Professional Documents

Culture Documents

Pressurization Components Test

Uploaded by

Ranjit ShawOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressurization Components Test

Uploaded by

Ranjit ShawCopyright:

Available Formats

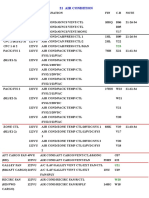

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

** ON A/C ALL

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

** ON A/C 016-017, 019-022, 024-039, 041-043, 045-100, 112-150, 208-209, 213-218, 222-230, 238-239, 242-

242, 301-450, 500-600

TASK 21-31-00-710-802-A

Operational Test of the Residual Pressure Control Unit (RPCU)

WARNING: MAKE SURE THAT AIR IS NOT SUPPLIED TO THE AIR CONDITIONING SYSTEM FROM THE

MAIN ENGINE, THE APU OR A GROUND SOURCE.

HOT COMPRESSED AIR CAN CAUSE INJURY TO PERSONNEL.

FIN : 9HL

1. Reason for the Job

Self explanatory

2 Job Set-up Information

A. Work Zones and Access Panels

ZONE/ACCESS ZONE DESCRIPTION

210 CKPT,FWD COMPT BHD TO FLT COMPT BULKHEAD

B. Referenced Information

REFERENCE DESIGNATION

(Ref. 24-41-00-861-002-A). Energize the Aircraft Electrical Circuits from the External Power

(Ref. 24-41-00-861-002-A-01). Energize the Aircraft Electrical Circuits from the APU

(Ref. 24-41-00-861-002-A-02). Energize the Aircraft Electrical Circuits from Engine 1(2)

(Ref. 24-41-00-862-002-A). De-energize the Aircraft Electrical Circuits Supplied from the External

Power

(Ref. 24-41-00-862-002-A-01). De-energize the Aircraft Electrical Circuits Supplied from the APU

(Ref. 24-41-00-862-002-A-02). De-energize the Aircraft Electrical Circuits Supplied from the Engine

1(2)

(Ref. 31-60-00-860-001-A). EIS Start Procedure

(Ref. 31-60-00-860-002-A). EIS Stop Procedure

3. Job Set-up

Subtask 21-31-00-865-080-A

A. Make sure that this(these) circuit breaker(s) is(are) closed:

PANEL DESIGNATION FIN LOCATION

49VU AIR COND/CAB/PRESS/CTL1 1HL D09

122VU RPCU 4HL X23

122VU AIR COND/CAB PRESS/CTL/MAN 3HL Y23

Print Date: August 23, 2020 Page 1 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

PANEL DESIGNATION FIN LOCATION

122VU AIR COND/CAB PRESS/CTL/2 2HL Y22

Subtask 21-31-00-860-076-A

B. Aircraft Maintenance Configuration

(1) Energize the aircraft electrical circuits

(Ref. AMM TASK 24-41-00-861-002) .

(2) Do the EIS start procedure (upper ECAM DU and lower ECAM DU only)

(Ref. AMM TASK 31-60-00-860-001) .

(3) On the ECAM control panel, push the PRESS pushbutton switch. The CAB PRESS page comes into

view on the lower ECAM display unit.

(4) On the AIR COND panel 30VU, make sure that:

· The PACK 1 and the PACK 2 pushbutton switches are in the OFF position (the OFF legends are

on).

· The RAM AIR pushbutton switch is in the OFF position (the ON legend is off).

(5) On the CABIN PRESS panel 25VU, make sure that:

· The MODE SEL pushbutton switch is in the AUTO configuration (with the FAULT and MAN legends

off).

· The LDG ELEV selector is in the AUTO position.

· The DITCHING pushbutton switch is in the AUTO configuration (with the ON legend off).

(6) Make sure there are no persons near the Outflow Valve (OFV) before you start this test.

4. Procedure

Subtask 21-31-00-710-071-A

WARNING: MAKE SURE THAT THE TRAVEL RANGES OF THE OUTFLOW VALVES ARE CLEAR.

MOVEMENT OF THE OUTFLOW VALVES CAN CAUSE INJURY TO PERSONS AND/OR

DAMAGE TO EQUIPMENT.

WARNING: MAKE SURE THAT THE TRAVEL RANGES OF THE OUTFLOW VALVES ARE CLEAR.

MOVEMENT OF THE OUTFLOW VALVES CAN CAUSE INJURY TO PERSONS AND/OR

DAMAGE TO EQUIPMENT.

A. Operational Test of the RPCU

ACTION RESULT

1.On the CABIN PRESS panel 25VU: On the CABIN PRESS panel 25VU:

· Push and release the MODE SEL pushbutton · The white MAN pushbutton switch light comes on.

switch.

NOTE: The accuracy of the cabin altitude indication

in MAN mode is +/- 1100ft.

On the ECAM lower display unit:

· The white LDG ELEV indication and the green

MAN xxx FT indication goes off.

· The green SYS 1 (or SYS 2) indication changes to

the green MAN indication.

· Push and hold the MAN V/S CTL toggle switch to · The OFV needle indication moves down.

DN.

· Keep the MAN V/S CTL toggle switch to DN until · The OFV needle indication continues to move

the OFV needle indication starts to move up. down and after a few seconds it starts to move up.

Print Date: August 23, 2020 Page 2 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

ACTION RESULT

· Release the MAN V/S CTL toggle switch. · The OFV needle indication continues to move up

until it shows that the OFV is in the open position.

2.On the CABIN PRESS panel 25VU: On the CABIN PRESS panel 25VU:

· Push the MODE SEL pushbutton switch. · The white MAN pushbutton switch light goes off.

On the ECAM lower display unit:

· The white LDG ELEV indication and the green

MAN xxx FT indication comes on.

· The green MAN indication changes to the green

SYS 1 (or SYS 2) indication.

5. Close-up

Subtask 21-31-00-860-077-A

A. Aircraft Maintenance Configuration

(1) Do the EIS stop procedure

(Ref. AMM TASK 31-60-00-860-002) .

(2) De-energize the aircraft electrical circuits

(Ref. AMM TASK 24-41-00-862-002) .

** ON A/C ALL

TASK 21-31-00-710-002-A

Operational Test of the Pressure Control and Monitoring

WARNING: MAKE SURE THAT AIR IS NOT SUPPLIED TO THE AIR CONDITIONING SYSTEM FROM THE

MAIN ENGINE, THE APU OR A GROUND SOURCE.

HOT COMPRESSED AIR CAN CAUSE INJURY TO PERSONNEL.

WARNING: MAKE SURE THAT THE FWD AVIONICS ACCESS DOOR 811 IS OPEN WITH A WARNING

PLACARD ATTACHED TO IT.

THE WARNING NOTICE MUST TELL PERSONS NOT TO CLOSE THE DOOR. THIS PREVENTS

ACCIDENTAL PRESSURIZATION OF THE AIRCRAFT.

1. Reason for the Job

Refer to the MPD TASK: 213100-01

OPERATIONAL CHECK OF SYSTEM VIA MCDU

2 Job Set-up Information

A. Work Zones and Access Panels

ZONE/ACCESS ZONE DESCRIPTION

210 CKPT,FWD COMPT BHD TO FLT COMPT BULKHEAD

B. Referenced Information

REFERENCE DESIGNATION

(Ref. 24-41-00-861-002-A). Energize the Aircraft Electrical Circuits from the External Power

(Ref. 24-41-00-861-002-A-01). Energize the Aircraft Electrical Circuits from the APU

(Ref. 24-41-00-861-002-A-02). Energize the Aircraft Electrical Circuits from Engine 1(2)

Print Date: August 23, 2020 Page 3 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

REFERENCE DESIGNATION

(Ref. 24-41-00-862-002-A). De-energize the Aircraft Electrical Circuits Supplied from the External

Power

(Ref. 24-41-00-862-002-A-01). De-energize the Aircraft Electrical Circuits Supplied from the APU

(Ref. 24-41-00-862-002-A-02). De-energize the Aircraft Electrical Circuits Supplied from the Engine

1(2)

(Ref. 31-32-00-860-002-A). Procedure to Get Access to the SYSTEM REPORT/TEST/AIR COND

Page

(Ref. 31-60-00-860-001-A). EIS Start Procedure

(Ref. 31-60-00-860-002-A). EIS Stop Procedure

(Ref. 34-10-00-860-002-A). ADIRS Start Procedure

(Ref. 34-10-00-860-005-A). ADIRS Stop Procedure

3. Job Set-up

Subtask 21-31-00-865-052-A

A. Make sure that this(these) circuit breaker(s) is(are) closed:

PANEL DESIGNATION FIN LOCATION

49VU AIR COND/CAB/PRESS/CTL1 1HL D09

122VU AIR COND/CAB PRESS/CTL/MAN 3HL Y23

122VU AIR COND/CAB PRESS/CTL/2 2HL Y22

Subtask 21-31-00-860-053-A

B. Aircraft Maintenance Configuration

(1) Energize the aircraft electrical circuits

(Ref. AMM TASK 24-41-00-861-002) .

(2) Do the EIS start procedure (upper ECAM DU and lower ECAM DU only)

(Ref. AMM TASK 31-60-00-860-001) .

(3) On the ECAM control panel push the PRESS pushbutton switch, the CAB PRESS page comes into

view on the lower ECAM display unit.

(4) On one MCDU get the SYSTEM REPORT/TEST AIR COND menu page (Ref. AMM TASK 31-32-00-

860-002) .

(5) On the AIR COND panel 30VU, make sure that:

· the PACK 1 and the PACK 2 pushbutton switches are in the off position (the OFF legends are on).

· the RAM AIR pushbutton switch is in the off position (the ON legend is off).

(6) On the CABIN PRESS panel 25VU, make sure that:

· the MODE SEL pushbutton switch is in the AUTO configuration (with the FAULT and MAN legends

off).

· the LDG ELEV selector is in the AUTO position.

· the DITCHING pushbutton switch is in the AUTO configuration (with the ON legend off).

(7) Do the ADIRS start procedure (Ref. AMM TASK 34-10-00-860-002) .

4. Procedure

Subtask 21-31-00-710-052-B

WARNING: MAKE SURE THAT THE TRAVEL RANGES OF THE OUTFLOW VALVES ARE CLEAR.

MOVEMENT OF THE OUTFLOW VALVES CAN CAUSE INJURY TO PERSONS AND/OR

DAMAGE TO EQUIPMENT.

Print Date: August 23, 2020 Page 4 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

WARNING: MAKE SURE THAT THE TRAVEL RANGES OF THE OUTFLOW VALVES ARE CLEAR.

MOVEMENT OF THE OUTFLOW VALVES CAN CAUSE INJURY TO PERSONS AND/OR

DAMAGE TO EQUIPMENT.

A. Operational Test of the Pressure Control and Monitoring

ACTION RESULT

1.On the MCDU SYSTEM REPORT/TEST AIR On the MCDU:

COND menu page: · the CAB PRESS CONT 1 page comes on.

· push the line key adjacent to the CPC 1 indica-

tion. NOTE: If the CAB PRESS CONT 1 page does not

show do a reset of CPC1 and CPC2 two

times:

For the reset of the CPCs the subsequent cir-

cuit breakers must be opened for at least 10

seconds:

- for the CPC 1, the circuit breaker 1HL which

is installed on the circuit breaker panel 49VU,

- for the CPC 2, the circuit breaker 2HL

which is installed on the circuit breaker panel

122VU.

2.On the MCDU CAB PRESS CONT 1 menu page: On the MCDU:

· push the line key adjacent to the TEST/CALIBRA- · the CAB PRESS CONT 1 TEST/CALIBRATION

TION indication. page comes on,

· the message

ECS PACKS ------------ OFF

GROUND AIR SUPPLY ---- OFF

LFES ----- SET TO 14000 FT

ADIRS 1,2,3 ----------- ON

MODE SEL ------------ AUTO comes on.

3.On the CABIN PRESS panel 25VU: On the ECAM upper display unit:

· set the LDG ELEV selector to 14000 FT. · the green MAN LDG ELEV memo message comes

on.

On the ECAM lower display unit:

· the green AUTO xxx FT indication changes to the

green MAN 14000 FT indication.

4.On the MCDU CAB PRESS CONT 1 TEST/CAL- On the MCDU:

IBRATION menu page: · the message

IN PROGRESS (20...90S) comes on, then the

· push the line key adjacent to CONTINUE. message

TEST OK

RESET LFES - > AUTO comes on.

NOTE: In case of interruption by a power-supply

transient the test may be aborted. If TEST

OK or TEST FAIL is not confirmed, the test

should be repeated.

NOTE: Do the test again for CPC 2.

Print Date: August 23, 2020 Page 5 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

5. Close-up

Subtask 21-31-00-860-054-A

A. Aircraft Maintenance Configuration

(1) On the CABIN PRESS panel 25VU, set the LDG ELEV selector to AUTO.

(2) Do the ADIRS stop procedure (Ref. AMM TASK 34-10-00-860-005) .

(3) Do the EIS stop procedure

(Ref. AMM TASK 31-60-00-860-002) .

(4) On the MCDU, push the line select key adjacent to the RETURN indication until the CFDS menu

page comes into view.

(5) De-energize the aircraft electrical circuits

(Ref. AMM TASK 24-41-00-862-002) .

TASK 21-31-00-710-003-A

Operational Test of Manual Mode Selection and Manual Mode Pressure Control and Functional Test of Manual

Mode Cabin Altitude/Outflow Valve Position Indication

WARNING: MAKE SURE THAT AIR IS NOT SUPPLIED TO THE AIR CONDITIONING SYSTEM FROM THE

MAIN ENGINE, THE APU OR A GROUND SOURCE.

HOT COMPRESSED AIR CAN CAUSE INJURY TO PERSONNEL.

1. Reason for the Job

Refer to the MPD TASK: 213100-02

OPERATIONAL CHECK OF MANUAL MODE SELECTION AND MANUAL MODE PRESSURE CONTROL

AND FUNCTIONAL CHECK OF MANUAL MODE CABIN ALTITUDE INDICATION AND OUTFLOW VALVE

POSITION INDICATION

2 Job Set-up Information

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY DESIGNATION

No specific AR SAFETY CLIP - CIRCUIT BREAKER

B. Work Zones and Access Panels

ZONE/ACCESS ZONE DESCRIPTION

210 CKPT,FWD COMPT BHD TO FLT COMPT BULKHEAD

C. Referenced Information

REFERENCE DESIGNATION

(Ref. 24-41-00-861-002-A). Energize the Aircraft Electrical Circuits from the External Power

(Ref. 24-41-00-861-002-A-01). Energize the Aircraft Electrical Circuits from the APU

(Ref. 24-41-00-861-002-A-02). Energize the Aircraft Electrical Circuits from Engine 1(2)

(Ref. 24-41-00-862-002-A). De-energize the Aircraft Electrical Circuits Supplied from the External

Power

(Ref. 24-41-00-862-002-A-01). De-energize the Aircraft Electrical Circuits Supplied from the APU

(Ref. 24-41-00-862-002-A-02). De-energize the Aircraft Electrical Circuits Supplied from the Engine

1(2)

Print Date: August 23, 2020 Page 6 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

REFERENCE DESIGNATION

(Ref. 31-60-00-860-001-A). EIS Start Procedure

(Ref. 31-60-00-860-002-A). EIS Stop Procedure

3. Job Set-up

Subtask 21-31-00-865-053-A

A. Make sure that this(these) circuit breaker(s) is(are) closed:

PANEL DESIGNATION FIN LOCATION

49VU AIR COND/CAB/PRESS/CTL1 1HL D09

122VU AIR COND/CAB PRESS/CTL/MAN 3HL Y23

122VU AIR COND/CAB PRESS/CTL/2 2HL Y22

Subtask 21-31-00-865-072-A

B. Open, safety and tag this(these) circuit breaker(s):

PANEL DESIGNATION FIN LOCATION

** ON A/C 016-017, 019-022, 024-039, 041-043, 045-100, 112-150, 208-209, 213-218, 222-230, 238-239,

242-242, 301-450, 500-600

122VU RPCU 4HL X23

** ON A/C ALL

Subtask 21-31-00-860-055-A

C. Aircraft Maintenance Configuration

(1) Energize the aircraft electrical circuits

(Ref. AMM TASK 24-41-00-861-002) .

(2) Do the EIS start procedure (upper ECAM DU and lower ECAM DU only)

(Ref. AMM TASK 31-60-00-860-001) .

(3) On the ECAM control panel push the PRESS pushbutton switch, the CAB PRESS page comes into

view on the lower ECAM display unit.

(4) On the AIR COND panel 30VU, make sure that:

· The PACK 1 and the PACK 2 pushbutton switches are in the OFF position (the OFF legends are

on).

· The RAM AIR pushbutton switch is in the OFF position (the ON legend is off).

(5) On the CABIN PRESS panel 25VU, make sure that:

· The MODE SEL pushbutton switch is in the AUTO configuration (with the FAULT and MAN legends

off).

· The LDG ELEV selector is in the AUTO position.

· The DITCHING pushbutton switch is in the AUTO configuration (with the ON legend off).

(6) Make sure that there are no persons near the Outflow Valve (OFV) before you start this test.

4. Procedure

Subtask 21-31-00-710-053-A

WARNING: MAKE SURE THAT THE TRAVEL RANGES OF THE OUTFLOW VALVES ARE CLEAR.

MOVEMENT OF THE OUTFLOW VALVES CAN CAUSE INJURY TO PERSONS AND/OR

DAMAGE TO EQUIPMENT.

Print Date: August 23, 2020 Page 7 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

WARNING: MAKE SURE THAT THE TRAVEL RANGES OF THE OUTFLOW VALVES ARE CLEAR.

MOVEMENT OF THE OUTFLOW VALVES CAN CAUSE INJURY TO PERSONS AND/OR

DAMAGE TO EQUIPMENT.

A. Operational Test of Manual Mode Selection and Manual Mode Pressure Control and Functional Test

Manual Mode Cabin Altitude / Outflow Valve Position Indication

ACTION RESULT

1.On the CABIN PRESS panel 25VU: On the ECAM upper display unit:

· Move the LDG ELEV selector clockwise away · The green MAN LDG ELEV memo message

from the AUTO position. comes on.

On the ECAM lower display unit:

· The green AUTO xxx FT indication changes to the

green MAN xxx FT indication.

NOTE: The actual manual altitude indication de-

pends on the LDG ELEV selector position.

2.On the CABIN PRESS panel 25VU: On the CABIN PRESS panel 25VU:

· Push and release the MODE SEL pushbutton · The white MAN pushbutton switch light comes on.

switch.

NOTE: The accuracy of the cabin altitude indication

in MAN mode is +/- 1100ft.

On the ECAM lower display unit:

· The white LDG ELEV indication and the green

MAN xxx FT indication goes off.

· The green SYS 1 (or SYS 2) indication changes to

the green MAN indication.

· Push and hold the MAN V/S CTL toggle switch to · The OFV needle indication moves down.

DN.

· Push and hold the MAN V/S CTL toggle switch to · The OFV needle indication moves up.

UP.

· Release the MAN V/S CTL toggle switch. · The OFV needle indication shows that the OFV is

in the open position.

3.On the CABIN PRESS panel 25VU: On the CABIN PRESS panel 25VU:

· Push the MODE SEL pushbutton switch. · The white MAN pushbutton switch light goes off.

On the ECAM lower display unit:

· The white LDG ELEV indication and the green

MAN xxx FT indication comes on.

· The green MAN indication changes to the green

SYS 1 (or SYS 2) indication.

4.On the CABIN PRESS panel 25VU: On the ECAM upper display unit:

· Move the LDG ELEV selector counterclockwise to · The green MAN LDG ELEV memo message goes

the AUTO position. off.

On the ECAM lower display unit:

· The green MAN xxx FT indication changes to the

green AUTO xxx FT indication..

5. Close-up

Subtask 21-31-00-865-073-A

A. Remove the safety clip(s) and the tag(s) and close this(these) circuit breaker(s):

Print Date: August 23, 2020 Page 8 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

PANEL DESIGNATION FIN LOCATION

** ON A/C 016-017, 019-022, 024-039, 041-043, 045-100, 112-150, 208-209, 213-218, 222-230, 238-239,

242-242, 301-450, 500-600

122VU RPCU 4HL X23

** ON A/C ALL

Subtask 21-31-00-860-056-A

B. Aircraft Maintenance Configuration

(1) Do the EIS stop procedure

(Ref. AMM TASK 31-60-00-860-002) .

(2) De-energize the aircraft electrical circuits

(Ref. AMM TASK 24-41-00-862-002) .

TASK 21-31-00-710-004-A

Operational Test of the Outflow Valve Closing in Ditching Configuration

WARNING: MAKE SURE THAT AIR IS NOT SUPPLIED TO THE AIR CONDITIONING SYSTEM FROM THE

MAIN ENGINE, THE APU OR A GROUND SOURCE.

HOT COMPRESSED AIR CAN CAUSE INJURY TO PERSONNEL.

WARNING: MAKE SURE THAT THE FWD AVIONICS ACCESS DOOR 811 IS OPEN WITH A WARNING

PLACARD ATTACHED TO IT.

THE WARNING NOTICE MUST TELL PERSONS NOT TO CLOSE THE DOOR. THIS PREVENTS

ACCIDENTAL PRESSURIZATION OF THE AIRCRAFT.

1. Reason for the Job

Refer to the MPD TASK: 213100-03

OPERATIONAL CHECK OF OUTFLOW VALVE CLOSING IN DITCHING CONFIGURATION

2 Job Set-up Information

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY DESIGNATION

No specific AR SAFETY CLIP - CIRCUIT BREAKER

B. Work Zones and Access Panels

ZONE/ACCESS ZONE DESCRIPTION

210 CKPT,FWD COMPT BHD TO FLT COMPT BULKHEAD

260 AFT CABIN UTILITY AREA

C. Referenced Information

REFERENCE DESIGNATION

(Ref. 21-31-00-100-001-A). Cleaning of the Moveable Seals of the Outflow-Valve

(Ref. 24-41-00-861-002-A). Energize the Aircraft Electrical Circuits from the External Power

(Ref. 24-41-00-861-002-A-01). Energize the Aircraft Electrical Circuits from the APU

(Ref. 24-41-00-861-002-A-02). Energize the Aircraft Electrical Circuits from Engine 1(2)

Print Date: August 23, 2020 Page 9 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

REFERENCE DESIGNATION

(Ref. 24-41-00-862-002-A). De-energize the Aircraft Electrical Circuits Supplied from the External

Power

(Ref. 24-41-00-862-002-A-01). De-energize the Aircraft Electrical Circuits Supplied from the APU

(Ref. 24-41-00-862-002-A-02). De-energize the Aircraft Electrical Circuits Supplied from the Engine

1(2)

(Ref. 31-60-00-860-001-A). EIS Start Procedure

(Ref. 31-60-00-860-002-A). EIS Stop Procedure

3. Job Set-up

Subtask 21-31-00-861-064-A

A. Energize the aircraft electrical circuits

(Ref. AMM TASK 24-41-00-861-002) .

Subtask 21-31-00-865-067-A

B. Open, safety and tag this(these) circuit breaker(s):

PANEL DESIGNATION FIN LOCATION

49VU AIR COND/CAB/PRESS/CTL1 1HL D09

122VU AIR COND/CAB PRESS/CTL/MAN 3HL Y23

122VU AIR COND/CAB PRESS/CTL/2 2HL Y22

Subtask 21-31-00-860-068-A

C. Outflow Valve Seals Inspection

(1) Do a check of the outflow valve moveable seals installed in the outflow valve gates:

· they must move freely with a light finger pressure.

· you must clean the seals if they do not move freely (Ref. AMM TASK 21-31-00-100-001) .

Subtask 21-31-00-865-054-A

D. Make sure that this(these) circuit breaker(s) is(are) closed:

PANEL DESIGNATION FIN LOCATION

49VU AIR COND/CAB/PRESS/CTL1 1HL D09

122VU AIR COND/CAB PRESS/CTL/MAN 3HL Y23

122VU AIR COND/CAB PRESS/CTL/2 2HL Y22

Subtask 21-31-00-860-057-A

E. Aircraft Maintenance Configuration

(1) Do the EIS start procedure (upper ECAM DU and lower ECAM DU only)

(Ref. AMM TASK 31-60-00-860-001) .

(2) Make sure that on the CABIN PRESS section of the panel 25VU:

· the MODE SEL pushbutton switch is in the AUTO position (the FAULT and the MAN legends are

off).

NOTE: Make sure there are no persons near the outflow valve before you start this test.

4. Procedure

Subtask 21-31-00-710-054-A

Print Date: August 23, 2020 Page 10 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

WARNING: MAKE SURE THAT THE TRAVEL RANGES OF THE OUTFLOW VALVES ARE CLEAR.

MOVEMENT OF THE OUTFLOW VALVES CAN CAUSE INJURY TO PERSONS AND/OR

DAMAGE TO EQUIPMENT.

WARNING: MAKE SURE THAT THE TRAVEL RANGES OF THE OUTFLOW VALVES ARE CLEAR.

MOVEMENT OF THE OUTFLOW VALVES CAN CAUSE INJURY TO PERSONS AND/OR

DAMAGE TO EQUIPMENT.

A. Operational Test of the Outflow Valve Closing in Ditching Configuration

ACTION RESULT

1.On the ECAM control panel 11VU: On the ECAM lower display unit:

· push the PRESS pushbutton switch. · the CAB PRESS page comes on.

2.On the CABIN PRESS panel 25VU: On the CABIN PRESS panel 25VU:

· lift the black guard and push the DITCHING push- · the white ON pushbutton switch light comes on.

button switch.

On the ECAM lower display unit:

· the outflow valve symbol closes.

3.On the CABIN PRESS panel 25VU: On the CABIN PRESS panel 25VU:

· lift the black guard and push the DITCHING push- · the white ON pushbutton switch light goes off.

button switch.

On the ECAM lower display unit:

· the outflow valve symbol opens.

5. Close-up

Subtask 21-31-00-860-058-A

A. Do the EIS stop procedure

(Ref. AMM TASK 31-60-00-860-002) .

Subtask 21-31-00-862-061-A

B. De-energize the aircraft electrical circuits

(Ref. AMM TASK 24-41-00-862-002) .

TASK 21-31-00-710-005-A

Operational Test of Outflow Valve Partial Opening by Emergency Ram Air Switch

WARNING: MAKE SURE THAT AIR IS NOT SUPPLIED TO THE AIR CONDITIONING SYSTEM FROM THE

MAIN ENGINE, THE APU OR A GROUND SOURCE.

HOT COMPRESSED AIR CAN CAUSE INJURY TO PERSONNEL.

1. Reason for the Job

Refer to the MPD TASK: 213100-04

OPERATIONAL CHECK OF OUTFLOW VALVE PARTIAL OPENING BY EMERGENCY RAM AIR SWITCH

2 Job Set-up Information

A. Work Zones and Access Panels

ZONE/ACCESS ZONE DESCRIPTION

210 CKPT,FWD COMPT BHD TO FLT COMPT BULKHEAD

Print Date: August 23, 2020 Page 11 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

B. Referenced Information

REFERENCE DESIGNATION

(Ref. 24-41-00-861-002-A). Energize the Aircraft Electrical Circuits from the External Power

(Ref. 24-41-00-861-002-A-01). Energize the Aircraft Electrical Circuits from the APU

(Ref. 24-41-00-861-002-A-02). Energize the Aircraft Electrical Circuits from Engine 1(2)

(Ref. 24-41-00-862-002-A). De-energize the Aircraft Electrical Circuits Supplied from the External

Power

(Ref. 24-41-00-862-002-A-01). De-energize the Aircraft Electrical Circuits Supplied from the APU

(Ref. 24-41-00-862-002-A-02). De-energize the Aircraft Electrical Circuits Supplied from the Engine

1(2)

(Ref. 31-60-00-860-001-A). EIS Start Procedure

(Ref. 31-60-00-860-002-A). EIS Stop Procedure

(Ref. 34-10-00-860-002-A). ADIRS Start Procedure

(Ref. 34-10-00-860-005-A). ADIRS Stop Procedure

3. Job Set-up

Subtask 21-31-00-861-066-A

A. Energize the aircraft electrical circuits

(Ref. AMM TASK 24-41-00-861-002) .

Subtask 21-31-00-865-055-A

B. Make sure that this(these) circuit breaker(s) is(are) closed:

PANEL DESIGNATION FIN LOCATION

49VU AIR COND/RAM/AIR/INLET 1HZ D10

49VU AIR COND/CAB/PRESS/CTL1 1HL D09

122VU AIR COND/CAB PRESS/CTL/MAN 3HL Y23

122VU AIR COND/CAB PRESS/CTL/2 2HL Y22

Subtask 21-31-00-860-059-A

C. Aircraft Maintenance Configuration

(1) Do the EIS start procedure (upper ECAM DU and lower ECAM DU only)

(Ref. AMM TASK 31-60-00-860-001) .

(2) Do the start procedure of the ADIRS (Ref. AMM TASK 34-10-00-860-002) .

(3) Make sure that:

· on the ECAM lower display unit the CAB PRESS page shows,

· on the AIR COND panel 30VU the PACK 1 and the PACK 2 pushbutton switches are in the OFF

position (the FAULT legend is off, the OFF legend is on).

· on the CABIN PRESS section of the panel 25VU the MODE SEL pushbutton switch is in the AUTO

position (the FAULT and the MAN legends are off).

NOTE: Make sure there are no persons near the outflow valve before you start this test.

4. Procedure

Subtask 21-31-00-710-055-A

Print Date: August 23, 2020 Page 12 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

WARNING: MAKE SURE THAT THE TRAVEL RANGES OF THE OUTFLOW VALVES ARE CLEAR.

MOVEMENT OF THE OUTFLOW VALVES CAN CAUSE INJURY TO PERSONS AND/OR

DAMAGE TO EQUIPMENT.

WARNING: MAKE SURE THAT THE TRAVEL RANGES OF THE OUTFLOW VALVES ARE CLEAR.

MOVEMENT OF THE OUTFLOW VALVES CAN CAUSE INJURY TO PERSONS AND/OR

DAMAGE TO EQUIPMENT.

A. Operational Test of the Outflow Valve (50 deg.) partial opening by the Emergency Ram Air Switch

NOTE: Make sure that the area around the emergency ram air-flap is free from ground equipment and

personnel.

(1) Do this test

ACTION RESULT

1.On the AIR COND panel 30VU: On the AIR COND panel 30VU:

· lift the black guard and push the RAM AIR · the white ON pushbutton switch light comes on.

pushbutton switch.

On the ECAM upper display unit:

· the green RAM AIR ON memo message comes

on.

On the ECAM lower display unit:

· The outflow valve symbol shows approx. 50

DEG. open when the differential pressure in the

fuselage is less than 1 psi.

2.On the ECAM control panel 11VU: On the ECAM lower display unit:

· push the BLEED pushbutton switch. · the BLEED page comes on.

On the ECAM lower display unit:

· the ram air inlet symbol opens (the maximum op-

eration time 20 s).

3.On the AIR COND panel 30VU: On the AIR COND panel 30VU:

· lift the black guard and push the RAM AIR · the white ON pushbutton switch light goes off.

pushbutton switch.

4.On the ECAM control panel 11VU: On the ECAM lower display unit:

· push the PRESS pushbutton switch. · the CAB PRESS page comes on.

On the ECAM lower display unit:

· the outflow valve symbol shows fully open.

On the ECAM upper display unit:

· the green RAM AIR ON memo message goes

off.

5.On the ECAM control panel 11VU: On the ECAM lower display unit:

· push the BLEED pushbutton switch. · the BLEED page comes on.

· the ram air inlet symbol is closed.

5. Close-up

Subtask 21-31-00-860-060-A

A. Put the aircraft back to its initial configuration.

(1) Do the ADIRS stop procedure (Ref. AMM TASK 34-10-00-860-005) .

Print Date: August 23, 2020 Page 13 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

(2) Do the EIS stop procedure

(Ref. AMM TASK 31-60-00-860-002) .

(3) De-energize the aircraft electrical circuits

(Ref. AMM TASK 24-41-00-862-002) .

TASK 21-31-00-710-006-A

Operational Test of Safety Valve Position Indication

WARNING: MAKE SURE THAT ALL THE CIRCUITS IN MAINTENANCE ARE ISOLATED BEFORE YOU

SUPPLY ELECTRICAL POWER TO THE AIRCRAFT. UNWANTED ELECTRICAL POWER CAN

BE DANGEROUS.

NOTE: For the test procedure two persons are required. One person must operate the safety valve, the other per-

son must monitor the ECAM upper and lower display units and the panels 130VU and 132VU in the cockpit.

1. Reason for the Job

Self explanatory

2 Job Set-up Information

A. Work Zones and Access Panels

ZONE/ACCESS ZONE DESCRIPTION

210 CKPT,FWD COMPT BHD TO FLT COMPT BULKHEAD

260 AFT CABIN UTILITY AREA

B. Referenced Information

REFERENCE DESIGNATION

(Ref. 24-41-00-861-002-A). Energize the Aircraft Electrical Circuits from the External Power

(Ref. 24-41-00-861-002-A-01). Energize the Aircraft Electrical Circuits from the APU

(Ref. 24-41-00-861-002-A-02). Energize the Aircraft Electrical Circuits from Engine 1(2)

(Ref. 24-41-00-862-002-A). De-energize the Aircraft Electrical Circuits Supplied from the External

Power

(Ref. 24-41-00-862-002-A-01). De-energize the Aircraft Electrical Circuits Supplied from the APU

(Ref. 24-41-00-862-002-A-02). De-energize the Aircraft Electrical Circuits Supplied from the Engine

1(2)

(Ref. 31-60-00-860-001-A). EIS Start Procedure

(Ref. 31-60-00-860-002-A). EIS Stop Procedure

3. Job Set-up

Subtask 21-31-00-010-050-A

A. Get access to the safety valves through the rear galley wall.

Subtask 21-31-00-865-056-A

B. Make sure that this(these) circuit breaker(s) is(are) closed:

PANEL DESIGNATION FIN LOCATION

49VU AIR COND/CAB/PRESS/CTL1 1HL D09

122VU AIR COND/CAB PRESS/CTL/MAN 3HL Y23

Print Date: August 23, 2020 Page 14 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

PANEL DESIGNATION FIN LOCATION

122VU AIR COND/CAB PRESS/CTL/2 2HL Y22

Subtask 21-31-00-860-061-A

C. Aircraft Maintenance Configuration

(1) Energize the aircraft electrical circuits

(Ref. AMM TASK 24-41-00-861-002) .

(2) Do the EIS start procedure (upper ECAM DU and lower ECAM DU only)

(Ref. AMM TASK 31-60-00-860-001) .

(3) Make sure that the PRESS page is shown on the ECAM lower display unit.

4. Procedure

Subtask 21-31-00-710-056-A

A. Operational Test of the Safety Valve Position Indication

NOTE: The test procedure is the same for the safety valves 6HL and 7HL.

ACTION RESULT

1.On one of the safety valves: On the ECAM lower display unit:

· hold the safety valve with both hands on the left · the white SAFETY indication changes to amber

and on the right side. Push the movable dia- and the valve symbol opens and changes to am-

phragm with your fingers against the spring force ber.

to operate the position switch and hold it in that

position for at least 1 minute.

On the panels 130VU and 132VU:

· the amber light in the two MASTER CAUTION

pushbutton switches come on.

· the single audio warning is heard.

On the ECAM upper display unit:

· the warning message CAB PR SAFETY VALVE

OPEN comes on.

· release the diaphragm. On the ECAM lower display unit:

· the open valve symbol closes and changes to

green and the amber SAFETY indication changes

to white.

On the panels 130VU and 132VU:

· the amber light in the two MASTER CAUTION

pushbutton switches go off.

On the ECAM upper display unit:

· the warning message CAB PR SAFETY VALVE

OPEN goes off.

NOTE: Do this test again for the other safety valve.

5. Close-up

Subtask 21-31-00-860-062-A

A. Do the EIS stop procedure

(Ref. AMM TASK 31-60-00-860-002) .

Subtask 21-31-00-410-050-A

Print Date: August 23, 2020 Page 15 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

B. Close Access

(1) Make sure that the work area is clean and clear of tools and other items.

(2) Close the access to the safety valves.

Subtask 21-31-00-862-055-A

C. De-energize the aircraft electrical circuits

(Ref. AMM TASK 24-41-00-862-002) .

TASK 21-31-00-720-001-A

Functional Test of the Positive and Negative Delta P Protection of the Safety Valves

NOTE: If the test set NORD MICRO PN 0622-19857-01 is not available the test set NORD MICRO PN 0622-

19857-02 can be used and vise versa. If either one of the test sets is not available send the safety valves in

shop for functional test.

1. Reason for the Job

Refer to the MPD TASK: 213100-05

FUNCTIONAL CHECK OF POSITIVE/NEGATIVE DELTA "P" PROTECTION OF THE SAFETY VALVES.

2 Job Set-up Information

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY DESIGNATION

No specific 1 ACCESS PLATFORM 4M (13 FT)-ADJUSTABLE

No specific AR AIR SOURCE 0.02 BAR (0.3 PSI)

No specific AR AIR SOURCE 1.7 TO 2 BAR (25 TO 30 PSI) - FILTERED, DRY

No specific AR SAFETY CLIP - CIRCUIT BREAKER

No specific AR TEST UNIT - VALVE ACTUATING (0622-19857-01 TYPE)

(0622-19857-02) 1 TEST SET - VALVE ACTUATING

B. Work Zones and Access Panels

ZONE/ACCESS ZONE DESCRIPTION

260 AFT CABIN UTILITY AREA

312AR

C. Referenced Information

REFERENCE DESIGNATION

(Ref. 21-31-00-710-006-A). Operational Test of Safety Valve Position Indication

(Ref. 24-41-00-861-002-A). Energize the Aircraft Electrical Circuits from the External Power

(Ref. 24-41-00-861-002-A-01). Energize the Aircraft Electrical Circuits from the APU

(Ref. 24-41-00-861-002-A-02). Energize the Aircraft Electrical Circuits from Engine 1(2)

(Ref. 24-41-00-862-002-A). De-energize the Aircraft Electrical Circuits Supplied from the External

Power

(Ref. 24-41-00-862-002-A-01). De-energize the Aircraft Electrical Circuits Supplied from the APU

(Ref. 24-41-00-862-002-A-02). De-energize the Aircraft Electrical Circuits Supplied from the Engine

1(2)

Safety Valve - Differential Pressure Test

Print Date: August 23, 2020 Page 16 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

Z260 Z310

C

A

FR70

PAX DOOR 2

FR65

G A

FR77

312AR

FR70

N_MM_213100_5_AAMA_01_01

Figure 21-31-00-991-00100-00-A / SHEET 1/4 - Safety Valve - Differential Pressure Test

** ON A/C ALL

Print Date: August 23, 2020 Page 17 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

F

D E

1

C

TYPICAL D

TYPICAL

REAR PRESSURE BULKHEAD

2

3

FR70

4 6HL E

7HL F

E F

TYPICAL

N_MM_213100_5_AAMA_02_01

Figure 21-31-00-991-00100-00-A / SHEET 2/4 - Safety Valve - Differential Pressure Test

** ON A/C ALL

Print Date: August 23, 2020 Page 18 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

H J

27

25 FR70

22

18 REAR PRESSURE BULKHEAD

26

24

23

A

19

12

20

21

GREEN

ORANGE 15

16

14

GREEN

36

17 32 34 35

33

A 30 NEUTRAL

31

ORANGE

PN 0622-19857-02

29 G 28

TYPICAL H PN 0622-19857-01

TYPICAL

J

TYPICAL

N_MM_213100_5_AAMA_03_00

Figure 21-31-00-991-00100-00-A / SHEET 3/4 - Safety Valve - Differential Pressure Test

** ON A/C ALL

Print Date: August 23, 2020 Page 19 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

POINT 'A' REAR PRESSURE BULKHEAD

4 12 14

15

16 GREEN

17

GREEN

37

30

29

ORANGE

32 31

POINT 'A'

36 35 34 33

NEUTRAL

FWD A A

TYPICAL

N_MM_213100_5_AAMA_04_00

Figure 21-31-00-991-00100-00-A / SHEET 4/4 - Safety Valve - Differential Pressure Test

** ON A/C ALL

Print Date: August 23, 2020 Page 20 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

3. Job Set-up

(Ref. Fig. Safety Valve - Differential Pressure Test)

Subtask 21-31-00-861-060-A

A. Energize the aircraft electrical circuits

(Ref. AMM TASK 24-41-00-861-002) .

Subtask 21-31-00-010-054-A

B. Get Access

(1) Put the ACCESS PLATFORM 4M (13 FT)-ADJUSTABLE in position at the access panel 312AR.

(2) Remove the access panel 312AR.

(3) In the cabin remove the food trolleys (1) and the access panel (5).

Subtask 21-31-00-865-060-A

C. Open, safety and tag this(these) circuit breaker(s):

PANEL DESIGNATION FIN LOCATION

49VU AIR COND/CAB/PRESS/CTL1 1HL D09

122VU AIR COND/CAB PRESS/CTL/MAN 3HL Y23

122VU AIR COND/CAB PRESS/CTL/2 2HL Y22

4. Procedure

Subtask 21-31-00-480-053-A

A. Functional Test of the Safety Valve

(1) Installation of the Test Equipment TEST SET - VALVE ACTUATING (0622-19857-02) TEST UNIT -

VALVE ACTUATING (0622-19857-01 TYPE).

(Ref. Fig. Safety Valve - Differential Pressure Test)

(a) On the Test Set

1 Make sure that the pressure controller (18) and the vacuum controller (25) are fully closed.

2 Connect these items:

· The pressure input (19) to a constant positive pressure supply AIR SOURCE 1.7 TO 2

BAR (25 TO 30 PSI) - FILTERED, DRY.

· The vacuum input (24) to a constant negative pressure/vacuum supply AIR SOURCE 0.02

BAR (0.3 PSI).

· The electrical-power connector (26) to a 28V DC power supply.

· The test wiring to the safety-valve position-switch connector (27).

· The connector with the orange color of the flexible hose assembly (29) to the vacuum

output connector (23).

· The connector with the green color of the flexible hose assembly (29) to the pressure

sense connector (21).

· The connector with the green color of the flexible hose (17) to the pressure output

connector (20).

3 On the check device (15) make sure that the fixed pressure connector (16) is screwed out.

(b) On the Aircraft:

1 Connect the test wiring to the safety valve electrical-connector (3).

2 Remove the nut (33), the strainer (34) and the washer (35).

3 Put the check device (15) in position on the bellmouth (14) and close the clamps (32).

Print Date: August 23, 2020 Page 21 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

4 Make sure that the pivoted pressure connector (30) is in position over the poppet valve outlet

(37).

NOTE: You can see this through the cut-outs in the check device (15).

5 Screw in the fixed pressure connector (16) until you get a seal at the poppet valve (12), and

the clamps (32) are tight.

6 Adjust the pivoted pressure connector (30) with the adjustment screw (31) until you get a

seal at the poppet valve outlet (37).

7 Connect these items:

· The connectors with the green color of the flexible hose (17) and the flexible hose

assembly (29) to the fixed pressure connector (16).

· The connector with the orange color of the flexible hose assembly (29) to the pivoted

pressure connector (30).

· The neutral colored connector of the flexible hose assembly (29) to the bulkhead

connector (36).

(2) Functional Test of the Test Equipment

(a) Apply hand pressure at points A to open the safety valve (4).

· The position indicator lamp (22) on the test set comes on.

(b) Allow the safety valve (4) to close.

· The position indicator lamp (22) on the test set goes off.

(c) For PN 0622-19857-01

Adjust the pressure monitor to zero:

1 Turn the adjustment screw (28) until the value shown on the pressure monitor is zero.

(d) For PN 0622-19857-02 (Druck display)

Adjust the pressure monitor to zero:

1 Press F1 and F2 keys at the same time to enter the function.

2 Use the keys AL1 and AL2 to set the zero value.

3 Press F2 key.

4 Press F2 key again to return the display to normal operation.

(e) For PN 0622-19857-02 (red lion display)

Adjust the pressure monitor to zero:

1 Disconnect the green connector of the flexible hose assembly (29) from the pressure sense

connector (21).

2 Connect a pneumatic connector to the pressure sense connector (21).

NOTE: The other side of the pneumatic connector is open to the ambient air.

3 Make sure that the electrical-power input connector (26) is connected to the 28V DC

POWER SUPPLY UNIT.

4 On the pressure monitor, push the RST button.

5 Make sure that the pressure value shown on the pressure monitor is 0.0000.

6 Disconnect the pneumatic connector from the pressure sense connector (21).

7 Connect the green connector of the flexible hose assembly (29) to the pressure sense

connector (21).

Print Date: August 23, 2020 Page 22 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

(f) Slowly open the vacuum control (25) until you get a stable pressure value shown on the pressure

monitor.

NOTE: Do not go above 588 mbar (8.53 psi) pressure. Failure to get a stable pressure value is

an indication of possible leaks. Check the seal at the poppet valve (12) and at the poppet

valve outlet (37).

(g) Close the vacuum control (25).

(h) Disconnect the connector with the orange color at the vacuum outlet (23) to release any pressure

in the system.

(i) Reconnect the connector with the orange color to the vacuum outlet (23).

Subtask 21-31-00-720-051-A

B. Functional Test of the Safety Valve

(Ref. Fig. Safety Valve - Differential Pressure Test)

(1) Testing of the Safety Valve

(a) Functional Test of the Positive Differential-Pressure Protection

1 Make sure that the value shown on the pressure monitor is set at zero.

NOTE: For adjustment to zero value refer to working step A2c or A2d.

2 Slowly open the vacuum control (25) to apply vacuum.

3 Increase the vacuum until the safety valve opens.

NOTE: You know this when the position indicator lamp (22) comes on.

4 When the position indicator lamp (22) comes on, you must make a note of the value shown

on the pressure monitor.

This value must be between 586 mbar (8.50 psi) and 600 mbar (8.70 psi) pressure.

5 Close the vacuum control.

6 Release the vacuum.

NOTE: To do this you must disconnect the connector with the orange color at the vacuum

output (23).

7 Reconnect the connector with the orange color to the vacuum output (23).

8 Do the test with the calibrated safety valve at least 2 times more to make sure the set point

adjustment is the same each time.

(b) Functional Test of the Negative Differential-Pressure Protection

1 Make sure that the value shown on the pressure monitor is set at zero.

NOTE: For adjustment to zero value refer to working step A2c or A2d.

2 Slowly open the pressure control (18) to give a positive pressure.

3 Increase the positive pressure until the safety valve opens.

NOTE: You know this when the position indicator lamp (22) comes on.

Print Date: August 23, 2020 Page 23 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

4 When the position indicator lamp (22) comes on you must make a note of the value shown

on the pressure monitor.

This value must be between 5 mbar (0.07 psi) and 18.0 mbar (0.26 psi).

5 Close the pressure control (18).

6 Release the positive pressure.

NOTE: To do this you must disconnect the connector with the green color at the pressure

output (20).

7 Do the negative relief set point check at least 2 times more to make sure the safety valve

function is correct.

Subtask 21-31-00-080-053-A

C. Removal of the Test Equipment

(Ref. Fig. Safety Valve - Differential Pressure Test)

(1) On the Aircraft

(a) Disconnect these items:

· The connectors with the green color the flexible hose (17) and the flexible hose assembly (29)

from the fixed pressure connector (16).

· The connector with the orange color of the flexible hose assembly (29) from the pivoted

pressure connector (30).

· The neutral colored connector of the flexible hose assembly (29) from the bulkhead connector

(36).

(b) Loosen the screw (31) and disengage the pivoted pressure connector from the poppet valve

outlet (37).

(c) Screw out the fixed pressure connector (16) to disengage it from the poppet valve (12).

(d) Release the clamps (32) and remove the check device (15) from the bellmouth (14).

(e) Disconnect the test wiring from the electrical connector (3).

(f) Remove the check device (15) and the test wiring from the aircraft.

(2) On the Test Set:

(a) Disconnect these items:

· The connector with the green color of the flexible hose (17) from the pressure output connector

(20).

· The connector with the green color of the flexible hose assembly (29) from the pressure sense

connector (21).

· The connector with the orange color of the flexible hose assembly (29) from the vacuum output

connector (23)

· The test wiring from the safety-valve position-switch connector (27).

· The electrical power connector (26).

· The pressure input (19) and the vacuum input (24).

Subtask 21-31-00-420-051-A

D. Aircraft Maintenance Configuration

(1) Install the washer (35), the strainer (34) and the nut (33).

(2) Remove the blanking caps from the disconnected electrical connectors.

(3) Make sure that all the electrical connections are clean and in the correct condition.

(4) Connect the electrical connector (2).

Print Date: August 23, 2020 Page 24 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

Subtask 21-31-00-865-061-A

E. Remove the safety clip(s) and the tag(s) and close this(these) circuit breaker(s):

PANEL DESIGNATION FIN LOCATION

49VU AIR COND/CAB/PRESS/CTL1 1HL D09

122VU AIR COND/CAB PRESS/CTL/MAN 3HL Y23

122VU AIR COND/CAB PRESS/CTL/2 2HL Y22

Subtask 21-31-00-710-061-A

F. Do the operational test of the safety valves and position indication (Ref. AMM TASK 21-31-00-710-006) .

5. Close-up

(Ref. Fig. Safety Valve - Differential Pressure Test)

Subtask 21-31-00-410-053-A

A. Close Access

(1) Make sure that the work area is clean and clear of tools and other items.

(2) Install the access panel (5) and the food trolleys (1).

(3) Install the access panel 312AR.

(4) Remove the access platform(s).

Subtask 21-31-00-862-059-A

B. De-energize the aircraft electrical circuits

(Ref. AMM TASK 24-41-00-862-002) .

TASK 21-31-00-760-001-A

Resistance Check of the Return Ground Connections - Cabin Pressure Controller (CPC) 1 (11HL) and 2 (12HL)

and the Electronic Modules 10HL-1 and 10HL-2

FIN : 10HL , 11HL , 12HL

1. Reason for the Job

Self explanatory

2 Job Set-up Information

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY DESIGNATION

No specific 2 ACCESS PLATFORM 1M(3 FT)

No specific 2 ACCESS PLATFORM 2M (6 FT)

No specific 1 MILLIOHMMETER 0.01 OHM - LOW VOLTAGE

No specific AR SAFETY CLIP - CIRCUIT BREAKER

B. Consumable Materials

REFERENCE DESIGNATION

(Material No. 04TMB2) Varnish-- Electrical Bonding Structure

(Material No. 06AAA1) Polysulfide Sealant-General Purpose Brushable -

FOR 11HL (PRESS CONT 1)

(Material No. 04TMB2) Varnish-- Electrical Bonding Structure

Print Date: August 23, 2020 Page 25 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

REFERENCE DESIGNATION

(Material No. 06AAA1) Polysulfide Sealant-General Purpose Brushable -

FOR 12HL (PRESS CONT 2)

(Material No. 04TMB2) Varnish-- Electrical Bonding Structure

(Material No. 06AAA1) Polysulfide Sealant-General Purpose Brushable -

C. Work Zones and Access Panels

ZONE/ACCESS ZONE DESCRIPTION

120 AVIONICS COMPARTMENT

160 BULK CARGO COMPARTMENT AFT BULKHEAD OF AFT CARGO

COMPARTMENT TO AFT BULKHEAD OF BULK CARGO COMPART-

MENT

162DW, 811, 826

D. Referenced Information

REFERENCE DESIGNATION

(Ref. 20-28-00-912-802-A). Electrical Bonding - General Maintenance Procedure

(Ref. 21-31-00-710-002-A). Operational Test of the Pressure Control and Monitoring

(Ref. 21-31-34-000-001-A). Removal of the Cabin Pressure Controller (CPC)

(Ref. 21-31-34-400-001-A). Installation of the Cabin Pressure Controller (CPC)

(Ref. 21-31-51-000-002-A). Removal of the Outflow Valve - Electronics Module 10HL-1 (10HL-2)

(Ref. 21-31-51-000-005-A). Removal of the Outflow Valve - Feedback Assembly 10HL-6

(Ref. 21-31-51-400-002-A). Installation of the Outflow Valve - Electronics Module 10HL-1 (10HL-2)

(Ref. 21-31-51-400-005-A). Installation of the Outflow Valve - Feedback Assembly 10HL-6

(Ref. 24-41-00-861-002-A). Energize the Aircraft Electrical Circuits from the External Power

(Ref. 24-41-00-861-002-A-01). Energize the Aircraft Electrical Circuits from the APU

(Ref. 24-41-00-861-002-A-02). Energize the Aircraft Electrical Circuits from Engine 1(2)

(Ref. 24-41-00-862-002-A). De-energize the Aircraft Electrical Circuits Supplied from the External

Power

(Ref. 24-41-00-862-002-A-01). De-energize the Aircraft Electrical Circuits Supplied from the APU

(Ref. 24-41-00-862-002-A-02). De-energize the Aircraft Electrical Circuits Supplied from the Engine

1(2)

(Ref. 25-55-12-000-001-A). Removal of the Aft Cargo-Compartment Partition at FR65

(Ref. 25-55-12-400-001-A). Installation of the Aft Cargo-Compartment Partition at FR65

(Ref. 52-30-00-860-001-A). Open the FWD or Aft Cargo-Compartment Door with the Yellow Elec-

tric Pump

(Ref. 52-30-00-860-002-A). Close the FWD or Aft Cargo-Compartment Door with the Yellow Elec-

tric Pump

Return Ground Connections - Earthing Points

FOR 11HL (PRESS CONT 1)

(Ref. 20-28-00-912-802-A). Electrical Bonding - General Maintenance Procedure

Return Ground Connections - Earthing Points

FOR 12HL (PRESS CONT 2)

(Ref. 20-28-00-912-802-A). Electrical Bonding - General Maintenance Procedure

Return Ground Connections - Earthing Points

Print Date: August 23, 2020 Page 26 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

FR24A

FR66

FR65

A B

Z120

FR1 90VU

162DW

Z160

FR59

A

92VU 91VU

94VU 93VU

96VU 95VU

12HL 11HL

PRESSURER CONTROLERS

N_MM_213100_5_ABNA_01_00

Figure 21-31-00-991-00400-00-B / SHEET 1/2 - Return Ground Connections - Earthing Points

** ON A/C ALL

Print Date: August 23, 2020 Page 27 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

B

10HL-B

10HL-2

10HL-A

10HL-E

10HL-6

10HL-D

10HL-1

6582VN/DC2

FR66

FR65

6587VN/DC1

N_MM_213100_5_ABNA_02_00

Figure 21-31-00-991-00400-00-B / SHEET 2/2 - Return Ground Connections - Earthing Points

** ON A/C ALL

Print Date: August 23, 2020 Page 28 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

3. Job Set-up

Subtask 21-31-00-480-055-A

A. Measurement Equipment

(1) MILLIOHMMETER 0.01 OHM - LOW VOLTAGE with the related leads and probes.

Subtask 21-31-00-861-063-A

B. Energize the aircraft electrical circuits

(Ref. AMM TASK 24-41-00-861-002)

Subtask 21-31-00-010-057-A

C. Get Access

(1) Put the ACCESS PLATFORM 1M(3 FT) in position at the access door 811.

(2) Open the access door 811.

(3) Open the AFT cargo-compartment door 826 (Ref. AMM TASK 52-30-00-860-001) .

(4) Put the ACCESS PLATFORM 2M (6 FT) in position at the AFT cargo-compartment door 826.

(5) Remove the access panel 162DW (Ref. AMM TASK 25-55-12-000-001) .

Subtask 21-31-00-865-063-A

D. Open, safety and tag this(these) circuit breaker(s):

PANEL DESIGNATION FIN LOCATION

49VU AIR COND/CAB/PRESS/CTL1 1HL D09

122VU AIR COND/LAV/GALLEY VENT CTL/EX- 6HU U19

TRACT FAN/SPLY

122VU AIR COND/CAB PRESS/CTL/MAN 3HL Y23

122VU AIR COND/CAB PRESS/CTL/2 2HL Y22

** ON A/C 201-201, 203-203, 207-211, 222-222, 227-228, 231-232, 234-235, 237-237, 240-240, 242-250

122VU AIR COND/AFT CARGO VENT/FAN 30HN S22

** ON A/C ALL

Subtask 21-31-00-020-052-A

E. Removal and Disconnection of the Applicable Components

(1) Remove the cabin pressure controllers 1 (11HL) and 2 (12HL) (Ref. AMM TASK 21-31-34-000-001) .

NOTE: It is not necessary to remove the cabin pressure controllers from the aircraft.

(2) Disconnect the electrical connectors 10HL-A and 10HL-B from the electronic modules 10HL-1 and

10HL-2 (Ref. AMM TASK 21-31-51-000-002) .

(3) Disconnect the electrical connectors 10HL-D and 10HL-E from the feedback assembly 10HL-6

(Ref. AMM TASK 21-31-51-000-005) .

4. Procedure

Subtask 21-31-00-760-050-A

A. Measure the Resistance

NOTE: Maximum Allowed Resistance Value The maximum resistance value at all measurement points

should not be more than 300 milliohms.

Print Date: August 23, 2020 Page 29 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

(1) Connect the measurement equipment (refer to the manufacturers instructions) to:

(a) FOR 11HL (PRESS CONT 1)

· the pin 2 on the electrical connector 11HL-AC and a good conductive surface on the aircraft

structure.

· measure the resistance value and make sure that it is not more than the maximum allowed

value.

· you must do the bonding of the bonding point 6587VN/DC1 (Ref. AMM TASK 20-28-00-912-

802) if the resistance value is more than the allowed value.

NOTE: For this application, when you do the bonding you must:

- apply the Polysulfide Sealant-General Purpose Brushable - (Material No. 06AAA1) to

the necessary areas and allow it to fully dry then,

- apply the Varnish-- Electrical Bonding Structure (Material No. 04TMB2) to the areas of

the dried sealant.

(Ref. Fig. Return Ground Connections - Earthing Points)

(b) FOR 12HL (PRESS CONT 2)

· the pin 2 on the electrical connector 12HL-AC and a good conductive surface on the aircraft

structure.

· measure the resistance value and make sure that it is not more than the maximum allowed

value.

· you must do the bonding of the bonding point 6582VN/DC2 (Ref. AMM TASK 20-28-00-912-

802) if the resistance value is more than the allowed value.

NOTE: For this application, when you do the bonding you must:

- apply the Polysulfide Sealant-General Purpose Brushable - (Material No. 06AAA1) to

the necessary areas and allow it to fully dry then,

- apply the Varnish-- Electrical Bonding Structure (Material No. 04TMB2) to the areas of

the dried sealant.

(Ref. Fig. Return Ground Connections - Earthing Points)

(c) For the electronics module (10HL-1)

1 the pin J on the electrical connector 10HL-A and a good conductive surface on the aircraft

structure.

· measure the resistance value and make sure that it is not more than the maximum

allowed value.

· you must do the bonding of the bonding point 6587VN/DC1 (Ref. AMM TASK 20-28-00-

912-802) if the resistance value is more than the allowed value.

NOTE: For this application, when you do the bonding you must:

- apply the Polysulfide Sealant-General Purpose Brushable - (Material No. 06AAA1)

to the necessary areas and allow it to fully dry then,

- apply the Varnish-- Electrical Bonding Structure (Material No. 04TMB2) to the

areas of the dried sealant.

2 the pin J on the electrical connector 10HL-D and a good conductive surface on the aircraft

structure.

· measure the resistance value and make sure that it is not more than the maximum

allowed value.

· you must do the bonding of the bonding point 6587VN/DC1 (Ref. AMM TASK 20-28-00-

912-802) if the resistance value is more than the allowed value.

NOTE: For this application, when you do the bonding you must:

Print Date: August 23, 2020 Page 30 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

- apply the Polysulfide Sealant-General Purpose Brushable - (Material No. 06AAA1)

to the necessary areas and allow it to fully dry then,

- apply the Varnish-- Electrical Bonding Structure (Material No. 04TMB2) to the

areas of the dried sealant.

(Ref. Fig. Return Ground Connections - Earthing Points)

(d) For the electronics module (10HL-2)

1 the pin J on the electrical connector 10HL-B and a good conductive surface on the aircraft

structure.

· measure the resistance value and make sure that it is not more than the maximum

allowed value.

· you must do the bonding of the bonding point 6582VN/DC2 (Ref. AMM TASK 20-28-00-

912-802) if the resistance value is more than the allowed value.

2 the pin H on the electrical connector 10HL-E and a good conductive surface on the aircraft

structure.

· measure the resistance value and make sure that it is not more than the maximum

allowed value.

· you must do the bonding of the bonding point 6582VN/DC2 (Ref. AMM TASK 20-28-00-

912-802) if the resistance value is more than the allowed value.

NOTE: For this application, when you do the bonding you must:

- apply the Polysulfide Sealant-General Purpose Brushable - (Material No. 06AAA1)

to the necessary areas and allow it to fully dry then,

- apply the Varnish-- Electrical Bonding Structure (Material No. 04TMB2) to the

areas of the dried sealant.

(Ref. Fig. Return Ground Connections - Earthing Points)

5. Close-up

Subtask 21-31-00-860-067-A

A. Aircraft Maintenance Configuration

(1) Make sure that:

(a) the ACCESS PLATFORM 1M(3 FT) is in position at the access door 811.

(b) the access door 811 is open.

(c) the AFT cargo-compartment door 826 (Ref. AMM TASK 52-30-00-860-001) is open.

(d) the ACCESS PLATFORM 2M (6 FT) is in position at the AFT cargo-compartment door 826.

(e) the access panel 162DW (Ref. AMM TASK 25-55-12-000-001) is removed.

Subtask 21-31-00-865-064-A

B. Make sure that this(these) circuit breaker(s) is(are) open, safetied and tagged:

PANEL DESIGNATION FIN LOCATION

49VU AIR COND/CAB/PRESS/CTL1 1HL D09

122VU AIR COND/LAV/GALLEY VENT CTL/EX- 6HU U19

TRACT FAN/SPLY

122VU AIR COND/CAB PRESS/CTL/MAN 3HL Y23

122VU AIR COND/CAB PRESS/CTL/2 2HL Y22

** ON A/C 201-201, 203-203, 207-211, 222-222, 227-228, 231-232, 234-235, 237-237, 240-240, 242-250

122VU AIR COND/AFT CARGO VENT/FAN 30HN S22

Print Date: August 23, 2020 Page 31 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Aug 01, 2020

21-31-00 PB 501 CONF 00 - PRESSURE CONTROL

AND MONITORING - ADJUSTMENT/TEST

** ON A/C ALL

Subtask 21-31-00-420-052-A

C. Installation and Connection of the Applicable Components

NOTE: It is not necessary to do the operational test of the pressure control and monitoring system

(Ref. AMM TASK 21-31-00-710-002) at this time.

(1) Install the cabin pressure controllers 1 (11HL) and 2 (12HL) (Ref. AMM TASK 21-31-34-400-001) .

(2) Connect the electrical connectors 10HL-A and 10HL-B to the electronic modules 10HL-1 and 10HL-2

(Ref. AMM TASK 21-31-51-400-002) .

(3) Connect the electrical connectors 10HL-D and 10HL-E to the feedback assembly 10HL-6

(Ref. AMM TASK 21-31-51-400-005) .

Subtask 21-31-00-865-066-A

D. Remove the safety clip(s) and the tag(s) and close this(these) circuit breaker(s):

PANEL DESIGNATION FIN LOCATION

49VU AIR COND/CAB/PRESS/CTL1 1HL D09

122VU AIR COND/LAV/GALLEY VENT CTL/EX- 6HU U19

TRACT FAN/SPLY

122VU AIR COND/CAB PRESS/CTL/MAN 3HL Y23

122VU AIR COND/CAB PRESS/CTL/2 2HL Y22

** ON A/C 201-201, 203-203, 207-211, 222-222, 227-228, 231-232, 234-235, 237-237, 240-240, 242-250

122VU AIR COND/AFT CARGO VENT/FAN 30HN S22

** ON A/C ALL

Subtask 21-31-00-410-055-A

E. Close Access

(1) Make sure that the work area is clean and clear of tools and other items.

(2) Close the access door 811.

(3) Install the access panel 162DW (Ref. AMM TASK 25-55-12-400-001) .

(4) Remove the access platform(s).

(5) Close the AFT cargo-compartment door 826 (Ref. AMM TASK 52-30-00-860-002) .

Subtask 21-31-00-862-060-A

F. De-energize the aircraft electrical circuits

(Ref. AMM TASK 24-41-00-862-002) .

Figure 21-31-00-991-00100-00-A / SHEET 1/4 - Safety Valve - Differential Pressure Test

Figure 21-31-00-991-00100-00-A / SHEET 2/4 - Safety Valve - Differential Pressure Test

Figure 21-31-00-991-00100-00-A / SHEET 3/4 - Safety Valve - Differential Pressure Test

Figure 21-31-00-991-00100-00-A / SHEET 4/4 - Safety Valve - Differential Pressure Test

Figure 21-31-00-991-00400-00-B / SHEET 1/2 - Return Ground Connections - Earthing Points

Figure 21-31-00-991-00400-00-B / SHEET 2/2 - Return Ground Connections - Earthing Points

End of document

Print Date: August 23, 2020 Page 32 of 32

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

You might also like

- On A/C All: Zone/Access Zone DescriptionDocument4 pagesOn A/C All: Zone/Access Zone DescriptionbillyNo ratings yet

- 01Document7 pages01Jai DeepNo ratings yet

- EfcsDocument4 pagesEfcsJai DeepNo ratings yet

- Emergency Generator TestDocument4 pagesEmergency Generator TestSarbari SenguptaNo ratings yet

- Amm Task Perf Each FlightDocument5 pagesAmm Task Perf Each Flightbilly100% (1)

- AMM Task May 20Document1,657 pagesAMM Task May 20sreejithNo ratings yet

- Eiu BiteDocument4 pagesEiu BiteMahendra VermaNo ratings yet

- AMM - 01-Aug-2023 - 22-63-00-710-001-A - Operational Test of The Yaw Damper FunctionDocument4 pagesAMM - 01-Aug-2023 - 22-63-00-710-001-A - Operational Test of The Yaw Damper Functionayan acharjeeNo ratings yet

- AMM 27-54-00-710-001-A - Operational Test of The Flap SystemDocument4 pagesAMM 27-54-00-710-001-A - Operational Test of The Flap SystemLuiz Fernando MibachNo ratings yet

- Weather Radar TestDocument7 pagesWeather Radar TestnaziaNo ratings yet

- Simulation of Flight (With Aircraft On Ground)Document3 pagesSimulation of Flight (With Aircraft On Ground)AsaadNo ratings yet

- Restore Air Conditioning and Communication SystemsDocument36 pagesRestore Air Conditioning and Communication SystemsLeonard Komon100% (1)

- Apu Fire TestDocument2 pagesApu Fire TestnaziaNo ratings yet

- Description and Operation: Component Maintenance ManualDocument8 pagesDescription and Operation: Component Maintenance ManualLou Parker100% (1)

- Acceleation CheckDocument5 pagesAcceleation Checkomarzaboub1997No ratings yet

- On A/C All: Reference Qty DesignationDocument6 pagesOn A/C All: Reference Qty DesignationMak OrNo ratings yet

- 27-94-00-040-002-A - Deactivation of The Spoiler Elevator Computer (SEC)Document7 pages27-94-00-040-002-A - Deactivation of The Spoiler Elevator Computer (SEC)Rendi 911No ratings yet

- PlenumDocument9 pagesPlenumAnuna Amanullah100% (1)

- ON A/C 051-100: Reference Qty DesignationDocument4 pagesON A/C 051-100: Reference Qty DesignationEder LucianoNo ratings yet

- Task 46!21!00-710-002-A VHF 3 Link Test of The AtsuDocument8 pagesTask 46!21!00-710-002-A VHF 3 Link Test of The AtsuSatishReddyNo ratings yet

- AMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Document3 pagesAMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Andre SanarNo ratings yet

- Mandatory Mandatory Mandatory: A318/A319/A320/A321Document60 pagesMandatory Mandatory Mandatory: A318/A319/A320/A321victorNo ratings yet

- rp-c4108 DMC 3Document3 pagesrp-c4108 DMC 3billyNo ratings yet

- Bite Test PDFDocument3 pagesBite Test PDFbillyNo ratings yet

- Task 46!21!00-740-001-A Bite Test of The AtimsDocument4 pagesTask 46!21!00-740-001-A Bite Test of The AtimsSatishReddy100% (1)

- UNITED A319-A320 Fault Verification GuideDocument113 pagesUNITED A319-A320 Fault Verification GuideBELISARIO100% (1)

- CFMIAutomatic StartDocument5 pagesCFMIAutomatic StartJaskaran Singh BhatiaNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument26 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- Fault Isolation ManualDocument7 pagesFault Isolation Manualmuchammad faruroziNo ratings yet

- Sharp 21hm 10f Chassis Ga 1eDocument33 pagesSharp 21hm 10f Chassis Ga 1eIBSDIALLONo ratings yet

- Yellow Electric Pump: Job Card Package Title: HIM - A318/A319/A320/ A321 Tail Number - MSN - FSN ALL ContinousDocument4 pagesYellow Electric Pump: Job Card Package Title: HIM - A318/A319/A320/ A321 Tail Number - MSN - FSN ALL ContinousSuman BajracharyaNo ratings yet

- Ram Open DeactivateDocument5 pagesRam Open DeactivateRendi 911No ratings yet

- Untitled 15Document24 pagesUntitled 15HENIGUEDRINo ratings yet

- OPERATIONAL TEST OF THE CABIN PRESSURE−CONTROL PANELDocument4 pagesOPERATIONAL TEST OF THE CABIN PRESSURE−CONTROL PANELBambang Agus RiadiNo ratings yet

- Airbus SB A320-23-1707 R08 Dated 18.feb.2021Document41 pagesAirbus SB A320-23-1707 R08 Dated 18.feb.2021Pradeep K sNo ratings yet

- Fault Isolation ManualDocument10 pagesFault Isolation Manualmuchammad faruroziNo ratings yet

- 73-21-00-740-803-A - Correct Faults of The Engine Scheduled Maintenance Report (SMR)Document3 pages73-21-00-740-803-A - Correct Faults of The Engine Scheduled Maintenance Report (SMR)victorNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument44 pagesA318/A319/A320/A321: Service BulletinKumar VishalNo ratings yet

- On A/C MSN All: Customization Aircraft Types Doctypes Revision Date Title Tail Number - MSNDocument1 pageOn A/C MSN All: Customization Aircraft Types Doctypes Revision Date Title Tail Number - MSNHastiyanFauziNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument53 pagesA318/A319/A320/A321: Service BulletinGuy Ulrich DouoguiNo ratings yet

- Amm LgciuDocument6 pagesAmm LgciuVolNo ratings yet

- AMM Task Aug 19 PDFDocument1,646 pagesAMM Task Aug 19 PDFSajith S Muhammed100% (2)

- AfsbitetestDocument6 pagesAfsbitetestSuphangchat U. AMNo ratings yet

- Sat Com GSR 56H: System Description: 1Document4 pagesSat Com GSR 56H: System Description: 1Felipe PedroneNo ratings yet

- Valve - Pressure Regulating - Removal & InstallationDocument8 pagesValve - Pressure Regulating - Removal & Installationjoby619No ratings yet

- Quick Turn Fault Assistance for Airbus A318/320Document134 pagesQuick Turn Fault Assistance for Airbus A318/320Carlos Andrés Escamilla González100% (1)

- A330 ECAM Warning Reset GuideDocument45 pagesA330 ECAM Warning Reset Guideelhamdi71100% (8)

- On A/C All: Reference Qty DesignationDocument21 pagesOn A/C All: Reference Qty DesignationRalph FernandesNo ratings yet

- GVI Brake Units - 32-40-00-210-801-A PDFDocument4 pagesGVI Brake Units - 32-40-00-210-801-A PDFpannNo ratings yet

- Amm InstallationDocument8 pagesAmm Installationsreenathsreekumar2009No ratings yet

- Ecam WarningDocument28 pagesEcam WarningBluto A Cuong100% (1)

- TASK 71-00-00-000-042-A Removal of The Power PlantDocument24 pagesTASK 71-00-00-000-042-A Removal of The Power PlantVijai PrakashNo ratings yet

- A330/340 Fuel System Controls and Indications GuideDocument5 pagesA330/340 Fuel System Controls and Indications GuideRicardo RubioNo ratings yet

- Computer Reset A320Document16 pagesComputer Reset A320Juliano JulianoNo ratings yet

- @A318/A319/A320/A321: Chapter 35 - OxygenDocument50 pages@A318/A319/A320/A321: Chapter 35 - OxygenhengwahchungNo ratings yet

- On A/C All: Mmel or CDL Ref Access Test Specific Tools MHR E/T NB MenDocument11 pagesOn A/C All: Mmel or CDL Ref Access Test Specific Tools MHR E/T NB MenCesar AceroNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument35 pagesA318/A319/A320/A321: Service BulletinGiraldo CardenasNo ratings yet

- A320 ResetsDocument253 pagesA320 ResetsEmin GulhanNo ratings yet

- C0218 Guide VaneDocument5 pagesC0218 Guide VaneSuperhypo100% (6)

- Flight Test Instrumentation: Proceedings of the Third International Symposium 1964From EverandFlight Test Instrumentation: Proceedings of the Third International Symposium 1964M. A. PerryNo ratings yet

- PW DrainlimitDocument13 pagesPW DrainlimitRanjit ShawNo ratings yet

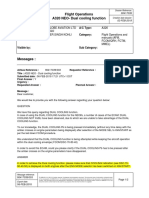

- Flight Operations A320 NEO-Dual Cooling Function: Customer ServicesDocument2 pagesFlight Operations A320 NEO-Dual Cooling Function: Customer ServicesRanjit Shaw100% (1)

- Engine - Alternate Climb/Model Conversion - Replacement or Reprogramming of The Data Storage Unit (Dsu)Document14 pagesEngine - Alternate Climb/Model Conversion - Replacement or Reprogramming of The Data Storage Unit (Dsu)Ranjit ShawNo ratings yet