Professional Documents

Culture Documents

9) - An Example That Demonstrates The Effect of Gusset Plates

Uploaded by

anwarali1975Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9) - An Example That Demonstrates The Effect of Gusset Plates

Uploaded by

anwarali1975Copyright:

Available Formats

8

2.3.4 Effectiveness of Gussets in Sign Support support structures do not appear to be susceptible to gal-

Structures loping because of their inherently high degree of three-

dimensional rigidity.

Results of the effectiveness of gussets in sign support

structures were based on a study by Gilani and Whittaker (8,

9). An example that demonstrates the effect of gusset plates Add to Specifications, Section 11.7.2:

was provided. Providing gusset plates was recommended to

increase the moment capacity of the connection. The moment The equivalent static pressure PVS shall be applied trans-

capacity can be further increased by appropriate design of versely (vertical direction) to nontapered horizontal mono-

the gusset. tubes of noncantilevered support structures if signs or sign

blanks are not used during construction.

2.3.5 Vibration Mitigation Measures in Sign Change to Specifications, Section 11.7.3:

Support Structures

From “Overhead cantilever . . .” to “Overhead cantilevered

Various vibration mitigation measures were studied. and noncantilevered . . .”

These include those considered by Kaczinski et al. (6), Cook

et al. in Florida (9a), and Hamilton et al. in Wyoming (9b).

The effectiveness of these measures in increasing the damp- Add to Specifications, Section 11.7.4:

ing in support structures was discussed. A brief analytical

Noncantilevered overhead sign and traffic signal support

study was conducted to demonstrate the effect of increased

structures shall be designed to resist the following static,

damping. Some of the devices were shown to increase the

truck-induced, gust pressure range of

damping; however, the only way to verify the effectiveness

of vibration mitigation is through testing and/or monitoring

PTG = 360Cd IF (Pa) Eq. 11-7

of structures in service.

PTG = 7.5 Cd IF (psf)

PTG = 490Cd IF (Pa) Eq. 11-8

2.3.6 Suggested Additions to Section 11 of the

2001 Specifications PTG = 10.2Cd IF (psf)

Add to Specifications, Section 11.4: The pressure range given by Eq. 11-7 shall be applied hor-

d) Noncantilevered overhead sign and traffic signal sup- izontally to the area of signs and horizontal members,

port structures while the values given by Eq. 11-8 shall be applied in the

vertical direction to the area of the structure elements and

the projected area of the sign. These pressures should be

Add to Specifications, Table 11-1: applied along the entire span of the structure or 24 feet (8

Importance Factors for Vibration and Fatigue Design for meters) of the span, whichever is smaller.

Noncantilevered Sign Support Structures

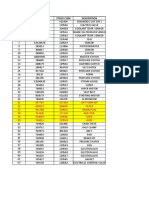

Category Structure Importance Factors

Type Galloping Vortex Natural Truck Gust Add to Commentary, Section 11.7.4:

shedding Wind

I Truss X X

*

1.0 1.0 Regarding the noncantilevered sign support structures, the

Monotube 1.0 X 1.0 1.0

II Truss X X 0.85 0.9 pressure values were based on analytical work of project

*

Monotube 0.72 X 0.85 0.9 NCHRP Project 17-10(2) considering truck-induced pres-

* Use the value of 1.0 for construction stage if signs or sign blanks are not used. sure values measured by Cook (1996). The values mea-

sured were applied to four noncantilever sign support struc-

Change to Specifications, Section 11.7.1: tures as a dynamic load, and the equivalent static loads

were obtained. The average value of the static loads was

From “Overhead cantilever . . .” to “Overhead cantilevered then multiplied by the factor of 1.3 to account for increase

and noncantilevered . . .” in the relative truck speed due to head wind.

Add to Specifications, Section 11.7.1, Commentary: Change to Specifications, Section 11.8 (Deflection):

Galloping loads are applied to monotube noncantilevered From “cantilevered single-arm . . .” to “cantilevered single-

support structures. Overhead noncantilevered truss-type arm and noncantilevered monotube . . .”

You might also like

- Astm-D3966 07 PDFDocument18 pagesAstm-D3966 07 PDFJaouad Id Boubker100% (1)

- IS 2911 Part 1 Sec2 2010Document26 pagesIS 2911 Part 1 Sec2 2010Maheswara VarmaNo ratings yet

- Driven Precast Concrete Pile Design and Construction CodeDocument28 pagesDriven Precast Concrete Pile Design and Construction CodeSunny RohillaNo ratings yet

- NSCP Drift LimitsDocument64 pagesNSCP Drift LimitsAries Villegas Montabon100% (1)

- Paint Insp ICorr Level 2 Notes PDFDocument133 pagesPaint Insp ICorr Level 2 Notes PDFravi00098100% (1)

- PCI Girder Stability CB-04-20 CalcDocument119 pagesPCI Girder Stability CB-04-20 CalcPurdiansyahNo ratings yet

- CSS Selector Cheat SheetDocument3 pagesCSS Selector Cheat SheetRodrigo-5553974No ratings yet

- Shotcrete Slope StabilizationDocument7 pagesShotcrete Slope StabilizationJ. Kumar Infraprojects Ltd100% (1)

- Is 2911 (PART 1, Sec-1) 2010 Design & Construction of Pile FoundationDocument22 pagesIs 2911 (PART 1, Sec-1) 2010 Design & Construction of Pile FoundationNaga Manikanta Tatikonda100% (1)

- Ceramic Tile TechniquesDocument13 pagesCeramic Tile TechniquesStefan Van CleemputNo ratings yet

- Development Length AASHTODocument4 pagesDevelopment Length AASHTOpicottNo ratings yet

- Failure Analysis of Transmission TowersDocument7 pagesFailure Analysis of Transmission TowersMahendra AbeywickramaNo ratings yet

- Reinforced Concrete DesignDocument3 pagesReinforced Concrete DesignRodel100% (2)

- Structural Vibration and Ways To Avoid It - Vibration, Dynamics and Noise PDFDocument3 pagesStructural Vibration and Ways To Avoid It - Vibration, Dynamics and Noise PDFwinarnobNo ratings yet

- AD 267 Notional Horizontal Forces and Industrial Platform Floors PDFDocument1 pageAD 267 Notional Horizontal Forces and Industrial Platform Floors PDFleodegarioporralNo ratings yet

- TECHNICAL NOTE 011 Lateral Loads On Falsework - Is Cross-Bracing Really Not Required at All PDFDocument2 pagesTECHNICAL NOTE 011 Lateral Loads On Falsework - Is Cross-Bracing Really Not Required at All PDFmyduyen75No ratings yet

- Most Open Valve Concept WWTP EE AnalysisDocument29 pagesMost Open Valve Concept WWTP EE AnalysisRahmi ArslanNo ratings yet

- IS 2911 Part 4 - 2013 PDFDocument17 pagesIS 2911 Part 4 - 2013 PDFAnshuman SinghNo ratings yet

- Structure Modelling ChecklistDocument4 pagesStructure Modelling ChecklistaomareltayebNo ratings yet

- Valve Seat Lathe Type VSL: Instruction ManualDocument25 pagesValve Seat Lathe Type VSL: Instruction ManualAmiya100% (4)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- 2911 (Part 4) 2013Document16 pages2911 (Part 4) 2013Sangram keshari bejaNo ratings yet

- 2.3.2 Establishing Equivalent Static Fatigue Loads For Noncantilevered Support StructuresDocument1 page2.3.2 Establishing Equivalent Static Fatigue Loads For Noncantilevered Support Structuresanwarali1975No ratings yet

- Ikby Uhao DH Fmtkbu VKSJ Fuekz.K JHFR Lafgrk: - Indian StandardDocument26 pagesIkby Uhao DH Fmtkbu VKSJ Fuekz.K JHFR Lafgrk: - Indian StandardvasuNo ratings yet

- A Parametric Assessment of Friction Damper in Eccentric Braced FrameDocument5 pagesA Parametric Assessment of Friction Damper in Eccentric Braced FrameAlam Mohammad Parvez SaifiNo ratings yet

- NCRP - Sign 12Document1 pageNCRP - Sign 12anwarali1975No ratings yet

- Seismic design requirements for building structuresDocument3 pagesSeismic design requirements for building structuresAkagami ShanksNo ratings yet

- ATC40Ch9 PDFDocument57 pagesATC40Ch9 PDFArunkumar SekarNo ratings yet

- Double Friction Dampers For Wind Excited Benchmark BuildingDocument20 pagesDouble Friction Dampers For Wind Excited Benchmark Buildingsukanya12345No ratings yet

- Shape Memory Alloy Tension/Compression Device For Seismic Retrofit of BuildingsDocument8 pagesShape Memory Alloy Tension/Compression Device For Seismic Retrofit of BuildingsYami YugiNo ratings yet

- Evaluating Reduction Factors for RC Buildings Retrofitted with CFRPDocument11 pagesEvaluating Reduction Factors for RC Buildings Retrofitted with CFRPAnna SanchezNo ratings yet

- Buckling Análysis of Telescopic Boom PDFDocument7 pagesBuckling Análysis of Telescopic Boom PDFAndonny Daq DelgadoNo ratings yet

- Multi-Storey Frame Design: Changes? or No Change?Document2 pagesMulti-Storey Frame Design: Changes? or No Change?nuwan01No ratings yet

- IS-2911-part-1sec-1-2010-design-and Construction-Of-Pile-Foundation PDFDocument22 pagesIS-2911-part-1sec-1-2010-design-and Construction-Of-Pile-Foundation PDFRajan VANo ratings yet

- Tuned Liquid DamperDocument86 pagesTuned Liquid Damperabdulloh_99No ratings yet

- Release Not Ese Tabs 2015 V 1510Document7 pagesRelease Not Ese Tabs 2015 V 1510jwanroNo ratings yet

- Load Combinations Section 12Document23 pagesLoad Combinations Section 12avikshit yNo ratings yet

- SAFE manual details factors affecting slab deflectionsDocument9 pagesSAFE manual details factors affecting slab deflectionsMahmood MuftiNo ratings yet

- Keywords: Steam Turbine Generator Foundation, Finite Element, Static Analysis, Dynamic AnalysisDocument6 pagesKeywords: Steam Turbine Generator Foundation, Finite Element, Static Analysis, Dynamic Analysissuresh kumarNo ratings yet

- Design Loads and Combinations for Bridge BearingsDocument2 pagesDesign Loads and Combinations for Bridge Bearingsavisek_basuNo ratings yet

- Is 2911 1 2 2010Document35 pagesIs 2911 1 2 2010Shiv GugwadeNo ratings yet

- IS 2911-Part-4Document17 pagesIS 2911-Part-4Prabhakaran S100% (1)

- Shallow Foundations: Serviceability: Learning OutcomesDocument46 pagesShallow Foundations: Serviceability: Learning OutcomesMatteo ContiNo ratings yet

- Testing Deep FoundationsDocument9 pagesTesting Deep FoundationsDRocha1No ratings yet

- Release Notes Sap 2000 V 1811Document10 pagesRelease Notes Sap 2000 V 1811ChiaChing HsiaoNo ratings yet

- Quasi Static Test Seismic Loading Protocols by Matthew PDFDocument4 pagesQuasi Static Test Seismic Loading Protocols by Matthew PDFSelva Ganesa Moorthi A ce19d763No ratings yet

- 2911 (Part 4) - 2013Document17 pages2911 (Part 4) - 2013Hari SinghNo ratings yet

- Structural Design Highlights of ACI 318 19 Part 2 of 2 ChaptersDocument240 pagesStructural Design Highlights of ACI 318 19 Part 2 of 2 ChaptersanonymNo ratings yet

- Codes Standards: StructureDocument3 pagesCodes Standards: StructureggggNo ratings yet

- Practice of Partial Prestressing for Continuous Post-Tensioned Structures in North AmericaDocument29 pagesPractice of Partial Prestressing for Continuous Post-Tensioned Structures in North AmericaJoão Paulo MendesNo ratings yet

- Is 2911 4 2013 PDFDocument17 pagesIs 2911 4 2013 PDFKishan KumarNo ratings yet

- EffectofdiaphragmflexibilityontheseismicresponseofRCCFramedbuildingconsideringdiaphragmdiscontinuity (1)Document10 pagesEffectofdiaphragmflexibilityontheseismicresponseofRCCFramedbuildingconsideringdiaphragmdiscontinuity (1)KarthikeyanNo ratings yet

- Wind Loads On Buildings - Mwfrs (Envelope Procedure) : Chapter C28Document5 pagesWind Loads On Buildings - Mwfrs (Envelope Procedure) : Chapter C28Van Len TranNo ratings yet

- Nonbuilding vs NonstructuralDocument30 pagesNonbuilding vs NonstructuralIsprotec IngenieriaNo ratings yet

- SAP2000 Release Notes: Notice Date: 2017-03-10Document9 pagesSAP2000 Release Notes: Notice Date: 2017-03-10Arturo Tipacti QuijanoNo ratings yet

- Dynamic Characteristics of A Squeeze Film Damper Used As Rear Bearing in A Single Spool Aeronautic Gas TurbineDocument6 pagesDynamic Characteristics of A Squeeze Film Damper Used As Rear Bearing in A Single Spool Aeronautic Gas TurbineIJAERS JOURNALNo ratings yet

- Foundation Modeling for Seismic Bridge LoadsDocument12 pagesFoundation Modeling for Seismic Bridge LoadslingamkumarNo ratings yet

- Appendix To Chapter 5 Nonlinear Static ProcedureDocument6 pagesAppendix To Chapter 5 Nonlinear Static ProcedureEnrique AbayNo ratings yet

- Report of Kanhpur Abutment 2 CIPDocument27 pagesReport of Kanhpur Abutment 2 CIPShamsul IslamNo ratings yet

- Rths Chae - enDocument12 pagesRths Chae - enMassimo LatourNo ratings yet

- Raft FDN Design 2Document6 pagesRaft FDN Design 2Saman janakaNo ratings yet

- Additional Class Materials BES322748 Breaking Down Steelto Concrete Connection Designand Workflow Limitations Mario FitzDocument10 pagesAdditional Class Materials BES322748 Breaking Down Steelto Concrete Connection Designand Workflow Limitations Mario FitzEDDYVECENo ratings yet

- Paper5 - Investigations of The Application of Gyro-Mass Dampers With Various Types of Supplemental Dampers For Vibration Control of Building StructuresDocument13 pagesPaper5 - Investigations of The Application of Gyro-Mass Dampers With Various Types of Supplemental Dampers For Vibration Control of Building StructuresRodrigo LezametaNo ratings yet

- Section 1613.5.1: Seismic Design Category A RequirementsDocument1 pageSection 1613.5.1: Seismic Design Category A RequirementsMrMasterNo ratings yet

- High Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorFrom EverandHigh Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- NCRP - Sign 28Document1 pageNCRP - Sign 28anwarali1975No ratings yet

- NCRP - Sign 33Document1 pageNCRP - Sign 33anwarali1975No ratings yet

- NCRP - Sign 32Document1 pageNCRP - Sign 32anwarali1975No ratings yet

- Drag Coefficient Table for Bend Radius MethodsDocument1 pageDrag Coefficient Table for Bend Radius Methodsanwarali1975No ratings yet

- NCRP - Sign 31Document1 pageNCRP - Sign 31anwarali1975No ratings yet

- Foundation selection criteria for transportation structuresDocument1 pageFoundation selection criteria for transportation structuresanwarali1975No ratings yet

- Drag Coefficient Transition Equations for Multisided Pole SectionsDocument1 pageDrag Coefficient Transition Equations for Multisided Pole Sectionsanwarali1975No ratings yet

- NCRP - Sign 30Document1 pageNCRP - Sign 30anwarali1975No ratings yet

- NCRP - Sign 27Document1 pageNCRP - Sign 27anwarali1975No ratings yet

- NCRP - Sign 18Document1 pageNCRP - Sign 18anwarali1975No ratings yet

- NCRP - Sign 25Document1 pageNCRP - Sign 25anwarali1975No ratings yet

- Table 3 Foundation Dimension For Washington DOT (33) : Typical Lead Section of Steel Screw-In FoundationDocument1 pageTable 3 Foundation Dimension For Washington DOT (33) : Typical Lead Section of Steel Screw-In Foundationanwarali1975No ratings yet

- Specifications Allows Waiving of Subsurface Exploration If: 2.5.2 Drilled Shaft FoundationDocument1 pageSpecifications Allows Waiving of Subsurface Exploration If: 2.5.2 Drilled Shaft Foundationanwarali1975No ratings yet

- 2.5 Foundations: Bridge Design Specifications (7) and A Number of Other PubliDocument1 page2.5 Foundations: Bridge Design Specifications (7) and A Number of Other Publianwarali1975No ratings yet

- Table 1 Calculated Bolt Sizes: 2.4.8 Recommendations For Anchor Bolt and Foundation DesignDocument1 pageTable 1 Calculated Bolt Sizes: 2.4.8 Recommendations For Anchor Bolt and Foundation Designanwarali1975No ratings yet

- Development Length of Anchor Bolt in A Drilled ShaftDocument1 pageDevelopment Length of Anchor Bolt in A Drilled Shaftanwarali1975No ratings yet

- NCRP - Sign 19Document1 pageNCRP - Sign 19anwarali1975No ratings yet

- Introduction and Research Approach: 1.1 BackgroundDocument1 pageIntroduction and Research Approach: 1.1 Backgroundanwarali1975No ratings yet

- Allow hooked anchor bolts due to cheaper costDocument1 pageAllow hooked anchor bolts due to cheaper costanwarali1975No ratings yet

- NCRP - Sign 15Document1 pageNCRP - Sign 15anwarali1975No ratings yet

- NCRP - Sign 16Document1 pageNCRP - Sign 16anwarali1975No ratings yet

- Recommendations for improving support structure specificationsDocument1 pageRecommendations for improving support structure specificationsanwarali1975No ratings yet

- Research Findings: 2.1.1 State DOT Survey and ResultsDocument1 pageResearch Findings: 2.1.1 State DOT Survey and Resultsanwarali1975No ratings yet

- NCRP - Sign 7Document1 pageNCRP - Sign 7anwarali1975No ratings yet

- Research Findings: 2.1.1 State DOT Survey and ResultsDocument1 pageResearch Findings: 2.1.1 State DOT Survey and Resultsanwarali1975No ratings yet

- NCRP - Sign 6Document1 pageNCRP - Sign 6anwarali1975No ratings yet

- NCRP - Sign 5Document1 pageNCRP - Sign 5anwarali1975No ratings yet

- NCRP - Sign 4Document2 pagesNCRP - Sign 4anwarali1975No ratings yet

- Dam PluggingDocument104 pagesDam PluggingMpho Vince MatlouNo ratings yet

- Scalding Documentation: Tutorials for Beginners and BeyondDocument89 pagesScalding Documentation: Tutorials for Beginners and BeyondrajaNo ratings yet

- Procem BrochureDocument20 pagesProcem BrochuremelvinkorahNo ratings yet

- DebugDocument295 pagesDebugkarthikNo ratings yet

- Aci 10 - 08Document434 pagesAci 10 - 08Muhammad Irfan Khan100% (1)

- 3-Weight Check Job Card - YA-PIDDocument5 pages3-Weight Check Job Card - YA-PIDmangz IfrNo ratings yet

- 400 Bad Request 400 Bad Request Nginx/1.2.9Document8 pages400 Bad Request 400 Bad Request Nginx/1.2.9bahramhooNo ratings yet

- Backscatter and Seabed Image ReflectivityDocument5 pagesBackscatter and Seabed Image ReflectivityJuan David SantanaNo ratings yet

- Aseptic Process TechnologyDocument19 pagesAseptic Process TechnologyHimanshu ShahuNo ratings yet

- Olt Config CuyDocument21 pagesOlt Config CuyEron RamdanyNo ratings yet

- GTSTRUDL 32 - Student Edition 13: Quick-Start InstructionsDocument3 pagesGTSTRUDL 32 - Student Edition 13: Quick-Start InstructionsVimalan KannanNo ratings yet

- Critical Spare For Manitou MT X1840 New ManitouDocument3 pagesCritical Spare For Manitou MT X1840 New ManitouamonNo ratings yet

- CW MasterDocument80 pagesCW MasterArianta RianNo ratings yet

- V 0 S 2 P 5Document78 pagesV 0 S 2 P 5DELIAL-ABABNo ratings yet

- Dual Output Ac Current - Voltage TransducerDocument7 pagesDual Output Ac Current - Voltage TransducerMagendran SurulivelNo ratings yet

- Design and Analysis of Gas Turbine Combustion Chamber For Producer Gas AsDocument5 pagesDesign and Analysis of Gas Turbine Combustion Chamber For Producer Gas AsPhạm Công ÁnhNo ratings yet

- DAL Keystones SSDocument8 pagesDAL Keystones SSyordanNo ratings yet

- Byv10ed 600pDocument10 pagesByv10ed 600pdavid.gjeorgevskiNo ratings yet

- Field Engineer ResumeDocument3 pagesField Engineer ResumesambhuNo ratings yet

- Lte Epc Umts 3GPPDocument222 pagesLte Epc Umts 3GPPjbarriospNo ratings yet

- Green Mark Manager 6 May 2019Document1 pageGreen Mark Manager 6 May 2019Haider Tyebally TyeballyNo ratings yet

- Big CreekDocument106 pagesBig CreekRewati RamanNo ratings yet

- All 31 9amDocument134 pagesAll 31 9amSikha KaushikNo ratings yet