Professional Documents

Culture Documents

Care and Use Manual APPC

Uploaded by

nhonducCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Care and Use Manual APPC

Uploaded by

nhonducCopyright:

Available Formats

[ CARE AND USE MANUAL ]

Anionic Polar Pesticide Column

CONTENTS I. INTRODUCTION

Thank you for choosing Waters™ Anionic Polar Pesticide

I. INTRODUCTION

Column. This column enables scientists to analyze and

II. GETTING STARTED separate highly anionic polar pesticides on HPLC, UHPLC, or

a. VanGuard™ (Pre-columns) UPLC™ instrumentation. This column is specifically designed

b. Column Installation (with or without for excellent peak shape, with added selectivity for analysis

VanGuard Pre-columns) of various polar pesticides such as glyphosate operating

c. eCord™ Installation under HILIC/WAX conditions. This column is based on new

d. Column Conditioning and Equilibration bonding technology used to create an adaptive selectivity

platform. Starting with the ethylene bridged hybrid (BEH)

E. USEFUL FUNCTIONAL TESTS FOR particle, the patent pending bonding consists of a two-stage

BENCHMARKING A NEW COLUMN functionalization of chromatographic particles. The first step

of the process controls retention characteristics, while the

III. COLUMN USE

second provides the unique selectivity of the phase.

a. Sample Preparation

b. Solvents Column: Anionic polar pesticide

c. Additives Stationary phase: Diethylamine

d. Pressure Particle shape: Spherical

e. Temperature

Particle size: 5 µm

f. pH

Pore size: 130 Å

g. Flow rate

Pore volume: 0.7 cc/g

Surface area: 185 m2/g

IV. TROUBLESHOOTING

Endcapped: Proprietary

V. CLEANING, REGENERATION,

AND STORAGE The packing materials used for the Anionic Polar Pesticide

a. Cleaning Column are optimized for use with the ACQUITY™ UPLC

b. Storage Systems. The Anionic Polar Pesticide Column is manufactured

in an ISO-certified plant using ultra-pure reagents. Each

batch of particles are tested, and the results are held to

narrow specification ranges to assure excellent, reproducible

performance. A Performance Chromatogram and Certificate

of Batch Analysis is provided, and the information is included

on the eCord Intelligent Chip. With the column part number

and lot number, this same column performance data and

batch information can be found on the Waters’ website at

www.waters.com/coa.

* US Patent # 7,399,410, UK Patent # GB2408469.

1

[ CARE AND USE MANUAL ]

II. GETTING STARTED 3. Orient the Anionic Polar Pesticide Column perpendicular to

the work surface so that the column inlet is on the bottom

Each Anionic Polar Pesticide Column comes with a Certificate

(facing down), with the column outlet on top (facing up).

of Analysis and a Performance Test Chromatogram. The

Certificate of Analysis is specific to each batch of packing 4. From below, insert VanGuard Pre-column into Anionic

material and includes the gel batch number, physical Polar Pesticide Column inlet and hand-tighten (collet

characterization, analysis of unbonded particle, analysis of and ferrule are not yet permanently attached).

bonded particles, and a UPLC chromatographic batch test. 5. While pushing the the VanGuard Pre-column into the

The Performance Test Chromatogram is specific to each column inlet, turn the assembled column and pre-column

batch and contains the following information: gel batch 180˚ so that the pre-column is now on top.

number, column serial number, USP plate count, USP tailing

6. Tighten with two 5/16" wrenches placed onto the flats of

factor, capacity factor, and chromatographic conditions under

the Anionic Polar Pesticide Column and VanGuard Pre-

normal-phase LC conditions. These data should be stored for

column hex nut (male end) as shown above.

future reference, in accordance with laboratory requirements.

7. Tighten 1/4 turn to set collet and ferrule.

a. VanGuard Pre-columns

8. Check that the ferrule is set by loosening the connection

VanGuard Pre-columns are 2.1 mm I.D. x 5 mm length guard and inspecting the ferrule depth. A properly set ferrule

column devices designed specifically for use on the ACQUITY depth will resemble other connections in the ACQUITY

UPLC Systems. VanGuard Pre-columns are packed with the UPLC Systems.

same chemistries and frits as the 2.1 mm I.D. Anionic Polar

9. Reattach the pre-column by connecting the VanGuard

Pesticide columns. VanGuard Pre-columns are designed

Pre-column with the analytical column.

to be attached directly to the inlet side of Anionic Polar

Pesticide Column.

b. Column Installation

Note: In order to ensure void-free and leak-free connections, the (with or without a VanGuard Pre-column)

VanGuard Pre-column is shipped with the collet and ferrule NOT Notes: It is not recommended to run with 100% water for an

permanently attached. Care must be taken when removing the extended period of time on this column. The Anionic Polar

O-ring that holds these two pieces on the pre-column tubing. Pesticide Columns are shipped dry.

1. Before connecting the column (or VanGuard and

analytical column combination) to the LC system,

ACQUITY UPLC Column VanGuard Pre-column

a. Ensure your LC and flow path are clean. For more

information, see Section IV of this manual.

b. Prime the solvent lines, to waste, with mobile phase A

(0.9 % formic acid in water) and mobile phase B (0.9 %

Place wrench here formic acid in acetonitrile) for at least 3 minutes.

Collet

Ferrule Place wrench here

Then connect the inlet end of the column to the injector

Flow outlet. Arrows on the column indicate the correct direction of

solvent flow.

Figure 1. Connecting a VanGuard Pre-column to a column.

c. eCord Installation

Installation Instructions The Anionic Polar Pesticide Column includes an eCord button

1. Remove VanGuard Pre-column from the box and shipping which can be attached to the ACQUITY UPLC Systems and

tube and then remove plastic plug. should be attached to the side of the instrument’s column

2. Orient the pre-column so that the male end is facing up heater module. The eCord button is magnetized and does

and carefully remove the rubber O-ring that holds collet not require specific orientation.

and ferrule in place during shipping (collet and ferrule are

not yet permanently attached).

Anionic Polar Pesticide Column 2

[ CARE AND USE MANUAL ]

d. Column Conditioning and Equilibration The below method describes LC methodologies for this column.

To obtain the retention time and peak shape performance, Please ensure your LC is clean. For more information on LC

it is necessary to equilibrate the column with a minimum of cleaning and maintenance, see section IV.

20 column volumes under the initial gradient conditions.

LC conditions:

Note: It is not recommended to run with 100% water for an ACQUITY UPLC I-Class PLUS

LC system

extended period of time on this column. with Sample manager with (FL)

Column 2.1 x 100 mm column

1. After installing the column in step b, flush the column with

Mobile phase A 0.9% formic acid in water

50:50 mobile phase A:B at a flow rate of 0.5 mL/minute for

approximately 25 minutes. Mobile phase B 0.9% formic acid in acetonitrile

Strong wash 10:90 Acetonitrile:Water

2. Equilibrate the column with the method’s initial gradient

Weak wash 90:10 Acetonitrile:Water

conditions. Allow the column the equilibrate with a

Seal wash 10% Methanol in water

minimum of 20 column volumes and the pressure (delta

Column temperature 50 °C

pressure <30 psi) and temperature to stabilize for a

minimum of 25 minutes. (Refer to Table 1 for a listing Sample temperature 10 °C

of empty column volumes.) Injection volume 10 µL

Flow rate 0.5 mL/min

Table 1. Empty column volumes in mL MS system Xevo™ TQ-S micro

(multiply by 10 for flush solvent volumes) Ionization mode ESI negative

Empty Glyphosate

column Column internal diameter (mm) MRM transitions 168 > 62.9

volumes (mL)

168 > 150

Column 2.1 3.0 4.6 10 19 30 50

length mm mm mm mm mm mm mm Gradient method:

50 mm 0.2 0.4 0.8 4 14 35 98 Time (min) %A %B Curve

100 mm 0.3 0.6 1.7 8 28 70 196 Initial* 10.0 90.0 –

150 mm 0.4 0.8 2.5 12 42 106 294 4.00 85.0 15.0 2

12.0 85.0 15.0 6

e. Useful Functional Tests for 18.0 10.0 90.0 1

Benchmarking a New Column

It may be useful to benchmark the performance of your * The gradient method shown is for the ACQUITY UPLC I-Class PLUS System

Anionic Polar Pesticide Column with glyphosate standard (BSM), where there is a gradient start delay of 320 µL after injection required

(shown in the Figure below).

as a representative benchmark of the intended application. For the ACQUITY UPLC H-Class PLUS System (QSM), please use the Column

Calculator on your instrument PC to maintain the method’s performance.

It is recommended to run six injections of blank (50:50 water: Note: the parameters included are intended to support the startup of this

methanol +0.5% formic acid) solvents before running column for the analysis of glyphosate. Additional method information is

your samples. available in the Quanpedia™ Databases (http://marketplace.waters.com)

and application notes (www.waters.com/polarpesticides). For optimum

MS performance, compound optimization is recommended (including

MS source parameters). For method extension and optimization on your

Waters’ Systems, please contact your local Waters office to discuss

specialist, application support.

Anionic Polar Pesticide Column 3

[ CARE AND USE MANUAL ]

3. Example chromatography of glyphosate b. Solvents

solvent standard achieved on the Anionic To maintain maximum column performance, use high

Polar Pesticide Column quality LC-MS grade solvents. Solvents containing

suspended particulate materials will generally clog the

4.32

100

outside surface of the inlet distribution frit of the column.

This will result in higher operating pressure, reduced

column lifetime, and compromised performance.

c. Additives

The Anionic Polar Pesticide Column can safely be used

%

with commonly used high purity acidic and basic additives

used in LC-MS such as formic acid, ammonium formate

and ammonium hydroxide. Consider the volatility, solubility,

and detector compatibility when choosing an appropriate

additive. Additives tend to improve peak shape and control

the retention characteristics of analytes but can also impart

0

-0.00 2.00 4.00 6.00 8.00 10.00 min. different selectivities. It is recommended to flush and

remove additives and salts from the column before placing

the column into storage.

III. COLUMN USE

To ensure the continued high performance of the Anionic Polar d. Pressure

Pesticide Columns, follow these guidelines: The Anionic Polar Pesticide Columns is packed to pressures

designed for use on UPLC/UHPLC/HPLC instrumentation.

a. Sample Preparation

It is highly recommended to use the methods provided with this *Maximum Maximum

Column

column (www.waters.com/polarpesticides) however if you are operating column operating column

dimensions

pressure pressure

developing a method of your own, it is important to remember

2.1 x 50 mm 1,800 psi 124 bar

the following for proper performance and column longevity.

2.1 x 100 mm 3,600 psi 248 bar

1. Consider preparing the sample in organic solvents (Methanol

2.1 x 150 mm 4,800 psi 331 bar

or Acetonitrile) for the best peak shape and sensitivity. It is

* Pressure drop across the column, does not include added system pressure

not recommended to use 100% water as a diluent since the

separation is operated under HILC condition. Using organic e. Temperature

sample diluents may avoid peak distortion due to “strong The general guideline for maximum temperature for the

solvent effects”. In particular, stronger solvents can impact Anionic Polar Pesticide Column is 60° C with most common

peak shapes of low retaining analytes. LC mobile phases and additives. However, some data

2. If the sample is not dissolved in the mobile-phase modifier, shows good stability beyond 60° C. This would need to be

ensure that the sample, solvent and mobile phases are verified experimentally.

miscible in order to avoid sample precipitation. All samples

f. pH

must be filtered before analysis to ensure removal of

The Anionic Polar Pesticide Columns can be used routinely

particulates.

under HILIC conditions between pH 2 to 7. As with any LC

3. Please use polypropylene vials (p/n: 186005222) for this column, operating at the extremes of pH, pressures and

application as glyphosate fixates to glass. temperatures will result in decreased column lifetime.

g. Flow rate

The Anionic Polar Pesticide Columns can be used with flow

rates between 0.1 and 0.7 mL/min. Any flow rates should be

acceptable as long as they fall within the pressure limits.

Anionic Polar Pesticide Column 4

[ CARE AND USE MANUAL ]

IV. TROUBLESHOOTING a. Cleaning

To achieve reliable performance of the method, ensuring Use the cleaning routine that matches the properties of the

sensitivity and peak shapes are acceptable, contamination samples and/or what you believe is contaminating the column.

of the LC system should be eliminated. For cleaning of the

Flush the Anionic Polar Pesticide Columns with 50:50

Waters LC system and other troubleshooting please refer

acetonitrile:water to remove polar contaminants. If this

to the startup guide.

flushing procedure does not solve the problem, purge

Please contact your local Waters representative if you need the column with 5:95 acetonitrile:water. To clean polar

more guidance and advice on troubleshooting or cleaning your contaminants from the Anionic Polar Pesticide Column, run

ACQUITY liquid chromatography system. a 10-minute gradient from 0–100% water and return to the

initial gradient method condition. Please note that as aqueous

For non-Waters LC systems, please contact your supplier for concentration increases, backpressure will rapidly increase

specific information on liquid chromatography system cleaning. as well. Reduce flow rate when operating at greater than 60%

aqueous. Repeat if necessary.

V. COLUMN CLEANING, EFFECTS OF Retest the column after using the cleaning procedure to

ADDITIVES, AGING, AND STORAGE determine if the specific problem has been fixed. If so, continue

using the column, avoiding samples and solvents that may

Changes in peak shape, peak splitting, shoulders on the

clog the column inlet. If the column performance is poor after

peak, shifts in retention, change in resolution, or increasing

cleaning and regenerating, call your local Waters office for

backpressure may indicate contamination of the column.

additional support.

Flushing the column while taking care not to precipitate

buffers, is usually sufficient to remove the contaminant.

b. Storage

Using a two step flushing procedure, divert the flow to waste

Purging out any additives with water/acetonitrile (50:50) and

and flush the column with an appropriate volume of 20:80

storing in 100% acetonitrile is recommended. Alternate storage

acetonitrile:water, and gradually return to 100% acetronitrile.

solvents can be used but may impact initial column equilibration.

Be sure to use a flow rate that does not over pressurize the

system or column. If the flushing procedure does not solve the

problem, purge the column using the following cleaning and

regeneration procedures.

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

Waters, The Science of What’s Possible, ACQUITY, UPLC, Xevo, eCord, Quanpedia, and VanGuard are

trademarks of Waters Corporation. All other trademarks are the property of their respective owners.

T: 1 508 478 2000

F: 1 508 872 1990

©2019 Waters Corporation. Produced in the U.S.A. September 2019 720006666EN Rev A IH-PDF www.waters.com

You might also like

- VanGuard Protection - Waters ColumnsDocument8 pagesVanGuard Protection - Waters ColumnsCristina ViiuNo ratings yet

- Acquity UPLC HSS ColumnsDocument9 pagesAcquity UPLC HSS ColumnsSiska Rotua Uli SihombingNo ratings yet

- GCP Sect5CAN Canning Line1196192Document24 pagesGCP Sect5CAN Canning Line1196192dingobkNo ratings yet

- Getting Started With Automated Two-Step Protein PurificationDocument23 pagesGetting Started With Automated Two-Step Protein Purificationsetuchakraborty90No ratings yet

- Probador de Fase y Rotación de MotorDocument32 pagesProbador de Fase y Rotación de Motornatsumyortiz02No ratings yet

- Qiacube SopDocument3 pagesQiacube SopNANDA AHSANINo ratings yet

- Xselect Charged Surface Hybrid (CSH) Columns: (Care and Use Manual)Document9 pagesXselect Charged Surface Hybrid (CSH) Columns: (Care and Use Manual)Angel VazquezNo ratings yet

- GCP Sect5RB RB LineDocument25 pagesGCP Sect5RB RB Linelevanvui161No ratings yet

- User Manual and Technical Description: E-8 Hydraulic Transport StretcherDocument11 pagesUser Manual and Technical Description: E-8 Hydraulic Transport Stretcherclaudia floresNo ratings yet

- SKC Biostage Sampler 1512Document2 pagesSKC Biostage Sampler 1512PalashNo ratings yet

- Purpose: TSB 117-039 ARCHITECT I1000sr iARM Hardware Upgrade - Doc Page 1 of 5Document5 pagesPurpose: TSB 117-039 ARCHITECT I1000sr iARM Hardware Upgrade - Doc Page 1 of 5Amilcar SavelliNo ratings yet

- Pumpsil Validation Summary Issue1 LRDocument7 pagesPumpsil Validation Summary Issue1 LRpedro fiolhaisNo ratings yet

- Form Euro.326 Rev.2 - Echo Preventive MaintenanceDocument6 pagesForm Euro.326 Rev.2 - Echo Preventive MaintenancesanazNo ratings yet

- Chemical Fact File: Dust: Respirable, Particulates Not Otherwise Regulated - NIOSH 0600Document1 pageChemical Fact File: Dust: Respirable, Particulates Not Otherwise Regulated - NIOSH 0600megacobNo ratings yet

- SpecDocument20 pagesSpecmubarek bekeleNo ratings yet

- Medidor de Rigidéz DieléctricaDocument22 pagesMedidor de Rigidéz DieléctricaRovi ElecNo ratings yet

- Adhesion/Release Tester: MODEL AR-2000 Operating InstructionsDocument35 pagesAdhesion/Release Tester: MODEL AR-2000 Operating InstructionsSarah Linville100% (1)

- Unit 2.20 - Determination of Solids by Imhoff Cone AnalysisDocument6 pagesUnit 2.20 - Determination of Solids by Imhoff Cone AnalysisRiyanNo ratings yet

- Vacuum Unit ManualDocument54 pagesVacuum Unit ManualNurlan ValiyevNo ratings yet

- Ac Cart ManualDocument33 pagesAc Cart Manualswana.intl131No ratings yet

- Getinge FP 102 ISOTESTDocument12 pagesGetinge FP 102 ISOTESTOfir YahavNo ratings yet

- 07 Liquid Level GaugingDocument6 pages07 Liquid Level GaugingKamal MuktarNo ratings yet

- Cleanup Efficiency PCR Purification Kits App NoteDocument4 pagesCleanup Efficiency PCR Purification Kits App NoteranaNo ratings yet

- MS - Gondola System Rev 2Document6 pagesMS - Gondola System Rev 2Non Etabas Gadnatam100% (1)

- Test Bench - Operating Instructions: 2nd EditionDocument8 pagesTest Bench - Operating Instructions: 2nd EditionКонстантин ДубенкоNo ratings yet

- Procedure de Test BOPDocument12 pagesProcedure de Test BOPkhireddineboulifaNo ratings yet

- LPG SOP Rev6Document26 pagesLPG SOP Rev6Kuldeepsingh Chandel100% (1)

- 50v 25A RectifierDocument20 pages50v 25A RectifierSuarezNo ratings yet

- Akta Pure Chromatography SystemDocument14 pagesAkta Pure Chromatography SystemCeli OlmedoNo ratings yet

- Wavevac - User's ManualDocument13 pagesWavevac - User's ManualAnonymous PYgnwOWKNo ratings yet

- Manual Camilla Obstetrica Electrica B-48-InglesDocument15 pagesManual Camilla Obstetrica Electrica B-48-InglesBrevas CuchoNo ratings yet

- Hardware SPECS-Digicel - PNG - FinalDocument12 pagesHardware SPECS-Digicel - PNG - Finalsebax123No ratings yet

- Rheodyne 2-Way SwitchDocument34 pagesRheodyne 2-Way SwitchOliver Müller100% (1)

- Avio 200 ICP OES Specifications 012884 - 01Document2 pagesAvio 200 ICP OES Specifications 012884 - 01hend hafezNo ratings yet

- GCP Sect5KEG KeggingDocument19 pagesGCP Sect5KEG Kegginglevanvui161No ratings yet

- Pre-Installation Checklist Vanquish 3.1 (EN)Document7 pagesPre-Installation Checklist Vanquish 3.1 (EN)nowsathali2022No ratings yet

- Amphenol WPS Boot Solution - June 2019Document10 pagesAmphenol WPS Boot Solution - June 2019Hansanee ChathurikaNo ratings yet

- High Pressure Carbon Dioxide Systems: Design, Installation, Recharge, and Maintenance ManualDocument5 pagesHigh Pressure Carbon Dioxide Systems: Design, Installation, Recharge, and Maintenance ManualMOHAMMED HADINo ratings yet

- Method Statement For Protection TestingDocument4 pagesMethod Statement For Protection TestingAfanda Rodgers100% (3)

- IBP1123 - 19 Caliper Ili Experience in Offshore Pre-CommissioningDocument10 pagesIBP1123 - 19 Caliper Ili Experience in Offshore Pre-CommissioningMarcelo Varejão CasarinNo ratings yet

- Data Sheet Lfbo 00 b1 Ds 001Document10 pagesData Sheet Lfbo 00 b1 Ds 001Agung SugiwantoNo ratings yet

- User - Manual 16 2080Document18 pagesUser - Manual 16 2080Daniel RiveraNo ratings yet

- GAC-12-VX-RMH-LAH-001 - Attachments - 1 To 7Document17 pagesGAC-12-VX-RMH-LAH-001 - Attachments - 1 To 7Dipayan DasNo ratings yet

- 0e81 Spe 10402.1: New Techniques of Pipeline InspectionDocument11 pages0e81 Spe 10402.1: New Techniques of Pipeline InspectionAhmed NabilNo ratings yet

- CRA-7 Chlorine Residual Analyzer: Installation, Operation & MaintenanceDocument11 pagesCRA-7 Chlorine Residual Analyzer: Installation, Operation & MaintenanceFernando PuentesNo ratings yet

- Fat Report For Fedegari SterilisersDocument4 pagesFat Report For Fedegari Sterilisersrahul_inj84100% (1)

- Method of Statement For Hydraulic Jack TestingDocument5 pagesMethod of Statement For Hydraulic Jack TestingAs-Syaff ResourcesNo ratings yet

- (Care and Use Manual) : Symmetry ColumnsDocument9 pages(Care and Use Manual) : Symmetry Columnssilfhany fatokhizarNo ratings yet

- Operation Manual: Caution RadioactiveDocument11 pagesOperation Manual: Caution RadioactiveMaritza EstefesNo ratings yet

- Keeler - Cryo Instruction Manual - 2509-P-8012-art-D - English1 PDFDocument24 pagesKeeler - Cryo Instruction Manual - 2509-P-8012-art-D - English1 PDFamirali.bme4527No ratings yet

- Water Softener 223100Document7 pagesWater Softener 223100ΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- en Pharma Feeder FAQDocument1 pageen Pharma Feeder FAQARK MurpheyNo ratings yet

- Flow Meter SpecsDocument5 pagesFlow Meter SpecsanasqumsiehNo ratings yet

- 01 - I-Line II Catalogue 2020 PDFDocument3 pages01 - I-Line II Catalogue 2020 PDFsajeevi piumikaNo ratings yet

- tEsT Performance Boiler PDFDocument136 pagestEsT Performance Boiler PDFPower PlantNo ratings yet

- Lembar Inspeksi Bell 412 600 FH 12 MonthDocument6 pagesLembar Inspeksi Bell 412 600 FH 12 MonthReza Setyo PermadiNo ratings yet

- Ohmega 402 OmicronDocument27 pagesOhmega 402 OmicronhossamNo ratings yet

- APFC O&M ManualDocument54 pagesAPFC O&M ManualTarun Godiyal100% (1)

- GM 4L60-E, 4L65-E, 4L70-E Vacuum Test Plate Kit: 77754-VTP InstructionsDocument8 pagesGM 4L60-E, 4L65-E, 4L70-E Vacuum Test Plate Kit: 77754-VTP InstructionsHenry SilvaNo ratings yet

- The Beta Equilibrium, Stability, and Transport Codes: Applications of the Design of StellaratorsFrom EverandThe Beta Equilibrium, Stability, and Transport Codes: Applications of the Design of StellaratorsFrances BauerNo ratings yet

- Richard A. Larson, Eric J. Weber - Reaction Mechanisms in Environmental Organic Chemistry-Lewis Publishers (1994)Document442 pagesRichard A. Larson, Eric J. Weber - Reaction Mechanisms in Environmental Organic Chemistry-Lewis Publishers (1994)nhonducNo ratings yet

- Text With EEA RelevanceDocument26 pagesText With EEA RelevancenhonducNo ratings yet

- Determination of Estrogens and Progestogens by Mass Spectrometric Techniques (GC/MS, LC/MS and LC/MS/MS)Document7 pagesDetermination of Estrogens and Progestogens by Mass Spectrometric Techniques (GC/MS, LC/MS and LC/MS/MS)nhonducNo ratings yet

- Determination of Estrogens and Progestogens by Mass Spectrometric Techniques (GC/MS, LC/MS and LC/MS/MS)Document7 pagesDetermination of Estrogens and Progestogens by Mass Spectrometric Techniques (GC/MS, LC/MS and LC/MS/MS)nhonducNo ratings yet

- Rainin Pipetting Handbook 17701066 ENDocument78 pagesRainin Pipetting Handbook 17701066 ENLaboratorio Detecto CaliNo ratings yet

- Quantification of Carbonate by Gas Chromatography-Mass SpectrometryDocument9 pagesQuantification of Carbonate by Gas Chromatography-Mass SpectrometrynhonducNo ratings yet

- Processes: GC-MS Fingerprints Profiling Using Machine Learning Models For Food Flavor PredictionDocument11 pagesProcesses: GC-MS Fingerprints Profiling Using Machine Learning Models For Food Flavor PredictionnhonducNo ratings yet

- Analysis of PesticidesDocument57 pagesAnalysis of PesticidesnhonducNo ratings yet

- Rapid Colorimetric Method To Detect Indole in Shrimp With Gas Chromatography Mass Spectrometry ConfirmationDocument6 pagesRapid Colorimetric Method To Detect Indole in Shrimp With Gas Chromatography Mass Spectrometry ConfirmationnhonducNo ratings yet

- Brief Introduction of Dept. of Laboratory MedicineDocument12 pagesBrief Introduction of Dept. of Laboratory MedicinenhonducNo ratings yet

- AN - Determination of Anionic Pesticide in High Water FoodstuffDocument3 pagesAN - Determination of Anionic Pesticide in High Water FoodstuffnhonducNo ratings yet

- CXS 234e PDFDocument80 pagesCXS 234e PDFnhonducNo ratings yet

- Controlling Contamination in LCMS SystemsDocument33 pagesControlling Contamination in LCMS SystemsnhonducNo ratings yet

- DSDC Introduction PDFDocument26 pagesDSDC Introduction PDFnhonducNo ratings yet

- Pira International Ltd-Introduction To Flexible Packaging-iSmithers Rapra Publishing (2012-05-29) PDFDocument122 pagesPira International Ltd-Introduction To Flexible Packaging-iSmithers Rapra Publishing (2012-05-29) PDFnhonducNo ratings yet

- Filmproperties Testsanddetails 130422033931 Phpapp02Document37 pagesFilmproperties Testsanddetails 130422033931 Phpapp02nhonducNo ratings yet

- Pira International Ltd-Introduction To Flexible Packaging-iSmithers Rapra Publishing (2012-05-29) PDFDocument122 pagesPira International Ltd-Introduction To Flexible Packaging-iSmithers Rapra Publishing (2012-05-29) PDFnhonducNo ratings yet

- Filmproperties Testsanddetails 130422033931 Phpapp02Document37 pagesFilmproperties Testsanddetails 130422033931 Phpapp02nhonducNo ratings yet

- Handbook of Plastic FilmsDocument422 pagesHandbook of Plastic FilmsStefan Boiadjiev100% (18)

- Bài Giảng - 8 Hành VI Quản Lý PDFDocument31 pagesBài Giảng - 8 Hành VI Quản Lý PDFnhonducNo ratings yet

- Electroanalytical MethodsDocument32 pagesElectroanalytical MethodsnhonducNo ratings yet

- PCS-9613S X DataSheet en Overseas General X R1.10Document57 pagesPCS-9613S X DataSheet en Overseas General X R1.10parveen115No ratings yet

- Topic 2.9 WorksheetDocument3 pagesTopic 2.9 WorksheethaniaNo ratings yet

- Life After Ashes: Understanding The Impact of Business Loss To The Livelihood of San Fernando City Wet Market VendorsDocument10 pagesLife After Ashes: Understanding The Impact of Business Loss To The Livelihood of San Fernando City Wet Market Vendorsalrichj29No ratings yet

- Various Executions MA: Series Foodstuffs ExecutionDocument17 pagesVarious Executions MA: Series Foodstuffs ExecutionKyriakos MichalakiNo ratings yet

- Ministry of Health and Family Welfare Pregnancy GuidelinesDocument173 pagesMinistry of Health and Family Welfare Pregnancy GuidelinesKhushi GuptaNo ratings yet

- CSC-160 Series Numerical Line Protection EquipmentDocument112 pagesCSC-160 Series Numerical Line Protection EquipmentMarkusKunNo ratings yet

- Grade 9 Module 5Document8 pagesGrade 9 Module 5alisoncielo45No ratings yet

- Exp 3 Rahul Singh 2k20-A18-12Document8 pagesExp 3 Rahul Singh 2k20-A18-12Dummy Account-Rahul SinghNo ratings yet

- Illness Narratives - Positioned IdentitiesDocument35 pagesIllness Narratives - Positioned IdentitiesAnaNo ratings yet

- P, PI and PID ControlDocument3 pagesP, PI and PID ControlsivaNo ratings yet

- Seasons and WeatherDocument2 pagesSeasons and WeatherОлінька СтецюкNo ratings yet

- English Solved SP3Document6 pagesEnglish Solved SP3Prem PatelNo ratings yet

- Timetable 12 Jan 2022Document54 pagesTimetable 12 Jan 2022abcNo ratings yet

- IHS Markit Seed Market Analysis and Data InfographicDocument1 pageIHS Markit Seed Market Analysis and Data Infographictripurari pandeyNo ratings yet

- Grade Thresholds - November 2018: Cambridge International AS & A Level Mathematics (9709)Document3 pagesGrade Thresholds - November 2018: Cambridge International AS & A Level Mathematics (9709)redwanNo ratings yet

- Arte PoveraDocument13 pagesArte PoveraSohini MaitiNo ratings yet

- Nuclear Models PDFDocument15 pagesNuclear Models PDFVijay SinghNo ratings yet

- Calibration Tools ListDocument5 pagesCalibration Tools ListdianNo ratings yet

- New Section: Jeff Is Quite Tall. Karl Is The Same Height As JeffDocument6 pagesNew Section: Jeff Is Quite Tall. Karl Is The Same Height As JeffIbrahim MahmoudNo ratings yet

- FS 2 - Learning Episode 4-7Document3 pagesFS 2 - Learning Episode 4-7dave puertollanoNo ratings yet

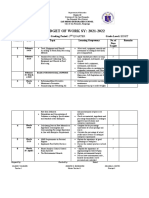

- BUDGET OF WORK SY: 2021-2022: Subject: Tle 8 Grading Period: 3Document2 pagesBUDGET OF WORK SY: 2021-2022: Subject: Tle 8 Grading Period: 3michelle dayritNo ratings yet

- Chapter 8Document3 pagesChapter 8JULLIE CARMELLE H. CHATTONo ratings yet

- Strategic Plan Executive SummaryDocument1 pageStrategic Plan Executive Summaryapi-532125110No ratings yet

- 003 Users Manuel of Safir 2016 - MechanicalDocument74 pages003 Users Manuel of Safir 2016 - Mechanicalenrico_britaiNo ratings yet

- Genomic and CDNA LibrariesDocument15 pagesGenomic and CDNA LibrariesPrabhleen KaurNo ratings yet

- Ancient AstronomyDocument26 pagesAncient AstronomyRodel RamosNo ratings yet

- Guidelines For Research ProjectsDocument10 pagesGuidelines For Research Projectspriyanshu shrivastavaNo ratings yet

- (IMP) Ancient Indian JurisprudenceDocument28 pages(IMP) Ancient Indian JurisprudenceSuraj AgarwalNo ratings yet

- CulvertsDocument14 pagesCulvertsMatsobane LekalaksNo ratings yet

- MRR1Document3 pagesMRR1Shaena LarezaNo ratings yet