Professional Documents

Culture Documents

AA-036322-001 Anchor Bolt Details PDF

Uploaded by

Mallela Sampath KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AA-036322-001 Anchor Bolt Details PDF

Uploaded by

Mallela Sampath KumarCopyright:

Available Formats

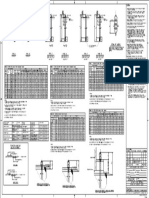

08 001 AA-036322 Q 990

NOTES:

REV. NO. SHT. NO. DRAWING NUMBER INDEX PLANT NO.

1. ANCHOR BOLTS SHALL BE SET ACCURATELY AND HELD IN

PLACE BY A TEMPLATE.

THREAD

THREAD

THREAD

THREAD

THREAD

THREAD

LENGTH

LENGTH

LENGTH

LENGTH

LENGTH

LENGTH

2. PLASTIC ANCHOR BOLT SLEEVES SHALL BE USED WHERE

SPECIFIED IN

CONSTRUCTION DRAWINGS. CENTER SLEEVES

AROUND BOLTS.

PROJ.

PROJ.

PROJ.

PROJ.

4d o

PROJ.

PROJ.

4d o

4d o

4d o

Lt

Lt

TOP OF ROUGH TOP OF ROUGH TOP OF ROUGH TOP OF ROUGH TOP OF ROUGH TOP OF ROUGH 3. THE BOTTOM OF ANCHOR BOLTS SHALL BE SECURED TO

CONC. CONC. CONC. CONC. CONC. CONC. PREVENT MOVEMENT OR TILTING OF THE BOLTS DURING

CONCRETE PLACEMENT.

SLEEVE SLEEVE SLEEVE

CUT LINE 4. FULLY THREADED ASTM A36/A36M RODS MAY BE USED TO

( SEE NOTE 8 ) ( SEE NOTE 8 ) ( SEE NOTE 8 )

SL

SL

FABRICATE TYPE 2 OR TYPE 2S ANCHOR BOLTS.

SL

SD SD SD

5. FULLY THREADED ASTM A193/A193M RODS MAY BE USED TO

FABRICATE TYPE 3 OR TYPE 3S ANCHOR BOLTS.

SD

SL

L

L

6. ANCHOR BOLT DESIGN SHALL COMPLY WITH SAES-Q-005

hef

hef

hef

hef

hef

AND ACI 318-02, APPENDIX D.

hef

do do do do do do

7. THE FINAL TIGHTENING OF ANCHOR BOLTS SHALL BE AS

FOLLOWS; AFTER GROUTING OF THE BASE PLATE THE

ANCHOR BOLTS SHALL BE BROUGHT TO A SNUG TIGHT

CONDITION. THIS IS DEFINED AS THE TIGHTNESS THAT

EXISTS AFTER A FEW IMPACTS FROM AN IMPACT WRENCH

OR THE FULL EFFORT OF A MAN USING A SPUD WRENCH.

AT THIS POINT ALL SURFACES SHOULD BE IN FULL

CONTACT.

T1

T1

T1

T1

L1

L1

8. ANCHOR BOLT SLEEVES SHALL BE FULLY GROUTED IN

L1

L1

ACCORDANCE WITH SAES-Q-010 AFTER THE BASE PLATE

HAS BEEN POSITIONED.

9. THE SPACING, EMBEDMENT AND EDGE DISTANCE

TACK TACK DETAIL OF SLEEVE

FOR NUT INSTALLATION DIMENSIONS SHOWN ON THIS DRAWING ARE MINIMUM

WELD WELD

( SEE NOTE 10 ) VALUES. EVERY ANCHOR BOLT MUST BE DESIGN PER

PLASTIC ANCHOR BOLT SLEEVES SHALL BE USED ACI 318-02 AND MINIMUM DIMENSIONS MAY NEED TO BE

WHERE REQUIRED BY DESIGN. TOP OF SLEEVE INCREASED AS REQUIRED BY DESIGN.

SHALL BE CUT OFF TO MAINTAIN EMBEDMENT

LENGTH. 10. TIGHTEN NUTS TO LOCK. APPLY TORQUE TO BOTTOM

NUT. LOCK BOTH NUTS IN POSITION BY COUNTER

PUNCHING THE THREADS AT JUNCTURE OF NUTS

TYPE 1 TYPE 1S TYPE 2 TYPE 2S TYPE 3 TYPE 3S AND BOLT.

ASTM A307 ASTM A307 ASTM A36/A36M or ASTM A36/A36M or ASTM A193/A193M or ASTM A193/A193M or 11. INSTALLATION TOLERANCES FOR ANCHOR BOLTS:

ASTM F1554, Gr. 36 ASTM F1554, Gr. 36 ASTM F1554, Gr. 105 ASTM F1554, Gr. 105

ANCHOR BOLTS AND FOUNDATION BOLTS ARE TO BE SET IN

( SEE NOTE 4 ) ( SEE NOTE 4 ) ( SEE NOTE 5 ) ( SEE NOTE 5 ) ACCORDANCE WITH AN APPROVED DRAWING. THEY MUST NOT

VARY FROM THE DIMENSIONS SHOWN ON THE DRAWINGS BY

MORE THAN THE FOLLOWING:

( a ) 1/2-INCH CENTER TO CENTER OF ANY TWO BOLTS WITHIN

Table 3 - ASTM A193, ASTM F1554 Grade 105 Anchor Rods-Inch Series AN ANCHOR BOLT GROUP, WHERE AN ANCHOR BOLT GROUP

Bolt Properties Type 3 Type 3S IS DEFINED AS THE SET OF ANCHOR BOLTS WHICH RECEIVE

A SINGLE FABRICATED STEEL SHIPPING PIECE .

Table 1- ASTM A307, Grade A Bolt Sizes-Inch Series Table 2 - ASTM A36, ASTM F1554 Grade 36 Anchor Rods-Inch Series Size Stress L1 T1 h efmin. Edge Dist. Spacing h efmin. Edge Dist. Spacing Sleeve

do TP1 Area 6do 100+do/2 (note b) (note c) SD SL ( b ) 1/4-INCH CENTER TO CENTER OF ADJACENT ANCHOR BOLT

Bolt Properties Type 1 Type 1S Bolt Properties Type 2 Type 2S 2do+13 3do 12do 6d o SL+150

2 GROUP .

Max. Proj. h efmin. Length (L) Edge Dist. Spacing h efmin. Length (L) Edge Dist. Spacing Sleeve L1 T1 h efmin. Edge Dist. Spacing h efmin. Edge Dist. Spacing Sleeve (in) ( in ) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm)

Size Stress Size Stress

Lt

do Type TP1 Area ( note c ) Proj.+ hef 4do 100+do/2 Proj.+ hef (note d) (note e) SD SL do TP1 Area 4do 100+do/2 (note b) (note c) SD SL 3/4 10 0.334 51 57 229 114 114 325 130 145 50 175 ( c ) ELEVATION OF THE TOP OF ANCHOR BOLTS + 1/2-INCH.

12d o 6d o SL+150 do+13 2d o 12d o 6d o SL+150

(in) (in) 2 (mm) (mm) (in) (mm) (mm) (mm) (in) (mm) (mm) (mm) (in) 2 (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) 7/8 9 0.462 57 67 267 133 133 325 147 161 50 175

( in ) (mm) ( in ) MAXIMUM ACCUMULATION OF 1/4-INCH PER HUNDRED FEET

( d )

1/2 Hex 1.50 13 0.142 107 152 10 108 76 275 15 127 114 50 125 1/2 13 0.142 26 25 152 108 76 275 127 114 50 125 1 8 0.606 64 76 305 152 152 400 177 202 75 250 ALONG THE ESTABLISHED COLUMN LINE OF MULTIPLE

175 95 325 50 343 195 218 ANCHOR BOLT GROUPS, BUT NOT TO EXCEED A TOTAL OF

5/8 Hex 1.75 11 0.226 115 191 12 110 95 325 17 1/2 127 129 50 5/8 11 0.226 29 32 191 110 127 129 175 1-1/8 8 0.790 70 86 171 171 421 75 250

1 IN ., WHERE THE ESTABLISHED COLUMN LINE IS THE

3/4 Hex 2.00 10 0.334 123 229 14 111 114 325 17 1/2 127 145 50 175 3/4 10 0.334 32 38 229 111 114 325 127 145 50 175 1-1/4 8 1.000 77 95 381 191 191 441 212 234 75 250

ACTUAL FIELD LINE MOST REPRESENTATIVE OF THE

7/8 Hex 2.25 9 0.462 267 15 1/2 113 133 325 18 127 161 50 175 7/8 9 0.462 35 44 267 113 133 325 127 161 50 175 1-3/8 8 1.234 83 105 419 210 210 460 230 250 75 250

131 CENTERS OF THE AS-BULIT ANCHOR BOLT GROUPS ALONG

1 Hex 2.50 8 0.606 139 305 17 1/2 114 152 400 21 139 202 75 250 1 8 0.606 38 51 305 114 152 400 139 202 75 250 1-1/2 8 1.492 89 114 457 229 229 604 260 291 100 375 A LINE OF COLUMNS .

1-1/8 Hex 2.75 7 0.763 146 343 19 1/2 116 171 421 22 1/2 139 218 75 250 1-1/8 7 0.763 42 57 343 116 171 421 139 218 75 250 1-3/4 8 2.082 102 133 533 267 267 642 294 322 100 375 ( e ) 1/4-INCH FROM THE CENTER OF ANY ANCHOR BOLT GROUP

1-1/4 Hex 3.00 7 0.969 154 381 21 127 191 441 23 1/2 149 234 75 250 1-1/4 7 0.969 45 64 381 127 191 441 149 234 75 250 2-1/4 8 3.557 127 171 686 343 343 793 364 386 100 450 TO THE ESTABLISHED COLUMN LINE THROUGH THAT GROUP .

1-3/8 Hex 3.25 6 1.155 162 419 23 140 210 460 24 1/2 160 250 250 1.155 48 70 419 140 210 460 160 75 250 2-1/2 8 4.442 140 191 762 381 381 981 424 468 150 600

75 1-3/8 6 250

( f ) THE TOLERANCE OF PARAGRAPHS b, c AND d APPLY TO

1-1/2 Hex 3.50 6 1.405 170 457 24 1/2 152 229 604 30 1/2 183 291 100 375 1-1/2 6 1.405 51 76 457 152 229 604 183 291 100 375 2-3/4 8 5.425 153 210 838 419 419 1019 459 499 150 600 OFFSET DIMENSIONS SHOWN ON THE PLAN, MEASURED

1-3/4 Heavy Hex 4.00 5 1.899 186 533 28 1/2 178 267 642 32 1/2 206 322 100 375 1-3/4 5 1.899 57 89 178 267 642 206 322 100 375 3 8 6.506 165 229 914 457 457 1057 494 531 150 600 PARALLEL AND PERPENDICULAR TO THE NEARST

533

ESTABLISHED COLUMN LINE FOR INDIVIDUAL COLUMN SHOWN

2 Heavy Hex 4.50 4.5 2.498 202 610 32 203 305 755 37 1/2 228 354 100 450 2 4.5 2.498 64 102 610 203 305 755 228 354 100 450

ON THE PLANS TO BE OFFSET FROM ESTABLISHED COLUMN

2-1/4 Heavy Hex 5.00 4.5 3.248 218 686 35 1/2 229 343 793 40 250 386 100 450 2-1/4 4.5 3.248 70 114 686 229 343 793 250 386 100 450

LINES .

NOTES:

2-1/2 Heavy Hex 5.50 4 3.999 234 762 39 254 381 981 48 297 150 600 2-1/2 4.0 3.999 77 127 762 254 381 981 297 468 150 600

468

( g ) UNLESS SHOWN OTHERWISE, ANCHOR BOLTS ARE SET

2-3/4 Heavy Hex 6.00 4 4.934 250 838 43 279 419 1019 50 319 499 150 600 2-3/4 4.0 4.934 83 140 838 279 419 319 499 150 600

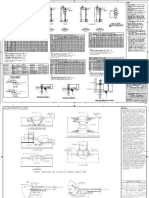

a. MINIMUM EDGE DISTANCE IS MEASURED FROM THE CENTERLINE OF THE

1019 PERPENDICULAR TO THE THEORETICAL BEARING SURFACE

ANCHOR BOLT TO THE EDGE OF THE CONCRETE.

3 Heavy Hex 6.50 4 5.967 266 914 46 1/2 305 457 1057 52 342 531 150 600 3 4.0 5.967 89 152 914 305 457 1057 342 531 150 600 MISALIGNMENT FROM VERTICAL MAY NOT EXCEED 1:40 .

b. EDGE DISTANCE FOR BOLTS WITH SLEEVES MUST BE INCREASED BY ( SD-do )/2

NOTES:

NOTES:

c. SPACING OF BOLTS WITH SLEEVES MUST BE INCREASED BY ( SD-d o)

a. MINIMUM EDGE DISTANCE IS MEASURED FROM THE CENTERLINE OF THE

a. MINIMUM EDGE DISTANCE IS MEASURED FROM THE CENTERLINE OF THE

ANCHOR BOLT TO THE EDGE OF THE CONCRETE.

ANCHOR BOLT TO THE EDGE OF THE CONCRETE. d. TPI = THREADS PER INCH.

b. ASTM A307 BOLT LENGTHS MAY NOT BE AVAILABLE FOR THE LARGER

b. EDGE DISTANCE FOR BOLTS WITH SLEEVES MUST BE INCREASED BY ( SD-do )/2

DIAMETER TYPE 1S BOLTS.

c. SPACING OF BOLTS WITH SLEEVES MUST BE INCREASED BY ( SD-d o)

c. IF THE REQUIRED PROJECTION EXCEED THE MAXIMUM PROJECTION

IN THE TABLE ABOVE, USE A TYPE 2 ANCHOR BOLT.

d. TPI = THREADS PER INCH.

Table 3M - ASTM A193M Anchor Rods - Metric

d. EDGE DISTANCE FOR BOLTS WITH SLEEVES MUST BE INCREASED BY

Bolt Properties Type 3 Type 3S

( SD-do )/2

Table 2M - ASTM A36 Anchor Rods - Metric Nominal Dia. ( do ) L1 T1 h efmin. Edge Dist. Spacing h efmin. Edge Dist. Spacing Sleeve

Stress

e. SPACING OF BOLTS WITH SLEEVES MUST BE INCREASED BY ( SD- do ) & thread pitch 6do 100+do/2

Area 2d o+13 3d o 12d o 6d o SL+150 (note b) (note c) SD SL

Bolt Properties Type 2 Type 2S

(mm) 2 (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm)

f. TPI= THREADS PER INCH. L1 T1 h efmin. Edge Dist. Spacing h efmin. Edge Dist. Spacing Sleeve (mm )

Nominal Dia. ( do ) Stress

M20x2.5 245 53 60 240 120 120 325 135 150 50 175

& thread pitch Area do+13 2d o 12d o 4do 100+do/2 6d o SL+150 (note b) (note c) SD SL

2 M24x3 353 61 72 288 144 144 400 170 195 75 250

(mm) (mm ) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm)

M27x3 459 67 81 324 162 162 400 186 210 75 250

Anchor Material Sizes Profile Thread Nut Material Coating Type M12x1.75 84.3 25 24 144 106 72 275 125 110 50 125

M30x3.5 561 73 90 360 180 180 400 203 225 75 250

Specification Profile Specification M16x2 157 29 32 192 108 96 275 125 130 50 125

M36x4 817 85 108 432 216 216 525 248 280 100 375

1/2 " thru 1-1/2" Hex Bolt ASTM A563, Gr. A Galvanized to ASTM A153/A153M, M20x2.5 245 33 40 240 110 120 325 125 150 50 175

ASTM A307, Grade A ASME B18.2.1, UNC M42x4.5 97 252 310 100

Heavy Hex Class C or ASTM B695, Class 50 1120 126 504 252 525 281 375

over 1-1/2" Heavy Hex Bolt M24x3 353 37 48 288 112 144 400 138 195 75 250

M48x5 1470 109 144 576 288 288 600 314 340 100 450

1/2 " thru 3" Rod ASME B1.1, UNC, Class 2 ASTM A563, Gr. A Galvanized to ASTM A153/A153M, M27x3 459 40 54 324 114 162 400 138 210 75 250

ASTM A36/A36M M56x5.5

ASME B1.13M Class C or ASTM B695, Class 50 2030 125 168 672 336 336 672 358 380 100 450

M12 thru M72 Heavy Hex M30x3.5 561 43 60 360 120 180 400 143 225 75 250

M64x6 2680 141 192 768 384 384 768 427 470 150 600

1/2 " thru 3" Rod ASME B1.1, UNC, Class 2 Galvanized to ASTM A153/A153M, M36x4 817 49 72 432 144 216 525 176 280 100 375

ASTM A563, Gr. A

ASTM F1554, Gr.36

M72x6 3460 157 216 864 432 432 864 471 510 150 600

Heavy Hex Class C or ASTM B695, Class 50 M42x4.5 1120 55 84 504 168 252 525 197 310 100 375

3/4 " thru 3" Bolts/Rods ASME B1.1, 8 UN, Class 2 ASTM A563, DH Heavy Hex Galvanized to ASTM A153/A153M, M48x5 1470 61 96 576 192 288 600 218 340 100 450

ASTM A193/A193M, Gr. B7

M20 thru M72 ASME B1.13M or ASTM A194/A 194M Class C or ASTM B695, Class 50 M56x5.5 2030 69 112 672 224 336 672 246 380 100 450 NOTES:

3/4 " thru 3" Rod ASME B1.1, 8 UN, Class 2 ASTM A563, DH Heavy Hex Galvanized to ASTM A153/A153M, M64x6 2680 77 128 768 256 384 768 299 470 150 600

a. MINIMUM EDGE DISTANCE IS MEASURED FROM THE CENTERLINE OF THE

ASTM F1554 Gr. 105

M20 thru M72 or ASTM A194/A 194M Class C or ASTM B695, Class 50 M72x6 3460 85 144 864 288 432 864 327 510 150 600 ANCHOR BOLT TO THE EDGE OF THE CONCRETE.

b. EDGE DISTANCE FOR BOLTS WITH SLEEVES MUST BE INCREASED BY ( SD-do )/2

NOTES: c. SPACING OF BOLTS WITH SLEEVES MUST BE INCREASED BY ( SD-d o)

FORMAT FOR ANCHOR BOLT

a. MINIMUM EDGE DISTANCE IS MEASURED FROM THE CENTERLINE OF THE

CALL OUT ON DRAWINGS ANCHOR BOLT TO THE EDGE OF THE CONCRETE.

DWG. RESPONSIBILITY:

b. EDGE DISTANCE FOR BOLTS WITH SLEEVES MUST BE INCREASED BY ( SD-do )/2

c. SPACING OF BOLTS WITH SLEEVES MUST BE INCREASED BY ( SD-d o) ONSHORE STRUCTURES STANDARDS COMMITTEE

ANCHOR BOLT TYPE

BOLT DIAMETER (do )

3 d

AB 3S-1-1/2"-100-600-(2) NUMBER OF NUTS

VESSEL SKIRT

08 DEC.20 MSM REVISED AS MARKED-UP PRINT CCB

BOLT LENGTH ( L )

VESSEL CHAIR HEIGHT

COMPLETELY REDRAWN. CHANGED

PROJECTION AUG02 MNL

PROJ.

07

2 d

DWG. SIZE FROM ’B’ TO ’A’.

3 d

PROJ.

TOP OF BASE PL REV. DATE BY JO/EWO DESCRIPTION CHKD. CERT. APPD.

PROJ.

INCH SIZES NO.

TOP OF THE GROUT

TOP OF BASE PL

SAUDI ARABIAN OIL COMPANY

TOP OF CONCRETE

TOP OF THE GROUT

VESSEL BASE RING

ANCHOR BOLT TYPE DRAWN BY CHECKED BY SCALE:

TOP OF CONCRETE

BOLT DIAMETER (do )

TOP OF GROUT DATE STARTED DATE COMPLETED

d

TOP OF CONCRETE ENG. DEPT.

AB 3S-M24-100-600-(2) NUMBER OF NUTS OPR’G. DEPT.

d

APP’D. FOR CONST.

BOLT LENGTH ( L )

THIS DRAWING IS NOT TO BE USED FOR CERTIFIED

d CONSTRUCTION OR FOR ORDERING

PROJECTION BY DATE

MATERIAL UNTIL CERTIFIED AND DATED

METRIC SIZES ANCHOR BOLT DETAILS

REQUIRED ANCHOR BOLT PROJECTION-SINGLE NUT

INCH AND METRIC SIZES

PROJ.=GROUT THICKNESS + BASE L

P THICKNESS + 2d

REQUIRED ANCHOR BOLT PROJECTION-DOUBLE NUT

PROJ.=GROUT THICKNESS + BASELP THICKNESS + 3d

STD. DWG.

REQUIRED ANCHOR BOLT PROJECTION FOR VERTICAL VESSELS (WITH CHAIRS) PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

PROJ.=GROUT THICKNESS + CHAIR HEIGHT + 3 d

990 Q AA-036322 001 08

Saudi Aramco 2615 ENG. (3/91)

CADD-02

You might also like

- Saer 5974 PDFDocument31 pagesSaer 5974 PDFZhiguo YangNo ratings yet

- Elastic Stability of Circular Cylindrical ShellsFrom EverandElastic Stability of Circular Cylindrical ShellsRating: 5 out of 5 stars5/5 (1)

- Concrete Breakout Strength in Tension For Vertical Vessel Anchorage in Octagon PedestalsDocument16 pagesConcrete Breakout Strength in Tension For Vertical Vessel Anchorage in Octagon Pedestalspositron9898No ratings yet

- Effective Length Factor For DiscontinuousDocument7 pagesEffective Length Factor For Discontinuoussaber javidNo ratings yet

- Seismic Design Rules For Flat Bottom Cylindrical Liquid Storage Tanks PDFDocument35 pagesSeismic Design Rules For Flat Bottom Cylindrical Liquid Storage Tanks PDFJose Felix AcevedoNo ratings yet

- Proposed Design Criteria For Stiffened Seated Connections To Column WebsDocument25 pagesProposed Design Criteria For Stiffened Seated Connections To Column WebsBùi Văn HợpNo ratings yet

- ACI 313R-97: Reported by ACI Committee 313Document20 pagesACI 313R-97: Reported by ACI Committee 313DIDIER ANGEL LOPEZ RINCONNo ratings yet

- Oil StorFage Tank Foundations BobergDocument3 pagesOil StorFage Tank Foundations BobergNabil Al-KhirdajiNo ratings yet

- Foundations For Vibrating Machines: Shamsher Prakash Vijay K. PuriDocument53 pagesFoundations For Vibrating Machines: Shamsher Prakash Vijay K. PuriAliNo ratings yet

- The Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsDocument12 pagesThe Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsMiguelNo ratings yet

- Process Industry Practices Structural: PIP STS02380 Application of ACI 336.1-01Document8 pagesProcess Industry Practices Structural: PIP STS02380 Application of ACI 336.1-01WNo ratings yet

- Ac 193 PDFDocument46 pagesAc 193 PDFDaniella Corredor100% (1)

- Tables for Allowable Axial Loads in Equal Single Angles in CompressionDocument4 pagesTables for Allowable Axial Loads in Equal Single Angles in CompressionMikeNo ratings yet

- Steel DesignDocument195 pagesSteel DesignJay PadamaNo ratings yet

- Basics of Tank Seismic OCRDocument35 pagesBasics of Tank Seismic OCRmario_gNo ratings yet

- AWWA D100 Tension TableDocument1 pageAWWA D100 Tension Tablejojo_323No ratings yet

- Aci 355 1R PDFDocument71 pagesAci 355 1R PDFZEC LIMITEDNo ratings yet

- Old Rebar EDR 48Document4 pagesOld Rebar EDR 48JimBobNo ratings yet

- Problem 1-015 PDFDocument3 pagesProblem 1-015 PDFOscar SanchezNo ratings yet

- Report On Foundations For Dynamic Equipment: Reported by ACI Committee 351Document14 pagesReport On Foundations For Dynamic Equipment: Reported by ACI Committee 351Erick Quan LunaNo ratings yet

- Verco Floor Deck Catalog VF4 03-2012 PDFDocument100 pagesVerco Floor Deck Catalog VF4 03-2012 PDFFerdie TolosaNo ratings yet

- Sharma Et Al-2017-Structural Concrete As PublishedDocument9 pagesSharma Et Al-2017-Structural Concrete As PublisheddebiNo ratings yet

- 1997 UBC CHAPTER 16 HIGHLIGHTSDocument39 pages1997 UBC CHAPTER 16 HIGHLIGHTShamidreza_m85No ratings yet

- Cast-in-Place Concrete SpecificationDocument217 pagesCast-in-Place Concrete SpecificationFarid ObandoNo ratings yet

- ASME 2286-2 Alternative Rules For Determining Allowable External PressureDocument16 pagesASME 2286-2 Alternative Rules For Determining Allowable External PressureMike Dukas100% (1)

- Aci 351 3R PDFDocument26 pagesAci 351 3R PDFLakshmi PrabhaNo ratings yet

- I S C e R C S: ACI 364.2T-08Document4 pagesI S C e R C S: ACI 364.2T-08jasminetsoNo ratings yet

- Pressure Vessel Handbook 10th Edition Megyesy PDFDocument864 pagesPressure Vessel Handbook 10th Edition Megyesy PDFamanmittal08No ratings yet

- Research Report On Single Plate Shear Connections: North Carolina State UniversityDocument51 pagesResearch Report On Single Plate Shear Connections: North Carolina State UniversityHarshaVeeragandhamNo ratings yet

- Steelwise Strength and EngagementDocument3 pagesSteelwise Strength and EngagementGiri DharanNo ratings yet

- Installation of Metal Ceiling Suspension Systems For Acoustical Tile and Lay-In PanelsDocument5 pagesInstallation of Metal Ceiling Suspension Systems For Acoustical Tile and Lay-In PanelsJuan Carlos Huisa ChuraNo ratings yet

- 2010 AISC Spec PresentationDocument48 pages2010 AISC Spec PresentationJuanCarlosNo ratings yet

- EPA wind load calculations for outdoor fixturesDocument1 pageEPA wind load calculations for outdoor fixturesSandip SenguptaNo ratings yet

- Anchor Bolt Design PhilosophyDocument6 pagesAnchor Bolt Design Philosophyprabhu81100% (1)

- A Bolts Aci318 05Document6 pagesA Bolts Aci318 05RnD2013No ratings yet

- For Buildings and Other Structures For Wind LoadsDocument28 pagesFor Buildings and Other Structures For Wind LoadsMarinos Giannoukakis100% (1)

- Design Aid For Triangular Bracket Plates Using AISC SpecificationsDocument10 pagesDesign Aid For Triangular Bracket Plates Using AISC Specificationsmaroco1098100% (7)

- Pages From ASME PTB-4-2013 - Section VIII-Division 1 Example Problem ManualDocument4 pagesPages From ASME PTB-4-2013 - Section VIII-Division 1 Example Problem Manualzguy360No ratings yet

- 1997 - Veletsos Et Al - Dynamics of Solid Containing TanksDocument93 pages1997 - Veletsos Et Al - Dynamics of Solid Containing TanksmahdiebNo ratings yet

- WELDED TANKS FOR OIL STORAGE tablesDocument2 pagesWELDED TANKS FOR OIL STORAGE tablesGerman DiBaccoNo ratings yet

- Sloshing Loads in Liquid-Storage Tanks With InsuffDocument9 pagesSloshing Loads in Liquid-Storage Tanks With Insuffjchavesz6100% (1)

- Enerpac CLRG Series CatalogDocument4 pagesEnerpac CLRG Series CatalogTitanplyNo ratings yet

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part3-Pull Out Strength in TensionDocument4 pagesConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part3-Pull Out Strength in TensionVenu GopalNo ratings yet

- Strength & Behaviour of Anchor Bolts in Pedestals PDFDocument136 pagesStrength & Behaviour of Anchor Bolts in Pedestals PDFEmanNo ratings yet

- Anchorbolt (318 08)Document26 pagesAnchorbolt (318 08)Anonymous 9MDGo2jNo ratings yet

- The Effect of Eccentricity On Brace-To-Gusset AnglesDocument6 pagesThe Effect of Eccentricity On Brace-To-Gusset AnglesAnonymous 7MdZQn10% (1)

- Detail of Sleeve: NotesDocument1 pageDetail of Sleeve: Notesطه حلمىNo ratings yet

- Anchor bolt installation guideDocument1 pageAnchor bolt installation guideFahadNo ratings yet

- Anchor bolt installation guideDocument1 pageAnchor bolt installation guideSHAIK ASIMUDDINNo ratings yet

- Anchor bolt installation guideDocument1 pageAnchor bolt installation guideMuhammad Najam AbbasNo ratings yet

- Anchor bolt installation guideDocument1 pageAnchor bolt installation guideErin JohnsonNo ratings yet

- Aa 036322 001 PDFDocument1 pageAa 036322 001 PDFErin JohnsonNo ratings yet

- Aa 036322 001Document1 pageAa 036322 001FahadNo ratings yet

- Detail of Sleeve: NotesDocument1 pageDetail of Sleeve: Notesطه حلمىNo ratings yet

- Detail of Sleeve: NotesDocument1 pageDetail of Sleeve: Notesطه حلمىNo ratings yet

- DS 6Document14 pagesDS 6hemantmech099200No ratings yet

- 4124 Fy VD SD17517L10100002 Is02Document2 pages4124 Fy VD SD17517L10100002 Is02titir bagchiNo ratings yet

- 1801-FR02-42-R-XD-00009 - C1 - General Arrangement - S42PD530A Scale Inhibitor - SubseaDocument1 page1801-FR02-42-R-XD-00009 - C1 - General Arrangement - S42PD530A Scale Inhibitor - SubseaNam DHNo ratings yet

- Sense and Sensibility: Lighting Ground PlanDocument1 pageSense and Sensibility: Lighting Ground Planapi-509024597No ratings yet

- CADWorx 2016 Quick Start Lesson Guide R2Document50 pagesCADWorx 2016 Quick Start Lesson Guide R2Luz Duarte100% (1)

- Autopipe: Connect V11.1Document29 pagesAutopipe: Connect V11.1Mallela Sampath KumarNo ratings yet

- Hanger SizingDocument26 pagesHanger SizingBùi Văn HợpNo ratings yet

- Cryogenic Pipe CalculationsDocument4 pagesCryogenic Pipe CalculationsEr NvNo ratings yet

- Autopipe New User Tips 9aDocument51 pagesAutopipe New User Tips 9aLuisRiosQNo ratings yet

- Material List - Fabrication: - / - A1ZA-1 2 PMDocument2 pagesMaterial List - Fabrication: - / - A1ZA-1 2 PMMallela Sampath KumarNo ratings yet

- Specific GravityDocument6 pagesSpecific GravityApril Trish AlbañaNo ratings yet

- Structural Engineering ScopeDocument5 pagesStructural Engineering ScopeMallela Sampath KumarNo ratings yet

- SampleCalculationspipingB3132008 PDFDocument13 pagesSampleCalculationspipingB3132008 PDFsosatlantiqueNo ratings yet

- Fatigue Stress Analysis PDFDocument228 pagesFatigue Stress Analysis PDFMallela Sampath Kumar100% (1)

- Spring Can Support With FrictionDocument15 pagesSpring Can Support With FrictionMallela Sampath KumarNo ratings yet

- Load CasesDocument8 pagesLoad Casestebodin_319100% (1)

- Completion Fluid SelectionDocument31 pagesCompletion Fluid Selectionandrew_yeap_2100% (3)

- ANNA W01 M00 GC 0600 12 General ArrangementDocument1 pageANNA W01 M00 GC 0600 12 General ArrangementMallela Sampath KumarNo ratings yet

- Completion Fluid SelectionDocument31 pagesCompletion Fluid Selectionandrew_yeap_2100% (3)

- Oi Lgas Engineering TrainingDocument236 pagesOi Lgas Engineering TrainingMallela Sampath Kumar100% (2)

- Intepretation ASME B31.3Document18 pagesIntepretation ASME B31.3abdulloh_99No ratings yet

- 3D Printer Model Specs GuideDocument1 page3D Printer Model Specs GuideMallela Sampath KumarNo ratings yet

- SIF (C2 Vs ANSYS)Document6 pagesSIF (C2 Vs ANSYS)Rockny2011No ratings yet

- Code of Practice For Oil Storage Installations 1992Document22 pagesCode of Practice For Oil Storage Installations 1992Hassan SleemNo ratings yet

- Anchor Support - Thermal ExpansionDocument99 pagesAnchor Support - Thermal ExpansionKCFUNG100% (1)

- Design of Offshore PlatformDocument16 pagesDesign of Offshore PlatformMd Azahary100% (1)

- Asme b31.3 InterpretationsDocument18 pagesAsme b31.3 InterpretationsMallela Sampath KumarNo ratings yet

- Torus centroid calculation for segment with parametric equationsDocument2 pagesTorus centroid calculation for segment with parametric equationsMallela Sampath KumarNo ratings yet

- Managing Transient Vibration Risks in Pump FacilitiesDocument8 pagesManaging Transient Vibration Risks in Pump FacilitiesMallela Sampath KumarNo ratings yet

- Ceasar2pipingsoftwaretutorialpdf PDFDocument3 pagesCeasar2pipingsoftwaretutorialpdf PDFMallela Sampath KumarNo ratings yet

- Ceasar2pipingsoftwaretutorialpdf PDFDocument3 pagesCeasar2pipingsoftwaretutorialpdf PDFMallela Sampath KumarNo ratings yet

- Approach 2: Considered Both Positive and Negative Impulse LoadsDocument2 pagesApproach 2: Considered Both Positive and Negative Impulse LoadsMallela Sampath KumarNo ratings yet

- Project Management FundamentalsDocument36 pagesProject Management FundamentalsRick Scream0% (1)

- Standard Specification Stage2 Interim Report AppendicesDocument64 pagesStandard Specification Stage2 Interim Report AppendicesMaxNo ratings yet

- Pipestem Dam ArticleDocument4 pagesPipestem Dam ArticleIsaias EnriquezNo ratings yet

- Technical Issues Mom #001Document2 pagesTechnical Issues Mom #001SLPlanner PlannerNo ratings yet

- W.planned Activity Schedule.v1.2023.03.04Document4 pagesW.planned Activity Schedule.v1.2023.03.04Amelia GüitrónNo ratings yet

- Steel - and Synthetic Fibre ReinforcedDocument12 pagesSteel - and Synthetic Fibre ReinforcedMangisi Haryanto ParapatNo ratings yet

- Sika PDS E SikaFix - 101Document2 pagesSika PDS E SikaFix - 101lwin_oo2435No ratings yet

- 02intro and Design DataDocument7 pages02intro and Design DataAyush SarrafNo ratings yet

- FGP XXXX - Mabini Pier Repair Bid FormDocument53 pagesFGP XXXX - Mabini Pier Repair Bid Formmr. oneNo ratings yet

- MARKS N Manual Instrucciones (35451180 07-02)Document84 pagesMARKS N Manual Instrucciones (35451180 07-02)Juan Francisco García GarcíaNo ratings yet

- Tronair 12 Ton Single Stage Jack 02-1248-0112Document32 pagesTronair 12 Ton Single Stage Jack 02-1248-0112Carlos Alberto Rozo R.No ratings yet

- BoqDocument35 pagesBoqcan_cer087No ratings yet

- Breaking Down Construction Management FoundationsDocument15 pagesBreaking Down Construction Management FoundationsJuan Pablo CortésNo ratings yet

- HTTP://WWW - scribd.com/doc/59613990/CIVIL-ENGINEERING-AND-ARCHITECTURE 3rd SemDocument21 pagesHTTP://WWW - scribd.com/doc/59613990/CIVIL-ENGINEERING-AND-ARCHITECTURE 3rd SemJinu Madhavan0% (1)

- Material Selection Using Ashby MethodDocument6 pagesMaterial Selection Using Ashby MethodRaúl AnelNo ratings yet

- Classified Advertising: Situation Vacant Contd On Following PageDocument3 pagesClassified Advertising: Situation Vacant Contd On Following PageKrishna UdayanNo ratings yet

- Presentation Application of Geosynthetics in Canal 171012052340Document71 pagesPresentation Application of Geosynthetics in Canal 171012052340Nitin RaoNo ratings yet

- DGS 1300 160 Bolt TorquingDocument12 pagesDGS 1300 160 Bolt TorquingMcmiltondmordom100% (1)

- Ceramic and Stone Tiling GuideDocument43 pagesCeramic and Stone Tiling Guidenick_bNo ratings yet

- Exhaust Temperature Spread 2Document5 pagesExhaust Temperature Spread 2nabil160874No ratings yet

- Bim and Remote Construction ProjectsDocument19 pagesBim and Remote Construction ProjectsVisionPurposeNo ratings yet

- DPR TJP September r1 v1Document258 pagesDPR TJP September r1 v1akbar suhadaNo ratings yet

- Meeg - PL - Dor - Second Fix Plumbing and Sanitary WorksDocument11 pagesMeeg - PL - Dor - Second Fix Plumbing and Sanitary WorksHaymanot BaynesagnNo ratings yet

- Reinforced Concrete Beam: Tank SupportDocument3 pagesReinforced Concrete Beam: Tank SupportMatiur Rahman BasumNo ratings yet

- Reference List - DemagDocument5 pagesReference List - DemagHarun Al-RasyidNo ratings yet

- Gypsum Plaster: Advantages and DisadvantagesDocument35 pagesGypsum Plaster: Advantages and DisadvantagesadkNo ratings yet

- 01 BIM Project Execution Planning Guide V2.1 (One-Sided)Document134 pages01 BIM Project Execution Planning Guide V2.1 (One-Sided)Mois DanielNo ratings yet

- Site Classification ReportDocument13 pagesSite Classification ReportGiri WakshanNo ratings yet

- Valve Specifications: (Đính kèm YCMS số /YCMS/2020/DVK.CK.77)Document1 pageValve Specifications: (Đính kèm YCMS số /YCMS/2020/DVK.CK.77)Tu PhamNo ratings yet

- Gb250 Series: Installation, Operation & Maintenance Manual and Replacement Parts ListDocument28 pagesGb250 Series: Installation, Operation & Maintenance Manual and Replacement Parts ListRodney LanagNo ratings yet