Professional Documents

Culture Documents

Cicind: Model Code Steel Chimneys

Uploaded by

Sugumar N ShanmugamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cicind: Model Code Steel Chimneys

Uploaded by

Sugumar N ShanmugamCopyright:

Available Formats

CICIND

Model Code

for

Steel Chimneys

Revision 1 - 1999

Amendment A – March 2002

Copyright CICIND 1999

ISBN 1-902998-09-X

and

Commentaries and Appendices

(December 2000)

Copyright CICIND 2000

ISBN 1-902998-11-1

DISCLAIMER

CICIND documents are presented to the best of the knowledge of its members as guides

only. CICIND is not, nor are any of its members, to be held responsible for any failure alleged

or proved to be due to adherence to recommendations, or acceptance of information,

published by the association in a Model Code or other publication or in any other way.

Office of the Secretary:

Preussenstrasse 11

40883 Ratingen

Germany

email: secretary@cicind.org

www:cicind.org

FOREWORD 6 Materials

When it was formed in 1973, the "Comite International 6.1 General

Des Cheminees Industrielles" (CICIND) adopted as a 6.2 Structural steels

major goal the harmonisation of national codes for the 6.3 Stainless and alloy steels

design of industrial chimneys. As a means to this end, a 6.4 Expansion characteristics

subcommittee was appointed in 1981, charged with

drafting a proposal for a model code for steel chimneys 7 Actions(External and Internal)

which reflected the current "state-of-the-art" and a 7.1 Permanent Load

consensus of views, internationally. This document was 7.1.1 Dust load (temporary load)

published in 1988, with Commentaries being published 7.2 Wind

the following year. 7.2.1 General

7.2.2 Wind Speed

Since 1988, the science and technology of chimneys 7.2.2.1 Basic wind speed

has advanced and in 1995, CICIND appointed a 7.2.2.2 Design wind speed

committee to revise the Model Code, recognising 7.2.2.3 The influence of topography

current best international practice and knowledge. 7.2.3 Wind load in direction of the wind

7.2.3.1 Wind load on isolated chimneys

7.2.3.2 Mean hourly wind load

The committee comprises: 7.2.3.3 Effect of fluctuating part of the wind-speed

J. Roberts (Great Britain) 7.2.4 Vortex shedding

B.N. Pritchard (Great Britain) 7.2.4.1 General principles

Max Beaumont (Great Britain) 7.2.4.2 Estimation of top amplitudes

Michael Beaumont (Great Britain) 7.2.5 Ovalling

G. Berger (Germany) 7.2.5.1 Static effects

J. Bouten (The Netherlands) 7.2.5.2 Dynamic effects

R. Ghermandi (Italy) 7.2.6 The increase of wind effects by nearby

S. Ole Hansen (Denmark) structures

G. Pinfold (Great Britain) 7.2.6.1 Increase in along-wind load

H. van Koten (The Netherlands) 7.2.6.2 Increase in cross-wind response

R.M. Warren (U.S.A.) 7.2.7 Damping ratio

7.2.8 The first and second natural frequencies

Expert advice was received from: 7.2.9 Passive dynamic control

B.J. Vickery (Canada) 7.2.9.1 Aerodynamic stabilisers

7.2.9.2 Dam, ping devices

7.2.9.3 Special chimney designs for damping.

7.3 Earthquake loading

Table of Contents 7.4 Thermal effects

7.5 Explosions

Foreword 7.5.1 External explosions

0 Introduction 7.5.2 Internal explosions

0.1 General 7.6 Internal effects governing the chimney

0.2 Appendices and Commentaries design

0.3 Philosophy 7.6.1 High temperature flue gases

7.6.2 Fire

1 Scope 7.6.3 Chemical effects

2 Field of Application 8 Design of Structural Shell

8.1 Minimum thickness

3 References 8.2 Required checks

8.3 Carrying capacity of shell

4 Notations, Units and Definitions 8.3.1 Load factors and load combinations

8.3.3 Biaxial stresses

4.1 General 8.3.4 Stability

4.2 Subscripts-Superscripts 8.4 Serviceability of shell

4.3 Units 8.5 Fatigue check

4.4 Definitions 8.5.1 Basic principles

8.5.2 Fatigue strength

5 Basis of Design and Safety Factors 8.5.3 Influence of high temperature

5.1 General 8.6 Allowance for corrosion

5.2 Reliability differentiation 8.6.1 External corrosion allowance

5.3 Partial Safety Factors 8.6.2 Internal corrosion allowance

5.4 Cross-wind effects

9 Design Details

9.1 Connections

9.1.1 General provisions

9.1.2 Bolted connections

9.1.2.1 Shear

9.1.2.2 Bearing on connected surfaces

9.1.2.3 Tension

9.1.2.4 Combined loading

9.1.2.5 Deduction for holes

9.1.3 Welded connections 0.2. Appendices and Commentaries

9.1.3.1 Full penetration welds

9.1.3.2 Fillet welds

9.1.3.3 Weld testing This Model Code is accompanied by extensive

9.2 Flanged connections appendices and commentaries. The appendices

9.3 The support at the base provide information which the committee believes will

9.3.1 Anchor bolts be of use to a steel chimney designer, even though its

9.3.2 Grouting inclusion in a chimney design code could not be

9.3.3 Temperature effects justified. The commentaries have the following

objectives:

10 Steel liners

a) Justification of the regulations of the model

11 Construction code.

11.1 General b) Simplification of the use of the model code.

11.2 Structural shell c) Understanding of the meaning of the

11.3 Structural flanges and opening regulations of the model code.

reinforcement d) Documentation of the areas in the model code

11.4 Stiffening rings where the present knowledge is sparse so that

11.5 Base plate the regulations are possibly or probably not

11.6 Straightness optimal.

11.7 Erection tolerance

The following items are not objectives of the CICIND

12 Surface Protection commentaries:

e) Change of the meaning of certain regulations

13 Openings of the model code where these are falsely

expressed or obviously wrong.

14 Guyed, Structure Supported and Stayed f) Definition of the meaning of certain regulations

Chimneys of the model code which are so badly

14.1 Structure supported and stayed chimneys formulated that they could easily be

14.2 Guyed chimneys misinterpreted even by experts.

15 Protection Against Lightning Certain information from the model code is repeated in

the commentaries when this simplifies the presentation

16 Access Ladders of the ideas.

17 Aircraft Warning Lights

0.3 Philosophy

0. INTRODUCTION One of the main objectives of any code governing

construction is the creation of a model which resembles

0.1 General as far as possible, the real situation. The model should

be sufficiently "safe, simple and true". It is very rarely

that simplicity and truth are compatible, so a model

Chimneys are required to carry vertically and discharge must be used which provides an optimum compromise

to the atmosphere, gaseous products of combustion, between truth, simplicity, safety and economy.

chemical waste gases, exhaust air or for the

combustion (flaring off) of industrial waste gases. While the judgements of 'sufficiently true' and

'sufficiently simple' are subjective, 'sufficiently safe' is

This Model Code contains guide-lines which reflect the capable of rational judgement. This code interprets

current state of art in the design and construction of 'sufficiently safe' in terms of the social and economic

steel chimneys. Nevertheless, the design, fabrication consequences of failure. It does this by comparing the

and erection of steel chimneys require a thorough probabilities of failure for given safety factors during its

knowledge of these structures, the properties of the design life with the failure probabilities required to

materials used, the actions occurring upon the structure satisfy accepted social and economic criteria. This

and the recognised rules of the relevant technologies. leads to the development of safety factors which ensure

The design of steel chimneys should therefore only be that a chimney will have a probability of failure during

entrusted to appropriately qualified and experienced

engineers. The construction and erection should be its design lifetime between 10-3 and 10-4, depending

carried out by firms competent in this class of work. At upon its reliability category.

all times the work should be under the direction of

appropriately qualified supervisors. CICIND has departed from generally accepted

principles of steelwork design and construction only

CICIND will continue to try to improve the when this was required by the philosophy outlined

understanding of the behaviour of chimneys. Further above or by specific chimney requirements.

revisions of this model code will therefore be published

from time to time.

You might also like

- RCC Chimneys - CICIND Code PDFDocument23 pagesRCC Chimneys - CICIND Code PDFVasanth KumarNo ratings yet

- CICIND Model Code For Concrete Chimneys Part A The Shell SecondDocument23 pagesCICIND Model Code For Concrete Chimneys Part A The Shell SecondFreddy MillenNo ratings yet

- (British Standard) Bs 6349-6-1989Document62 pages(British Standard) Bs 6349-6-1989jesusgameboy100% (1)

- BS 05234-1-1992 (1999) Partitions (Including Matching Linings) - Code of Practice For Design and Installation.Document38 pagesBS 05234-1-1992 (1999) Partitions (Including Matching Linings) - Code of Practice For Design and Installation.ironface100% (2)

- EN 1995-2 Timber BridgesDocument29 pagesEN 1995-2 Timber BridgesRicardo GonçalvesNo ratings yet

- BS 05234-1-1992 (1999)Document38 pagesBS 05234-1-1992 (1999)murali krishNo ratings yet

- BS 5950 Part 5Document73 pagesBS 5950 Part 5Irete Femi100% (1)

- 2017 Student Design Competition: Hvac System SelectionDocument28 pages2017 Student Design Competition: Hvac System SelectionAbhishek ChakrabortyNo ratings yet

- Design of Liquid Retaining Structure R D AngorDocument198 pagesDesign of Liquid Retaining Structure R D Angorjhoward2012np100% (4)

- Design of Structural SteelworkDocument12 pagesDesign of Structural SteelworkSitche ZisoNo ratings yet

- Bridge Design-Eurocodes-Worked Examples-Main Only PDFDocument310 pagesBridge Design-Eurocodes-Worked Examples-Main Only PDFShamaNo ratings yet

- Bridge Design Eurocodes Worked Examples Annex OnlyDocument150 pagesBridge Design Eurocodes Worked Examples Annex OnlyAhmed AjelNo ratings yet

- Bridge Design Eurocodes Worked Examples Annex OnlyDocument150 pagesBridge Design Eurocodes Worked Examples Annex OnlyhoustonhimselfNo ratings yet

- Straw-Construction-in-the-UK - Technical-Guide - February-2022 InglesDocument80 pagesStraw-Construction-in-the-UK - Technical-Guide - February-2022 InglesclaudioquijadaNo ratings yet

- Ccip Ec2 BridgesDocument140 pagesCcip Ec2 BridgesnuNo ratings yet

- ConcreteCentre EC2 Bridges Extract PDFDocument6 pagesConcreteCentre EC2 Bridges Extract PDFAlin SalageanNo ratings yet

- P 00220141 en 02Document7 pagesP 00220141 en 02fajaraminwahyullah0% (1)

- CP 00143-10-1973 (2007) PDFDocument22 pagesCP 00143-10-1973 (2007) PDFStanislav PerevezentsevNo ratings yet

- BS 8206-2 - Lighting For Buildings - Code of Practice For DaylightingDocument44 pagesBS 8206-2 - Lighting For Buildings - Code of Practice For DaylightingHong Wong100% (1)

- Duracrete Report BE1347R01Document170 pagesDuracrete Report BE1347R01mjmv1yahoo.comNo ratings yet

- Tshwane University of Technology: Design of A 2.4 GHZ Wifi Array Patch AntennasDocument51 pagesTshwane University of Technology: Design of A 2.4 GHZ Wifi Array Patch AntennasIvandro Peterson Alves RodriguesNo ratings yet

- Full download book High Temperature Gas Cooled Reactors Pdf pdfDocument41 pagesFull download book High Temperature Gas Cooled Reactors Pdf pdfvonda.ives161100% (19)

- Eurocode 3 - Design of Steel Structures - Part 6 - Crane Supporting StructuresDocument37 pagesEurocode 3 - Design of Steel Structures - Part 6 - Crane Supporting StructuresErmal RulaNo ratings yet

- Asce Blast Design Petrochemical PDFDocument5 pagesAsce Blast Design Petrochemical PDFErnesto Noe0% (1)

- Composite StructuresDocument184 pagesComposite StructuresAbhinav50% (2)

- Bs 2654-1989 - Vertical TanksDocument102 pagesBs 2654-1989 - Vertical TanksMohanadNo ratings yet

- Marine Energy ConversionDocument64 pagesMarine Energy Conversionsachu chandranNo ratings yet

- BCGA 2002 Code of Practice CP 36Document55 pagesBCGA 2002 Code of Practice CP 36wssengltdNo ratings yet

- prEN1993 1 1 2nd Draft 2nd RevDocument95 pagesprEN1993 1 1 2nd Draft 2nd RevJosé CarlosNo ratings yet

- Guidebook-1 Load Effects On StructuresDocument218 pagesGuidebook-1 Load Effects On Structuresaskro100% (4)

- BS 4429 PDFDocument24 pagesBS 4429 PDFbich100% (1)

- Anexo 2 Manual CNC 4.0 160-250-315Document94 pagesAnexo 2 Manual CNC 4.0 160-250-315ALEX ALBERTO ALCANTARA VEGANo ratings yet

- Piping and Equipment InsulationDocument28 pagesPiping and Equipment InsulationRizki AhmadNo ratings yet

- IStructE - Achievement of structural adequacy in buildings Nov 1990Document29 pagesIStructE - Achievement of structural adequacy in buildings Nov 1990Wilson ChangNo ratings yet

- Design and Analysis of Steel Truss Bridge with Solar Panel InstallationDocument372 pagesDesign and Analysis of Steel Truss Bridge with Solar Panel Installationovikbasu100% (3)

- Calc Report - CD - Mahameru - Struktur - FumigasiDocument52 pagesCalc Report - CD - Mahameru - Struktur - FumigasiMochamad BhadawiNo ratings yet

- 625-NR Consolidated NovemberDocument321 pages625-NR Consolidated NovemberArturoNo ratings yet

- Worked Examples To Eurocode 2 PDFDocument224 pagesWorked Examples To Eurocode 2 PDFMatt100% (2)

- Hail StrikeDocument133 pagesHail StrikeGabriel Grácio VelosoNo ratings yet

- (BS 6187 - 1982) - Code of Practice For Demolition.Document44 pages(BS 6187 - 1982) - Code of Practice For Demolition.AdelNo ratings yet

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- Pe Endorsement For Design of New FCC and Guard House BuildingDocument7 pagesPe Endorsement For Design of New FCC and Guard House Buildingjasekan.dcNo ratings yet

- Notation: 8.0 Aashto Specification References 8.1 Principles and Advantages of PrestressingDocument33 pagesNotation: 8.0 Aashto Specification References 8.1 Principles and Advantages of PrestressingRammiris ManNo ratings yet

- Norsok n-003 Actions and Action EffectsDocument60 pagesNorsok n-003 Actions and Action EffectsnicNo ratings yet

- Design, Construction, Modification, Maintenance and Decommissioning of Filling StationsDocument316 pagesDesign, Construction, Modification, Maintenance and Decommissioning of Filling StationsMaurizio Busu75% (4)

- BS 5950 Part 3.1Document36 pagesBS 5950 Part 3.1Irete FemiNo ratings yet

- HRSG Lifing BriefDocument12 pagesHRSG Lifing BriefAnonymous utxGVB5Vy100% (1)

- STADD Report for 18° Solar Module Mounting StructureDocument39 pagesSTADD Report for 18° Solar Module Mounting StructureMohammed Moin MotalaNo ratings yet

- ETAG018 Fisproma 2 January 06 Part3Document63 pagesETAG018 Fisproma 2 January 06 Part3Serban RaduNo ratings yet

- G21 Fire and Blast Databook Panels2.0Document149 pagesG21 Fire and Blast Databook Panels2.0Lakshmi Binoy MenonNo ratings yet

- Bcga Code of Practice CP 20: Bulk Liquid Oxygen Storage at Production SitesDocument55 pagesBcga Code of Practice CP 20: Bulk Liquid Oxygen Storage at Production Sitesfadlul akbar herfiantoNo ratings yet

- Sheet Roof and Wall Coverings - : Code of PracticeDocument30 pagesSheet Roof and Wall Coverings - : Code of PracticeStanislav PerevezentsevNo ratings yet

- A Practical Guide to The Wiring Regulations: 17th Edition IEE Wiring Regulations (BS 7671:2008)From EverandA Practical Guide to The Wiring Regulations: 17th Edition IEE Wiring Regulations (BS 7671:2008)No ratings yet

- Designing Indoor Solar Products: Photovoltaic Technologies for AESFrom EverandDesigning Indoor Solar Products: Photovoltaic Technologies for AESNo ratings yet

- Methods of Structural AnalysisDocument83 pagesMethods of Structural AnalysisSugumar N ShanmugamNo ratings yet

- Chapter3 - Basic StructureDocument26 pagesChapter3 - Basic StructureJayson TeeNo ratings yet

- Fluid Mech ModuleDocument66 pagesFluid Mech ModuleVudayagirisivaNo ratings yet

- Plastic Anal Ysis of Steel StructuresDocument20 pagesPlastic Anal Ysis of Steel StructuresSHashika Sandaruwan EkanayakeNo ratings yet

- Design of Steel Beam to Column Bolted ConnectionDocument3 pagesDesign of Steel Beam to Column Bolted ConnectionibrahimNo ratings yet

- Is 819 1957 PDFDocument25 pagesIs 819 1957 PDFSugumar N ShanmugamNo ratings yet

- Hus 3h HiltiDocument25 pagesHus 3h HiltiPablo RamosNo ratings yet

- 5 Plastic AnalysisDocument14 pages5 Plastic AnalysisParveen RidhalNo ratings yet

- Beam Deflection FormulaeDocument2 pagesBeam Deflection Formulae7575757575100% (6)

- 6 Portal FramesDocument7 pages6 Portal FramesGeoffrey ArmstrongNo ratings yet

- Role of Project Managers in ConstructionDocument11 pagesRole of Project Managers in ConstructionSugumar N ShanmugamNo ratings yet

- Aadhar Enrollment FormDocument1 pageAadhar Enrollment FormDevika BalasubramanianNo ratings yet

- WA Building Note Re Structural BoltsDocument1 pageWA Building Note Re Structural BoltsSugumar N ShanmugamNo ratings yet

- Parking Standard - Dept of Environment UKDocument23 pagesParking Standard - Dept of Environment UKEmdad YusufNo ratings yet

- Aluco BondDocument1 pageAluco BondSugumar N ShanmugamNo ratings yet

- Spring Washers DataDocument6 pagesSpring Washers DataSugumar N ShanmugamNo ratings yet

- Vinayagar StothiramDocument3 pagesVinayagar StothiramSugumar N ShanmugamNo ratings yet

- Deflection of BeamsDocument41 pagesDeflection of BeamsMubaaracq Meerasahib100% (3)

- Principles of Louver DesignDocument3 pagesPrinciples of Louver Designsaravanaplus100% (2)

- Bulding Regulations PDF ADK 1998Document0 pagesBulding Regulations PDF ADK 1998Sugumar N ShanmugamNo ratings yet

- Vinayaga ManthiramDocument2 pagesVinayaga ManthiramSugumar N ShanmugamNo ratings yet

- TITLE NATA Sample Question Papers 2009Document4 pagesTITLE NATA Sample Question Papers 2009Ayan JainNo ratings yet

- 3.0 Tdi 2015 - 2019Document314 pages3.0 Tdi 2015 - 2019gume pesa67% (3)

- Whirlpool FL 5090aDocument14 pagesWhirlpool FL 5090aLiviu PetreNo ratings yet

- PS - Booster Rack For Dry Gas SealsDocument6 pagesPS - Booster Rack For Dry Gas SealsSacha ApécéchéaNo ratings yet

- Service Electrical Fuel Injection System and Its ComponentsDocument50 pagesService Electrical Fuel Injection System and Its ComponentsBiruk TilahunNo ratings yet

- 981-0259 Onan HDCAA HDCAB (Spec A-D) Diesel Mobile Genset Parts Manual (10-2013)Document68 pages981-0259 Onan HDCAA HDCAB (Spec A-D) Diesel Mobile Genset Parts Manual (10-2013)Granville BarkerNo ratings yet

- Reducing The Cover-To-Diameter Ratio For Shallow Tunnels in Soft SoilsDocument177 pagesReducing The Cover-To-Diameter Ratio For Shallow Tunnels in Soft SoilsNguyễn Vũ Nam ChiếnNo ratings yet

- HH 1200 - BrochureDocument2 pagesHH 1200 - BrochureCentrifugal SeparatorNo ratings yet

- Additional Pressure and Temperature Switch Application InformationDocument2 pagesAdditional Pressure and Temperature Switch Application InformationJean GonzalezNo ratings yet

- BMW Ews 3 - Pinout and DescriptionDocument2 pagesBMW Ews 3 - Pinout and DescriptionFrancisco López Rosas88% (8)

- Astm D-638Document13 pagesAstm D-638Vân Anh100% (1)

- Djordjevic - Two Component of Blast FragmentationDocument5 pagesDjordjevic - Two Component of Blast FragmentationIbnu Al Farobi100% (1)

- Testing and Adjusting Bomba Hidraulica d6n - AlyDocument5 pagesTesting and Adjusting Bomba Hidraulica d6n - AlyElibey Cuadros BerbesiNo ratings yet

- Asme B107.9M-1994Document42 pagesAsme B107.9M-1994noahb110No ratings yet

- Why core of a transformer is laminatedDocument4 pagesWhy core of a transformer is laminatedAbhinav SinghNo ratings yet

- Fluid Kat99fk00Document28 pagesFluid Kat99fk00soulpowertibuNo ratings yet

- Control Philosophy - Rev 5Document113 pagesControl Philosophy - Rev 5Rakesh Karan SinghNo ratings yet

- Esr 3187Document38 pagesEsr 3187Marcelo ElguetaNo ratings yet

- QO390-SS200025 Technical Sheet (Actuated On Off Valve & RESDVForel Bronang)Document2 pagesQO390-SS200025 Technical Sheet (Actuated On Off Valve & RESDVForel Bronang)Iqbal MatondangNo ratings yet

- Daily Lesson Plan (DLP) Section / Time:: Worksheets/simple-Machines-Worksheet-1Document7 pagesDaily Lesson Plan (DLP) Section / Time:: Worksheets/simple-Machines-Worksheet-1Elizabeth Dugay MendozaNo ratings yet

- Section: The Johns Hopkins University Applied Physics LaboratoryDocument67 pagesSection: The Johns Hopkins University Applied Physics Laboratoryinam vfNo ratings yet

- ES ES ES ES ES: Tubular Cement - Flyash Screw ConveyorsDocument53 pagesES ES ES ES ES: Tubular Cement - Flyash Screw ConveyorsJhon Jairo Arango MarquezNo ratings yet

- Adittel 912Document1 pageAdittel 912RimmerNo ratings yet

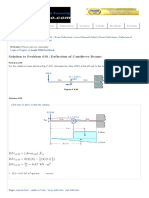

- Solution To Problem 638 - Deflection of Cantilever Beams - Strength of Materials ReviewDocument4 pagesSolution To Problem 638 - Deflection of Cantilever Beams - Strength of Materials ReviewJhundel Factor PajarillagaNo ratings yet

- Basics of Reinforced Concrete Slab Design and DetailingDocument31 pagesBasics of Reinforced Concrete Slab Design and DetailingMligo ClemenceNo ratings yet

- Hh150a P&idDocument3 pagesHh150a P&idttplan800No ratings yet

- Outside Packed Floating HeadDocument11 pagesOutside Packed Floating HeadGurunath EpiliNo ratings yet

- C24 BTTS-9 PhysicsDocument19 pagesC24 BTTS-9 Physicshello2006aditankNo ratings yet

- 512 Army Base WorkshopDocument8 pages512 Army Base WorkshopSinZahoNo ratings yet

- CIVL 4750 Numerical Solutions Geotechnical ProblemsDocument3 pagesCIVL 4750 Numerical Solutions Geotechnical ProblemsChoffo YannickNo ratings yet