Professional Documents

Culture Documents

SLAB ON GRADE ANALYSIS AND DESIGN

Uploaded by

arvind sharmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SLAB ON GRADE ANALYSIS AND DESIGN

Uploaded by

arvind sharmaCopyright:

Available Formats

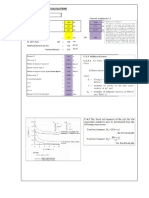

CONCRETE SLAB ON GRADE ANALYSIS AND DESIGN

For Slab Subjected to Uniformly Distributed Loading

th

Designed as per TR 34 4 Edition

Job Name: WOLP- Bhiwandi-Suroj Buildcon Pvt.Ltd Subject: Saw-cut Floor Designer: H Thejas/ Nectarc

Design Date: 25/05/2020 Design Case: UDL = 5 tons/sq.m Checker: VJ

π π π Top of Slab

Input Data:

λ 2λ λ

q q

Slab Thickness, h = 175 mm

Concrete Strength Class = C25/30

h

Char. Concrete Compressive Strength, fck = 25 MPa (cylinder)

Char. Concrete Compressive Strength, fcu = 30 MPa (cube) (Sub-base)

Mean Concrete Axial Tensile Strength, fctm = 2.59 MPa Loading scheme causing maximum negative bending

2

Secant Modulus of Elasticity, Ecm = 31 kN/mm π Top of Slab

Concrete Poisson's Ratio, μ = 2λ

0.15

q

Reinforcing Yield, fy = 500 MPa

Sub-base Modulus, k = 0.040 N/mm3

Uniformly Distriuted Load, q = 50.0 kN/m2 h

Load Safety Factor, γL = 1.20 (Sub-base)

Material Safety Factor - Concrete, γc = 1.50 Loading scheme causing maximum positive bending

Material Safety Factor - Steel, γs = 1.15

Top Rebar Dia., dt = 0 mm Bottom Rebars, Asb h/4 deep sawn joint

Top Rebar Spacing, st = 0 mm Bottom Rebar Cover = 30 mm

Bottom Rebar Dia., db = 7 mm

h

Bottom Rebar Spacing, sb = 200 mm

Saw-cut Joint Spacing, L = 4.0 m

Calculations: Typical Saw-cut Joint

Capacity Calculations

Parameter λ = 0.00092 /mm = 3 / ℎ (Eqn. 33)

Critical Aisle Width, π/2λ = 1710.40 mm

Design Concrete Flexural Tensile Strength, fctd,fl = 2.46 MPa , = (1.6 − 0.001ℎ)/ (Eqn.1)

Ultimate Cracking Moment Capacity, Mun = 12.57 kNm/m = , (ℎ /6000) (Eqn.2)

Top Area of Steel Reinforcement, Ast = 0.00 mm2/m = (250 ⁄ )

Top Moment Capacity due to Rebars, Muns = 0.00 kNm/m = 0.95 / (Eqn.3)

2

Bottom Area of Steel Reinforcement, Asb = 192.42 mm /m = (250 ⁄ )

Bottom Moment Capacity due to Rebars, Mup = 11.52 kNm/m = 0.95 / (Eqn.3)

Ultimate Load Capacity (Negative Bending), qun = 63.09 kN/m2 = 5.95 (Eqn. 35)

2

Ultimate Load Capacity (Positive Bending), qup = 60.36 kN/m = 6.21 (Eqn. 36)

Ultimate Factored Acting UDL, qu = 60.00 kN/m

2

=

q(allow) >= q(actual), SAFE

Shrinkage Reinforcement: (assuming subgrade drag method)

Friction Factor, F = 0.50 F = 0.5 (assumed friction factor between sub-base and slab)

2

Loaded Slab Weight, W = 54.38 kN/m W = 25 × (h/1000) + UDL

Reinf. Allow. Stress, fs = 300 MPa fs = 0.6fy

2

Ashrinkage = 181.3 mm /m Ashrinkage = F×L×W/(2×fs)

As, provided = 192 mm2/m As(provided) >= As(shrinkage), O.K.

Results:

Design Outcome = SAFE

Concrete Grade (Cube), fcu = 30 MPa

Slab Thickness, h = 175 mm

Bottom Reinforcement Area, Asb = 192 mm2/m

Bottom Rebar Diameter, db = 7 mm

Spacing c/c, sb = 200 mm

Cover to Bottom Rebar = 35 mm

Top Reinforcement Area, Ast = 0

Rebar Diameter, dt = NA

Spacing c/c, st = NA

Cover to Top Rebar = NA

3

Modulus of Sub-base to be considered, k = 0.04 N/mm

Maximum Saw-cut Panel Size, L = 4.0 m

Page 1 of 1

You might also like

- 7 Ton Point LoadDocument2 pages7 Ton Point Loadarvind sharmaNo ratings yet

- Apron Design With Fiber MeshDocument2 pagesApron Design With Fiber Mesharvind sharmaNo ratings yet

- E.Naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - v2.1.1Document2 pagesE.Naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - v2.1.1Johny Mark AsuncionNo ratings yet

- Desain Balok Lentur: 1. General InformationDocument2 pagesDesain Balok Lentur: 1. General InformationPuji KurniawanNo ratings yet

- E.Naldoza Design of Singly Reinforced Rectangular Section-ACI318M-14 (NSCP 2015) V2.1.2-08june2021Document2 pagesE.Naldoza Design of Singly Reinforced Rectangular Section-ACI318M-14 (NSCP 2015) V2.1.2-08june2021RL SanNo ratings yet

- 02-Design of Grade Slab - As Per TR-34Document42 pages02-Design of Grade Slab - As Per TR-34Anonymous Clm40C1No ratings yet

- Pile Design Cal - Rev-1Document9 pagesPile Design Cal - Rev-1Nitin SakpalNo ratings yet

- B1-Floorbeam (250 X 500) Beam DesignDocument2 pagesB1-Floorbeam (250 X 500) Beam DesignAshish GNo ratings yet

- Valve Pit DesignDocument3 pagesValve Pit DesignersivarajNo ratings yet

- Box Culvert Without CushionDocument23 pagesBox Culvert Without CushionPrafulla Malla100% (1)

- Base PlateDocument13 pagesBase PlateNaga Manikanta TatikondaNo ratings yet

- Design of Walkway Slab (WS1) ReinforcementDocument2 pagesDesign of Walkway Slab (WS1) ReinforcementRaju SainiNo ratings yet

- DESIGN OF FLOOR SLAB (0.15m Thick)Document9 pagesDESIGN OF FLOOR SLAB (0.15m Thick)Living Life100% (1)

- Pile Design Cal - 23.01 (Upd)Document8 pagesPile Design Cal - 23.01 (Upd)Nitin SakpalNo ratings yet

- Valve Pit Wall DesignDocument3 pagesValve Pit Wall DesignersivarajNo ratings yet

- End Plate Column Splice Connection by IS CodeDocument15 pagesEnd Plate Column Splice Connection by IS CodeStructural SpreadsheetsNo ratings yet

- Element Location: Subject: Made by Design Code: Loading On Slab Value Units JamesDocument5 pagesElement Location: Subject: Made by Design Code: Loading On Slab Value Units JamesJames AswaNo ratings yet

- Design of Two Way Slab (Continuous) : Given DataDocument3 pagesDesign of Two Way Slab (Continuous) : Given DataParwan Exceltech100% (1)

- Engr Vic (LRFD Sample)Document173 pagesEngr Vic (LRFD Sample)Victor DlreyesNo ratings yet

- AISC2005-Anchor BoltDocument9 pagesAISC2005-Anchor Boltnmtam.sdh20No ratings yet

- RDSODocument8 pagesRDSOVikasNo ratings yet

- Corner Wall Design - CulvertDocument5 pagesCorner Wall Design - CulvertSuresh MahalingamNo ratings yet

- E.naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - V2.0.2Document2 pagesE.naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - V2.0.2Max100% (1)

- Dowel Bar Design 32mm BarDocument1 pageDowel Bar Design 32mm BarGobinder Singh VirdeeNo ratings yet

- Plate Girder BridgeDocument14 pagesPlate Girder BridgeDHANALAKSHMI G TeachingNo ratings yet

- 21Document4 pages21Sarah Mae GarciaNo ratings yet

- Spreader Beam Design for 10 Ton LiftingDocument25 pagesSpreader Beam Design for 10 Ton LiftingWalterNo ratings yet

- One Way Continuous SlabDocument12 pagesOne Way Continuous Slabvenkatesh19701No ratings yet

- Calcs for Concrete Industrial Ground Floor DesignDocument3 pagesCalcs for Concrete Industrial Ground Floor DesignRuemu Godwin InikoriNo ratings yet

- 01 SPECIFICATION, CONCRTE COVER AND LOADING ANALYSIS FOR SLABbDocument11 pages01 SPECIFICATION, CONCRTE COVER AND LOADING ANALYSIS FOR SLABbbasitNo ratings yet

- Design of A R.C.C Mountable Drain Slab CoverDocument4 pagesDesign of A R.C.C Mountable Drain Slab CoverBilal Ahmed Barbhuiya100% (8)

- New Bearing Stopper 25mDocument2 pagesNew Bearing Stopper 25mAmit VarmaNo ratings yet

- 25m Span Superstructure of Bridge DesignDocument45 pages25m Span Superstructure of Bridge Designshekhar Nath chapagain75% (4)

- Top Slab Design SheetDocument3 pagesTop Slab Design SheetersivarajNo ratings yet

- Design of Pile and Pile Cap BeamDocument4 pagesDesign of Pile and Pile Cap Beamshivendra kumarNo ratings yet

- Beam DesignDocument14 pagesBeam DesignAbinash MandalNo ratings yet

- Crack Width2Document1 pageCrack Width2RajeshNo ratings yet

- Spreader Beam AttachmentDocument28 pagesSpreader Beam AttachmentAKSHAY BHATKAR100% (1)

- 150mm Thick FloorDocument11 pages150mm Thick FloorAnil UdaleNo ratings yet

- 13.0 Desing of Staircase 13.1 For Flight 1 To 6: Hence SafeDocument7 pages13.0 Desing of Staircase 13.1 For Flight 1 To 6: Hence SafeSmit PatelNo ratings yet

- Design Capacity of HCS: 265 Carpark 2 - Basement Level 1Document9 pagesDesign Capacity of HCS: 265 Carpark 2 - Basement Level 1anilkv66No ratings yet

- Phytorid STPDocument4 pagesPhytorid STPsamirbendre1No ratings yet

- Example 5.1.10 (Page 109) : 1) Input Design DataDocument12 pagesExample 5.1.10 (Page 109) : 1) Input Design DatasNo ratings yet

- Embedded PlateDocument2 pagesEmbedded PlateAlma M. LaraNo ratings yet

- Design Sheet: DPWH DesignedDocument5 pagesDesign Sheet: DPWH DesignedEdward Albert Mendoza BañagaNo ratings yet

- 341+265 Design Report - 32Document1 page341+265 Design Report - 32VivekNo ratings yet

- Design of Two Way Slab (Continuous) : Given DataDocument3 pagesDesign of Two Way Slab (Continuous) : Given DataParwan ExceltechNo ratings yet

- Base Slab Design - CulvertDocument6 pagesBase Slab Design - CulvertSuresh MahalingamNo ratings yet

- Base Plate DesignDocument1 pageBase Plate DesignJimit PayNo ratings yet

- Project Delhi Metro BC17 Wall Panel Flexural Crack Width CalculationDocument10 pagesProject Delhi Metro BC17 Wall Panel Flexural Crack Width CalculationpsconsultantsNo ratings yet

- Ribbed Slab DesignDocument4 pagesRibbed Slab Designyusuf abdinasir100% (1)

- Base Slab Design - RampDocument6 pagesBase Slab Design - RampSuresh Mahalingam100% (1)

- Lintal Beam and Wall OpeningDocument4 pagesLintal Beam and Wall Openingkc chanNo ratings yet

- Column Base Plate DesignDocument1 pageColumn Base Plate DesignBunkun15No ratings yet

- Engineering and Development Corporation of The PhilippinesDocument4 pagesEngineering and Development Corporation of The Philippinesmark ignacioNo ratings yet

- Project: Subject:: Design of SheathingDocument2 pagesProject: Subject:: Design of Sheathingbmurali19783190No ratings yet

- Crack WidthDocument21 pagesCrack WidthBalaji HariNo ratings yet

- Design of two-way reinforced concrete slabDocument15 pagesDesign of two-way reinforced concrete slabMohammed Saleem Syed KhaderNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Rigid-Pavement-Design-as-Per-IRC-58-2011-DesignDocument5 pagesRigid-Pavement-Design-as-Per-IRC-58-2011-Designarvind sharma100% (1)

- Rigid Pavement Design As Per IRC 58 2011 Axle Load SpectrumDocument1 pageRigid Pavement Design As Per IRC 58 2011 Axle Load Spectrumarvind sharmaNo ratings yet

- Rigid Pavement Design As Per IRC 58 2011 Axle Load SpectrumDocument1 pageRigid Pavement Design As Per IRC 58 2011 Axle Load Spectrumarvind sharmaNo ratings yet

- Rigid Pavement Design As Per IRC 58 2011 BUC and TDC AnalysisDocument3 pagesRigid Pavement Design As Per IRC 58 2011 BUC and TDC Analysisarvind sharmaNo ratings yet

- Rigid Pavement Design As Per IRC 58 2011 BUC and TDC AnalysisDocument3 pagesRigid Pavement Design As Per IRC 58 2011 BUC and TDC Analysisarvind sharmaNo ratings yet

- 5.paver Block Subbase DesignDocument4 pages5.paver Block Subbase Designarvind sharmaNo ratings yet

- 03.05.2020-Design Calculation - SewageDocument1 page03.05.2020-Design Calculation - Sewagearvind sharmaNo ratings yet

- Annexure I - Water - STP - LS CalculationDocument3 pagesAnnexure I - Water - STP - LS Calculationarvind sharmaNo ratings yet

- 03.05.2020-Design Calculation - Sewage PDFDocument1 page03.05.2020-Design Calculation - Sewage PDFarvind sharmaNo ratings yet

- FLEXILBE PAVEMENT - Design ReportDocument12 pagesFLEXILBE PAVEMENT - Design Reportarvind sharmaNo ratings yet

- 03.05.2020-Design Calculation - SewageDocument1 page03.05.2020-Design Calculation - Sewagearvind sharmaNo ratings yet

- Apron Design For Ware HouseDocument2 pagesApron Design For Ware Housearvind sharmaNo ratings yet

- Kanai Technology Parks Flexible Pavement DesignDocument6 pagesKanai Technology Parks Flexible Pavement Designarvind sharmaNo ratings yet

- Commented Embassy Road Design For Suroj With Fibres PDFDocument2 pagesCommented Embassy Road Design For Suroj With Fibres PDFarvind sharmaNo ratings yet

- Dreyer Analysis 1988Document349 pagesDreyer Analysis 1988Yutt WattNo ratings yet

- Corbel and NibDocument17 pagesCorbel and NibCatherine Mohanji GeraNo ratings yet

- Week4 Work Energy PDFDocument17 pagesWeek4 Work Energy PDFramadan rashadNo ratings yet

- SAP 2000 Structural Analysis and Design Training CourseDocument40 pagesSAP 2000 Structural Analysis and Design Training CourseSomaNo ratings yet

- Reynolds Apparatus ExperimentDocument4 pagesReynolds Apparatus ExperimentRaj PratyushNo ratings yet

- Navier Stokes EquationsDocument9 pagesNavier Stokes EquationsNikhil AgrawalNo ratings yet

- Wetted Wall ColumnDocument8 pagesWetted Wall ColumnSameer NasirNo ratings yet

- Turbomachinery Fundamentals: Turbines, Compressors and Fluid MechanicsDocument39 pagesTurbomachinery Fundamentals: Turbines, Compressors and Fluid MechanicsHailu FekaduNo ratings yet

- CH12 - 4 - ProjectilesDocument14 pagesCH12 - 4 - ProjectilesKayla T NyakudangaNo ratings yet

- Common Mistakes in Fatigue AnalysisDocument14 pagesCommon Mistakes in Fatigue AnalysismuhannedNo ratings yet

- Dance Newtons Laws RubricDocument2 pagesDance Newtons Laws Rubricapi-588118709No ratings yet

- Exp. 6Document10 pagesExp. 6Kamran AliNo ratings yet

- A2 Gravitational FieldDocument57 pagesA2 Gravitational Fieldincorrect37No ratings yet

- Joule Thomson EffectDocument2 pagesJoule Thomson EffectMukesh EmkayNo ratings yet

- Non-Newtonian Flow in Annuli: of ofDocument6 pagesNon-Newtonian Flow in Annuli: of ofLaura NathaliaNo ratings yet

- Significance of Damage Models Applied in AbaqusDocument11 pagesSignificance of Damage Models Applied in Abaquspankaj216No ratings yet

- EC8651 TLWG - Unit 1 - QBDocument3 pagesEC8651 TLWG - Unit 1 - QBSundar 2151No ratings yet

- Activity Sheet 4Document3 pagesActivity Sheet 4Shiebastian ArietaNo ratings yet

- Hydrostatic Pressure CenterDocument19 pagesHydrostatic Pressure CenterTinotendaNo ratings yet

- Numerical Simulacion of Watter HammerDocument4 pagesNumerical Simulacion of Watter HammerWilliam Lopez AyalaNo ratings yet

- PHYS 1120 Waves Solutions PDFDocument15 pagesPHYS 1120 Waves Solutions PDFYen Aduana100% (1)

- ChokesDocument6 pagesChokesRubén De la CruzNo ratings yet

- Theoretical Analysis of The Thermal Resistance of Non-Uniform Fouling On Cross-Flow Heat Exchanger TubesDocument8 pagesTheoretical Analysis of The Thermal Resistance of Non-Uniform Fouling On Cross-Flow Heat Exchanger TubesShalehAhmadNo ratings yet

- Waverider Design: Caret WingDocument8 pagesWaverider Design: Caret Wingtasham380No ratings yet

- Postharvest Technology-Units Operations NotesDocument83 pagesPostharvest Technology-Units Operations Notesntjanv100% (4)

- Literature StudyDocument281 pagesLiterature StudybramiozoNo ratings yet

- Ultrasonography in The ICU - Practical ApplicationsDocument152 pagesUltrasonography in The ICU - Practical ApplicationsShueyd BorgesNo ratings yet

- AZ Element Design Strength CalculationsDocument208 pagesAZ Element Design Strength CalculationsDipak BorsaikiaNo ratings yet

- Elastomeric Bearing DesignDocument1 pageElastomeric Bearing DesignSabbir SiddiqueNo ratings yet

- AE3301 EAE Model QPDocument2 pagesAE3301 EAE Model QPVivekananda SubramaniNo ratings yet