Professional Documents

Culture Documents

WHRB Sop

Uploaded by

Mohan BabuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WHRB Sop

Uploaded by

Mohan BabuCopyright:

Available Formats

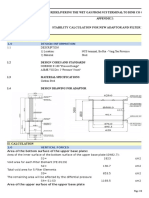

THERMAX LIMITED POWER DIVISION

O&M site Document title Revision Page no

!L"# Si$o%i# Raast%an Standard Operating ' (

Procedure 1x15 MW Power

Plant

STANDARD OPERATING PROCEDURE

FOR 1X 15 MW POWER PLANT WITH 5 NO. WHRB

AT JK LAKHSMI CEMENT,

SIROHI

The plant has 6 boilers operating on the waste heat from the Cement Kiln.

1. 3 Nos

Nos.. PH

PH B

Boi

oile

lers

rs heate

heated

db by

y the

the exi

exitt gas

gases

es from

from th

the

e pre

prehea

heate

terr il

ilns

ns 1!"!

1!"!3

3

". 3 Nos

Nos.. #$C

#$C Boi

Boile

lers

rs heate

heated

d by

by exi

exitt gas

gases

es from

from %rat

%rate

e Cool

Cooler

er Ki

Kiln

lns

s 1!"

1!"

PH &1 1".'(' TPH

PH ) " "3.* TPH

PH ) 3 "1.+6' TPH

#$C&1# ,.3,* TPH

#$C&1B 6.' TPH

#$C&" 1*.""* TPH

T-rbine iemens mae 1'/0

%enerator TP mae 1'/0

P$e)a$e* +,- T%e$ma. limite* Po/e$ Division

THERMAX LIMITED POWER DIVISION

O&M site Document title Revision Page no

!L"# Si$o%i# Raast%an Standard Operating ' 0

Procedure 1x15 MW Power

Plant

STANDARD PROCEDURE

FOR

DAMPER OPERATION

DAMPER OPERATION

OPERATION DURING WHRB START UP

2ns-re that waste heat gas is aailable at re4-ired temperat-re with

re4-ired 4-antity.

0H5B by pass damper is open.

Boiler dr-m leel is maintained at operating leel '*78

5e9ir9-lation p-mp is in operation and re9ir9-lation flow is established at

re4-isite al-e

The gas :!; damper are open 9lose type whereas the bypass damper will

be reg-lating type and 9ontrolled by CPP;C. The /otori<ed ampers also

hae end portion limit swit9hes whi9h indi9ate open!9lose position of

dampers.

%as bypass damper will be opened!9losed step by step and 9ontrolled by

CPP;C.

:n9rease in 0H5B inlet gas temperat-re and draft a9ross boiler will ens-re

the fl-e gas flow thro-gh 0H5B.

Che9 boiler inlet fl-e

fl-e gas parameter lie

lie fl-e gas temperat-re = draft.

P$e)a$e* +,- T%e$ma. limite* Po/e$ Division

THERMAX LIMITED POWER DIVISION

O&M site Document title Revision Page no

!L"# Si$o%i# Raast%an Standard Operating ' 1

Procedure 1x15 MW Power

Plant

STANDARD START UP AND SHUT DOWN PROCEDURE

PROCEDURE FOR WHRB

1X 15 MW WHRB BASE POWER PLANT

START UP OF WHRB

1. 2ns

2ns-r

-re

e th

that

Normal operating leel of water is maintained in boiler.

#ll the ents are open.

#ll the boiler drains are 9losed

tart -p ent is f-lly open.

>l-e gas is aailable with re4-isite temperat-re and flowing thro-gh

the 0H5B bye& pass line

5e9ir9-lation p-mp is in operation and re9ir9-lation

r e9ir9-lation flow is established

at re4-isite al-e.

Hammering system of PH Boilers is in operating 9ondition. Before

operating the hammering system ens-re that all the hammers are free

to rotate.

". tart CC?s

CC?s and 5#@?s

5#@?s of the

the 9orresponding

9orresponding boiler

boiler and obsere

obsere that

that Boiler

Boiler

AN Permissie is generated. #lso ens-re the Boiler is not tripped. Hen9e

the damper operation will start a-tomati9ally.

3. #fter Boiler

Boiler AN Permissi

Permissie

e the damper

damper operation

operation is as

as follows

follows

a8 0H5B fl-e gas iinlet

nlet damper will be opened.

opened.

b8 0H5B

0H5B o-tlet

o-tlet damp

damper

er will

will be o

open

pened.

ed.

98 Close

Close Bypass

Bypass damper

damper is steps

steps

,. Absere

Absere that amper

amper %ro

%ro-p

-p 5eady signal

signal is generated

generated on C

C -pon

s-99essf-l 9ompletion of damper operation.

'. #s the bypass

bypass damper

damper is partially

partially 9losed

9losed gas

gas starts

starts flowi

flowing

ng thro-gh

thro-gh

0H5B.

6. Control

Control the gas flow thro-gh

thro-gh 0H5B

0H5B by 9losing

9losing step

step wise8

wise8 bypass

bypass damper

damper

in s-9h a way that in9rease in /ain

/ain steam temperat-re does not in9rease

more that 3 deg C per min-te.

(. ee that

that 0H5B

0H5B star

starts

ts stea

steamin

ming.

g.

P$e)a$e* +,- T%e$ma. limite* Po/e$ Division

THERMAX LIMITED POWER DIVISION

O&M site Document title Revision Page no

!L"# Si$o%i# Raast%an Standard Operating ' 2

Procedure 1x15 MW Power

Plant

+. Close ents at dr-m press-re at " g!9m".

. tart one B>P if re4-ired and maintain dr-m leel

1*. Charge /ain steam line at 1" to 1, g!9m" and temp at 3** deg C if 1st

boiler is started8.

started8. Apen the main steam line when normal operating press-re

and temp are a9hieed for 9onne9ting with the main steam header.

11. %rad-ally 9lose bye&pass damper and 9lose start -p ents f-lly as steam

demand is in9reased.

1". tart HP = ;P dosing p-mp.

SHUT DOWN PROCEDURE OF WHRB

>ollow below mentioned steps for stopping of 0H5B

1. :nform DK;C 9ontrol

9ontrol room

room for

for stoppa

stoppage

ge of 0H5B

". lowly

lowly operate

operate bypass

bypass damper

damper for by passin

passing

g fl-e gas from 0H5B

3. Absere

Absere that

that steam

steam generation

generation is de9reas

de9reasing

ing

,. 5ed-

5ed-9e

9e loa

load

d iin

n T%

T%

'. An9e steam generation

generation be9omes

be9omes <ero

<ero 9lose

9lose /@

6. Apen bypas

bypass

s damp

damper

er f-lly.

f-lly.

(. Close fl-e

fl-e gas o-tlet

o-tlet damper a

and

nd s-bse4-en

s-bse4-ently

tly 9lose

9lose inlet

inlet damper

damper

+. /a

/ain

inta

tain

in dr

dr-m

-m lee

leell

. Kee

Keep

p 5C p-m

p-mp

p operati

operation

on for ff-rt

-rther

her on

one

e 1 hr.

1*. top hammering system after 1 hr of stoppage of boiler

1*. top HP dosing

dosing p-mp

P$e)a$e* +,- T%e$ma. limite* Po/e$ Division

THERMAX LIMITED POWER DIVISION

O&M site Document title Revision Page no

!L"# Si$o%i# Raast%an Standard Operating ' 3

Procedure 1x15 MW Power

Plant

STANDARD START UP AND SHUT DOWN

PROCEDURE FOR

TOTAL POWER PLANT

START UP PROCEDURE OF POWER PLANT

.

>ollow below mentioned

mentioned steps for start -p of power plant.

1. P-t tt-rb

-rbine

ine on Barr

Barring

ing gear

gear by star

startin

ting

g #AP

". tart C2P on re9ir9-lati

re9ir9-lation

on mod

mode

e and maint

maintain

ain CT leel.

3. tart PH" and

and #$C"

#$C" as per start

start pro9ed-

pro9ed-re

re of 0H5B

,. Charge steam

steam line

line and heat

heat -p line

line -p to t-

t-rbine

rbine inlet

inlet by opening

opening warm

warm -p

ent line and drain lines.

'. P-ll a9--m

a9--m in

in 9ondenser

9ondenser by tain

taing

g hogger eEe9tor

eEe9tor first

first and m

mainta

aintain

in

a9--m by taing seri9e eEe9tor in line.

6. An9e re4-isi

re4-isite

te temperat-re

temperat-re 3", deg C8 is a9hieed

a9hieed roll the

the t-rbine

t-rbine as

per t-rbine start-p pro9ed-re.

(. 0hile steam

steam line

line is 9harged

9harged with

with the steam

steam from

from PH an

and

d #$C boilers

boilers

mae ready to start other 0H5B . Please

Please note that with only PH1 and

AQC1 alone, turbine can not be loaded. So it is advisable tto

o have at

turbine 8

least one more WHRB ready beore synchroni!in" the turbine8

+. yn

yn9hr

9hroni

oni<e

<e T% with

with two

two 0H5

0H5B?s

B?s in

in line.

line.

. %ra

%rad-a

d-ally

lly in9rea

in9rease

se load

load in

in T

T%.

%.

1*. tart 9ooling tower fans as per re4-irement.

11. -bse4-ently tae other 0H5B in line one by one.

1". tabili<e the power plant and note down all the parameter.

P$e)a$e* +,- T%e$ma. limite* Po/e$ Division

THERMAX LIMITED POWER DIVISION

O&M site Document title Revision Page no

!L"# Si$o%i# Raast%an Standard Operating ' 4

Procedure 1x15 MW Power

Plant

SHUT DOWN PROCEDURE OF POWER PLANT

>ollow below mentioned steps for taing sh-t down of power plant

1. Tae sh-t

sh-t down of

of 0H5B as

as per standar

standard

d pro9ed-re

pro9ed-re of 0H5B

0H5B sh-t d

down.

own.

-ring sh-t down red-9e load and maintain t-rbine inlet steam press-re.

". -bse4-entl

-bse4-ently

y tae sh-t

sh-t down of

of other 0H5B

0H5B one by one followi

following

ng aboe

mentioned step.

3. #99ordingly

#99ordingly red

red-9e

-9e load

load to T%. -ring

-ring red-9tio

red-9tion

n of load maintain

maintain steam

steam

press-re by opening start -p ents of 0H5Bs.

,. Ap

Apen

en gen

genera

erato

torr brea

breae

er.

r.

'. 2ns-re that l-be oil press-re

press-re is maintained.

maintained.

6. 2ns-re barring

barring gear a-to start at 1'*rpm speed of T%.

(. Kee

Keep

p C2P in o

oper

perati

ation

on fo

forr another

another one

one ho-r.

ho-r.

+. Keep T%

T% on barring

barring gear till

till the bearing

bearing tem

temperat-

perat-re

re is aro-nd

aro-nd ,* deg C.

C.

P$e)a$e* +,- T%e$ma. limite* Po/e$ Division

THERMAX LIMITED POWER DIVISION

O&M site Document title Revision Page no

!L"# Si$o%i# Raast%an Standard Operating ' 5

Procedure 1x15 MW Power

Plant

EMERGENCIES

IN

1X 15 MW WHRB BASE POWER PLANT

P$e)a$e* +,- T%e$ma. limite* Po/e$ Division

THERMAX LIMITED POWER DIVISION

O&M site Document title Revision Page no

!L"# Si$o%i# Raast%an Standard Operating ' 6

Procedure 1x15 MW Power

Plant

EMERGENCIES IN 15 MW POWER PLANT

>ollowing emergen9ies are enisaged d-ring operation of 1' /0 power plant.

1. Stu

Stuck

ck u

u

!" F#u

F#u$

$ %&

%&'

' (&)$

(&)$*.

*.

+. T*

T*

-%

-% !" R$

R$c*

c*cu#

cu#&t

&t!-

!- u)

u).

.

. T*

T*

-%

-% !" B!

B!#$*

#$* "$$(

"$$( u).

u).

/. S0$&*-%

S0$&*-% !" D*&% c0&-

c0&- c!-$

c!-$2!*

2!* S0$&*

S0$&* -.

5. I-c*$&'$

I-c*$&'$ - "#u$

"#u$ %&' t$)$

t$)$*&tu*

*&tu*$

$ 3$2!-(

3$2!-( /44 ($%

($% C.

. T*

T*

-%

-% !" &'0 Sc*

Sc*$6

$67P&

7P&-

- c!-$2

c!-$2!*.

!*.

8. T*

T*

-%

-% 7 't!

't!&

&%$

%$ !" WHR

WHR B!#$

B!#$*'.

*'.

9. T*

T*

-%

-% !" k

k#-

#-

:. T*-%

T*-% !" tu*3-

tu*3-$

$ &-( &## WHRB'

WHRB' &*

&*$

$ - '

'$*

$*c$.

c$.

P$e)a$e* +,- T%e$ma. limite* Po/e$ Division

THERMAX LIMITED POWER DIVISION

O&M site Document title Revision Page no

!L"# Si$o%i# Raast%an Standard Operating ' 7

Procedure 1x15 MW Power

Plant

1. Stuck u !" F#u$ %&' (&)$*

Tae following a9tions while fl-e gas damper!s are st-9 -p

Aperate damper man-ally as per se4-en9e mentioned in D&)$*

O$*&t!- P*!c$(u*$

Boiler 9an be ept in operation een by operating the dampers man-ally.

-ring sh-t down please stop! 9lose damper as per the se4-en9e

mentioned in damper operation pro9ed-re.

+. T*-% !" R$c*cu#&t!-

R$c*cu#&t!- u).

Tae following a9tions are to be taen while 5e9ir9-lation p-mp trips

5C p-mp shall trip on low dr-m leel and ele9tri9al fa-lt.

:f the p-mp trips on ele9tri9al fa-lt restart stand by p-mp. Normal

dr-m leel ens-res that 5C p-mp tripped on ele9tri9al fa-lt8

:f there is low dr-m leel try to maintain dr-m leel as early as possible.

:f dr-m leel 9an not be maintained within 1* min-tes by pass fl-e gas to

tae sh-t down of the boiler.

-ring bypassing the se4-en9e of damper operation shall be as per the

damper operating pro9ed-re.

. T*-% !" B!#$*

B!#$* "$$( u)

Boiler feed p-mp may trip d-e to low deaerator leel or d-e to any ele9tri9al

fa-lt

:f B>P trips on ele9tri9al fa-lt start stand by B>P immediately within '

min-tes8.

:f stand by 9an not be started d-e to any reason follow the steps to tae sh-t

down of all the boilers

Apen fl-e gas by pass damper.

Close 0H5B o-tlet damper.

Close inlet damper.

P$e)a$e* +,- T%e$ma. limite* Po/e$ Division

THERMAX LIMITED POWER DIVISION

O&M site Document title Revision Page no

!L"# Si$o%i# Raast%an Standard Operating ' ('

Procedure 1x15 MW Power

Plant

:solate main steam line ales.

/. S0$&*-% !" D*&% c0&- S0$&* -

:nform Cement plant 9ontrol room.

tart by passing fl-e gas and a99ordingly red-9e load in T%.

An9e fl-e gas is totally by passed repla9e shear pin.

An9e the rag 9hain feeder is operatable start taing fl-e gas in 0H5B as

per 0H5B start -p pro9ed-re.

:n9rease load in T%.

5. I-c*$&'$ - "#u$ %&' t$)$*&tu*$ 3$2!-( /44 ($% C

By in9reasing fl-e gas temperat-re / temp will in9rease beyond 3"' deg C.

Apen by pass damper partially and see that /ain steam temperat-re is

-nder 9ontrol and 0H5B steam generation has red-9ed.

e9rease T% load.

:nform DK;C 9ontrol room.

An9e >l-e gas temp is within ,** deg C grad-ally 9lose the by pass

damper.

ee that boiler load has again in9reased in9rease T% load and normali<e.

. T*-% !" &'0 'c*$6 c!-$2!*

:nform DK;C 9ontrol room as maintenan9e of s9rew!pan 9oneyor is in

9-stomer?s s9ope.

:> the same is not attended within 1* min-tes by pass fl-e gas from

0H5B following the damper operating se4-en9e.

8. T*-% 7 't!&%$ !" WHRB

:nform DK;C 9ontrol room and grad-ally de9rease load in T%.

2ns-re that 0H5B fl-e gas by passing has been done as per damper

operation pro9ed-re.

P$e)a$e* +,- T%e$ma. limite* Po/e$ Division

THERMAX LIMITED POWER DIVISION

O&M site Document title Revision Page no

!L"# Si$o%i# Raast%an Standard Operating ' ((

Procedure 1x15 MW Power

Plant

9. T*-% !" k#-

An9e iln is tripped! stopped 9orresponding Boiler is re4-ired to be

stopped.

top the Boiler as per Boiler h-t down pro9ed-re mentioned aboe.

5ed-9e T% load grad-ally. #t 1.' /0 load open the generator breaer.

top t-rbine as per normal sh-t down pro9ed-re.

:. T*-% !" tu*3-$ &-( &## WHRB'

WHRB' &*$ - '$*c$

'$*c$

/aintain dr-m press-re by opening start -p ents of all the 0H5B

:nform DK;C 9ontrol room.

By pass fl-e gas from 0H5Bs one by one

Tae sh-t down of all 0H5Bs one by one as per sh-t down pro9ed-re.

/aintain dr-m leel all the time.

P$e)a$e* +,- T%e$ma. limite* Po/e$ Division

THERMAX LIMITED POWER DIVISION

O&M site Document title Revision Page no

!L"# Si$o%i# Raast%an Standard Operating ' (0

Procedure 1x15 MW Power

Plant

D!' AND D!-;t'

FOR

1X 15 MW WHRB BASE POWER PLANT

IMPORTANT D!' AND D!-;t' DURING PLANT OPERATION

OPERATION

D!'

1. %o thro-gh

thro-gh all APs

APs in detai

details

ls and eep

eep se4-en9e

se4-en9e of dampers

dampers operat

operation

ion in

mind.

". o as in

in 9ase

9ase of any do-bts

do-bts to

to yo-r seniors

seniors before

before any

any operation.

operation.

3. o note all

all parameter

parameter of 0H5Bs and

and T% areas

areas on reg-la

reg-larr basis.

basis.

,. o tae

tae safety

safety meas-res

meas-res while worin

woring

g in power

power plant.

plant.

D!-;t'

1. o not 9arry

9arry o-t

o-t any of the

the operation

operation in

in h-rry and

and with o-t -nderstandi

-nderstanding

ng

the reason for operation.

". o not do any mainte

maintenan9

nan9e

e a9tiities

a9tiities witho-t

witho-t 0or permit

permit an

and

d informing

informing

DK;C CC5.

3. o not allow

allow any

any -na-thori<e

-na-thori<ed

d person to

to perform

perform plan

plantt operations

operations from

from

C.

,. o not by pass any

any prote9tion

prote9tion and

and interlo9

interlo9 of the power

power plant

plant

'. o no

nott hesitat

hesitate

e to as in

in 9ase

9ase of do-bts

do-bts..

P$e)a$e* +,- T%e$ma. limite* Po/e$ Division

THERMAX LIMITED POWER DIVISION

O&M site Document title Revision Page no

!L"# Si$o%i# Raast%an Standard Operating ' (1

Procedure 1x15 MW Power

Plant

STEAM T8R9INE :ENERA

:ENERATOR

TOR ; (NO< =>REE

=>REE S8PPL

S8PPL?# ERE"TION

ERE"TION AND

"OMMISSIONIN: 9? "8STOMER@

Parameter Unit Value

Power at generator terminal (Approx) kW 15000

Main Steam Pressure at Turbine inlet Ata 15

Main Steam Temperature at Turbine inlet °C 324.3

Main S

Stteam l

low a

att Turbine in

inlet iin

n!lu"ing au

auxiliaries TP# 72

$x%aust steam Pressure Ata 0.2

Cooling water &nlet Temperature °C 33

Cooling water outlet Temperature °C 42

P$e)a$e* +,- T%e$ma. limite* Po/e$ Division

You might also like

- Aarti Steel WHR PDDDocument34 pagesAarti Steel WHR PDDKvvPrasadNo ratings yet

- Deh Governing-LancoDocument35 pagesDeh Governing-LancoPRAMOD KUMAR NANDANo ratings yet

- My Latest CV - EngineerDocument3 pagesMy Latest CV - EngineersasibhushanNo ratings yet

- Gopal Prasad Yadav: Career SummaryDocument2 pagesGopal Prasad Yadav: Career SummaryAnonymous ZSol6ZOHIpNo ratings yet

- Equipment Changeover Practice ProposedDocument2 pagesEquipment Changeover Practice ProposedRakesh MishraNo ratings yet

- Calibration Procedure For BFP-T Turbine Rotor Expansion SensorDocument9 pagesCalibration Procedure For BFP-T Turbine Rotor Expansion Sensornaresh977977No ratings yet

- Pulkit PPT Steam Turbine3Document42 pagesPulkit PPT Steam Turbine3Abhishek KumarNo ratings yet

- Boiler ConstructionDocument4 pagesBoiler ConstructionrpshvjuNo ratings yet

- CCTV Locations For 2 X 520 MW, IPP, HNPCL, Vishakhapatnam: BTG Unit-1Document7 pagesCCTV Locations For 2 X 520 MW, IPP, HNPCL, Vishakhapatnam: BTG Unit-1Rupesh SinhaNo ratings yet

- 6.6 KV Switchgear Charging & IsolationDocument12 pages6.6 KV Switchgear Charging & IsolationSreekanthMylavarapuNo ratings yet

- Enmas India Private Limited: (SMC Power Generation LTD Unit 2)Document3 pagesEnmas India Private Limited: (SMC Power Generation LTD Unit 2)Sachin nandgayeNo ratings yet

- BTLD Presentation 2Document23 pagesBTLD Presentation 2Yos Wita SantosoNo ratings yet

- Axial Shift Sensors (Thurst Bearing) : Model No. Axial Shift - 1 Sr. No. Axial Shift - 2 Sr. No. Axial Shift - 3 Sr. NoDocument3 pagesAxial Shift Sensors (Thurst Bearing) : Model No. Axial Shift - 1 Sr. No. Axial Shift - 2 Sr. No. Axial Shift - 3 Sr. NoShiva KotamrajuNo ratings yet

- U6OHREPORT2008Document89 pagesU6OHREPORT2008Anonymous pKsr5vNo ratings yet

- Protection & InterlocksDocument18 pagesProtection & InterlocksSanjay GuptaNo ratings yet

- Super-Critical BoilerDocument67 pagesSuper-Critical BoilerPrakash PatelNo ratings yet

- Dec 09Document35 pagesDec 09Krishnan SanthanarajNo ratings yet

- Sesi-Tspl-Opn-Sop-Btg-001 (Idf)Document14 pagesSesi-Tspl-Opn-Sop-Btg-001 (Idf)shubham vermaNo ratings yet

- TESTDocument244 pagesTESTvenkateshbitraNo ratings yet

- SOP HP HeatersDocument1 pageSOP HP HeatersShailenderNo ratings yet

- HR 1 - 2008Document1,642 pagesHR 1 - 2008Jay Rameshbhai ParikhNo ratings yet

- Standard Quality Plan: Conforming To Code: Is 8183Document4 pagesStandard Quality Plan: Conforming To Code: Is 8183jagan100% (1)

- Thermax Combloc Multi Fuel Compact 1500 6000 KG Steam BoilerDocument2 pagesThermax Combloc Multi Fuel Compact 1500 6000 KG Steam BoilerPRABA KARAN100% (1)

- ABB 500 MW Steam TurbineDocument11 pagesABB 500 MW Steam TurbineRama Ranjan Samantaray100% (1)

- 500mw Checking and Setting of Hydraulic and ElectroDocument15 pages500mw Checking and Setting of Hydraulic and Electrothangarajm1984No ratings yet

- Operation Results of IHI Flue Gas Desulfurization System - Unit No.1 (1000 MW) of Hitachinaka Thermal Power Station For TEPCODocument5 pagesOperation Results of IHI Flue Gas Desulfurization System - Unit No.1 (1000 MW) of Hitachinaka Thermal Power Station For TEPCODaniel DubeNo ratings yet

- Lalitpur Superthermal Power Project - 3 X 660 MWDocument10 pagesLalitpur Superthermal Power Project - 3 X 660 MWpramod_nandaNo ratings yet

- WHRB Interlocks: S. No Boiler Equipment Logic For InterlocksDocument2 pagesWHRB Interlocks: S. No Boiler Equipment Logic For InterlocksAmeer MeerNo ratings yet

- Steam and Water Flow Circuit: Talwandi Sabo Power Limited 3 660Mw ProjectDocument2 pagesSteam and Water Flow Circuit: Talwandi Sabo Power Limited 3 660Mw ProjectHemantNo ratings yet

- 2 X 115 TPH CFBC Boiler: Ultratech Cement Limited - Apcw TadipatriDocument51 pages2 X 115 TPH CFBC Boiler: Ultratech Cement Limited - Apcw TadipatriChanna BasavaNo ratings yet

- O & M Manual Ut-13000 - Dalmia DSP Unit-1Document62 pagesO & M Manual Ut-13000 - Dalmia DSP Unit-1ranjan shiveshNo ratings yet

- B-Asic of Super Critical Boiler (660mw)Document48 pagesB-Asic of Super Critical Boiler (660mw)Arvind Shukla100% (1)

- Dokumen - Tips Coordinated Master Control in Thermal Power PlantDocument40 pagesDokumen - Tips Coordinated Master Control in Thermal Power Plant150819850No ratings yet

- Sop For HTmotor PDFDocument4 pagesSop For HTmotor PDFSunny Biswal100% (1)

- 57-62 1m809 - Eng72dpiDocument6 pages57-62 1m809 - Eng72dpiAbhinav TewariNo ratings yet

- 2 HP WTR Hdr-Seal Trough FlushingDocument10 pages2 HP WTR Hdr-Seal Trough Flushingsekhar_ntpcNo ratings yet

- Valve Inspection ChecklistDocument1 pageValve Inspection ChecklistTengku Mohd ImranNo ratings yet

- The Steam Turbine: 7.3.3 Rotor BalancingDocument2 pagesThe Steam Turbine: 7.3.3 Rotor BalancingBhavana KewlaniNo ratings yet

- Bhel Pipe Color Code-Aa10630 1Document7 pagesBhel Pipe Color Code-Aa10630 1Vamsikrishna LakamsaniNo ratings yet

- 660mw Boiler Steam and Water Flow CircuitDocument2 pages660mw Boiler Steam and Water Flow CircuitSenthil KumarNo ratings yet

- CW, CWR & CWX Pumps Installation, Operation and Maintenance ManualDocument20 pagesCW, CWR & CWX Pumps Installation, Operation and Maintenance ManualNadeemNo ratings yet

- First Fill Bed Material Calculation For Bed Plate W DDocument3 pagesFirst Fill Bed Material Calculation For Bed Plate W DRAJKUMARNo ratings yet

- List of Part-3Document2,000 pagesList of Part-3Gỗ Mộc100% (1)

- DH3-31MA-T-SCT-0018 Commissioning Procedure of Varying Load of Turbine-Generator REV.0ADocument6 pagesDH3-31MA-T-SCT-0018 Commissioning Procedure of Varying Load of Turbine-Generator REV.0AhungNo ratings yet

- Deh System CommissioningDocument11 pagesDeh System Commissioningdreamboy87No ratings yet

- Familiarisation of PP-3 Power PlantsDocument11 pagesFamiliarisation of PP-3 Power PlantsPushpendra Mishra100% (1)

- Scanner Air FanDocument3 pagesScanner Air FanSamNo ratings yet

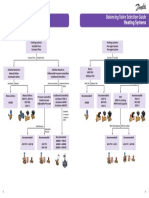

- BalancingValve Selection Guide PDFDocument1 pageBalancingValve Selection Guide PDFsahirprojectsNo ratings yet

- Dehydration and Combined Cycle Power Plant of 50 MMSCFD Low BTU Natural GasDocument42 pagesDehydration and Combined Cycle Power Plant of 50 MMSCFD Low BTU Natural GasShaikh BilalNo ratings yet

- Black Out Is Land OperationDocument41 pagesBlack Out Is Land Operationstubborn002No ratings yet

- LP Turbine Assembly ProcedureDocument8 pagesLP Turbine Assembly Procedurebhushanbharat_843298No ratings yet

- Presentation ON Cerc Discussion Paper On Terms & Conditions of Tariff Applicable FROM 01.04.2004Document74 pagesPresentation ON Cerc Discussion Paper On Terms & Conditions of Tariff Applicable FROM 01.04.2004Mohit MalikNo ratings yet

- Sop For LP PumpDocument5 pagesSop For LP PumpSonratNo ratings yet

- Thermal Power PlantDocument13 pagesThermal Power PlantSanat KumarNo ratings yet

- SOP For BFPDocument2 pagesSOP For BFPsambhuNo ratings yet

- Turbine Stress EvaluationDocument24 pagesTurbine Stress EvaluationBrahma Dutt100% (1)

- Generator Turbine Shutdown ProcedureDocument3 pagesGenerator Turbine Shutdown ProcedureAfifexNo ratings yet

- Bhel Block 3 Turbine FileDocument35 pagesBhel Block 3 Turbine Filerajdeep6panchalNo ratings yet

- PDF Condenser DLDocument72 pagesPDF Condenser DLboeiniNo ratings yet

- PDF 01 Heat Loss in Bare Finned Amp Lagged Pipes DLDocument17 pagesPDF 01 Heat Loss in Bare Finned Amp Lagged Pipes DLBharat SharmaNo ratings yet

- .. Na NaDocument2 pages.. Na NaMohan BabuNo ratings yet

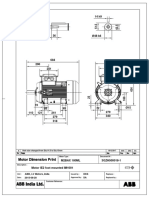

- Gad 30KW 2P Ie2Document1 pageGad 30KW 2P Ie2Mohan BabuNo ratings yet

- Gad 18.5KW 4P Ie2Document1 pageGad 18.5KW 4P Ie2Mohan BabuNo ratings yet

- M2BAX 160ML (Short) Motor IE2 Foot Mounted IM1001 3GZH500016-1Document1 pageM2BAX 160ML (Short) Motor IE2 Foot Mounted IM1001 3GZH500016-1Mohan BabuNo ratings yet

- DOT Pipeline RepairsDocument18 pagesDOT Pipeline RepairsSeng HeangNo ratings yet

- Wire AbbreviationsDocument6 pagesWire Abbreviationssarat chandNo ratings yet

- Dorma: Structural SolutionsDocument20 pagesDorma: Structural Solutionspraveen0907No ratings yet

- POLYLAC® PA-765: Page 1 of 3 "POLYLAC®" PA-765 Data Provided by IDESDocument3 pagesPOLYLAC® PA-765: Page 1 of 3 "POLYLAC®" PA-765 Data Provided by IDESPhuoc Thinh TruongNo ratings yet

- Acceptance Criteria of ConcreteDocument26 pagesAcceptance Criteria of ConcretevempadareddyNo ratings yet

- En 13941 OriginalDocument112 pagesEn 13941 Originalboban njagulovićNo ratings yet

- ScrubberDocument3 pagesScrubberabdulsalam alqhtaniNo ratings yet

- MaterialData 7754Document2 pagesMaterialData 7754Joko TriwardonoNo ratings yet

- 4325e Contoil VzoDocument28 pages4325e Contoil VzoChristian Believers' Assembly BorivaliNo ratings yet

- PowerPoint Sample: BioDiesel Production Power Point PresentationDocument16 pagesPowerPoint Sample: BioDiesel Production Power Point PresentationJohn MelendezNo ratings yet

- GRP Pipe Socket JointDocument80 pagesGRP Pipe Socket JointMAGUNAM100% (1)

- Dr. Kirti Chandra Sahu Department of Chemical Engineering IIT HyderabadDocument15 pagesDr. Kirti Chandra Sahu Department of Chemical Engineering IIT HyderabadAnonymous P7J7V4No ratings yet

- Sipcot RanipetDocument18 pagesSipcot RanipetTamil Selvam79% (42)

- Pond Accessories Price Catalog 2015Document8 pagesPond Accessories Price Catalog 2015Relu MititeluNo ratings yet

- Q150 R Plus Brochure V1Document4 pagesQ150 R Plus Brochure V1toansNo ratings yet

- Self-Operated Temperature Regulators Temperature Regulator Type 1Document6 pagesSelf-Operated Temperature Regulators Temperature Regulator Type 1Pocola AdrianNo ratings yet

- Carborundum Universal Ltd. (CUMI) : HistoryDocument3 pagesCarborundum Universal Ltd. (CUMI) : HistoryNavjot SidhuNo ratings yet

- EasyShrink® 20 OPERATING INSTRUCTIONS SHRINKFITDocument62 pagesEasyShrink® 20 OPERATING INSTRUCTIONS SHRINKFITBasarabeanu50% (2)

- STADIUM EstimateDocument13 pagesSTADIUM EstimateRajeswari Ramakrishnan100% (1)

- Assignment: Submitted by R.Deepa 116011001503 Ii Yr / Iv SemDocument6 pagesAssignment: Submitted by R.Deepa 116011001503 Ii Yr / Iv SemR. Deepa - ANo ratings yet

- Box Culverts - Humes BookletDocument17 pagesBox Culverts - Humes BookletScott Downs100% (3)

- Ijms 23 12652 v2Document12 pagesIjms 23 12652 v2Deym GómezNo ratings yet

- Calculation SpreadSheetDocument8 pagesCalculation SpreadSheetSally LuciaNo ratings yet

- C3Document18 pagesC3Nick LeeNo ratings yet

- Mastertop TC 405 W PDFDocument3 pagesMastertop TC 405 W PDFFrancois-No ratings yet

- Rhinotuff CanvasDocument8 pagesRhinotuff CanvasRhinotuff CanvasNo ratings yet

- White Paper ThermographyDocument3 pagesWhite Paper ThermographyKarthik Mandya100% (1)

- Che2060 Distillation of Wine s16Document5 pagesChe2060 Distillation of Wine s16Aaliyah MohamedNo ratings yet

- Catalog - Small FUEL & OIL DRAIN VALVESDocument5 pagesCatalog - Small FUEL & OIL DRAIN VALVESJessie O.Bechayda100% (1)

- What Every Engineer Should Know About Welding 2Document5 pagesWhat Every Engineer Should Know About Welding 2Sanjay BhootakaNo ratings yet