Professional Documents

Culture Documents

TBA 19 Package Check Sheet JM Ad PDF

Uploaded by

Atish Kissoon0 ratings0% found this document useful (0 votes)

54 views3 pagesOriginal Title

TBA 19 Package Check Sheet jm ad pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

54 views3 pagesTBA 19 Package Check Sheet JM Ad PDF

Uploaded by

Atish KissoonCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

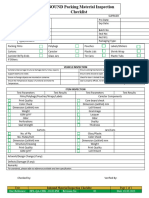

TBA 19 Pack Check Sheet

Details Machine Check Yield Waste Counters Package

Technician Name Date of last production Start: Physical On pallets: Total waste: Monitoring Window

TBA

count of Incoming Package

Production Date Date of last machine report Counter End: Lab Sample: Design Correction:

Packs Packed Counter:

Exiting Package

Product Brand Last prod. machine report good? Conveyor: Reject: Filling System:

Total Counter:

Qty Quantity Last point DE Package

Product Flavour Sterilisation Agent Drop Chute: Packed: Strip Splice:

Reject Counter :

Packages per tray/Unit

Product Volume H2O2 concentration at 34 - 36%? Straw: % Reject Pkgs Mat Splice:

Counter:

Start Time Tab:

CIP Counter Checked by :

Dating Unit Code End Time Manual waste:

Additional Remarks:

Time Start Pre-heating

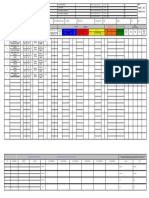

Exp Date TS Flaps LS Package Conductivity

Time Weight/g Remarks Done by

&Production Code Top Bottom Top Bottom Overlap Strip shape/Crease Value

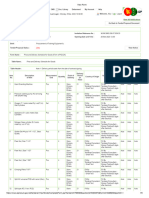

Packages Checks Illustrations

Checks Description Checks Description

Package Forming

1.Flap Sealing and 2. LS Overlap

Crease Lines Unfold the flaps and Check the width of the

check they are LS overlap,

properly sealed distance A

3.Weight 4.Shape and Design Check the shape of the

packages.

Check that the preformed

Weigh the packages. creases in the

Record their weights packaging material are

correctly aligned

along the top crease and

the bottom crease

Transversal Sealing

5.TS (rough) 6. TS - Accurate Check

Cut a sample strip (1) of

about 25 mm in width

Gently squeezing the from the top and bottom

package by hand. transversal seals.

Check the corners, Cut off no more than 1

intersection between mm from each

LS and TS crease side of the package at a

and the crosses 90° angle to the

between TS and LS TS.

meet. The TS must be stretched

and evaluated

along the entire seal.

Longitudinal Sealing

7.LS Strip Applicator check that the LS 8.Red Ink Injection in

strip is positioned Air Gap

40%:60% on one

package Check there

are no blisters in the

heated area. Check This test will determine if

the strip sealing by the package is leaking

slowly pulling underneath the LS-strip

approximately 20

mm of the strip

outwards at an angle

of 90°.

Inside Layers Ruptures

9.Surfaces Check the outside 10.Conductivity Test

and inside surfaces of

This test will determine if

the package for

there is a breakage in the

scratches or other

inner plastic layers of the

possible defects that

packaging material

can be detected with

the eye

Procedures:

1) Take three packages from the conveyor after they have passed the first package counter photocell on the machine

conveyor.

2) Use the same two packages to perform all of the checks that require two packages. The third package is only used

for the LS/SA check.

These checks should be performed on packages at start up and repeated at an interval of 20 mins during production

You might also like

- In Process Staples Quality Check Report.Document2 pagesIn Process Staples Quality Check Report.shiva7821No ratings yet

- Weighing SystemDocument3 pagesWeighing Systemparuliansaut89No ratings yet

- PT Report Form FA17 - SimplifiedDocument2 pagesPT Report Form FA17 - SimplifieddonciriusNo ratings yet

- Form Inspection Report (Pre Final) - 1Document2 pagesForm Inspection Report (Pre Final) - 1wahyu kurniadyNo ratings yet

- Packing List: Ship To: ConsigneeDocument1 pagePacking List: Ship To: Consigneezarul arjunaNo ratings yet

- File 590023120Document1 pageFile 590023120yohanneshaymanot777No ratings yet

- Daily Production ReportDocument4 pagesDaily Production ReportRugadya PaulNo ratings yet

- CraneDocument1 pageCraneRejo AbrahamNo ratings yet

- Draft: Table of ContentsDocument25 pagesDraft: Table of ContentsLeandroSilvaNo ratings yet

- Mechanical Works at Habshan-5 & Habshan Complex Igd-E Project (Phase 1) Package 3Document1 pageMechanical Works at Habshan-5 & Habshan Complex Igd-E Project (Phase 1) Package 3samkarthik47No ratings yet

- Cover and Content of PackageDocument2 pagesCover and Content of Packageคุณพ่อน้อง บิ๊กบอสNo ratings yet

- SGS OGC SAT Example EN 202001Document25 pagesSGS OGC SAT Example EN 202001Sephiwe MafilikaNo ratings yet

- Idabb PSSS: Inspection and Test Record Diesel Generators 1 Katolight Corporation 2Document2 pagesIdabb PSSS: Inspection and Test Record Diesel Generators 1 Katolight Corporation 2nana arya sumardjaNo ratings yet

- CLEARANCE RUDDER (S) - DikonversiDocument8 pagesCLEARANCE RUDDER (S) - DikonversiNoveta FernaldinatanNo ratings yet

- Traverse Reading Testing FormDocument1 pageTraverse Reading Testing FormJHON CHRISTOPHER CENTINONo ratings yet

- Check Point & Out Put DecorationDocument2 pagesCheck Point & Out Put DecorationNas SyahidNo ratings yet

- Field Service Report: Trip Dispatch Arrival at Jobsite Travel Hour Mileage Date Time Date Time 1 2 3Document2 pagesField Service Report: Trip Dispatch Arrival at Jobsite Travel Hour Mileage Date Time Date Time 1 2 3Henny Komala Sari SibaraniNo ratings yet

- Cwpf-Pb-Qa9: Hourly Checks Operators Name: Shift: Date: ASW Code: WO No: Product DescriptionDocument3 pagesCwpf-Pb-Qa9: Hourly Checks Operators Name: Shift: Date: ASW Code: WO No: Product Descriptionhoney loveNo ratings yet

- Smoke Leak Testing FormDocument1 pageSmoke Leak Testing FormJHON CHRISTOPHER CENTINONo ratings yet

- DPT ReportDocument1 pageDPT ReportSaqlain MalikNo ratings yet

- Form QCPC Evap CleanerDocument1 pageForm QCPC Evap Cleanerwilly dwinovNo ratings yet

- Applicant/Consignee: Manufacturer/Seller:: Packing ListDocument6 pagesApplicant/Consignee: Manufacturer/Seller:: Packing ListHasibul Ehsan KhanNo ratings yet

- Concrete Traceability: Ambient TemperatureDocument1 pageConcrete Traceability: Ambient Temperatureum erNo ratings yet

- Instrument Commissioning Checklist PDFDocument9 pagesInstrument Commissioning Checklist PDFBrijesh Srivastav100% (1)

- Instrumentation Switch ChecklistDocument9 pagesInstrumentation Switch Checklistgeorge stanley paceteNo ratings yet

- Formatos CHECKLIST PDFDocument9 pagesFormatos CHECKLIST PDFHarold David Gil MuñozNo ratings yet

- Instrumentation Switch ChecklistDocument9 pagesInstrumentation Switch ChecklistIñaki EseberriNo ratings yet

- Instrument Check List PDFDocument9 pagesInstrument Check List PDFBrijesh Srivastav100% (1)

- Instrumentation Switch ChecklistDocument9 pagesInstrumentation Switch ChecklistAli Mukhtar ShigriNo ratings yet

- 639-2017 - Forms (ITP)Document9 pages639-2017 - Forms (ITP)george stanley paceteNo ratings yet

- Instrument Check List PDFDocument9 pagesInstrument Check List PDFIgor PaivaNo ratings yet

- Dispensing Procedure, JewelDocument24 pagesDispensing Procedure, JewelMd. JewelNo ratings yet

- Steam Control Valve - Pnumatic ValveDocument2 pagesSteam Control Valve - Pnumatic Valvepsonu92No ratings yet

- QAR-QD#419-2 Single PartsDocument2 pagesQAR-QD#419-2 Single PartsIrwanto ManafNo ratings yet

- Surface Preparation & Coating Application RecordDocument2 pagesSurface Preparation & Coating Application RecordANIL PLAMOOTTILNo ratings yet

- Form - PackagingDocument1 pageForm - PackagingAce MiadzNo ratings yet

- Calibration Format ReportDocument3 pagesCalibration Format ReportNugraha Munthe100% (1)

- Water Heater Calculation - PW (XZSGTCTWVFTQWJT)Document3 pagesWater Heater Calculation - PW (XZSGTCTWVFTQWJT)himajcpNo ratings yet

- Pipe Material Received: NO Item Material Description Quantity (PCS) Length (MTR) RemarksDocument13 pagesPipe Material Received: NO Item Material Description Quantity (PCS) Length (MTR) RemarksAlfian ImaduddinNo ratings yet

- Leak Test Valve ReportDocument2 pagesLeak Test Valve Reportadnansh1No ratings yet

- 8D FormatDocument6 pages8D FormatGeorge SubaNo ratings yet

- QC Surveillance Report: As Per P.OrderDocument3 pagesQC Surveillance Report: As Per P.OrderRahul MoottolikandyNo ratings yet

- All Point Measurement Data Comparison Sheet: Measuring Equipment LegendDocument5 pagesAll Point Measurement Data Comparison Sheet: Measuring Equipment LegendJake Floyd G. FabianNo ratings yet

- Job Information: Job No Sheet No RevDocument3 pagesJob Information: Job No Sheet No RevJedidiahClementNo ratings yet

- QA-CHK-01.02 Inbound Packing Material InspectionDocument1 pageQA-CHK-01.02 Inbound Packing Material InspectionYazeen 777No ratings yet

- Saudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Document1 pageSaudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Mohammed Hamed BaganNo ratings yet

- Check Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportDocument1 pageCheck Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportJovianto PrisilaNo ratings yet

- Afinion Maintenance ReportDocument1 pageAfinion Maintenance ReportLabpkm psmNo ratings yet

- GPR ( (53-1) - 2021) GR Code 01ACGSDECATLO000016 (Hydrogen Test)Document1 pageGPR ( (53-1) - 2021) GR Code 01ACGSDECATLO000016 (Hydrogen Test)Ahmed RezkNo ratings yet

- Concrete Casting Inspection Checklist2Document1 pageConcrete Casting Inspection Checklist2Thulani BethuelNo ratings yet

- Property Equipment CardDocument1 pageProperty Equipment CardJune Anthony DobleNo ratings yet

- Kiểm Tra Lắp Ráp Cabinet: Bh Nm Qaqc Ktlr Cabinet Lần BH: 01Document3 pagesKiểm Tra Lắp Ráp Cabinet: Bh Nm Qaqc Ktlr Cabinet Lần BH: 01Kiều Nguyễn Khánh BảoNo ratings yet

- Please State Reason For Break Out Request:: Joint TAG Location Drawing(s) To Be Attached To This CertificateDocument1 pagePlease State Reason For Break Out Request:: Joint TAG Location Drawing(s) To Be Attached To This CertificateRamy HewaitNo ratings yet

- Check List Truck MixerDocument4 pagesCheck List Truck MixeralongNo ratings yet

- Form View: Tender/Proposal DetailDocument5 pagesForm View: Tender/Proposal DetailOvee MurshedNo ratings yet

- Annexure 6 Gim Format (Raw Material) Raw Material Series: Page 1 of 1Document1 pageAnnexure 6 Gim Format (Raw Material) Raw Material Series: Page 1 of 1sandeep sharmaNo ratings yet

- Gim Format Raw MaterialDocument1 pageGim Format Raw Materialatia fawzyNo ratings yet

- LPG Valves and Equipment 2023 24 Rev5.2 WebDocument84 pagesLPG Valves and Equipment 2023 24 Rev5.2 WebNicholas mongute gichanaNo ratings yet

- Caspian Combined Cycle Power Plant ProjectDocument2 pagesCaspian Combined Cycle Power Plant ProjectLipika GayenNo ratings yet

- MSS - FormB - Indicative Procurement Plan - 2017-18Document3 pagesMSS - FormB - Indicative Procurement Plan - 2017-18Atish KissoonNo ratings yet

- Communiqué For Foreign Students Edited 30.11.2020 V2Document1 pageCommuniqué For Foreign Students Edited 30.11.2020 V2Atish KissoonNo ratings yet

- Motaxi Online ApplicationDocument1 pageMotaxi Online ApplicationAtish KissoonNo ratings yet

- Notice To UoM Alumni - CSC Scholarships at BIT 2022-2023Document2 pagesNotice To UoM Alumni - CSC Scholarships at BIT 2022-2023Atish KissoonNo ratings yet

- ANNUAL REPORT ON PERFORMANCE 2016-17 - Min of Social Security and National SolidarityDocument74 pagesANNUAL REPORT ON PERFORMANCE 2016-17 - Min of Social Security and National SolidarityAtish KissoonNo ratings yet

- Protocol For Identification and Reporting of Suspected Cases of COVIDDocument6 pagesProtocol For Identification and Reporting of Suspected Cases of COVIDAtish KissoonNo ratings yet

- Communique - Egypt - 2020-2021Document1 pageCommunique - Egypt - 2020-2021Atish KissoonNo ratings yet

- The Use of Bleach: Guidelines Forcleaning and DisinfectingDocument3 pagesThe Use of Bleach: Guidelines Forcleaning and DisinfectingAtish KissoonNo ratings yet

- Communique PSAC AssessmentDocument1 pageCommunique PSAC AssessmentAtish KissoonNo ratings yet

- Post of Assistant Supervisor OL (Marathi)Document3 pagesPost of Assistant Supervisor OL (Marathi)Atish KissoonNo ratings yet

- Specimen Application Form For A Seat in Grade 10 (2021-22) in An Academy FinalDocument1 pageSpecimen Application Form For A Seat in Grade 10 (2021-22) in An Academy FinalAtish KissoonNo ratings yet

- The Rockefeller and Gates Foundations in Global Health GovernanceDocument22 pagesThe Rockefeller and Gates Foundations in Global Health GovernanceAtish KissoonNo ratings yet

- Ministry of Education, Tertiary Education, Science and Technology Admission To Academies Grade 10 (2021 - 2022) Information For ApplicantsDocument4 pagesMinistry of Education, Tertiary Education, Science and Technology Admission To Academies Grade 10 (2021 - 2022) Information For ApplicantsAtish KissoonNo ratings yet

- Communique Application For A Seat in Academy 13 Feb FinalDocument1 pageCommunique Application For A Seat in Academy 13 Feb FinalAtish KissoonNo ratings yet

- DN0458Document1 pageDN0458Atish KissoonNo ratings yet

- PAIX France Télévisions - CommuniquéDocument1 pagePAIX France Télévisions - CommuniquéAtish KissoonNo ratings yet

- Call For Application MASS2021finalDocument1 pageCall For Application MASS2021finalAtish KissoonNo ratings yet

- The Rockefeller Foundation and The League of Nations: Cooperation in International HealthDocument20 pagesThe Rockefeller Foundation and The League of Nations: Cooperation in International HealthAtish KissoonNo ratings yet

- Flat Earth All Names of Channels Sources Person Giving Information On Flat EarthDocument6 pagesFlat Earth All Names of Channels Sources Person Giving Information On Flat EarthAtish KissoonNo ratings yet

- Human Development Report 2020Document1 pageHuman Development Report 2020Atish KissoonNo ratings yet

- Cedaw C Mar 6 7Document63 pagesCedaw C Mar 6 7Atish KissoonNo ratings yet

- WWW Reformation Org Nikola Tesla Discovered The Dome in 1899 HTMLDocument5 pagesWWW Reformation Org Nikola Tesla Discovered The Dome in 1899 HTMLAtish KissoonNo ratings yet

- Tourism Statistics Year 2016Document9 pagesTourism Statistics Year 2016Atish KissoonNo ratings yet

- Procurement Plan 2021Document2 pagesProcurement Plan 2021Atish KissoonNo ratings yet

- Handbook of Statistical Data On Tourism 2019Document35 pagesHandbook of Statistical Data On Tourism 2019Atish KissoonNo ratings yet

- Tourism Statistics2019Document10 pagesTourism Statistics2019Atish KissoonNo ratings yet

- Ministry of Energy - Re Roadmap 2030 - Final ProofDocument126 pagesMinistry of Energy - Re Roadmap 2030 - Final ProofAtish KissoonNo ratings yet

- Office of DirectorDocument5 pagesOffice of DirectorAtish KissoonNo ratings yet

- Toolpost Attachment For A High Speed Rotary ToolDocument32 pagesToolpost Attachment For A High Speed Rotary Toolkokisko100% (1)

- Science & Cooking: From Haute Cuisine To Soft Matter Science (Chemistry)Document2 pagesScience & Cooking: From Haute Cuisine To Soft Matter Science (Chemistry)Truc TranNo ratings yet

- 24/10/2017. ",, IssnDocument2 pages24/10/2017. ",, IssnMikhailNo ratings yet

- SanternoDocument468 pagesSanternoFrank DicksonNo ratings yet

- Foot AbnormalityDocument23 pagesFoot AbnormalityKezia PaneNo ratings yet

- Modbus RegisterDocument7 pagesModbus RegisterZuniiga AndersonNo ratings yet

- 6-Heat Transfer in Multi Phase Materials PDFDocument460 pages6-Heat Transfer in Multi Phase Materials PDFJoselinaSosaZavalaNo ratings yet

- g12 Module CapacitorsDocument8 pagesg12 Module CapacitorsHarold Vernon MartinezNo ratings yet

- Changes Around Us Science - Class-ViDocument28 pagesChanges Around Us Science - Class-ViAmit SharmaNo ratings yet

- UNIT - 1 Formula and ProcedureDocument4 pagesUNIT - 1 Formula and ProcedurevinothNo ratings yet

- Reviews QuestionsDocument6 pagesReviews QuestionsBerryNo ratings yet

- Cuda GDBDocument64 pagesCuda GDBVinícius LisboaNo ratings yet

- Tutorial 4Document3 pagesTutorial 4chinnu rokzNo ratings yet

- Christie Roadster S+20K Serial CommunicationsDocument87 pagesChristie Roadster S+20K Serial Communicationst_wexNo ratings yet

- BS Iso 21573-1-2014Document32 pagesBS Iso 21573-1-2014Salafi MhmdNo ratings yet

- Finishing EnglDocument49 pagesFinishing EnglSalim NgaosNo ratings yet

- Chapter - 20 3-6-05Document30 pagesChapter - 20 3-6-05samandondonNo ratings yet

- Searox SL 480: Marine Slab 200Document1 pageSearox SL 480: Marine Slab 200sivlag01No ratings yet

- Assignment 2 DCNDocument4 pagesAssignment 2 DCNkainat KhalidNo ratings yet

- Mobile Working Hydraulic System DynamicsDocument107 pagesMobile Working Hydraulic System Dynamicsbr1404100% (1)

- Week 1Document3 pagesWeek 1DELMAR REYES100% (1)

- In Context: Subject Area: Organic Chemistry Level: 14-16 Years (Higher) Topic: Addition Polymers Source: RSC - Li/2GrwsijDocument5 pagesIn Context: Subject Area: Organic Chemistry Level: 14-16 Years (Higher) Topic: Addition Polymers Source: RSC - Li/2GrwsijRajlaxmi JainNo ratings yet

- ISO 3384 2005-Stress RelaxationDocument18 pagesISO 3384 2005-Stress RelaxationshashaNo ratings yet

- SMS CommandDocument51 pagesSMS CommandMẫn Chiếm QuangNo ratings yet

- Motion 2000 Hydraulic v8 42-02-1P20 B7Document248 pagesMotion 2000 Hydraulic v8 42-02-1P20 B7ElputoAmo XD100% (1)

- Intro S4HANA Using Global Bike Case Study CO-CCA en v4.1Document36 pagesIntro S4HANA Using Global Bike Case Study CO-CCA en v4.1jspm3912No ratings yet

- Yagi Antenna Desig 00 Un SeDocument232 pagesYagi Antenna Desig 00 Un Sefrankmhowell100% (1)

- Kenelm Digby On Quantity As Divisibility PDFDocument28 pagesKenelm Digby On Quantity As Divisibility PDFvalexandrescuNo ratings yet

- Elogic Learning Use Case Scenarios TemplateDocument206 pagesElogic Learning Use Case Scenarios TemplatepuuziNo ratings yet

- Math5 Q4 Mod11 OrganizingDataInTabularFormAndPresentingThemInALineGraph V1Document45 pagesMath5 Q4 Mod11 OrganizingDataInTabularFormAndPresentingThemInALineGraph V1ronaldNo ratings yet