Professional Documents

Culture Documents

Types of Welded Splices: Code?

Uploaded by

PaulWalterTorregosa0 ratings0% found this document useful (0 votes)

11 views2 pagesOriginal Title

permissible stresses

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views2 pagesTypes of Welded Splices: Code?

Uploaded by

PaulWalterTorregosaCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

permissible stresses, both for the strength design

method and the working stress method; splice details;

workmanship; filler metal (electrodes) re q u i re m e n t s ;

welding technique; welder qualification; and inspection.

These are explained in the following series of questions

and answers.

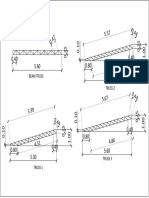

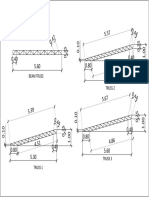

Types of welded splices

Q: What types of welded splices are included in the AWS

code?

A: Direct and indirect butt splices, and lap-welded

splices.

Q: Is special end preparation of the bars required for direct

butt splices?

A: Yes, the particular end details—V- grooves or bevels—

depend upon whether the bars will be placed in a horizontal

or vertical position.

Q: What is an indirect butt splice?

A: A splice where both bars are welded to a common

splice member such as a plate, angle or other shape.

The bars are nearly aligned; bar ends are separated no

more than 3⁄4 inch; and the cross section of the bars is not

welded.

Q: What types of lap-welded splices are included in the

AWS code?

A: There are two types: direct and indirect. A direct type

is one in which the bars are in contact and welded together;

single or double lap joints can be used; they are

suitable only for small bars, preferably #5 or smaller.

Double lap joints would be preferred if eccentricity of

the splice is a consideration. In an indirect type, the bars

are welded to a common splice plate; there is a space between

the bars.

Q: Where are fillet welds used?

A: An example would be connections of rebars to structural

steel members, provided sufficient stru c t u ra l

strength can be achieved.

Q: What welding processes does the AWS code cover?

A: Shielded metal arc, flux cored arc, pressure gas and

thermite welding processes.

Q: What is thermite welding?

A: It is a process in which the ends of the bars are fusion

welded. Refractory molds are assembled on the bars and

sealed in place. Heat- generating powders are filled into a

separate cavity in the molds. The powders are ignited

and burn with enough heat to form superheated molten

steel. The steel flows through the gap between the bars

and some flows into a second cavity beyond the bars,

preheating them. Subsequent flow completes the

process.

Q: When or why would thermite welding be used?

A: Thermite welding has been used with success in making

butt-welded joints in the large #14 and #18 bars. This

process has been successful in joining hard - t o - we l d

steels, because it welds the entire cross section at the

same time and automatically provides preheat and slow

cooling.

Q: Is thermite welding popular?

A: Not so much in recent years for splicing rebars. It

seems to be extensively used in other applications such

as continuously welded railroad rails; the suppliers of

the proprietary molds and other materials may be concentrating

their attention on the other applications.

Q: The AWS code discusses filler metal (electrodes). What

kind of electrodes are required for arc welding?

A: The electrodes should conform to AWS Specifications

A5.1 or A5.5. They should be of a classification and size

appropriate to the welding conditions and to the tensile

strength and analysis of the bars to be welded. It is important

that the coatings of low - h yd rogen-type electrodes

such as Classes E70XX and E80XX be thoroughly

dry when used. For example, E80XX electrodes taken

from hermetically sealed packages must be used within

4 hours.

Weldability and carbon equivalent

Q: When the subject of welding is discussed, the term

weldability is often mentioned. What is meant by weld -

ability?

A: A metallurgist defines weldability in terms of the

chemical composition of the steel; his measure is carbon

equivalent content. A structural engineer probably

thinks of weldability in terms of the strength achieved at

a splice, while a welder or contractor considers it in

terms of cost, welding method required, and amount of

preheat. The AWS code defines weldability as “the capacity

of a metal to be welded under the fabrication conditions

imposed into a specific suitably designed structure

and to perform satisfactorily in the intended

service.”

Q: What is carbon equivalent?

A: This is a quantitative measure of weldability. The carbon

equivalent (C.E.) is based on the chemical composition

of steel; it accounts for those chemical elements affecting

weldability, and it is a numerical value expressed

as a percent. The AWS code and the ASTM A706 rebar

specification have the same formula for C.E.

%Mn %Cu %Ni %Cr %Mo %V

C.E. = %C + ––––– + ––––– + ––––– + ––––– - ––––– - –––––

6 40 20 10 50 10

Note that fractions of the percentages of manganese

( Mn), copper (Cu), nickel (Ni) and chromium (Cr) are

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Welding TechnologyDocument218 pagesWelding Technologywbl_200789% (9)

- ElectrodesDocument10 pagesElectrodesGanesh BaskerNo ratings yet

- Oracle IFRS Solution ERP FinalDocument44 pagesOracle IFRS Solution ERP FinalJai SoniNo ratings yet

- Questions & Answers: NDT Viernes, 15 de Septiembre de 2017Document7 pagesQuestions & Answers: NDT Viernes, 15 de Septiembre de 2017Percy Junior Berrios MuñozNo ratings yet

- Welding Technology: An Introduction to Procedures and ProcessesDocument35 pagesWelding Technology: An Introduction to Procedures and ProcessesAlejandro Cano100% (1)

- Gas Welding PDFDocument42 pagesGas Welding PDFManickamEllampoorananNo ratings yet

- Gmaw PDFDocument169 pagesGmaw PDFsalman GtrNo ratings yet

- Intoduction To WeldingDocument334 pagesIntoduction To WeldingAsad Bin Ala QatariNo ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Welding BasicsDocument37 pagesWelding BasicsSnehal DeshmukhNo ratings yet

- Flux Cored Arc Welding PDFDocument147 pagesFlux Cored Arc Welding PDFCedric MercadoNo ratings yet

- Principles and Practices of Stud Welding: State-Of-The-Art PaperDocument0 pagesPrinciples and Practices of Stud Welding: State-Of-The-Art PaperTenkre TenNo ratings yet

- Leading Malaysian Telco DiGi's History and ServicesDocument2 pagesLeading Malaysian Telco DiGi's History and ServicesJy Tan77% (13)

- Flux Cored Arc WeldingDocument147 pagesFlux Cored Arc WeldingArnel MoralesNo ratings yet

- Crane Rail Welding 978Document3 pagesCrane Rail Welding 978Jurie_sk3608No ratings yet

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- WeldingDocument71 pagesWeldingg4gohar100% (2)

- Resistance WeldingDocument22 pagesResistance WeldingLOKENDRA91100% (2)

- Welding EngineeringDocument338 pagesWelding EngineeringMuhammed Sulfeek100% (3)

- Controls in Revenue - Expenditure CycleDocument28 pagesControls in Revenue - Expenditure CycleKhen CaballesNo ratings yet

- Welding SlidesDocument334 pagesWelding SlidesAsad Bin Ala Qatari100% (13)

- GRADE 12 SMAW MODULE 4A 1st QuarterDocument20 pagesGRADE 12 SMAW MODULE 4A 1st QuarterClare GarcesNo ratings yet

- 14250A ch3 PDFDocument82 pages14250A ch3 PDFKamarul NizamNo ratings yet

- Welding Steel and TankDocument39 pagesWelding Steel and Tankprasanth bhadranNo ratings yet

- WTDocument299 pagesWTrsarunprasathNo ratings yet

- Case 08-29 Cravat Sales CompanyDocument5 pagesCase 08-29 Cravat Sales Companysubash1111@gmail.comNo ratings yet

- Standard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsFrom EverandStandard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsNo ratings yet

- Metal Core WireDocument30 pagesMetal Core WireHuỳnh TrươngNo ratings yet

- The Efficacy of Talent Management in International Business The Case of European MultinationalsDocument16 pagesThe Efficacy of Talent Management in International Business The Case of European MultinationalstheonlypaulNo ratings yet

- Die Casting Metallurgy: Butterworths Monographs in MaterialsFrom EverandDie Casting Metallurgy: Butterworths Monographs in MaterialsRating: 3.5 out of 5 stars3.5/5 (2)

- Design of Welded ConnectionsDocument51 pagesDesign of Welded Connectionscutefrenzy100% (1)

- Agile Use CasesDocument80 pagesAgile Use CasesJessica PetersonNo ratings yet

- Welding Technology Course Covers Procedures and VariablesDocument35 pagesWelding Technology Course Covers Procedures and VariablesKrishnamoorthi Venkatesan100% (1)

- WELDING QUESTIONS AND ANSWERSDocument6 pagesWELDING QUESTIONS AND ANSWERSengrzia76No ratings yet

- Welding DefectsDocument36 pagesWelding DefectsSunilNo ratings yet

- Discussing customer survey results to improve serviceDocument3 pagesDiscussing customer survey results to improve serviceSyeda AmeenaNo ratings yet

- FPL TVL q2 Mod1 Liham PangnegosyoDocument24 pagesFPL TVL q2 Mod1 Liham PangnegosyoJeff Marges100% (4)

- PHD Thesis Topics in WeldingDocument5 pagesPHD Thesis Topics in Weldingjennawelchhartford100% (2)

- Welding QuestionsDocument10 pagesWelding Questionsbalakumar rajaram100% (1)

- Weld-FAQ-A (Page A) : and The Correct AnswersDocument22 pagesWeld-FAQ-A (Page A) : and The Correct AnswerssanthakumarNo ratings yet

- 14250A ch9 PDFDocument147 pages14250A ch9 PDFAyush VermaNo ratings yet

- Arc WeldingDocument42 pagesArc WeldingrkpnakNo ratings yet

- WELD-Arc Welding Electrode Classification System - Maine Welding CompanyDocument5 pagesWELD-Arc Welding Electrode Classification System - Maine Welding CompanypeterNo ratings yet

- Astm ManualDocument2 pagesAstm ManualAashifCairoNo ratings yet

- The First L555 (X80) Pipeline in JapanDocument11 pagesThe First L555 (X80) Pipeline in JapanMarcelo Varejão CasarinNo ratings yet

- Effect of Welding Current on A36 Steel Joint PropertiesDocument10 pagesEffect of Welding Current on A36 Steel Joint PropertiesBasim Al-bhadleNo ratings yet

- Welding Technology Course Covers ProceduresDocument35 pagesWelding Technology Course Covers ProceduresKrishna VachaNo ratings yet

- 14250A ch1 PDFDocument25 pages14250A ch1 PDFnagarajNo ratings yet

- Essential Vs NonEssential VariablesDocument3 pagesEssential Vs NonEssential VariablesMohd AizieNo ratings yet

- WeldingDocument20 pagesWeldingnvemanNo ratings yet

- AnggeDocument28 pagesAnggeGizelle DueñasNo ratings yet

- Stud WeldingDocument5 pagesStud Weldingvinamap27No ratings yet

- Mig Welding Literature ReviewDocument8 pagesMig Welding Literature Reviewklbndecnd100% (1)

- Shipbuilding Course Covers Welding ProcessesDocument56 pagesShipbuilding Course Covers Welding ProcessesMd. Omar FarukNo ratings yet

- Resistance Welding ThesisDocument5 pagesResistance Welding Thesisdwt3zbkq100% (2)

- Q & A During L&T VisitDocument4 pagesQ & A During L&T VisitHarshitkumarNo ratings yet

- Aws Brazing Handbook PDFDocument22 pagesAws Brazing Handbook PDFHARISH PNo ratings yet

- Assignment CE561Document2 pagesAssignment CE561Karen Mae TingNo ratings yet

- FMP 221 Lecture 10 and 11Document44 pagesFMP 221 Lecture 10 and 11SarojKumarSinghNo ratings yet

- AAR TC 128 GR B Weld Failure Analysis - EdittedDocument3 pagesAAR TC 128 GR B Weld Failure Analysis - Edittedamir ghabraeiNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Welded Splices of Reinforcing Bars: Both Contractor and Engineer Must Be Aware of Special RequirementsDocument2 pagesWelded Splices of Reinforcing Bars: Both Contractor and Engineer Must Be Aware of Special RequirementsPaulWalterTorregosaNo ratings yet

- OQ$ADocument3 pagesOQ$APaulWalterTorregosaNo ratings yet

- S-curve project progress trackingDocument1 pageS-curve project progress trackingPaulWalterTorregosaNo ratings yet

- Truss PDFDocument1 pageTruss PDFPaulWalterTorregosaNo ratings yet

- Truss PDFDocument1 pageTruss PDFPaulWalterTorregosaNo ratings yet

- Volume Per F Total Volume (Cu.m) (F X Quantity) 13.60 68.00 7.39 51.76 6.30 31.50 4.38 17.50 0.22 0.00 0.18 0.00 0.17 0.00 0.63 0.00Document1 pageVolume Per F Total Volume (Cu.m) (F X Quantity) 13.60 68.00 7.39 51.76 6.30 31.50 4.38 17.50 0.22 0.00 0.18 0.00 0.17 0.00 0.63 0.00PaulWalterTorregosaNo ratings yet

- Weather Chart PDFDocument1 pageWeather Chart PDFPaulWalterTorregosaNo ratings yet

- THE Magsaysay. OnDocument1 pageTHE Magsaysay. OnPaulWalterTorregosaNo ratings yet

- Er Or: Gnified F NDocument1 pageEr Or: Gnified F NPaulWalterTorregosaNo ratings yet

- Basic Principles (PLUMBING)Document2 pagesBasic Principles (PLUMBING)Louis Montenegro50% (6)

- Er Or: Gnified F NDocument1 pageEr Or: Gnified F NPaulWalterTorregosaNo ratings yet

- MixtureDocument1 pageMixturePaulWalterTorregosaNo ratings yet

- Cylinder Sample Curing ProcessDocument1 pageCylinder Sample Curing ProcessPaulWalterTorregosaNo ratings yet

- Optimizing wind farm performanceDocument1 pageOptimizing wind farm performancePaulWalterTorregosaNo ratings yet

- Estimate SampleDocument2 pagesEstimate SamplePaulWalterTorregosaNo ratings yet

- THE Magsaysay. OnDocument1 pageTHE Magsaysay. OnPaulWalterTorregosaNo ratings yet

- MixtureDocument1 pageMixturePaulWalterTorregosaNo ratings yet

- Basic Principles (PLUMBING)Document2 pagesBasic Principles (PLUMBING)Louis Montenegro50% (6)

- Fencing Sample PDFDocument1 pageFencing Sample PDFPaulWalterTorregosaNo ratings yet

- History of Plumbing in the PhilippinesDocument1 pageHistory of Plumbing in the PhilippinesPaulWalterTorregosaNo ratings yet

- Fencing PDFDocument1 pageFencing PDFPaulWalterTorregosaNo ratings yet

- Fencing PDFDocument1 pageFencing PDFPaulWalterTorregosaNo ratings yet

- Cistern 1Document1 pageCistern 1PaulWalterTorregosaNo ratings yet

- Iso-14001 Certificate Environment Management SystemDocument2 pagesIso-14001 Certificate Environment Management SystemwavchanakyaNo ratings yet

- A. Short Answer Questions: Answer:: Chapter-1 Entrepreneurial Skills Basics of EntrepreneurshipDocument2 pagesA. Short Answer Questions: Answer:: Chapter-1 Entrepreneurial Skills Basics of EntrepreneurshipHawK GaMiNG100% (1)

- Operations Management: Dr. Joann M. AmargoDocument24 pagesOperations Management: Dr. Joann M. AmargoGoal Digger Squad VlogNo ratings yet

- Ananas Marketing ChannelsDocument48 pagesAnanas Marketing ChannelsPham Tri TaiNo ratings yet

- Introduction To Cadbury's: - Cadbury Schweppes Was Founded in The Year 1831 byDocument17 pagesIntroduction To Cadbury's: - Cadbury Schweppes Was Founded in The Year 1831 bySahil AnandNo ratings yet

- P - Issn: 2503-4413 E - Issn: 2654-5837, Hal 35 - 42: Jurnal Ekonomi Dan Bisnis, Vol. 11 No. 1 Juli 2022Document8 pagesP - Issn: 2503-4413 E - Issn: 2654-5837, Hal 35 - 42: Jurnal Ekonomi Dan Bisnis, Vol. 11 No. 1 Juli 2022Nova KartikaNo ratings yet

- Stock TradingDocument31 pagesStock TradingSunil ChoudharyNo ratings yet

- Business PlanDocument12 pagesBusiness PlanNatalya BadionNo ratings yet

- Joule L0Document12 pagesJoule L0matheusdetoniabapNo ratings yet

- Public Distribution SystemDocument10 pagesPublic Distribution SystemNitika DhatwaliaNo ratings yet

- Unit 6 SeDocument54 pagesUnit 6 Se7killers4uNo ratings yet

- Republic Act NoDocument2 pagesRepublic Act NoLEAHNAH NAHNo ratings yet

- Reliable internet for all with green fiber opticsDocument2 pagesReliable internet for all with green fiber opticsNicaNo ratings yet

- Assignment - Phung Van HungDocument28 pagesAssignment - Phung Van HungNguyễn Phương UyênNo ratings yet

- Tcs Employment Application FormDocument6 pagesTcs Employment Application FormRaveenaNo ratings yet

- Retrieve PDFDocument1 pageRetrieve PDFSilat Millenium24No ratings yet

- Unit4 - 488 - Assignment 1 Frontsheet (Group)Document40 pagesUnit4 - 488 - Assignment 1 Frontsheet (Group)Minh Thi TrầnNo ratings yet

- Filsyn Corporation Parent Company FS 12.31.2021Document50 pagesFilsyn Corporation Parent Company FS 12.31.2021Elsa MendozaNo ratings yet

- Satish K Srivastava Resume LatestDocument2 pagesSatish K Srivastava Resume LatestPrashant KumarNo ratings yet

- Assessed Task Two Part A: Analysis and Editing of A Written Professional TextDocument8 pagesAssessed Task Two Part A: Analysis and Editing of A Written Professional TextShehbaz KhanNo ratings yet

- Automotive Test Probe ConstructionDocument4 pagesAutomotive Test Probe ConstructionLy Fotoestudio DigitalcaNo ratings yet

- Avoiding Fraudulent TransfersDocument8 pagesAvoiding Fraudulent TransfersNamamm fnfmfdnNo ratings yet