Thermal properties Value Unit Test Standard

Melting temperature, 10°C/min 225 °C ISO 11357-1/-3

Glass transition temperature, 10°C/min 73 °C ISO 11357-1/-2

Temp. of deflection under load, 1.80 MPa 193 °C ISO 75-1/-2

Electrical properties Value Unit Test Standard

Relative permittivity, 100Hz 4.7 - IEC 60250

Relative permittivity, 1MHz 4.4 - IEC 60250

Dissipation factor, 100Hz 260 E-4 IEC 60250

Dissipation factor, 1MHz 240 E-4 IEC 60250

Volume resistivity 7E12 Ohm*m IEC 60093

Surface resistivity >1E15 Ohm IEC 60093

Electric strength 28 kV/mm IEC 60243-1

Other properties Value Unit Test Standard

Humidity absorption 0.09 % Sim. to ISO 62

Density 1640 kg/m³ ISO 1183

Characteristics

Regional Availability

North America

NOTICE TO USERS: Values shown are based on testing

of laboratory test specimens and represent data that fall

within the standard range of properties for natural material.

These values alone do not represent a sufficient basis for

any part design and are not intended for use in

establishing maximum, minimum, or ranges of values for

specification purposes. Colorants or other additives may

cause significant variations in data values.

Properties of molded parts can be influenced by a wide

variety of factors including, but not limited to, material

selection, additives, part design, processing conditions and

environmental exposure. Any determination of the

suitability of a particular material and part design for any

use contemplated by the users and the manner of such

use is the sole responsibility of the users, who must assure

themselves that the material as subsequently processed

meets the needs of their particular product or use.

Created: 2014-04-16 Source: http://www.campusplastics.com Page: 1/2

CELANEX LW2333R - PBT-(GB+GF)50

Ticona

To the best of our knowledge, the information contained in

this publication is accurate; however, we do not assume

any liability whatsoever for the accuracy and completeness

of such information. The information contained in this

publication should not be construed as a promise or

guarantee of specific properties of our products. It is the

sole responsibility of the users to investigate whether any

existing patents are infringed by the use of the materials

mentioned in this publication.

Moreover, there is a need to reduce human exposure to

many materials to the lowest practical limits in view of

possible adverse effects. To the extent that any hazards

may have been mentioned in this publication, we neither

suggest nor guarantee that such hazards are the only ones

which exist. We recommend that persons intending to rely

on any recommendation or to use any equipment,

processing technique, or material mentioned in this

publication should satisfy themselves that they can meet

all applicable safety and health standards.

We strongly recommend that users seek and adhere to the

manufacturer's current instructions for handling each

material they use, and to entrust the handling of such

material to adequately trained personnel only. Please call

the telephone numbers listed for additional technical

information. Call Customer Services for the appropriate

Materials Safety Data Sheets (MSDS) before attempting to

process our products.

The products mentioned herein are not intended for use in

medical or dental implants.

Created: 2014-04-16 Source: http://www.campusplastics.com Page: 2/2

You might also like

- Campus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHDocument2 pagesCampus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHAngererNo ratings yet

- RHODIA Technyl A218 V30Document3 pagesRHODIA Technyl A218 V30paquienNo ratings yet

- Makrolon® 2805Document8 pagesMakrolon® 2805Dridi BadredineNo ratings yet

- TDS MakrolonET3113Document3 pagesTDS MakrolonET3113It WittayaNo ratings yet

- Celanex 3316Document5 pagesCelanex 3316klausoshoNo ratings yet

- PocanB3235000000 GF30 1Document5 pagesPocanB3235000000 GF30 1rihabNo ratings yet

- 2024 03 06 TDS Elastollan1185ADocument4 pages2024 03 06 TDS Elastollan1185AChaker AbdellatifNo ratings yet

- PE-UHMW - Celanese - GUR 5129Document2 pagesPE-UHMW - Celanese - GUR 5129bobNo ratings yet

- ULTRASON Sup ® Sup +E1010+NATURALDocument2 pagesULTRASON Sup ® Sup +E1010+NATURALnikos.a.kyriakouNo ratings yet

- Ultradur® B 6550 LN en SI - Product DatasheetDocument2 pagesUltradur® B 6550 LN en SI - Product Datasheetnoto.sugiartoNo ratings yet

- Product Texts: P:Partial BreakDocument8 pagesProduct Texts: P:Partial BreakDridi BadredineNo ratings yet

- Celanex 3300-2 PBTDocument3 pagesCelanex 3300-2 PBTDiegoTierradentroNo ratings yet

- ABS - Novodur P2HGVDocument2 pagesABS - Novodur P2HGVarmandoNo ratings yet

- Bayer Makrolon 2407Document3 pagesBayer Makrolon 2407DiegoTierradentro100% (1)

- CELCON CE66FC - Unfilled: Celanese Engineered Materials Product Data DatasheetDocument2 pagesCELCON CE66FC - Unfilled: Celanese Engineered Materials Product Data DatasheetNguyễn Hồng NamNo ratings yet

- Document 1Document2 pagesDocument 1renebbNo ratings yet

- R42000249GKF - Celanex 2003 - PBT - TDSDocument4 pagesR42000249GKF - Celanex 2003 - PBT - TDSCarlos AgianiNo ratings yet

- TDS PBT 5829F-105Document2 pagesTDS PBT 5829F-105TRUONGNo ratings yet

- 76 StyrolutionPS454NDocument5 pages76 StyrolutionPS454N59074No ratings yet

- CAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfDocument4 pagesCAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfAngererNo ratings yet

- Ultramid A3 KDocument8 pagesUltramid A3 Kmani01kandanNo ratings yet

- Asa Ineos Styrolution Europe GMBH: Luran® S 776seDocument6 pagesAsa Ineos Styrolution Europe GMBH: Luran® S 776sebobNo ratings yet

- Abs (Basf Terluran Gp22)Document1 pageAbs (Basf Terluran Gp22)hakangokceNo ratings yet

- CAMPUS® Datasheet: Ultramid® T KR 4355 G5 - PA6T/6-GF25 BasfDocument6 pagesCAMPUS® Datasheet: Ultramid® T KR 4355 G5 - PA6T/6-GF25 BasfcurioushoainamNo ratings yet

- Campus® Datasheet: Alcom Pa6 900/1 Cf15 Im - Pa6-Cf15 Mocom Compounds GMBH & Co. KGDocument2 pagesCampus® Datasheet: Alcom Pa6 900/1 Cf15 Im - Pa6-Cf15 Mocom Compounds GMBH & Co. KGLuis PalenzuelaNo ratings yet

- BCE111NPDocument3 pagesBCE111NPdignityymartNo ratings yet

- Chang Chun Plastics CO., LTDDocument2 pagesChang Chun Plastics CO., LTDChunYenHuangNo ratings yet

- Lexan™ Copolymer 943X: Region AmericasDocument3 pagesLexan™ Copolymer 943X: Region AmericasAdirSchoierNo ratings yet

- Ultramid A205fDocument3 pagesUltramid A205fSATHISH KUMAR SNo ratings yet

- CAMPUS® Datasheet: Akulon® F223-D - PA6 DSM Engineering MaterialsDocument7 pagesCAMPUS® Datasheet: Akulon® F223-D - PA6 DSM Engineering MaterialsAgoenk KertawijayaNo ratings yet

- Dupont™ Crastin Sk615Sf Nc010 (Preliminary Data) : Thermoplastic Polyester ResinDocument6 pagesDupont™ Crastin Sk615Sf Nc010 (Preliminary Data) : Thermoplastic Polyester ResinomarNo ratings yet

- Luran S757 GDocument5 pagesLuran S757 GPeter EvansNo ratings yet

- POM Celcon M270Document3 pagesPOM Celcon M270Er Shashi SinghNo ratings yet

- Ultradur B2520Document2 pagesUltradur B2520Phung LucNo ratings yet

- POM KEPITAL F30-03 enDocument2 pagesPOM KEPITAL F30-03 enAthonioMourinhoNo ratings yet

- Elix ABS M220: Technical InformationDocument3 pagesElix ABS M220: Technical InformationDiegoTierradentroNo ratings yet

- Kepital F20 - 03Document2 pagesKepital F20 - 03Kumaar RanjanNo ratings yet

- TDS Infinam ST 6100 LDocument5 pagesTDS Infinam ST 6100 LKacperNo ratings yet

- Ultrason® E 2010 G6 UN en SI - Product DatasheetDocument2 pagesUltrason® E 2010 G6 UN en SI - Product Datasheetshahin_723No ratings yet

- Ultramid: Product Information ®Document2 pagesUltramid: Product Information ®muthuNo ratings yet

- CAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfDocument5 pagesCAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfdivyarasinNo ratings yet

- TerluranGP 22Document5 pagesTerluranGP 22Chu ChuNo ratings yet

- OsiSense XM - XMLB300D2S12Document6 pagesOsiSense XM - XMLB300D2S12Cricri CriNo ratings yet

- Nylacast Moly Cast Nylon 6, MoS2 FilledDocument3 pagesNylacast Moly Cast Nylon 6, MoS2 Filledprasad.jppmNo ratings yet

- Celanese Corporation Celanex® 1400A Polybutylene TerephthalateDocument2 pagesCelanese Corporation Celanex® 1400A Polybutylene TerephthalateTomGaliciaNo ratings yet

- VESTAMID® L1670 - EvonikDocument5 pagesVESTAMID® L1670 - EvonikShikha MishraNo ratings yet

- PD Arnite t06 204 SN (En)Document2 pagesPD Arnite t06 204 SN (En)MuthuswamyNo ratings yet

- Wanhua PC Injection Moulding 20 Mfi Clarnate A1227Document2 pagesWanhua PC Injection Moulding 20 Mfi Clarnate A1227lucasNo ratings yet

- PP Copolimero - Lloyndellbasell Purell RP373RDocument1 pagePP Copolimero - Lloyndellbasell Purell RP373RarmandoNo ratings yet

- Elix ABS E401: Technical InformationDocument3 pagesElix ABS E401: Technical InformationDiegoTierradentroNo ratings yet

- Luran 368 RDocument5 pagesLuran 368 RmucahitkaraballNo ratings yet

- Styrolution PS 454N: High Impact Polystyrene (HIPS)Document3 pagesStyrolution PS 454N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- GENESTAR™ GP2300S - KurarayDocument4 pagesGENESTAR™ GP2300S - KurarayRafael CastroNo ratings yet

- Pressostato - Schneider - XMLA-300-D2S11 - MI-D-610-IN-DF-0007-R0-8-13 PDFDocument6 pagesPressostato - Schneider - XMLA-300-D2S11 - MI-D-610-IN-DF-0007-R0-8-13 PDFRichard Mayk teodoroNo ratings yet

- Technyl Safe C 116FC NCDocument3 pagesTechnyl Safe C 116FC NCkls.thorodinsonNo ratings yet

- Product Summary: CZ-1030 Is A 30% Pitch Based Carbon Fiber Reinforced PPS Color: BlackDocument1 pageProduct Summary: CZ-1030 Is A 30% Pitch Based Carbon Fiber Reinforced PPS Color: BlackMark DingalNo ratings yet

- Techtron PPSDocument5 pagesTechtron PPSSenthil Kumar GanesanNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- MST WRN Overview UsDocument4 pagesMST WRN Overview UsedgarNo ratings yet

- The Anatomy and Physiology of The Stomach: Ian R. Daniels and William H. AllumDocument21 pagesThe Anatomy and Physiology of The Stomach: Ian R. Daniels and William H. Allummutia aNo ratings yet

- HFWB - 170224 - Floor StandingDocument2 pagesHFWB - 170224 - Floor StandingAkilaJosephNo ratings yet

- How Stress Affects Your Brain: Madhumita Murgia - TED-EdDocument4 pagesHow Stress Affects Your Brain: Madhumita Murgia - TED-EdQueency Tabora-MacalindongNo ratings yet

- Unit 1: Energy and Motion: Chapter 5: Work and Machines 5.1: 5.2Document78 pagesUnit 1: Energy and Motion: Chapter 5: Work and Machines 5.1: 5.2Tomboy ReginaNo ratings yet

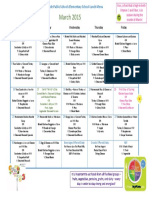

- Seaside Elementary School Lunch Menu LewisDocument1 pageSeaside Elementary School Lunch Menu Lewisapi-345910065No ratings yet

- Acoustics and Vibrations - Noise and Vibration Control - Beranek - Noise and Vibration Control Engineering - Wiley - 1992 - Ch11 Vibration IsolationDocument22 pagesAcoustics and Vibrations - Noise and Vibration Control - Beranek - Noise and Vibration Control Engineering - Wiley - 1992 - Ch11 Vibration IsolationgrymiNo ratings yet

- InvoiceDocument1 pageInvoiceRohankant TateluNo ratings yet

- Tanuj Ghimire - CVDocument4 pagesTanuj Ghimire - CVsujankhanal10No ratings yet

- JY Gembox 2Document5 pagesJY Gembox 2Krepus BlackNo ratings yet

- Chapter 3 - Transducer and Sensors Part 1Document46 pagesChapter 3 - Transducer and Sensors Part 1Zersh EthioNo ratings yet

- Evaluation of PV-Wind Hybrid Energy System For A Small IslandDocument3 pagesEvaluation of PV-Wind Hybrid Energy System For A Small Islandhamza malikNo ratings yet

- STRATAGEN STIMPRO Software Product Information Sheet 1001 1Document2 pagesSTRATAGEN STIMPRO Software Product Information Sheet 1001 1Oussama AissaouaNo ratings yet

- Stomatognathic SystemDocument71 pagesStomatognathic SystemRaj Singh83% (6)

- 0748640843Document273 pages0748640843Zia Ullah100% (1)

- Past-Sensitive Pointer Analysis For Symbolic ExecutionDocument12 pagesPast-Sensitive Pointer Analysis For Symbolic Execution石远翔No ratings yet

- Data Sheet Tiristor s701c15n3sDocument8 pagesData Sheet Tiristor s701c15n3sLeo SalgadoNo ratings yet

- Mobility Driven Network Slicing: An Enabler of On Demand Mobility Management For 5GDocument12 pagesMobility Driven Network Slicing: An Enabler of On Demand Mobility Management For 5GgirishryenniNo ratings yet

- BookDocument182 pagesBookSebastian Aguayo FritzNo ratings yet

- Favipiravir Tablet Manual: Please Read The Instructions Carefully and Use Under The Guidance of A PhysicianDocument4 pagesFavipiravir Tablet Manual: Please Read The Instructions Carefully and Use Under The Guidance of A Physicianchard xuNo ratings yet

- Krishna Kathamrita Bindu 167Document5 pagesKrishna Kathamrita Bindu 167Citraka dasaNo ratings yet

- Ansi Ies RP-8-21Document547 pagesAnsi Ies RP-8-21cristianbaileyeNo ratings yet

- The Impact of VGM (Verified Gross Mass) Implementation As Solas'S New Regulation - Case Study at Port of TG - PriokDocument11 pagesThe Impact of VGM (Verified Gross Mass) Implementation As Solas'S New Regulation - Case Study at Port of TG - PriokDilip SharmaNo ratings yet

- SP 187 BDocument4 pagesSP 187 BBryan CarvacheNo ratings yet

- March, 2023 Domestic: Customer Number: Billing Month: Tariff/Customer Class: Bill ID: 158856022712Document1 pageMarch, 2023 Domestic: Customer Number: Billing Month: Tariff/Customer Class: Bill ID: 158856022712Yasir KhanNo ratings yet

- TraderJoes CookbookDocument150 pagesTraderJoes Cookbookjennifer.farris12No ratings yet

- Hanson PDFDocument10 pagesHanson PDFAlberto Caceres ValenciaNo ratings yet

- Parity-Time Symmetry in Optical MicrocavityDocument25 pagesParity-Time Symmetry in Optical MicrocavityNaman KapoorNo ratings yet

- EY Making India Brick by Brick PDFDocument96 pagesEY Making India Brick by Brick PDFRKVSK1No ratings yet

- Florence Nightingales Environmental TheoryDocument5 pagesFlorence Nightingales Environmental TheoryRoshin Tejero100% (1)