Professional Documents

Culture Documents

Competency - Based Learning Materials: Metals and Engineering

Competency - Based Learning Materials: Metals and Engineering

Uploaded by

International Technology Center IncOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Competency - Based Learning Materials: Metals and Engineering

Competency - Based Learning Materials: Metals and Engineering

Uploaded by

International Technology Center IncCopyright:

Available Formats

COMPETENCY - BASED LEARNING MATERIALS

Sector:

METALS AND ENGINEERING

Qualification:

Shielded Metal Arc Welding (SMAW) NCI

Unit of Competency:

Apply Safety Practices

Module Title:

Applying Safety Practices

UNIVERSITY OF PERFETUAL HELP SYSTEM DALTA - CALAMBA CAMPUS

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 1 /64

HOW TO USE THIS COMPETENCY BASED LEARNING MATERIAL

Welcome

The unit of competency Apply Safety Practices is one of the competencies of

SHIELDED METAL ARC WELDING NC I. This module covers the knowledge, skills

and attitudes required for TVET trainee to possess.

The module on, Applying Safety practices contains training materials and

activities related to identifying learner’s requirement.

In this module you are required to go through a series of learning activities

in order to complete each learning outcome such as Information- Sheets, Self-

checks, Operation Sheets and Task/Job Sheets. Follow and perform the

activities on your own. If you have questions do not hesitate to ask for assistance

from your trainer.

Remember to:

Work through all the information and complete the activities in each section.

Read information sheets and complete the self-check. Suggested references are

included to supplement the materials provided in this module.

Most probably, your trainer will also your supervisor or manage. he is there

to support you and show you the correct way to do things.

You will be given plenty of opportunities to ask questions and practice on the

job make sure you practice your new skills during regular work shifts. This

way you will improve your speed, memory and your confidence.

Use the self-check, Operation Sheets and Task/job Sheets at the end of each

section to test your own progress. Use the Performance Criteria Checklist or

Procedural Checklist located after the sheet to check your own performance.

When you feel confident that you have sufficient practice, ask your trainer to

evaluate you. The result of your assessment will be recorded in your Progress

Chart and Accomplishment Chart.

You need to complete this module before you can perform the next module

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 2 /64

LIST OF COMPETENCIES

No. Unit of Competency Module Title Code

Applying Safety

1. Apply Safety Practices MEE721201

Practices

Interpret Working Interpreting Working

2 MEE721202

Drawings and Sketches Drawings and Sketches

Perform Industry Performing Industry

3 MEE721203

Calculations Calculations

Contribute to Quality Contributing to Quality

4 MEE721204

System System

5 Use Hand Tools Using Hand Tools MEE721205

6 Prepare Weld Materials Preparing Weld Materials MEE721206

Setup Welding Setting up Welding

7 MEE721207

Equipment Equipment

8 Fit up Weld Materials Fitting up Weld Materials MEE721208

9 Repair Welds Repairing Welds MEE721209

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 3 /64

SUMMARY OF LEARNING OUTCOMES

QUALIFICATION: Shielded Metal Arc Welding NCI

UNIT OF COMPETENCY: Apply Safety Practices

MODULE TITLE: Applying Safety Practices

MODULE DESCRIPTION: This module covers safety practices applied in the

workplace.

NOMINAL DURATION: 8 Hrs.

LEARNING OUTCOMES:

LO1. Identify hazardous areas

LO2. Use protective clothing and devices

LO3. Perform safe handling of tools, equipment and materials

LO4. Perform first aid

LO5. Use Fire extinguisher

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 4 /64

DETAILS OF LEARNING OUTCOME

LEARNING OUTCOME 1: Identify hazardous areas

CONTENTS:

Hazard to be avoided in welding

Welding safety signs and symbols

Occupational safety standards and enterprise safety policies

ASSESSMENT CRITERIA:

Hazards are identified correctly in accordance with OHS procedures.

Safety signs and symbols are identified and adhered to in accordance

with workplace safety procedure

CONDITIONS:(Tools, equipment, s/m, references/materials)

Safety sign and

symbols

Instructional materials

- Reference book

- Learning Modules /manuals

- Safety Standards manual

- Enterprise Safety Policies /guidelines

METHODOLOGIES:

Lecture/demonstrations

Self-pace learning

Group discussion

ASSESSMENT METHODS:

Written/oral

Direct observation

Interview

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 5 /64

LEARNING EXPERIENCE

LEARNING OUTCOME 1: Identify hazardous areas

Learning Activities Special Instructions

1. Read Information sheet 1.1.1

about hazard to be avoided in welding

2. Answer Self-Check 1.1.1 Compare your answers to

Answer Key 1.1.1

3. Read Information sheet 1.1.2

about welding safety signs and symbols

4. Answer Self-Check 1.1.2 Compare your answers to

Answer Key 1.1.2

5. Read Information sheet 1.1.3

about occupational safety standards and

enterprise safety policies

6. Answer Self-Check 1.1.3 Compare your answers to

Answer Key 1.1.3

7. Watch video presentation about hazard to Take notes from a

be avoided in welding presentation about hazard

to be avoided in welding

8. Perform Task sheet 1.1.1 Your performance will be

evaluated by your trainer

using Performance Criteria

Checklist 1.1.1

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 6 /64

INFORMATION SHEET 1.1.1

HAZARD TO BE AVOIDED IN WELDING

LEARNING OBJECTIVE/S:

After reading this INFORMATION SHEET you will able to:

Identify hazard to be avoided in welding

Arc welding is a safe occupation when sufficient measures are taken to protect the

welder from potential hazards. When these measures are overlooked or ignored,

however, welders can encounter such dangers as electric shock, overexposure to

fumes and gases, arc radiation, and fire and explosion; which may result in

serious or even fatal injuries.

OSHA Standard 29 CFR 1910.252 (c) (I) (IV) (A)

All containers of filler metal, electrodes & flux materials should carry warning

labels that the welding produces hazardous fumes & gases.

HAZARD TO BE AVOIDED IN WELDING

Safety is a critical consideration for any welding project. Arc welding is a safe

occupation when proper precautions are taken. But, if safety measures are

ignored, welders face an array of hazards which can be potentially dangerous,

including electric shock, fumes and gases, fire and explosions and more.

Identifies Hazards correctly in accordance with OHS procedures.

Identifies Safety signs and symbols and adhered to in accordance with

workplace safety procedure.

Identifies Personal protective clothing/equipment (PPE) as per job

requirements

Properly observes proper wearing of PPE in accordance with workplace

safety policies.

Approve PPE conformed with the occupational safety standards

Awareness of the most common welding hazards and knowing how to avoid them

ensures a safe, productive work environment for all.

Electric shock.

Fumes and gases.

Fire and explosions.

Injuries from insufficient PPE.

Other safety considerations.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 7 /64

Electric shock

Electric shock is one of the most serious and immediate risks facing a

welder. Electric shock can lead to severe injury or death, either from the shock

itself or from a fall caused by the reaction to a shock.

Electric shock occurs when welders touch two metal objects that have a voltage

between them, thereby inserting themselves into the electrical circuit. For

instance, if a worker holds a bare wire in one hand and a second bare wire with

another, electric current will pass through that wire and through the welding

operator, causing an electric shock. The higher the voltage, the higher the current

and, thus the higher the risk for the electric shock to result in injury or death.

Fumes and gases

It’s no surprise that overexposure to welding fumes and gases can be hazardous

to your health. Welding fume contains potentially harmful complex metal oxide

compounds from consumables, base metal and the base-metal coatings, so it’s

important to keep your head out of the fumes and use enough ventilation and/or

exhaust to control your exposure to substances in the fume, depending on the

type of rod and base metal being used.

Welding areas require adequate ventilation and local

exhaust to keep fumes and gases from the breathing zone

and the general area. In most situations, employers will

provide a ventilation system- such as a fan, and an

exhaust system or fixed or removable exhaust hoods- to

remove fumes and gases from the work area.

Fire and explosions

The welding arc creates extreme temperatures, and may pose a significant fire

and explosions hazard if safe practices are not followed. While the welding arc

may reach temperatures of 10,000 degrees Fahrenheit, the real danger is not

from the arc itself, but rather the intense near the arc and the heat, sparks and

spatter created by the arc. This spatter can reach up to 35 feet away from the

welding space.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 8 /64

Injuries from insufficient PPE

Personal protective equipment (PPE) helps keep welding operators free from injury,

such as burns – the most common welding injury – and exposure to arc rays. The

right PPE allows for freedom of movement while still providing adequate protection

from welding hazards.

Other safety considerations

Welders should also be aware of other safety considerations within the work

environment. For example, those working in a confined space or in an elevated

area make need to take extra precautions. In any welding situation, welding

operators should pay close attention safety information on the products being

used and the material safety data sheets provided by the manufacturer and work

with their employer and co-workers to follow appropriate safe practices for their

workplace.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 9 /64

SELF CHECK 1.1.1

HAZARD TO BE AVOIDED IN WELDING

Multiple Choice - Directions: Choose the letter of the correct answer

Use separate sheet of paper.

1. __________ is one of the most serious and immediate risks facing a welder. It

can lead to severe injury or death, either from the shock itself or from a fall

caused by the reaction to a shock.

A. Fumes and gases

B. Fire and explosions

C. Electric shock

2. Welding areas require adequate ventilation and local exhaust to keep ________

from the breathing zone and the general area.

A. Fumes and gases

B. Fire and explosions

C. Electric shock

3. The welding arc creates extreme temperatures, and may pose a significant

___________and hazard if safe practices are not followed.

A. Fumes and gases

B. Fire and explosions

C. Electric shock

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 10 /64

ANSWER KEY 1.1.1

HAZARD TO BE AVOIDED IN WELDING

1. C

2. A

3. B

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 11 /64

TASK SHEET 1.1.1

Title of Task:

Hazard to be avoided in welding

Performance Objective:

Given necessary materials, tools, and equipment the student/trainee must be

able to remind hazard to be avoided in welding.

Supplies / Materials:

Safety sign and symbols

Instructional materials

- Reference book

- Learning Modules /manuals

- Safety Standards manual

- Enterprise Safety Policies /guidelines

Equipment / Accessories :

Safety goggles

Safety cotton gloves (not use for rotating parts)

Safety shoes

Welding Apron

Steps / Procedure:

1. Check cluttered tools and materials

2. Check slippery floors (caused by oil, grease or any liquid)

3. Check exposed electrical wires

4. Check sharp edges

5. Check machine without guards or with exposed moving parts

Assessment method : Demonstration

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 12 /64

TASK SHEET

PERFORMANCE CRITERIA CHECKLIST 1.1.1

HAZARD TO BE AVOIDED IN WELDING

Trainee’s Name: __________________________________ Date: ________________

CRITERIA YES NO

The trainee…

1. Identify hazards correctly in accordance with OHS

procedures.

2. Identify safety signs and symbols and adhered to in

accordance with workplace safety procedure.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 13 /64

INFORMATION SHEET 1.1.2

WELDING SAFETY SIGNS AND SYMBOLS

LEARNING OBJECTIVE/S:

After reading this INFORMATION SHEET you will able to:

Identify Welding safety signs and symbols

Warning signs are to warn of hazards or a hazardous condition that is not likely

to be life-threatening. The hazard symbol should be black on a yellow background

and a triangle should be depicted around the hazard symbol. Warning sign

wording, if necessary, is in black lettering on a yellow background.

Mandatory signs

Are regulatory signs which indicate that an instruction must be carried out?

When symbols are used they are white on a blue disc. Text-only mandatory

signs are black or white in a portrait format.

PROTECTIVE EQUIPMENT MUST BE WORN IN THIS AREA

Failure to comply with them constitutes an offense under law, standing orders,

company policy, etc.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 14 /64

Warning Signs

Signs which warn of a hazard or hazardous condition that is not likely to be life-

threatening. The symbolic shape used on warning signs is black triangle with

yellow interior and black symbol. The word warning is not required to print on the

sign, although it is often used for added impact.

Danger Signs

Safety signage has many uses and can warn of many dangerous situations – such

as fuel storage, radiation, high voltage, chemicals, open holes and much more

Fire Signs

Advice the location of fire alarms and firefighting equipment. Fire signs contain a

white symbol and/or text on a red background

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 15 /64

Emergency Information Signs

Indicate the location of, or direction to, emergency- related facilities (exits, first

aid, safety equipment, etc.). These signs feature a white symbol and/or text on a

green background

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 16 /64

SELF CHECK 1.1.2

WELDING SAFETY SIGNS AND SYMBOLS

Multiple Choice - Directions: Choose the letter of the correct answer

Use separate sheet of paper.

1. Are regulatory signs which indicate that an instruction must be carried out?

When symbols are used they are white on a blue disc. Text-only

mandatory signs are black or white in a portrait format.

A. Mandatory signs

B. Warning Signs

C. Danger Signs

2. Signs which ____ of a hazard or hazardous condition that is not likely to be life-

threatening. The symbolic shape used on ______ is black triangle with yellow

interior and black symbol.

A. Mandatory signs

B. Warning Signs

C. Danger Signs

3. Safety signage has many uses and can warn of many _______ situations such

as fuel storage, radiation, high voltage, chemicals, open holes and much more.

A. Mandatory signs

B. Warning Signs

C. Danger Signs

4. Advice the location of ____ alarms and firefighting equipment. ______ contain a

white symbol and/or text on a red background

A. Danger Signs

B. Fire Signs

C. Emergency Information Signs

5. Indicate the location of, or direction to, ______ related facilities (exits, first aid,

safety equipment, etc.). These signs feature a white symbol and/or text on a

green background

A. Danger Signs

B. Fire Signs

C. Emergency Information Signs

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 17 /64

ANSWER KEY 1.1.2

WELDING SAFETY SIGNS AND SYMBOLS

1. A

2. B

3. C

4. B

5. C

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 18 /64

TASK SHEET 1.1.2

Title of Task:

Welding safety signs and symbols

Performance Objective:

Given necessary materials, tools, and equipment the student/trainee must be

able to identify welding safety signs and symbols

Supplies / Materials:

Safety sign and signs

Instructional materials

- Reference book

- Learning Modules /manuals

- Safety Standards manual

- Enterprise Safety Policies /guidelines

Equipment / Accessories :

Safety goggles

Safety cotton gloves (not use for rotating parts)

Safety shoes

Welding Apron

Steps / Procedure:

1. Label cluttered tools and materials

2. Label slippery floors (caused by oil, grease or any liquid)

3. Label exposed electrical wires

4. Label sharp edges

5. Label machine without guards or with exposed moving parts

Assessment method : Demonstration

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 19 /64

TASK SHEET

PERFORMANCE CRITERIA CHECKLIST 1.1.2

WELDING SAFETY SIGNS AND SYMBOLS

Trainee’s Name: __________________________________ Date: ________________

CRITERIA YES NO

The trainee…

1. Identify hazards correctly in accordance with OHS

procedures.

2. Identify safety signs and symbols and adhered to in

accordance with workplace safety procedure.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 20 /64

INFORMATION SHEET 1.1.3

OCCUPATIONAL SAFETY STANDARDS

AND ENTERPRISE SAFETY POLICIES

LEARNING OBJECTIVE/S:

After reading this INFORMATION SHEET you will able to:

To know Occupational safety standards and enterprise safety policies

RULE 1080

PERSONAL PROTECTIVE EQUIPMENT AND DEVICES

1081 : General Provisions:

1081.01: Every employer as defined in 1002:

1. Shall at his own expense furnish his workers with protective equipment for

the eyes, face, hands and feet, protective shields and barriers whenever

necessary by reason of the hazardous nature of the process or environment,

chemical or radiological or other mechanical irritants or hazards capable of

causing injury or impairment in the function of any part of the body through

absorption, inhalation or physical contact.

2. Deduction for the loss or damage of personal protective equipment shall be

governed by Article 114, Book III, Labor Code of the Philippines, and Section

14, Rule VIII, Book III, Omnibus Rules Implementing the Labor Code.

1081.03:

The employer shall be responsible for the adequacy and proper maintenance

of personal protective equipment used in his Workplace.

1081.04:

No person shall be subjected or exposed

to a hazardous environmental condition

without protection.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 21 /64

1082 : Eye and Face Protection:

1082.01:

Eyes and face protective equipment shall be required where there is

reasonable probability of exposure to such hazards. In such cases, the

employer shall furnish a type of protective equipment suitable for the work

to be performed and the employees shall use such equipment. Eye

protection shall be provided where the processes or operations present

hazards of flying objects, liquids, injurious radiation, glare or a combination

of these hazards

1082.02:

Whenever eye protection is needed, persons whose visions require the use

of corrective lenses shall wear goggles or spectacles of any of the following

types:

1. Spectacles which provide optical correction;

2. Goggles that can be worn over corrective spectacles without disturbing

the adjustment of the spectacles; or

3. Goggles that incorporate corrective lenses mounted behind the

protective lenses.

1083: Respiratory Protection:

1083.01

1. The primary corrective measure in the control of occupational diseases

caused by harmful, dusts, fogs, fumes, mists, gases, smokes, sprays or

vapors shall be to prevent atmospheric contamination. This shall be

accomplished through the use or application of accepted engineering

control measures, like enclosure or confinement of the operation

1084: Head Protection:

1. Hard hats for the protection of workers from impact penetration from

falling and flying objects, blows, and from limited electric shock and

burns shall be provided where there is reasonable probability of exposure

to such hazards.

2. For the purpose of proper selection, design, construction, testing and

use of head protectors the American National Standards Safety

Requirement for Industrial Head Protection (ANSI z59-1-1969) is

adopted.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 22 /64

1085: Hand and Arm Protection:

1085.01:

When selecting gloves, consideration should be given to the hazards to

which the wearer may be exposed to and the ease and free movement of the

fingers.

1085.02:

Gloves shall not be worn by workers operating drills, punch presses or other

machinery in which the hand may be caught by moving parts.

1085.03:

Gloves, mittens and sleeves for workers handling hot metals shall be made

of suitable heat resisting material.

(1) Cover the forearm as much as possible, have a close fit at the

Upper end and not have the slightest break. Gloves torn during use

shall be replaced immediately.

1087: Use of Safety Shoes:

Workers shall be provided with approved safety shoes and leg protection

whenever necessary as determined by the nature of work

RULE 1100: GAS AND ELECTRIC WELDING AND CUTTING

OPERATIONS

1100.01: General Provisions:

1. Welding or cutting operations shall not be permitted in rooms or areas

containing combustible materials or in proximity to explosives or flammable

liquids, dusts, gases or vapors, until all fire and explosion hazards are

eliminated.

2. Welding or cutting operations on containers with explosives or flammable

substance is prohibited. Welding closed containers that have held explosive

or flammable substance shall only be undertaken after the containers have

been thoroughly cleaned and found completely free of combustible gases or

vapors or the containers are filled with inert gas or with water.

3. A portable fire extinguisher shall be provided at the place where

Welding and cutting operations are being undertaken.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 23 /64

4. Welding and cutting operations carried out or done in places where persons

other than the welders work or pass shall be enclosed by means of suitable

stationary or portable screens. Screens shall be opaque, of sturdy

construction to withstand rough usage of a material which will not readily

be set on fire by sparks or hot metal, at least 2 m. (6.5 ft.) high and

preferably painted with light flat paint

5. Authorization, before welding and cutting operations are allowed in large

establishments, the area shall be inspected by the safetyman. He shall issue

a written permit or authorization for welding and cutting, indicating therein

the precautions to be followed to avoid fire or accidents

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 24 /64

SELF CHECK 1.1.3

OCCUPATIONAL SAFETY STANDARDS

AND ENTERPRISE SAFETY POLICIES

Multiple Choice - Directions: Choose the letter of the correct answer

Use separate sheet of paper.

1. Workers shall be provided with approved _______ and leg protection whenever

necessary as determined by the nature of work

A. Hand and Arm Protection

B. Head Protection

C. Use of Safety Shoes

2. When selecting ______, consideration should be given to the hazards to which

the wearer may be exposed to and the ease and free movement of the fingers.

A. Hand and Arm Protection

B. Head Protection

C. Use of Safety Shoes

3. _______ for the protection of workers from impact penetration from falling and

flying objects, blows, and from limited electric shock and burns shall be

provided where there is reasonable probability of exposure to such hazards.

A. Hand and Arm Protection

B. Head Protection

C. Use of Safety Shoes

4. The primary corrective measure in the control of occupational diseases caused

by harmful, dusts, fogs, fumes, mists, gases, smokes, sprays or vapors shall

be to prevent atmospheric contamination.

A. Respiratory Protection

B. Eye and Face Protection

C. Head Protection

5. ________ protection shall be provided where the processes or operations present

hazards of flying objects, liquids, injurious radiation, glare or a combination of

these hazards

A. Respiratory Protection

B. Eye and Face Protection

C. Head Protection

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 25 /64

ANSWER KEY 1.1.3

OCCUPATIONAL SAFETY STANDARDS

AND ENTERPRISE SAFETY POLICIES

1. C

2. A

3. B

4. A

5. B

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 26 /64

TASK SHEET 1.1.3

Title of Task:

Occupational safety standards and enterprise safety policies

Performance Objective:

Given necessary materials, tools, and equipment the student/trainee must be

able to explain occupational safety standards and enterprise safety policies

Supplies / Materials:

Safety sign and signs

Instructional materials

- Reference book

- Learning Modules /manuals

- Safety Standards manual

- Enterprise Safety Policies /guidelines

Equipment / Accessories :

Steps / Procedure: Hazard & Risk

1. Explain cluttered tools and materials

2. Explain slippery floors (caused by oil, grease or any liquid)

3. Explain exposed electrical wires

4. Explain sharp edges

5. Explain machine without guards or with exposed moving parts

Assessment method : Demonstration

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 27 /64

TASK SHEET

PERFORMANCE CRITERIA CHECKLIST 1.1.3

OCCUPATIONAL SAFETY STANDARDS

AND ENTERPRISE SAFETY POLICIES

Trainee’s Name: __________________________________ Date: ________________

CRITERIA YES NO

The trainee…

1. Identify hazards correctly in accordance with OHS

procedures.

2. Identify safety signs and symbols and adhered to in

accordance with workplace safety procedure.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 28 /64

DETAILS OF LEARNING OUTCOME

LEARNING OUTCOME 2: Use protective clothing and devices

CONTENTS:

Personal protective equipment (PPE) for different welding operations

Proper uses of different types of personal protective equipment (PPE)

Occupational safety standards and enterprise safety policies.

ASSESSMENT CRITERIA:

Personal protective clothing/equipment (PPE) identified as per job

requirements

Proper wearing of PPE are properly observed in accordance with

workplace safety policies.

PPE conformed to the approved occupational safety standards.

CONDITIONS:(Tools, equipment, s/m, references/materials)

Personal protective equipment (PPE)

- Hard hat

- Safety shoes

- Gloves

- Goggles

- Welder apron

Instructional materials for:

- Reference book

- Learning modules/manuals

- Safety standards

- Enterprise safety policies/guidelines

METHODOLOGIES:

Lecture/demonstrations

Self-pace learning

Group discussion

ASSESSMENT METHODS:

Written/oral

Direct observation

Interview

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 29 /64

LEARNING EXPERIENCE

LEARNING OUTCOME 2: Use protective clothing and devices

Learning Activities Special Instructions

1. Read Information sheet 1.2.1

about proper uses of different types of

Personal Protective Equipment (PPE)

2. Answer Self-Check 1.2.1 Compare your answers to

Answer Key 1.2.1

3. Watch video presentation about proper uses Take notes from a

of different types of Personal Protective presentation about proper

Equipment (PPE) uses of different types of

Personal Protective

Equipment (PPE)

4. Perform Task sheet 1.2.1 Your performance will be

evaluated by your trainer

using Performance Criteria

Checklist 1.2.1

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 30 /64

INFORMATION SHEET 1.2.1

PROPER USES OF DIFFERENT TYPES OF

PERSONAL PROTECTIVE EQUIPMENT (PPE)

LEARNING OBJECTIVE/S:

After reading this INFORMATION SHEET you will able to:

Apply the uses of different types of Personal protective equipment (PPE)

Welding helmet

It protect the welder from sparks, UV rays and

bright light of the torch. Auto darkening. These

are the advantages in using an auto darkening

helmet. You need not flip the viewing lid or the

whole helmet. Because of this it's easier on your

neck, without all that flipping

Respirators to protect themselves from chemical

exposures during welding, torch cutting.

Earmuffs / Ear plug

It will safeguard your ears against flying hot metal

and also guard them from extreme noise

Safety spectacles, Oxy-Acetylene goggles, Face shield

It will limit eye hazards. Some goggles have plastic windows which resist

shattering upon impact. Others are designed to limit harmful infrared and

ultraviolet radiation from arcs or flames by appropriate filter lenses.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 31 /64

Welding apron

It protects you and your clothes from hot sparks as you

weld, cut or grind.

Leather gloves, long

It will protect them from any molten material that may

drop while they are working with the weld

Leather welding leggings

It protects foot and lower leg against welding spatter

and radiant heat.

Safety shoes Protect against welding molten

Metal and falling debris

Welding Cap

A welder’s cap should be worn to protect the head

from hot metal and slag splatter. In addition, long

hair should be tied back and tucked inside the

welding jacket

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 32 /64

SELF CHECK 1.2.1

PROPER USES OF DIFFERENT TYPES OF

PERSONAL PROTECTIVE EQUIPMENT (PPE)

Multiple Choice - Directions: Choose the letter of the correct answer

Use separate sheet of paper.

1. Should be worn to protect the head from hot metal and slag splatter. In

addition, long hair should be tied back and tucked inside the welding jacket.

A. welder’s cap

B. Safety shoes

C. Leather gloves, long

2. Protect against welding molten metal and falling debris

A. welder’s cap

B. Safety shoes

C. Leather gloves, long

3. It will protect them from any molten material that may drop while they are

working with the weld.

A. welder’s cap

B. Safety shoes

C. Leather gloves, long

4. It protects you and your clothes from hot sparks as you weld, cut or grind.

A. Respirators

B. Leather welding leggings

C. Welding apron

5. It protects foot and lower leg against welding spatter and radiant heat.

A. Respirators

B. Leather welding leggings

C. Welding apron

6. To protect themselves from chemical exposures during welding, torch

cutting.

A. Respirators

B. Leather welding leggings

C. Welding apron

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 33 /64

7. It will limit eye hazards. Some have plastic windows which resist

shattering upon impact. Others are designed to limit harmful infrared and

ultraviolet radiation from arcs or flames by appropriate filter lenses

A. Leather welding leggings

B. Welding apron

C. Safety spectacles, Oxy-Acetylene goggles, Face shield

8. It will safeguard your ears against flying hot metal and also guard them from

extreme noise

A. Leather welding leggings

B. Earmuffs / Ear plug

C. Safety spectacles, Oxy-Acetylene goggles, Face shield

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 34 /64

ANSWER KEY 1.2.1

PROPER USES OF DIFFERENT TYPES OF

PERSONAL PROTECTIVE EQUIPMENT (PPE)

1. A

2. B

3. C

4. C

5. B

6. A

7. C

8. B

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 35 /64

TASK SHEET 1.2.1

Title of Task:

Proper uses of different types of Personal Protective Equipment (PPE)

Performance Objective:

Given necessary materials, tools, and equipment the student/trainee must be

able to check the proper uses of different types of Personal Protective Equipment

(PPE)

Supplies / Materials:

Personal protective equipment (PPE)

- Hard hat

- Safety shoes

- Gloves

- Goggles

- Welder apron

Instructional materials for:

- Reference book

- Learning modules/manuals

- Safety standards

- Enterprise safety policies/guidelines

Equipment / Accessories :

Steps / Procedure: deteriorates PPE

1. Check hard hat

2. Check safety shoes

3. Check gloves

4. Check goggles

5. Check welding apron

Assessment method : Demonstration

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 36 /64

TASK SHEET 1.2.1

PERFORMANCE CRITERIA CHECKLIST

OCCUPATIONAL SAFETY STANDARDS

AND ENTERPRISE SAFETY POLICIES

Trainee’s Name: __________________________________ Date: ________________

CRITERIA YES NO

The trainee…

1. Identify Personal Protective Clothing/Equipment

(PPE) as per job requirements

2. Properly observe proper wearing of PPE in accordance

with workplace safety policies.

3. Conform PPE to the approved occupational safety

standards.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 37 /64

DETAILS OF LEARNING OUTCOME

LEARNING OUTCOME 4: Perform first aid

CONTENTS:

Different types of injuries

First aid treatment procedure

Emergency hotline number and offices

Proper handling of injured individual

ASSESSMENT CRITERIA:

First aid treatment of injuries are carried out according to

recommended procedures

Emergency hotline and proper authority are accessed and contacted in

accordance with workplace procedure.

CONDITIONS:(Tools, equipment, s/m, references/materials)

Equipment

- First aid kit (different types)

- Oxygen

- Stretcher

- Medicine

Learning materials

- Video tape, CD’s, transparencies

Directory hotline number and offices

METHODOLOGIES:

Lecture/demonstrations

Self-pace learning

Group discussion

ASSESSMENT METHODS:

Written/oral

Direct observation

Interview

Demonstration

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 38 /64

LEARNING EXPERIENCE

LEARNING OUTCOME 4: Perform first aid

Learning Activities Special Instructions

1. Read Information sheet 1.4.1

about first aid treatment procedure

2. Answer Self-Check 1.4.1 Compare your answers to

Answer Key 1.4.1

3. Watch video presentation about first aid Take notes from a

treatment procedure presentation about first aid

treatment procedure.

4. Perform Task sheet 1.4.1 Your performance will be

evaluated by your trainer

using Performance Criteria

Checklist 1.4.1

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 39 /64

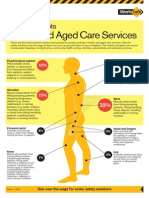

INFORMATION SHEET 1.4.1

FIRST AID TREATMENT PROCEDURE

LEARNING OBJECTIVE/S:

After reading this INFORMATION SHEET you will able to:

Apply first aid treatment procedure

PERFORM FIRST AID

Carries out First aid treatment of injuries according to recommended

procedures

Access and contacts Emergency hotline and proper authority in

accordance with workplace procedure.

BURN

Hold burned skin under cool (not cold) running water or

immerse in cool water until pain subsides. Use

compresses if running water isn't available.

Protect Burn. Cover with sterile, non-adhesive bandage

or clean cloth.

SLIPS & FALLS

In the meantime you can try to stem blood flow from

wounds by using cloth or tissue and applying pressure

to the wound. You may need to use CPR if the person

has lost consciousness and is not breathing

SPRAIN

Rest the injured limb, Ice the area, Compress the area

with an elastic wrap or bandage &Elevate the injured

limb above your heart whenever possible to help prevent

or limit swelling.

Clean Cuts and Scrapes Gently

Ouch! Got another cut or scrape? Your first step is

easy: Soothe and clean the wound with cool water.

Then remove any pebbles or splinters with alcohol-

sterilized tweezers. Gently wash around the wound

with soap and a washcloth. Do not use irritating

soap, iodine, alcohol, or hydrogen peroxide -- fresh,

clean water should be all you need.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 40 /64

Do You Need an Antibiotic Cream?

Antibiotic creams and ointments not only keep

wounds moist but they can reduce the risks of

infection. If you do use an antibiotic, apply a thin

layer on the wound. Certain antibiotic ingredients

can trigger a rash in some people. If you get a rash,

stop using that ointment.

Signs of Adhesive or Latex Allergy

If you feel like its itchy, blistery, or burning under

your bandage, you may have an allergy to the

adhesive used in some bandages. For sensitive

skin, try switching to sterile gauze and paper tape,

or an adhesive-free dressing.

For a Foreign Particle in Eye

Don't rub the eye. Pull the upper lid down and blink

repeatedly. If particle is still there, rinse with eyewash.

If rinsing doesn't help, close eye, bandage it lightly, and

see a doctor.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 41 /64

SELF CHECK 1.4.1

FIRST AID TREATMENT PROCEDURE

Multiple Choice - Directions: Choose the letter of the correct answer

Use separate sheet of paper.

1. Hold burned skin under cool (not cold) running water or immerse in cool water

until pain subsides. Use compresses if running water isn't available.

Protect Burn Cover with sterile, non-adhesive bandage or clean cloth.

A. SLIPS & FALLS

B. BURN

C. SPRAIN

2. In the meantime you can try to stem blood flow from wounds by using cloth or

tissue and applying pressure to the wound. You may need to use CPR if the

person has lost consciousness and is not breathing

A. SLIPS & FALLS

B. BURN

C. SPRAIN

3. Rest the injured limb, Ice the area, Compress the area with an elastic wrap or

bandage &Elevate the injured limb above your heart whenever possible to help

prevent or limit swelling.

A. SLIPS & FALLS

B. BURN

C. SPRAIN

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 42 /64

ANSWER KEY 1.4.1

FIRST AID TREATMENT PROCEDURE

1. B

2. A

3. C

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 43 /64

TASK SHEET 1.4.1

Title of Task:

First aid treatment procedure

Performance Objective:

Given necessary materials, tools, and equipment the student/trainee must be

able to perform first aid treatment procedure

Supplies / Materials:

Learning materials

- Video tape, CD’s, transparencies

Directory hotline number and offices

Equipment / Accessories :

Equipment

- First aid kit (different types)

- Oxygen

- Stretcher

- Medicine

Steps / Procedure:

1. Demonstrate first aid treatment of burns/scalds

2. Demonstrate first aid treatment of fractures

3. Demonstrate first aid treatment of cuts and abrasions

4. Demonstrate first aid treatment of poisoning

5. Demonstrate first aid treatment of foreign bodies in the eye

6. Demonstrate first aid treatment of concussion

7. Demonstrate first aid treatment of electric shock

Assessment method : Demonstration

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 44 /64

TASK SHEET

PERFORMANCE CRITERIA CHECKLIST 1.4.1

FIRST AID TREATMENT PROCEDURE

Trainee’s Name: __________________________________ Date: ________________

CRITERIA YES NO

The trainee…

1. Carry out first aid treatment of injuries according to

recommended procedures

2. Access and contact Emergency hotline and proper

authority in accordance with workplace procedure.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 45 /64

DETAILS OF LEARNING OUTCOME

LEARNING OUTCOME :5 Use fire extinguisher

CONTENTS:

Types of firefighting equipment

Types of fire extinguishers

Fire hoses

Fire hydrants

Sources/causes of fires

Proper use of firefighting equipment

ASSESSMENT CRITERIA:

Firefighting equipment identified according to types/source of fires.

Use of firefighting equipment demonstrated in accordance with

manufacturer’s instructions.

Used firefighting equipment and accessories are recorded/reported for

replacement/refill in accordance with enterprise approved safety

regulations.

CONDITIONS:(Tools, equipment, s/m, references/materials)

Equipment

- Fire extinguishers (different types)

- Fire hydrants

- Video players/monitors

Learning materials

- Types of fires/sources

- Types of firefighting equipment and its operations

- Manuals on fire protection regulations

- Video tape, CD’s, transparencies

- Report cards/checklist

METHODOLOGIES:

Lecture/demonstrations

Self-pace learning

Group discussion

ASSESSMENT METHODS:

Written/oral

Direct observation

Interview

Demonstration

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 46 /64

LEARNING EXPERIENCE

LEARNING OUTCOME 5: Use fire extinguisher

Learning Activities Special Instructions

1. Read Information sheet 1.5.1

about types of fire extinguishers

2. Answer Self-Check 1.5.1 Compare your answers to

Answer Key 1.5.1

3. Read Information sheet 1.5.2

on Sources/causes of fires

4. Answer Self-Check 1.5.2 Compare your answers to

Answer Key 1.5.2

5. Watch video presentation about different Take notes from a

types of injuries presentation about different

types of injuries

6. Perform Task sheet 1.5.1 Your performance will be

evaluated by your trainer

using Performance Criteria

Checklist 1.5.1

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 47 /64

INFORMATION SHEET 1.5.1

TYPES OF FIRE EXTINGUISHERS

LEARNING OBJECTIVE/S:

After reading this INFORMATION SHEET you will able to:

Identifies firefighting equipment according to

types/source of fires.

Demonstrates use of firefighting equipment in

accordance with manufacturer’s instructions.

Records/reports used firefighting equipment and

accessories for replacement/refill in accordance

with enterprise approved safety regulations

Fire extinguisher

Is an active fire protection device used to extinguish or control small fires, often in

emergency situations.

Classification of fire extinguishers. Always follow the guidelines below and

choose the proper extinguisher.

1. Class A fires

Fires involving ordinary combustible materials

such as paper, wood, textiles, and plastics.

2. Class B fires

Fires involving flammable liquids, greases, cooking

liquids, oil, gasoline, kerosene, or paint

3. Class C fires

Fires involving energized electrical equipment.

Both mono ammonium phosphate and sodium

bicarbonate are commonly used to fight this type of

fire because of their nonconductive properties.

4. Class D fires

Fires involving combustible metal such as

magnesium, titanium, zirconium, sodium and

potassium.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 48 /64

Requirements for fire extinguisher

1. Be kept fully charged & in their designated places along normal paths of

travel

2. Not be obstructed or obscured from view

3. Not be mounted higher than 5 ft. or 1.5 meters to the top of the extinguisher

if the weigh 40 lbs.

4. Be inspected by the management or a chosen employee at least monthly to

make sure it is in the designated places. It is not tampered or actuated, no

corrosion and impairments.

5. Be hydrostatically tested.

6. Be selected on the basis of type of hazard, degree of hazard and the area to

be protected.

After use

1. The extinguisher re-charged or replace immediately even if only partially

discharged.

2. Bring your extinguisher to a qualified service agency for re-charging, repair

or test.

3. Do not dispose used fire extinguisher by throwing on fire

4. Do not refill your extinguisher with any material other than specified on the

name plate.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 49 /64

PROCEDURES FOR USING A FIRE EXTINGUISHER

You should only try to fight fires after you have been properly trained on how to use a fire

extinguisher and if the fire in contained in a small area.

P. Pull the pin on the fire extinguisher in order to break the tamper seal.

A. Aim the fire extinguisher low, with the nozzle pointed at the base of the fire.

S. Squeeze the handle of the fire extinguisher to release the extinguishing

agent.

S. Sweep the nozzle from side to side while pointed at the base of the fire

until it is extinguished.

If the fire re-ignites, repeat the last 3 steps.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 50 /64

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 51 /64

SELF CHECK 1.5.1

TYPES OF FIRE EXTINGUISHERS

Multiple Choice - Directions: Choose the letter of the correct answer

Use separate sheet of paper.

1. This unlocks the operating lever and allows you to discharge the

extinguisher.

A. Pull

B. Aim the nozzle

C. Squeeze

2. The action of directing nozzle of the extinguisher at the base of the fire.

A. Pull

B. Aim the nozzle

C. Squeeze

3. Releasing the lever will stop the discharge of the extinguisher agent.

A. Pull

B. Aim the nozzle

C. Squeeze

4. From side to side. Moving carefully toward the fire, keep the extinguisher

aimed at the base of the fire and span back and forth until the flames appear

to be out. Watch the area closely and if a fire restarts, repeat the process.

A. Pull

B. Aim the nozzle

C. Sweep with a nozzle

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 52 /64

ANSWER KEY 1.5.1

TYPES OF FIRE EXTINGUISHERS

1. A

2. B

3. C

4. C

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 53 /64

TASK SHEET 1.5.1

Title of Task:

Types of fire extinguishers

Performance Objective:

Given necessary materials, tools, and equipment the student/trainee must be

able to identify the types of fire extinguishers

Supplies / Materials:

Learning materials

- Types of fires/sources

- Types of firefighting equipment and its operations

- Manuals on fire protection regulations

- Video tape, CD’s, transparencies

- Report cards/checklist

Equipment / Accessories :

Equipment

- Fire extinguishers (different types)

- Fire hydrants

- Video players/monitors

Steps / Procedure:

1. Classify common combustibles (wood, cloth, paper, rubber and plastic)

2. Classify flammable liquids (gasoline, oil, solvents, paints, etc.)

3. Classify energized electrical equipment (wiring, fuse boxes, circuit breakers,

appliances, etc.

4. Classify combustible metals (magnesium, sodium, etc.)

Assessment method : Demonstration

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 54 /64

TASK SHEET

PERFORMANCE CRITERIA CHECKLIST 1.5.1

TYPES OF FIRE EXTINGUISHERS

Trainee’s Name: __________________________________ Date: ________________

CRITERIA YES NO

The trainee…

1. Identify firefighting equipment according to

types/source of fires.

2. Demonstrate use of firefighting equipment in

accordance with manufacturer’s instructions.

3. Record/report used firefighting equipment and

accessories for replacement/refill in accordance with

enterprise approved safety regulations.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 55 /64

INFORMATION SHEET 1.5.2

SOURCES/CAUSES OF FIRES

LEARNING OBJECTIVE/S:

After reading this INFORMATION SHEET you will able to:

Identify Sources/causes of fires

Fire

The result of the chemical combination of a combustible material (Fuel) with the

oxygen in the presence of enough heat

Hot Work – Operations such as welding, cutting, burning, heating, grinding, or similar

spark, slag, or intense heat producing activities that are capable of igniting combustible

materials or flammable atmospheres or providing a source of ignition for a fire. Also defined

as cutting and welding operations for construction/demolition activities that involve the use

of portable gas or arc welding equipment, open flame or spark-producing apparatus.

Electric shock

As the principal danger is an electric shock from the live parts of the welding circuit (the

electrode and the workpiece), the following practices are recommended.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 56 /64

Equipment

Installation of welding equipment should be carried out by suitably qualified staff who must

check that the equipment is suitable for the operation and connected in accordance with

the manufacturer's recommendations. The welder is responsible for checking the

equipment (cable, electrode holder and coupling devices) daily for damage and reporting

defects.

All external connections should be clean and tight and checked each time a reconnection

is made. The welding return clamp should be connected directly to the workpiece, as close

as possible to the point of welding or to the work bench on which the workpiece is placed.

There is a high chance of your encountering an out-of-control fire at least once in your

life, so knowing how to use a fire extinguisher is an important skill to be able to resort to.

This article explains the process of using a fire extinguisher in an emergency.

Fire Triangle

Fire requires the following three elements to exist:

• Heat:

Heat is required to elevate the temperature of a material to its ignition point. Sources of

heat include matches, stoves, sparks, etc.

• Fuel:

The fuel for a fire may be a solid (e.g., coal, wood, paper, cloth, hay, etc.), liquid (e.g.

gasoline, kerosene, alcohol, paint, cooking oil, etc.), or gas (e.g., propane, natural gas,

butane, etc.). The type and quantity of the fuel will determine which method should be

used to extinguish the fire.

• Oxygen:

We need 16% oxygen to sustain fire sufficient heat to raise the temperature of the fuel

surface to a point where chemical union of the fuel & oxygen occurs.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 57 /64

3 Methods of heat transfer

Conduction

Direct conduct of heat from one body to another.

Convention

The circulating medium of heat transfer occurs upward

Radiation

When energy travels through space or material in waves

Product of combustion

When a fuel burns it undergoes chemical changes & there are four products of

combustions.

Fire gases

Refers to the vaporized product of combustions

Flame

Is the visible luminous body of burning gas which become hotter & less

luminous when it mixed with increased amount of oxygen.

Heat

Is a form of energy which is measured in degrees of temperature to signify

its intensity & it is responsible for the spread of fire.

Smoke

Is a visible product of incomplete combustion.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 58 /64

PROVIDING A SOURCE OF IGNITION FOR A FIRE

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 59 /64

SELF CHECK 1.5.2

SOURCES/CAUSES OF FIRES

Multiple Choice - Directions: Choose the letter of the correct answer

Use separate sheet of paper.

1. It is required to elevate the temperature of a material to its ignition point. The sources

include matches, stoves, sparks, etc.

A. Fuel

B. Oxygen

C. Heat

2. A fire may be a solid, liquid or gas. The type and quantity of the ______ will determine

which method should be used to extinguish the fire.

A. Fuel

B. Oxygen

C. Heat

3. Without________, most fuels could be heated until entirely vaporized, yet would not

burn. These three elements, called the “fire triangle,” create a chemical exothermic

reaction, which is fire.

A. Fuel

B. Oxygen

C. Heat

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 60 /64

ANSWER KEY 1.5.2

SOURCES/CAUSES OF FIRES

1. C

2. A

3. B

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 61 /64

TASK SHEET 1.5.2

Title of Task:

Sources/causes of fires

Performance Objective:

Given necessary materials, tools, and equipment the student/trainee must be

able to identify sources/causes of fires

Supplies / Materials:

Learning materials

- Types of fires/sources

- Types of firefighting equipment and its operations

- Manuals on fire protection regulations

- Video tape, CD’s, transparencies

- Report cards/checklist

Equipment / Accessories :

Equipment

- Fire extinguishers (different types)

- Fire hydrants

Steps / Procedure:

1. Demonstrate types of fire extinguisher for common combustibles (wood, cloth,

paper, rubber and plastic)

2. Demonstrate types of fire extinguisher for flammable liquids (gasoline, oil,

solvents, paints, etc.)

3. Demonstrate types of fire extinguisher for energized electrical equipment

(wiring, fuse boxes, circuit breakers, appliances, etc.

4. Demonstrate types of fire extinguisher for combustible metals (magnesium,

sodium, etc.)

Assessment method : Demonstration

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 62 /64

TASK SHEET

PERFORMANCE CRITERIA CHECKLIST 1.5.2

SOURCES/CAUSES OF FIRES

Trainee’s Name: __________________________________ Date: ________________

CRITERIA YES NO

The trainee…

1. Identify firefighting equipment according to

types/source of fires.

2. Demonstrate use of firefighting equipment in

accordance with manufacturer’s instructions.

3. Record/report used firefighting equipment and

accessories for replacement/refill in accordance with

enterprise approved safety regulations.

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 63 /64

JOB SHEET

PERFORMANCE CRITERIA CHECKLIST 1.1

APPLY SAFETY PRACTICES

Trainee’s Name: __________________________________ Date: ________________

CRITERIA YES NO

Did you…

1. Identify hazardous area

2. Use protective clothing and devices

3. Perform safe handling of tools, equipment and

materials

4. Perform first aid

5. Use fire extinguisher

Date Developed: Document No. MEE721201

SHIELDED METAL ARC

May 7, 2019 Issued by: GMT

WELDING (SMAW) NC I

Apply Safety Practices Developed by: Revision Page No.

Guillermo M. Taiza No._1_ 64 /64

You might also like

- RA 012 Taking Trial PitsDocument2 pagesRA 012 Taking Trial Pitsahmedshah512100% (1)

- Risk Assessment TrainingDocument36 pagesRisk Assessment TrainingAnnisa Nurbaity100% (2)

- Industry Guide For Formwork: Construction Industry South Australia JUNE 2012Document37 pagesIndustry Guide For Formwork: Construction Industry South Australia JUNE 2012tino3528100% (6)

- 428 Trak Pact orDocument300 pages428 Trak Pact orFerneli Moises Barbosa Ojeda100% (6)

- CBLM Core Smaw nc1Document57 pagesCBLM Core Smaw nc1MANPOWER ORMOC100% (5)

- Civil EHS Risk Assessment - 1. ExcavationDocument2 pagesCivil EHS Risk Assessment - 1. Excavationshamshu123No ratings yet

- COMPETENCY - BASED - LEARNING - MATERIAL - Massa (1) .OdtDocument142 pagesCOMPETENCY - BASED - LEARNING - MATERIAL - Massa (1) .OdtHenry OdulioNo ratings yet

- Welding Module 2-1Document21 pagesWelding Module 2-1Marwin NavarreteNo ratings yet

- Competency-Based Learning Materials: Sain T Joseph Vocatio Al and Technical N Training and Assessment Center IncDocument38 pagesCompetency-Based Learning Materials: Sain T Joseph Vocatio Al and Technical N Training and Assessment Center IncREZEL CHARMIN GUINTE-MASANGKAY100% (1)

- NCC Excavation Collapse Emergency PlanDocument10 pagesNCC Excavation Collapse Emergency PlanhassanNo ratings yet

- Maintain Strategies For Safe Food Storage: D1.HCC - CL2.04 Trainee ManualDocument92 pagesMaintain Strategies For Safe Food Storage: D1.HCC - CL2.04 Trainee ManualPhttii phttiiNo ratings yet

- 2020-CBLM Smaw HandoutsDocument93 pages2020-CBLM Smaw HandoutsRoddx PalosNo ratings yet

- Provide Gueridon Service: D1.HBS - CL5.11 Trainee ManualDocument98 pagesProvide Gueridon Service: D1.HBS - CL5.11 Trainee Manualhemant8487No ratings yet

- Cblm-Smaw-Nc IiDocument80 pagesCblm-Smaw-Nc IiERIC NARAGANo ratings yet

- COMMON 4 Contribute To Quality System FINALDocument92 pagesCOMMON 4 Contribute To Quality System FINALJoyLyn Sarmiento AmitNo ratings yet

- Manage and Operate A Coffee Shop: D1.HPA - CL4.01 Trainer GuideDocument64 pagesManage and Operate A Coffee Shop: D1.HPA - CL4.01 Trainer GuidePhttii phttiiNo ratings yet

- SMAW NC I (Module 3 Basic) Demonstrate Work ValuesDocument14 pagesSMAW NC I (Module 3 Basic) Demonstrate Work ValuesCelso Amoto100% (1)

- CBLM - SMAW NC II - CORE PIPES NewDocument207 pagesCBLM - SMAW NC II - CORE PIPES NewCharity GarrateNo ratings yet

- Smaw CBLM Applying Safety PracticesDocument140 pagesSmaw CBLM Applying Safety PracticesYang Cole100% (1)

- Operate A Bar Facility: D1.HBS - CL5.04 Trainee ManualDocument88 pagesOperate A Bar Facility: D1.HBS - CL5.04 Trainee ManualPhttii phttiiNo ratings yet

- Apply Safety Practices (Common)Document38 pagesApply Safety Practices (Common)Edwin SanbuenaventuraNo ratings yet

- CBLM Smaw NciiDocument44 pagesCBLM Smaw NciiJacaskills Jstac50% (2)

- SMAW NC I CBLM CoreDocument146 pagesSMAW NC I CBLM CoreSeniorito Louiesito100% (2)

- COMMON 2 Interpret Drawing and Sketches FINALDocument82 pagesCOMMON 2 Interpret Drawing and Sketches FINALJoyLyn Sarmiento AmitNo ratings yet

- Reb TM1Document87 pagesReb TM1Weird Nahuman0% (1)

- CBLM PipeDocument44 pagesCBLM PipeAko Lang Poh100% (5)

- CBLM in SMAW NC IDocument37 pagesCBLM in SMAW NC IChristian Gervacio91% (11)

- Smaw NC IiDocument61 pagesSmaw NC IiEvan James BeldadNo ratings yet

- Performing Fillet Welding On Carbon Steel PlateDocument35 pagesPerforming Fillet Welding On Carbon Steel PlateJM Llaban Ramos72% (18)

- Smaw Ncii ModuleDocument47 pagesSmaw Ncii ModuleRonald Miguel AlconisNo ratings yet

- Specific Instruction SmawDocument1 pageSpecific Instruction SmawMay Esban100% (1)

- CBLMDocument50 pagesCBLMLowen Tabance Simbit100% (2)

- CBLM Common 3 Perform Industry CalculationDocument23 pagesCBLM Common 3 Perform Industry CalculationAnonymous jGHeIS100% (1)

- CBC - Shielded Metal Arc Welding NC IIDocument87 pagesCBC - Shielded Metal Arc Welding NC IIEllen Susas86% (22)

- Smaw PTSDocument19 pagesSmaw PTSGissele AbolucionNo ratings yet

- CBLM Set Up Welding Equipment NC 2 OCT. 2022Document43 pagesCBLM Set Up Welding Equipment NC 2 OCT. 2022Mark KimhitaNo ratings yet

- CBLM-SMAW NC I Use Hand ToolsDocument68 pagesCBLM-SMAW NC I Use Hand ToolsRichard Chaneco100% (1)

- Tour Guiding: Wikipedia:Tour Guide August 2007Document6 pagesTour Guiding: Wikipedia:Tour Guide August 2007Hailey RutherfordNo ratings yet

- CBLM Module VictorDocument123 pagesCBLM Module Victorvictor100% (2)

- Self - Assessment Guide: Shielded Metal Arc Welding (Smaw) NC Ii Weld Carbon Steel Plates and Pipes Using SmawDocument1 pageSelf - Assessment Guide: Shielded Metal Arc Welding (Smaw) NC Ii Weld Carbon Steel Plates and Pipes Using SmawAJ AcuñaNo ratings yet

- LESSON PLAN GRADE 11 SMAWEssentials in Cleaning Root Pass After WeldingDocument2 pagesLESSON PLAN GRADE 11 SMAWEssentials in Cleaning Root Pass After Weldingjoebert agraviadorNo ratings yet

- Doc.34 05 PracticeQuestionnaireDocument5 pagesDoc.34 05 PracticeQuestionnairejvigneshiseNo ratings yet

- Competency-Based Learning Material: Shielded Metal Arc Welding (SMAW) I.Learn Center PhilippinesDocument39 pagesCompetency-Based Learning Material: Shielded Metal Arc Welding (SMAW) I.Learn Center PhilippinesRuel Daitol100% (3)

- 6 Prepare Weld MaterialsDocument80 pages6 Prepare Weld MaterialsRobinson Concordia50% (2)

- Employee Relationship Management - A Case Study On UnileverDocument18 pagesEmployee Relationship Management - A Case Study On Unileversimran manwani100% (1)

- Perform Industry CalculationDocument22 pagesPerform Industry CalculationYang Cole100% (2)

- Training Matrix Smaw NC IDocument10 pagesTraining Matrix Smaw NC IEdward LyleNo ratings yet

- Maintain Training FacilitiesDocument14 pagesMaintain Training Facilitiesrodel megollasNo ratings yet

- CBC SMAW NCII Feb. 9 2018Document76 pagesCBC SMAW NCII Feb. 9 2018jayson platino100% (1)

- CBLM SMAW NC I 1 Common CompetencyDocument58 pagesCBLM SMAW NC I 1 Common CompetencyESTRELLA PALER100% (2)

- SMAW NC I (Module 3 Common) Perform Industry CalculationDocument10 pagesSMAW NC I (Module 3 Common) Perform Industry CalculationCelso Amoto100% (1)

- SMAW NC I (Module 2 Common) Interpret Drawing and SketchesDocument22 pagesSMAW NC I (Module 2 Common) Interpret Drawing and SketchesCelso Amoto100% (1)

- CBLM SMAWNCI HazelDocument36 pagesCBLM SMAWNCI HazelAnnie Mae Dumot Arcangeles100% (1)

- Parts of A Competency-Based Learning Material PackageDocument19 pagesParts of A Competency-Based Learning Material PackageRoedfrey OrtizNo ratings yet

- CBLM Smaw Plates 1g-4gDocument39 pagesCBLM Smaw Plates 1g-4gMarlon Ty Manalo85% (27)

- SMAW TestDocument4 pagesSMAW TestBapunNo ratings yet

- Institutional Assessment (SMAW NC II)Document11 pagesInstitutional Assessment (SMAW NC II)greatcenter registrarNo ratings yet

- Y3 - Module 1 - Interpreting Drawings and Symbols EditedDocument137 pagesY3 - Module 1 - Interpreting Drawings and Symbols EditedIP G80% (15)

- CBLMDocument60 pagesCBLMfelicity lincuna100% (2)

- Contribute To Quality SystemDocument13 pagesContribute To Quality SystemYang Cole100% (2)

- Perform Child Protection Duties Relevant To The Tourism IndustryDocument44 pagesPerform Child Protection Duties Relevant To The Tourism IndustryPhttii phttii100% (1)

- Core Smaw NC IDocument13 pagesCore Smaw NC INICOSAT CollegesNo ratings yet

- Smaw NC IIDocument42 pagesSmaw NC IILloyd Arnold Catabona100% (1)

- CBLM-SMAW NC I Use Hand ToolsDocument74 pagesCBLM-SMAW NC I Use Hand ToolsJoselito UbaldoNo ratings yet

- Q1 TLE Shielded Metal Arc Welding (SMAW) NC II Module 1Document30 pagesQ1 TLE Shielded Metal Arc Welding (SMAW) NC II Module 1Pladie Salomon100% (1)

- TM1 WDDocument124 pagesTM1 WDJohn Wilner DirectoNo ratings yet

- Performance Criteria ChecklistDocument2 pagesPerformance Criteria ChecklistShallimar AlcarionNo ratings yet

- Session Plan in Smaw PipesDocument7 pagesSession Plan in Smaw PipesGuada Lupe100% (1)

- RATING SHEET FOR DEMONSTRATION SmawDocument3 pagesRATING SHEET FOR DEMONSTRATION SmawLudivino Toto Ledesma Condalor100% (2)

- Data Gathering Instrument For TraineeDocument34 pagesData Gathering Instrument For TraineeMario Tan0% (1)

- Content Content Standard Performance Standard Learning Competencies Code Learning Materials Week Prepare Weld Materials (WM) LO 1. Set-Up Cutting EquipmentDocument9 pagesContent Content Standard Performance Standard Learning Competencies Code Learning Materials Week Prepare Weld Materials (WM) LO 1. Set-Up Cutting Equipmentlip100% (1)

- CBLM Smaw Ncii 2023com1Document23 pagesCBLM Smaw Ncii 2023com1Marco ArellanoNo ratings yet

- COMMON 1 Apply Safety Practices FINALDocument96 pagesCOMMON 1 Apply Safety Practices FINALJoyLyn Sarmiento AmitNo ratings yet

- 1 Apply Safety PracticesDocument103 pages1 Apply Safety PracticesRobinson ConcordiaNo ratings yet

- CBLM For NezaDocument50 pagesCBLM For NezaManilyn TalingtinganNo ratings yet

- TG Promote Product Services 190312 V2Document334 pagesTG Promote Product Services 190312 V2Phttii phttiiNo ratings yet

- Receive and Store Stock: D2.TGA - CL6.11 Trainee ManualDocument88 pagesReceive and Store Stock: D2.TGA - CL6.11 Trainee ManualPhttii phttiiNo ratings yet