Professional Documents

Culture Documents

Pages From Jace.12657-4

Uploaded by

Jason AlexOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pages From Jace.12657-4

Uploaded by

Jason AlexCopyright:

Available Formats

166 Journal of the American Ceramic Society—Bertrand et al. Vol. 97, No.

glass transition temperature, Tg, is constant for the three ranging from 420°C to 435°C, suggesting surface crystalliza-

experiments and is equal to 335°C. The increase in the mean tion as the dominant mechanism in the investigated composi-

particle size from 6 lm (fine) to 167 lm (coarse) causes a tion.22 The broadening of the crystallization peaks for the

shift of the crystallization peaks toward higher temperatures bulk as well as the study of Cß elikbilek et al.20 also confirms

this observation.

To identify the nature of the different crystalline phases

appearing upon heating, Raman spectroscopy data were col-

lected as a function of temperature applying the same heat-

ing rate as the DSC runs, that is, 10°C/min. The Raman

(a) shifts evidenced for these crystalline phases associated with

the different crystallization peaks, respectively, corresponds

to c-TeO2, a-TeO2, and WO3 for the coarse particles and

c-TeO2, WO3, and a-TeO2 for the fine particles (Fig. 4).23

(b)

(2) SPS of the 85TeO2–15WO3 Amorphous Powder

The SPS parameters (pressure, temperature, vertical displace-

ment of punches) during the sintering process are shown in

Fig. 5. The sintering temperature was chosen accordingly to

lie between the glass transition and the first crystallization

temperatures. The sintering process starts in the temperature

(c) range 310°C–325°C and ends around 350°C or 370°C

depending on the pressureless sintering treatment made or

not prior to the SPS experiments. The dwell temperature of

370°C was therefore chosen. Different experiments were car-

Fig. 3. DSC curves of coarse (a), fine (b) 85TeO2–15WO3 glass ried out at constant pressure (50 MPa) and temperature

particles, and (c) glass bulk. (370°C) but different dwell times were applied (ranging from

(a) Heat flow (a.u.)

300

1) TeO2γ 2) 0.35

TeO2 α

350

0.30

WO3

0.25

400

Temperature (°C)

Intensity

0.20

450

(1)

(2) 0.15

(3)

500

0.10

0.05

550

40

0.00

200 400 600 800 1 000

Wavenumber (cm–1)

(b) Heat flow (a.u.)

300

0.30

1) TeO2γ 2)

TeO2 α

350

0.25

WO3

400

0.20

Temperature (°C)

Intensity

(1) 0.15

450

(2) 0.10

500

(3)

0.05

550

40

0.00

200 400 600 800 1 000

Wavenumber (cm–1)

Fig. 4. Temperature-dependent Raman spectroscopy data recorded for coarse (a) and fine (b) 85TeO2–15WO3 glass particles showing the

appearance sequence of the different crystalline phases. The Raman data are compared to the DSC thermograms of the corresponding powder.

You might also like

- Carbide Formation and Dissolution in Biomedical Co-Cr-Mo Alloys With Different Carbon Contents During Solution Treatment PDFDocument10 pagesCarbide Formation and Dissolution in Biomedical Co-Cr-Mo Alloys With Different Carbon Contents During Solution Treatment PDFJason AlexNo ratings yet

- Carbide Formation and Dissolution in Biomedical Co-Cr-Mo Alloys With Different Carbon Contents During Solution Treatment PDFDocument10 pagesCarbide Formation and Dissolution in Biomedical Co-Cr-Mo Alloys With Different Carbon Contents During Solution Treatment PDFJason AlexNo ratings yet

- Reaction Engineering I-Problem Sheet IIDocument7 pagesReaction Engineering I-Problem Sheet IISimay AydoganNo ratings yet

- Chemical Vapour Deposition of Silicon Carbide by Pyrolysis of MethylchlorosilanesDocument4 pagesChemical Vapour Deposition of Silicon Carbide by Pyrolysis of MethylchlorosilanesnileshdjNo ratings yet

- Sales Proposal 291KW Karachi Club Annex v1Document7 pagesSales Proposal 291KW Karachi Club Annex v1junaid ahmadNo ratings yet

- G10 Lesson1 DLPDocument15 pagesG10 Lesson1 DLPAngeles, Mark Allen CNo ratings yet

- Exploring The Sensitivity of Thermal Analysis Techniques To The Glass TransitionDocument15 pagesExploring The Sensitivity of Thermal Analysis Techniques To The Glass TransitionAgustin Jose MarcuzziNo ratings yet

- Exploring The Sensitivity of Thermal Analysis TechniquesDocument15 pagesExploring The Sensitivity of Thermal Analysis TechniquespedroNo ratings yet

- Mechanism of Thermal Decomposition of LigninDocument13 pagesMechanism of Thermal Decomposition of LigninDinu AndreiNo ratings yet

- Chabbi 2006Document7 pagesChabbi 2006karthikeyan gNo ratings yet

- Duplex Yayın 1Document10 pagesDuplex Yayın 1Hüseyin ZenginNo ratings yet

- Chalcogenide Letters Vol. 6, No. 8, September 2009, P. 403Document12 pagesChalcogenide Letters Vol. 6, No. 8, September 2009, P. 403Brandon StoneNo ratings yet

- Dilatometric and Hardness Analysis of C45 Steel PDFDocument4 pagesDilatometric and Hardness Analysis of C45 Steel PDFInaamNo ratings yet

- Dilatometric and Hardness Analysis of C45 Steel Tempering With Different Heating-Up RatesDocument4 pagesDilatometric and Hardness Analysis of C45 Steel Tempering With Different Heating-Up RatesInaamNo ratings yet

- Dilatometric and Hardness Analysis of C45 Steel Tempering With Different Heating-Up RatesDocument4 pagesDilatometric and Hardness Analysis of C45 Steel Tempering With Different Heating-Up RatesInaamNo ratings yet

- Asanovic, 2004Document7 pagesAsanovic, 2004Muhammad Falqi YusufNo ratings yet

- 1984 The Thermal Stability of Binary Alkali Metal NitratesDocument10 pages1984 The Thermal Stability of Binary Alkali Metal NitratesAdrian CaraballoNo ratings yet

- Rank Booster TEst - II, 15.03.2024Document20 pagesRank Booster TEst - II, 15.03.2024ntype795No ratings yet

- Effect of Heating Rate and Grain Size On The Melting Behavior of The Alloy NB 47 Mass% Ti in Pulse-Heating ExperimentsDocument12 pagesEffect of Heating Rate and Grain Size On The Melting Behavior of The Alloy NB 47 Mass% Ti in Pulse-Heating ExperimentsLakshan FonsekaNo ratings yet

- 2008 The LiCl-KCl Binary SystemDocument3 pages2008 The LiCl-KCl Binary SystemAdrian CaraballoNo ratings yet

- Material FactorsDocument9 pagesMaterial FactorsSajjad k. AmhawiNo ratings yet

- Corrosion and Surface Chemistry of Metals - Iran-Mavad - Com-205-409Document205 pagesCorrosion and Surface Chemistry of Metals - Iran-Mavad - Com-205-409Julio CastañedaNo ratings yet

- Boiling Point Distribution of Crude Oils Based On TBP and Astm D-86 Distillation DataDocument17 pagesBoiling Point Distribution of Crude Oils Based On TBP and Astm D-86 Distillation DataFAH MANNo ratings yet

- BCZT Crystallo-GjitDocument8 pagesBCZT Crystallo-GjitRachna SelvamaniNo ratings yet

- TBP Distribution of CrudeDocument16 pagesTBP Distribution of CrudeAayushi AggarwalNo ratings yet

- DSC 60Document2 pagesDSC 60Omar SaebNo ratings yet

- ppt mgco3-2====Precipitation of Magnesium Carbonate== رامین فریدی ==Document10 pagesppt mgco3-2====Precipitation of Magnesium Carbonate== رامین فریدی ==raminNo ratings yet

- Kim HT - 1996 - Article - StudyOnTheSolidificationCracki - PDF - Borland EquationDocument6 pagesKim HT - 1996 - Article - StudyOnTheSolidificationCracki - PDF - Borland Equation이상벽No ratings yet

- Differential Scanning Calorimetry (DSC) Uses A Servo System To Supply EnergyDocument3 pagesDifferential Scanning Calorimetry (DSC) Uses A Servo System To Supply EnergyPaulo FragaNo ratings yet

- Final Quiz-ME-170Document4 pagesFinal Quiz-ME-170omeo habibNo ratings yet

- Dehydration of Crystalline K, C03-1.5 H, O: Thermochimica Acta, 66 (1983) 255-265Document11 pagesDehydration of Crystalline K, C03-1.5 H, O: Thermochimica Acta, 66 (1983) 255-265Engineering Office ShahrakNo ratings yet

- Nulife-08-23 - SCC Pilot Study Ra-3Document51 pagesNulife-08-23 - SCC Pilot Study Ra-3Otso CronvallNo ratings yet

- Hydrogen Reduction Kinetics of Electrometallurgical SlimeDocument8 pagesHydrogen Reduction Kinetics of Electrometallurgical SlimeFabian de Jesus Orozco MartinezNo ratings yet

- Pages From Jace.12657-3Document1 pagePages From Jace.12657-3Jason AlexNo ratings yet

- Armstrong Lecture Ionic Liquids in Separations and Mass SpeDocument102 pagesArmstrong Lecture Ionic Liquids in Separations and Mass SpeAvinash GillNo ratings yet

- Study On Curve of Pe-Heating Temperature Control in Selective Laser SinteringDocument3 pagesStudy On Curve of Pe-Heating Temperature Control in Selective Laser SinteringqualityfreekNo ratings yet

- C - H 3 O H: A Thermal Analysis Study of IbuprofenDocument8 pagesC - H 3 O H: A Thermal Analysis Study of IbuprofenJose CordobaNo ratings yet

- The Iron - Niobium Phase Diagram and The Viscosity of Liquid Alloys in This SystemDocument7 pagesThe Iron - Niobium Phase Diagram and The Viscosity of Liquid Alloys in This SystemMehroos AliNo ratings yet

- Vanessa PDFDocument4 pagesVanessa PDFosnaider chamorro cardenasNo ratings yet

- Effect of Austempering Time On Microstructure and Properties of A Low-Carbon Bainite SteelDocument7 pagesEffect of Austempering Time On Microstructure and Properties of A Low-Carbon Bainite Steelمسعود بوزويرNo ratings yet

- Samuneva 1990Document6 pagesSamuneva 1990kawmokNo ratings yet

- Exp Ring N BallDocument12 pagesExp Ring N BallSiti Aishah Sahul Hamid100% (4)

- Annerel & Taerwe 2008 Diagnosis of The State of Concrete Structures After FireDocument6 pagesAnnerel & Taerwe 2008 Diagnosis of The State of Concrete Structures After FireRm1262No ratings yet

- The Use of Differential Scann# G Calorimetry To Study Polymer Crystallization KineticsDocument10 pagesThe Use of Differential Scann# G Calorimetry To Study Polymer Crystallization Kineticsapi-3733260No ratings yet

- Unsteady State Heat Transfer-MSTDocument16 pagesUnsteady State Heat Transfer-MSTsukhmaniNo ratings yet

- Robertopereira 2014Document6 pagesRobertopereira 2014ElnurNo ratings yet

- Low Temperature Deformation of The R-Phase in A NiTiFe Shape Memory AlloyDocument4 pagesLow Temperature Deformation of The R-Phase in A NiTiFe Shape Memory AlloyLive LivedNo ratings yet

- WJ 1989 12 s510 PDFDocument11 pagesWJ 1989 12 s510 PDFSudeep KumarNo ratings yet

- Presentation 1Document25 pagesPresentation 1vanithaethirajNo ratings yet

- K00337 - 20180906121226 - Exercises 1Document3 pagesK00337 - 20180906121226 - Exercises 1andiana siona100% (1)

- Straight Ammonium Nitrate Fertilizer Stabilization:theoritical PossibilitiesDocument26 pagesStraight Ammonium Nitrate Fertilizer Stabilization:theoritical PossibilitiesMagdy SalehNo ratings yet

- Using Thermal Analysis Methods To Better Understand Asphalt RheologyDocument6 pagesUsing Thermal Analysis Methods To Better Understand Asphalt RheologyNatalia KovalovaNo ratings yet

- Thermodynamics Problems and SolutionDocument19 pagesThermodynamics Problems and SolutionQ_TNo ratings yet

- PETROV Roumen, SIDOR Jurij, KALUBA Wlodzimierz and KESTENS LeoDocument6 pagesPETROV Roumen, SIDOR Jurij, KALUBA Wlodzimierz and KESTENS LeoRoumen PetrovNo ratings yet

- Kasih Dari SurgaDocument31 pagesKasih Dari Surgadevi kristanty marpaungNo ratings yet

- Effects of Temperature On Tribological Properties of Al O - Tio CoatingDocument6 pagesEffects of Temperature On Tribological Properties of Al O - Tio CoatingDjm AlgNo ratings yet

- CHM2 Kinetics and Equilibria QDocument41 pagesCHM2 Kinetics and Equilibria QHakim AbbasNo ratings yet

- The (TL, Na, Li) NO, (TL, Na, RB) NO, (TL, Na, CS) N0 Ternary SystemsDocument3 pagesThe (TL, Na, Li) NO, (TL, Na, RB) NO, (TL, Na, CS) N0 Ternary SystemsBelgasem AsselNo ratings yet

- 2005 Article BF01062315Document3 pages2005 Article BF01062315terryphiNo ratings yet

- Lab Report TemplateDocument6 pagesLab Report Templatecgjp120391No ratings yet

- A Modern Course in Statistical PhysicsFrom EverandA Modern Course in Statistical PhysicsRating: 3.5 out of 5 stars3.5/5 (2)

- Heat Transfer in Polymer Composite Materials: Forming ProcessesFrom EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardNo ratings yet

- Data Sheet: Zao (Azo) Rotatable Sputtering TargetsDocument4 pagesData Sheet: Zao (Azo) Rotatable Sputtering TargetsJason AlexNo ratings yet

- Pages From Jace.12657-5Document1 pagePages From Jace.12657-5Jason AlexNo ratings yet

- Pages From Jace.12657Document1 pagePages From Jace.12657Jason AlexNo ratings yet

- Pages From Jace.12657-3Document1 pagePages From Jace.12657-3Jason AlexNo ratings yet

- Jace 12657 PDFDocument10 pagesJace 12657 PDFJason AlexNo ratings yet

- Advanced Engineering Materials: Material Safety Data SheetDocument3 pagesAdvanced Engineering Materials: Material Safety Data SheetJason AlexNo ratings yet

- Data Sheet: Zao (Azo) Rotatable Sputtering TargetsDocument4 pagesData Sheet: Zao (Azo) Rotatable Sputtering TargetsJason AlexNo ratings yet

- Azo (Zno:Al 0) Targets: Transparent Conductive Oxides For Photovoltaic DevicesDocument2 pagesAzo (Zno:Al 0) Targets: Transparent Conductive Oxides For Photovoltaic DevicesJason AlexNo ratings yet

- A Novel Route For Processing Cobalt-Chromium-Molybdenum Orthopaedic Alloys PDFDocument5 pagesA Novel Route For Processing Cobalt-Chromium-Molybdenum Orthopaedic Alloys PDFJason AlexNo ratings yet

- Advanced Engineering Materials: Material Safety Data SheetDocument3 pagesAdvanced Engineering Materials: Material Safety Data SheetJason AlexNo ratings yet

- Chapter 4. Sputtering Target ManufacturingDocument1 pageChapter 4. Sputtering Target ManufacturingJason AlexNo ratings yet

- Tribological Behavior of A Heat-Treated Cobalt-Based Alloy PDFDocument7 pagesTribological Behavior of A Heat-Treated Cobalt-Based Alloy PDFJason AlexNo ratings yet

- A Hip Joint SimulatorDocument6 pagesA Hip Joint SimulatorJason AlexNo ratings yet

- A Novel Route For Processing Cobalt-Chromium-Molybdenum Orthopaedic Alloys PDFDocument5 pagesA Novel Route For Processing Cobalt-Chromium-Molybdenum Orthopaedic Alloys PDFJason AlexNo ratings yet

- Microstructural Effects On The Wear Resistance of Wrought and As-Cast Co-Cr-Mo-C Implant Alloys PDFDocument6 pagesMicrostructural Effects On The Wear Resistance of Wrought and As-Cast Co-Cr-Mo-C Implant Alloys PDFJason AlexNo ratings yet

- Effect of C Content On The Mechanical Properties of Solution Treated As-Cast ASTM F-75 Alloys PDFDocument5 pagesEffect of C Content On The Mechanical Properties of Solution Treated As-Cast ASTM F-75 Alloys PDFJason AlexNo ratings yet

- A Hip Joint SimulatorDocument6 pagesA Hip Joint SimulatorJason AlexNo ratings yet

- Fluid-Solid Non-Catalytic Reaction: Kinetics: Lecture OnDocument13 pagesFluid-Solid Non-Catalytic Reaction: Kinetics: Lecture OnshubhamNo ratings yet

- Session 07 Sewage Treatment (2021-22) PDFDocument42 pagesSession 07 Sewage Treatment (2021-22) PDFLeslie LeeNo ratings yet

- Science-Reviewer TyphoonsDocument10 pagesScience-Reviewer TyphoonsLaxiava VaniaNo ratings yet

- Electric Charge and Electric Field Chapter-21: Topics CoveredDocument8 pagesElectric Charge and Electric Field Chapter-21: Topics CovereddibyamparidaNo ratings yet

- SHM Ex2Document1 pageSHM Ex2Kshitij BansalNo ratings yet

- The Miller-Urey ExperimentDocument4 pagesThe Miller-Urey ExperimentGitaga Jeremiah100% (1)

- Wave Notes 4 - Refraction1Document5 pagesWave Notes 4 - Refraction1Syed Mairaj Ul HaqNo ratings yet

- Eco-Friendly Approach For The Synthesis of MWCNTs From Waste Tires Via Chemical Vapor Deposition - ScienceDirectDocument4 pagesEco-Friendly Approach For The Synthesis of MWCNTs From Waste Tires Via Chemical Vapor Deposition - ScienceDirectalfonsoNo ratings yet

- Al 03402180221Document4 pagesAl 03402180221International Journal of computational Engineering research (IJCER)No ratings yet

- Lewis StructureDocument28 pagesLewis Structurebasaallen566No ratings yet

- Disaster Management TsunamiDocument7 pagesDisaster Management TsunamiishikaNo ratings yet

- Final Report - Solar Cold StorageDocument75 pagesFinal Report - Solar Cold StorageAKSHEYMEHTANo ratings yet

- The Electrical Worker July 2010Document20 pagesThe Electrical Worker July 2010Kathryn R. ThompsonNo ratings yet

- MB4039 HomeworkDocument7 pagesMB4039 HomeworkSocdal AbdiNo ratings yet

- General ScienceDocument6 pagesGeneral ScienceSalvari VitasNo ratings yet

- 50 de Thi Thu THPT Quoc Gia 2020 Mon Tieng Anh Co Dap An Va Giai Chi Tiet 4154Document20 pages50 de Thi Thu THPT Quoc Gia 2020 Mon Tieng Anh Co Dap An Va Giai Chi Tiet 4154khanh nguyenNo ratings yet

- MSE 3300-Lecture Note 01-Chapter 01 IntroductionDocument28 pagesMSE 3300-Lecture Note 01-Chapter 01 IntroductionChuongNo ratings yet

- Save The Penguins Storyboard UseDocument21 pagesSave The Penguins Storyboard Useapi-306869230No ratings yet

- Deep Explanation of Kinetic EnergyDocument2 pagesDeep Explanation of Kinetic EnergyPaul Brian ferrarisNo ratings yet

- DistillationDocument12 pagesDistillationAbhishek SardaNo ratings yet

- TF 33 VaporPhaseDesignDocument12 pagesTF 33 VaporPhaseDesignAdnen GuedriaNo ratings yet

- Đề 6.Mh2022.Key Chi TiếtDocument18 pagesĐề 6.Mh2022.Key Chi Tiếttailieu hienNo ratings yet

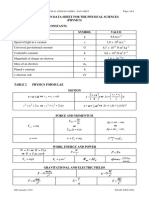

- Physical Sciences Ieb NSC Grade 12 Past Exam Papers 2016 p1 Data SheetDocument2 pagesPhysical Sciences Ieb NSC Grade 12 Past Exam Papers 2016 p1 Data Sheetoluhlevumisa07No ratings yet

- BSDS 105 Environmental ManagementDocument7 pagesBSDS 105 Environmental ManagementEmmanuel M. ChiwaNo ratings yet

- CH 6 Water ResourcesDocument18 pagesCH 6 Water ResourcesVishesh RajputNo ratings yet

- Fission Track Dating PDFDocument3 pagesFission Track Dating PDFzaqiNo ratings yet

- Integrated Aquaculture, Hydroponics and Vermiculture For Rooftop Food Production - Central Queensland UniversityDocument38 pagesIntegrated Aquaculture, Hydroponics and Vermiculture For Rooftop Food Production - Central Queensland UniversityPennsylvania Association for Sustainable AgricultureNo ratings yet

- Requirements For A Tidal Power Demonstration SchemeDocument6 pagesRequirements For A Tidal Power Demonstration SchemeMarlon MataNo ratings yet