Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

25 viewsData Sheet P-0560 - Hot Oil Drain Tank Sump Pump PDF

Data Sheet P-0560 - Hot Oil Drain Tank Sump Pump PDF

Uploaded by

cygnus marine panamaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Data Sheet WB RU VDocument5 pagesData Sheet WB RU VMaharani Putri IndrianurNo ratings yet

- PVV Cal Sheet LabixDocument45 pagesPVV Cal Sheet LabixPranpath Narupantawart50% (2)

- Tank Thickness Calculation: Is 2825 S.No Description Unit Value InputDocument10 pagesTank Thickness Calculation: Is 2825 S.No Description Unit Value InputdineshNo ratings yet

- TEMA Sheet Heat Exchanger Specification SheetDocument3 pagesTEMA Sheet Heat Exchanger Specification SheetSonNguyen100% (1)

- PSV Tag No. 10A1 Set Pressure Loop Considered Calculation Reference C-22 and HX-27 API-521, 5TH EDITION, MARCH 2007Document7 pagesPSV Tag No. 10A1 Set Pressure Loop Considered Calculation Reference C-22 and HX-27 API-521, 5TH EDITION, MARCH 2007ktejankarNo ratings yet

- PR1978 Workbook July-24-2017Document1,085 pagesPR1978 Workbook July-24-2017rewqNo ratings yet

- 32-SAMSS-007 Manufacture of Heat ExchangerDocument39 pages32-SAMSS-007 Manufacture of Heat ExchangerAwais Jamil50% (2)

- AYC CHECKLIST PAINTING Rev.01Document3 pagesAYC CHECKLIST PAINTING Rev.01moytabura96No ratings yet

- Sullair ES-8 Air Compressor Operation, Maintenance, TroubleshootingDocument74 pagesSullair ES-8 Air Compressor Operation, Maintenance, TroubleshootingElvis100% (4)

- CN5191 - L2 - A1-Centrifugal Pump Process Data SheetDocument1 pageCN5191 - L2 - A1-Centrifugal Pump Process Data SheetMochi CumilinaNo ratings yet

- WI06-0260 Calculations For Obround Nozzle ConnectionsDocument4 pagesWI06-0260 Calculations For Obround Nozzle ConnectionskumarNo ratings yet

- Annex V External PressureDocument26 pagesAnnex V External PressureJohnny Villarroel100% (1)

- Data Sheet: Document NoDocument3 pagesData Sheet: Document Nobagus handokoNo ratings yet

- Input From Simulation Result From Table or Chart AssumptionDocument31 pagesInput From Simulation Result From Table or Chart AssumptionMohamed Mamdouh AbdelHameed100% (1)

- Sample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)Document3 pagesSample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)Jack SonNo ratings yet

- CPI SeparatorDocument3 pagesCPI SeparatorRajdeepsinhNo ratings yet

- Suction Heaters and Heating Coils Suction Heaters and Heating CoilsDocument3 pagesSuction Heaters and Heating Coils Suction Heaters and Heating CoilsDaysianne100% (1)

- Sa-516 70 TDCDocument2 pagesSa-516 70 TDCshazan100% (1)

- 400 KPH Boiler IBR Design Calculations - R1-6-2-13Document8 pages400 KPH Boiler IBR Design Calculations - R1-6-2-13Vishal KandNo ratings yet

- Data SheetDocument6 pagesData Sheetnalawade_pradeepNo ratings yet

- Pressure Control Valve Rev. 2Document1 pagePressure Control Valve Rev. 2Shibu ThomasNo ratings yet

- API 650 Water Storage TankDocument6 pagesAPI 650 Water Storage TankJoeNo ratings yet

- Pressure Drop Equivalent Length of Pipes and Fittings - Engineers EdgeDocument2 pagesPressure Drop Equivalent Length of Pipes and Fittings - Engineers EdgeallovidNo ratings yet

- Specification Sheet: Case I Case Ii Operating ConditionsDocument1 pageSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarNo ratings yet

- Output Summary: SI UnitsDocument42 pagesOutput Summary: SI UnitsAkhil JoseNo ratings yet

- Sizing of Two Phase Vertical SeparatorDocument3 pagesSizing of Two Phase Vertical SeparatorJatin RamboNo ratings yet

- Perhitungan Pressure Vessel LengkapDocument70 pagesPerhitungan Pressure Vessel LengkapReo Aditya MahesaNo ratings yet

- Desing of CoolerDocument25 pagesDesing of CoolermeetNo ratings yet

- Oil Cooler - Pre Design Data SheetDocument3 pagesOil Cooler - Pre Design Data SheetSakthi VelNo ratings yet

- Breather Valves DatasheetDocument4 pagesBreather Valves Datasheetmilton1987No ratings yet

- Limpet Coil On Dish Design As Per PD5500Document1 pageLimpet Coil On Dish Design As Per PD5500ABIDEEN BAMNENo ratings yet

- Valve Sizing SelectionDocument15 pagesValve Sizing SelectionbariNo ratings yet

- Equivalent PressureDocument1 pageEquivalent PressureSarfaraz KhanNo ratings yet

- DH01 M E 0007 - Mechanical Datashet For TankDocument4 pagesDH01 M E 0007 - Mechanical Datashet For TankDuy NamNo ratings yet

- Vessel Data SheetDocument1 pageVessel Data Sheetaryo93100% (1)

- Boiler Specification 2Document3 pagesBoiler Specification 2AbdulBasitNo ratings yet

- Process Data Sheet Funnel Rev.1Document1 pageProcess Data Sheet Funnel Rev.1DangolNo ratings yet

- SKH3-DS-20-007A-A4 Data Sheet Overhead Crane REV 0.1Document31 pagesSKH3-DS-20-007A-A4 Data Sheet Overhead Crane REV 0.1kebarongan12No ratings yet

- 7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksDocument2 pages7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksJatin Vadhera VCSPNo ratings yet

- Exchanger Tube Min ThicknessDocument2 pagesExchanger Tube Min ThicknessMohamed ElshehnyNo ratings yet

- Arts NPSH TutorialDocument3 pagesArts NPSH TutorialDidier SanonNo ratings yet

- Liquid Distributor DesignDocument10 pagesLiquid Distributor Designtaenker123No ratings yet

- Volum Water HydrotestDocument2 pagesVolum Water HydrotestFerinoviardi100% (1)

- Design of Spherical Pressure Vessel Agai PDFDocument5 pagesDesign of Spherical Pressure Vessel Agai PDFSumit PrasadNo ratings yet

- Hydrocyclone Request DatasheetDocument11 pagesHydrocyclone Request DatasheetMile ZoricNo ratings yet

- Kalkulasi Steam Trap MFO Rev 00Document20 pagesKalkulasi Steam Trap MFO Rev 00Rifka AisyahNo ratings yet

- Activated Carbon For Biogas TreatmentDocument8 pagesActivated Carbon For Biogas TreatmentVipul JainNo ratings yet

- SA-980-P-11449 - API 685 Submerged Pump PZ - Vert02Document5 pagesSA-980-P-11449 - API 685 Submerged Pump PZ - Vert02altipatlarNo ratings yet

- Strainer DatasheetDocument1 pageStrainer DatasheetdgmprabhakarNo ratings yet

- Stress RelievingDocument1 pageStress RelievingCruz Gabriel Rosetti100% (1)

- Quick Opening ClosuresDocument4 pagesQuick Opening ClosuresJuan CarvajalNo ratings yet

- Valve Sizing Calculation Sheet: Version: V3.1.0 Date: 20/01/2016Document4 pagesValve Sizing Calculation Sheet: Version: V3.1.0 Date: 20/01/2016JOSE MARTIN MORA RIVEROSNo ratings yet

- Sagging of The Pipe (F) Between 2 Pipe Clamps (1/"?") X LDocument7 pagesSagging of The Pipe (F) Between 2 Pipe Clamps (1/"?") X LEdwardhutaurukNo ratings yet

- C:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchDocument1 pageC:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchFadhila Ahmad AnindriaNo ratings yet

- Process Calculation: Flare Diameter (D)Document2 pagesProcess Calculation: Flare Diameter (D)kristian08No ratings yet

- Skid Weight Calculation HHI-RAR-SD-SCAL-004. REV.BDocument8 pagesSkid Weight Calculation HHI-RAR-SD-SCAL-004. REV.BAgus MarpaungNo ratings yet

- Special Process Items - Excerpt From Mihir's HandbookDocument17 pagesSpecial Process Items - Excerpt From Mihir's HandbookPedrito CalapuchaNo ratings yet

- A 1 KDocument5 pagesA 1 KSumantrra ChattopadhyayNo ratings yet

- Thickness Calculation of Pressure Vessel ShellDocument16 pagesThickness Calculation of Pressure Vessel ShellClaudia BonocoreNo ratings yet

- Condensate Tank - For 250Document3 pagesCondensate Tank - For 250Sakthi VelNo ratings yet

- S-Stamp Calculation Nozzle ShellDocument4 pagesS-Stamp Calculation Nozzle ShellmukeshNo ratings yet

- Data Sheet Centrifugal Pump: Client: Location: Service: Plant: Supplier MFR.: Equipment No.Document4 pagesData Sheet Centrifugal Pump: Client: Location: Service: Plant: Supplier MFR.: Equipment No.zvlcar nainNo ratings yet

- 4823-DS-2287-0 (P-5007A&B Separated Water Submersible Pumps)Document1 page4823-DS-2287-0 (P-5007A&B Separated Water Submersible Pumps)Sara KhanNo ratings yet

- Design Example 1: Example 1 - Elastomeric Leveling Pad Method A 1Document3 pagesDesign Example 1: Example 1 - Elastomeric Leveling Pad Method A 1koreshNo ratings yet

- Shed Work Details: S.No Building Fabrication Bom Material Description QTYDocument7 pagesShed Work Details: S.No Building Fabrication Bom Material Description QTYBala SundharamNo ratings yet

- Boiler Lab ReportDocument6 pagesBoiler Lab ReportYomal Wijesinghe0% (2)

- SFD Aisc 360 05Document197 pagesSFD Aisc 360 05mikollimNo ratings yet

- EagleBurgmann - AX Type Expansion Joints - ENDocument5 pagesEagleBurgmann - AX Type Expansion Joints - ENEl riza annamlNo ratings yet

- Construction and Building Materials: Idoia Arribas, Amaia Santamaría, Estela Ruiz, Vanesa Ortega-López, Juan M. MansoDocument12 pagesConstruction and Building Materials: Idoia Arribas, Amaia Santamaría, Estela Ruiz, Vanesa Ortega-López, Juan M. MansoLaura Michelle Rodriguez AriasNo ratings yet

- Automatic Tank Temperature SystemDocument6 pagesAutomatic Tank Temperature SystemShariq ZeibNo ratings yet

- Ansys Project WorkDocument24 pagesAnsys Project Workvicky120950% (2)

- Qcs 2010 Section 5 Part 05 AdmixturesDocument7 pagesQcs 2010 Section 5 Part 05 AdmixturesRotsapNayrbNo ratings yet

- Steam Source Book PDFDocument108 pagesSteam Source Book PDFJose Levican A100% (1)

- S-43, Phase-1, Badli Industrial Area Delhi-110042 (INDIA)Document9 pagesS-43, Phase-1, Badli Industrial Area Delhi-110042 (INDIA)Rakesh SharmaNo ratings yet

- 20-100/200/300 Series: Submittal Sheet Bronze Water GaugeDocument2 pages20-100/200/300 Series: Submittal Sheet Bronze Water GaugeDaniel SanNo ratings yet

- Catalogo Comercial Línea Blindada AkkapDocument6 pagesCatalogo Comercial Línea Blindada AkkapToni RenedoNo ratings yet

- Belleville SpringsDocument26 pagesBelleville SpringsMuthu Kumar RNo ratings yet

- Analysis and Comparison of Connections in Steel Structures PDFDocument55 pagesAnalysis and Comparison of Connections in Steel Structures PDFĐình Tuấn NguyễnNo ratings yet

- Brushbond Ultraflex BFLDocument2 pagesBrushbond Ultraflex BFLpeashNo ratings yet

- BS 81110 ReviewDocument52 pagesBS 81110 ReviewIbrahim MeharoofNo ratings yet

- Unequal Angles-ASIAN-STANDARD SIZEDocument6 pagesUnequal Angles-ASIAN-STANDARD SIZEBunheng LonNo ratings yet

- 2018 IebcDocument31 pages2018 IebcmuhannedNo ratings yet

- 230kv Cable Sizing 1Document6 pages230kv Cable Sizing 1Thirunavukkarasu VaratharajanNo ratings yet

- Water-Tite 103: Premium Flexible Cementitious WaterproofingDocument2 pagesWater-Tite 103: Premium Flexible Cementitious WaterproofingGerald Ordoñez Delos ReyesNo ratings yet

- BPD 3Document10 pagesBPD 3hemant sakhareNo ratings yet

- Jacketing Techniques For Retrofitting of RC Column and BeamDocument28 pagesJacketing Techniques For Retrofitting of RC Column and BeamJai Keerthi100% (4)

- Mehran University of Engineering and Technology SZAB Campus Khairpur Mir'sDocument64 pagesMehran University of Engineering and Technology SZAB Campus Khairpur Mir'sMarcusHuynh88No ratings yet

- Experiment 1 - Friction Losses in Pipes-ReportDocument41 pagesExperiment 1 - Friction Losses in Pipes-ReportKhairil Ikram67% (3)

- Physics ProjectDocument14 pagesPhysics Projectrgmaran06No ratings yet

- Natural Convection Heat Transfer Coe Cients in Phase Change Material (PCM) Modules With External Vertical FinsDocument11 pagesNatural Convection Heat Transfer Coe Cients in Phase Change Material (PCM) Modules With External Vertical FinsResearcherzNo ratings yet

Data Sheet P-0560 - Hot Oil Drain Tank Sump Pump PDF

Data Sheet P-0560 - Hot Oil Drain Tank Sump Pump PDF

Uploaded by

cygnus marine panama0 ratings0% found this document useful (0 votes)

25 views2 pagesOriginal Title

Data Sheet P-0560- Hot Oil Drain Tank Sump Pump.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views2 pagesData Sheet P-0560 - Hot Oil Drain Tank Sump Pump PDF

Data Sheet P-0560 - Hot Oil Drain Tank Sump Pump PDF

Uploaded by

cygnus marine panamaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

TM

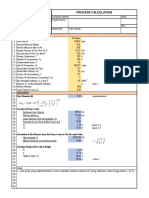

CENTRIFUGAL PUMP DATA SHEET

Customer Cardon IV Project No. INT143 By PBD

Project 345MMSCFD Gas Plant Item No. P-0560 Checked DC

Revision

Location Venezuela Date 30-Jan-2014 Revision C

Service Hot Oil Drain Tank Sump Pump

1 Size Manufacturer

2 Type ANSI No. Pumps Required One (100%)

3 SERVICE CONDITIONS

4 Fluid Name Hot Oil Capacity Normal (gpm) 80 Suction Specific Speed

5 Temperature Normal (°F) 100 Capacity Rated (gpm) 88 NPSH Available (ft) 30+

6 Temperature Max. (°F) 350 Suction Press. Normal (psig) 0.2 NPSH Required (ft) <30 (Note 1)

7 Sp.Gr. @ P&T 0.850 Suction Press. Max. (psig) 50 Efficiency @ Rated Flow (%)

8 Viscosity @ P&T (cP) 8.000 Discharge Pressure (psig) 75 Speed (RPM)

9 Vapor Pressure (psia) 0.13 Differential Pressure (psi) 75 Max. BHP Rated Impeller (hp)

10 Specific Heat (Btu/lb-°F) 0.588 Differential Head (ft) 203 Max. Head Rated Impeller (ft)

11 Corrosion Factors Estimated BHP (hp) Minimum Continuous Flow (gpm)

12 Erosion Factors Rotation (Viewed from Cplg End)

13 CONSTRUCTION DETAILS SHOP TESTS

14 Nozzles Size Rating Facing Location Non-Wit. Perf. Wit. Perf.

15 Suction 150# RF Bottom Non-Wit. Hydro. Wit. Hydro.

16 Discharge 150# RF Side Non-Wit. NPSH Wit. NPSH

17 Auxilliary Connections Vent No. Size Type Shop Inspection

18 Drain No. Size Type Dismantle & Inspect After Test

19 Gauge No. Size Type Other

20 Casing Mounting Centerline Foot Bracket Vertical

21 Split Case Axial Radial

22 Casing Type Single Volute Multiple Volute Diffuser MATERIALS

23 Casing MAWP psig @ °F Hydrotest Pressure (psig) Case Ductile Iron Wear Rings

24 Impeller Size Minimum Rated Maximum Barrel -Impeller

25 Impeller Type Impellers SS -Case

26 Bearings Radial No. Thrust No. Shaft SS

27 Lubrication Grease Oil Purge Oil Mist Pure Oil Mist Shaft Sleave

28 Coupling Manufacturer Model Diffusers Seal faces

29 Coupling Guard Coupling Spacer Length VERTICAL PUMPS

30 Mech. Seal Manufacturer Mech. Seal Type Pit or Sump Depth (ft) 5 (Note 3)

31 Mech. Seal Mfgr Code Mech. Seal API Code Min. Submergence Required (ft)

32 Primary Seal Flush Plan C.S. S.S. Tubing Pipe Column Pipe

33 Secondary Seal Flush Plan C.S. S.S. Tubing Pipe Line Shaft

34 Secondary Seal Flush Fluid Bearings

35 Baseplate Baseplate API Number Bearing Lube Water Oil Grease

36 DRIVER Float & Rod C.S. S.S. Bronze

37 Type Electric Motor Manufacturer Insulation Class F Float Switch

38 HP 15 V / P / Hz 460 3 60 Temp Rise Pump Thrust (lb) Up Down

39 S.F. 1.15 Enclosure Space Heater

40 RPM Duty Severe VFD Compatible No

41 Electrical Area Classification: Class 1 Group D Div. 2

42 SITE DATA MANUFACTURER'S FINAL DATA

43 Elevation (ft) 16 Barometric Pressure (psia) 14.65 Installation Outside Test Curve No.

44 Ambient Temperature (°F) Max. 104 Min. 72.8 Inside Outline Dwg. No.

45 Relative Humidity (%) Max. 84 Min. 81 Pump Sect.Dwg. No.

46 Unusual Conditions Dust Fumes Other: Seaside Loaction Seal Dwg. No.

47 MISCELLANEOUS Pump Serial No.

48 Standards

49 Specifications

50 Maximum Sound Pressure Level 85 dBA @ 3 ft

51 NOTES

52 1. Design per attached Scope of Supply, Cardon Specifications, Valerus Standards, and Inspection and Testing Requirements.

53 2. Vendor to supply seal pot with all seal plan instrumentation required.

54 3. Pump is a vertical sump pump that should sit 6" above the bottom seam of the Sump.

55 4. Pump motor must be explosion proof.

56

57

58

59

60

61

62

63

64

65

66

67

This document is the propty of Valerus Compression Services, LP. This information is proprietary and shall not be disclosed outside your organization, nor shall it be duplicated, used or

disclosed for any purpose other than as permitted under written agreement with Valerus Compression Services, LP or its subsidiaries.

INT143-30-800-0560-01-RC P-0560 Hot Oil Drain Tank Sump Pump Page 1 of 2

CENTRIFUGAL PUMP DATA SHEET

Customer Cardon IV Project No. INT143 By PBD

Project 345MMSCFD Gas Plant Item No. P-0560 Checked DC

Revision

Location Venezuela Date 30-Jan-2014 Revision C

Service Hot Oil Drain Tank Sump Pump

1 SCOPE OF SUPPLY

2

3

4 The following checked items for design and scope of supply shall be included by vendor:

5

6 1 Base plates shall be fabricated from structural steel or plate material.

7

8 2 Pumps in amine service (including Amine Still Reflux): do not use copper, copper alloys (such as brass), aluminum,

9 zinc, galvanized iron or viton in contact with the process fluid. Elastomer materials such as EPDM are acceptable

10 if sulfur or peroxide-cure, flourinated viton, or kalrez. Resin-cured EPDM and standard viton are not acceptable.

11 HNBR preferred.

12

13 3 Furnish pump with tandem seals as specified complete with seal pot, pressure gauge, pressure switch, level

14 gauge and restriced orifice.

15

16 4 Vendor to confirm proper seal flush plan for application, 1/2" or larger SS tubing to be utilized for seal flush.

17

18 5 Shop tests requires: Non-witness hydrotest only.

19

20 6 Provide VFD compliant motor. Premium efficiency, severe duty; Class F Inul.; 80 °C Temp. rise; 1.15 S.F.

21

22 7 Electrical Area Classification: Class I, Division 2, Groups C & D.

23

24 8 Pump impeller diameter to be no greater than 95 percent of maximum for that pump case.

25

26 9 Pump motor to be sized for the smaller of:

27

28 10 Quote low NPSHR and provide 1750 max. RPM for pumps with bubble point fluids.

29

30 11 Quote 1750 RPM for pumps with fluids hotter than 300 °F.

31

32 12 Make sure multi-stage pumps have all pressure containing parts designed and rated for the maximum discharge.

33

34 13 Site Conditions: Please refer to Section 10 in document INT143-80-005-DDDD-00 R2, "Onshore Design Basis Standard".

35

36 14 Wind Design shall be in accordance with document INT143-80-005-DDDD-00 R2, "Onshore Design Basis Standard".

37 Design Criteria shall cover: Covenin 2003-89, 100 MPH, Exp. Cat D, Imp. Factor: 1.15

38 15 Seismic Design shall be in accordance with document INT143-80-005-DDDD-00 R2, "Onshore Design Basis Standard".

39 ("Civil Design Document" shall be for reference only.)

40 16 Paint Standard shall be in accordance with document INT143-80-014-DDDD R1, "AEP PAINTING SPECIFICATION".

41

42 17 Material Test Reports, including country of origin , are required.

43

44 18 Pump design shall be in accordance with document INT143-80-006-DDDD-00 R2, "Onshore Design Criteria Standard".

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

This document is the property of Valerus Compression Services, LP. This information is proprietary and shall not be disclosed outside your organization, nor shall it be duplicated,

used or disclosed for any purpose other than as permitted under written agreement with Valerus Compression Services, LP or its subsidiaries.

INT143-30-800-0560-01-RC P-0560 Hot Oil Drain Tank Sump Pump Page 2 of 2

You might also like

- Data Sheet WB RU VDocument5 pagesData Sheet WB RU VMaharani Putri IndrianurNo ratings yet

- PVV Cal Sheet LabixDocument45 pagesPVV Cal Sheet LabixPranpath Narupantawart50% (2)

- Tank Thickness Calculation: Is 2825 S.No Description Unit Value InputDocument10 pagesTank Thickness Calculation: Is 2825 S.No Description Unit Value InputdineshNo ratings yet

- TEMA Sheet Heat Exchanger Specification SheetDocument3 pagesTEMA Sheet Heat Exchanger Specification SheetSonNguyen100% (1)

- PSV Tag No. 10A1 Set Pressure Loop Considered Calculation Reference C-22 and HX-27 API-521, 5TH EDITION, MARCH 2007Document7 pagesPSV Tag No. 10A1 Set Pressure Loop Considered Calculation Reference C-22 and HX-27 API-521, 5TH EDITION, MARCH 2007ktejankarNo ratings yet

- PR1978 Workbook July-24-2017Document1,085 pagesPR1978 Workbook July-24-2017rewqNo ratings yet

- 32-SAMSS-007 Manufacture of Heat ExchangerDocument39 pages32-SAMSS-007 Manufacture of Heat ExchangerAwais Jamil50% (2)

- AYC CHECKLIST PAINTING Rev.01Document3 pagesAYC CHECKLIST PAINTING Rev.01moytabura96No ratings yet

- Sullair ES-8 Air Compressor Operation, Maintenance, TroubleshootingDocument74 pagesSullair ES-8 Air Compressor Operation, Maintenance, TroubleshootingElvis100% (4)

- CN5191 - L2 - A1-Centrifugal Pump Process Data SheetDocument1 pageCN5191 - L2 - A1-Centrifugal Pump Process Data SheetMochi CumilinaNo ratings yet

- WI06-0260 Calculations For Obround Nozzle ConnectionsDocument4 pagesWI06-0260 Calculations For Obround Nozzle ConnectionskumarNo ratings yet

- Annex V External PressureDocument26 pagesAnnex V External PressureJohnny Villarroel100% (1)

- Data Sheet: Document NoDocument3 pagesData Sheet: Document Nobagus handokoNo ratings yet

- Input From Simulation Result From Table or Chart AssumptionDocument31 pagesInput From Simulation Result From Table or Chart AssumptionMohamed Mamdouh AbdelHameed100% (1)

- Sample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)Document3 pagesSample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)Jack SonNo ratings yet

- CPI SeparatorDocument3 pagesCPI SeparatorRajdeepsinhNo ratings yet

- Suction Heaters and Heating Coils Suction Heaters and Heating CoilsDocument3 pagesSuction Heaters and Heating Coils Suction Heaters and Heating CoilsDaysianne100% (1)

- Sa-516 70 TDCDocument2 pagesSa-516 70 TDCshazan100% (1)

- 400 KPH Boiler IBR Design Calculations - R1-6-2-13Document8 pages400 KPH Boiler IBR Design Calculations - R1-6-2-13Vishal KandNo ratings yet

- Data SheetDocument6 pagesData Sheetnalawade_pradeepNo ratings yet

- Pressure Control Valve Rev. 2Document1 pagePressure Control Valve Rev. 2Shibu ThomasNo ratings yet

- API 650 Water Storage TankDocument6 pagesAPI 650 Water Storage TankJoeNo ratings yet

- Pressure Drop Equivalent Length of Pipes and Fittings - Engineers EdgeDocument2 pagesPressure Drop Equivalent Length of Pipes and Fittings - Engineers EdgeallovidNo ratings yet

- Specification Sheet: Case I Case Ii Operating ConditionsDocument1 pageSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarNo ratings yet

- Output Summary: SI UnitsDocument42 pagesOutput Summary: SI UnitsAkhil JoseNo ratings yet

- Sizing of Two Phase Vertical SeparatorDocument3 pagesSizing of Two Phase Vertical SeparatorJatin RamboNo ratings yet

- Perhitungan Pressure Vessel LengkapDocument70 pagesPerhitungan Pressure Vessel LengkapReo Aditya MahesaNo ratings yet

- Desing of CoolerDocument25 pagesDesing of CoolermeetNo ratings yet

- Oil Cooler - Pre Design Data SheetDocument3 pagesOil Cooler - Pre Design Data SheetSakthi VelNo ratings yet

- Breather Valves DatasheetDocument4 pagesBreather Valves Datasheetmilton1987No ratings yet

- Limpet Coil On Dish Design As Per PD5500Document1 pageLimpet Coil On Dish Design As Per PD5500ABIDEEN BAMNENo ratings yet

- Valve Sizing SelectionDocument15 pagesValve Sizing SelectionbariNo ratings yet

- Equivalent PressureDocument1 pageEquivalent PressureSarfaraz KhanNo ratings yet

- DH01 M E 0007 - Mechanical Datashet For TankDocument4 pagesDH01 M E 0007 - Mechanical Datashet For TankDuy NamNo ratings yet

- Vessel Data SheetDocument1 pageVessel Data Sheetaryo93100% (1)

- Boiler Specification 2Document3 pagesBoiler Specification 2AbdulBasitNo ratings yet

- Process Data Sheet Funnel Rev.1Document1 pageProcess Data Sheet Funnel Rev.1DangolNo ratings yet

- SKH3-DS-20-007A-A4 Data Sheet Overhead Crane REV 0.1Document31 pagesSKH3-DS-20-007A-A4 Data Sheet Overhead Crane REV 0.1kebarongan12No ratings yet

- 7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksDocument2 pages7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksJatin Vadhera VCSPNo ratings yet

- Exchanger Tube Min ThicknessDocument2 pagesExchanger Tube Min ThicknessMohamed ElshehnyNo ratings yet

- Arts NPSH TutorialDocument3 pagesArts NPSH TutorialDidier SanonNo ratings yet

- Liquid Distributor DesignDocument10 pagesLiquid Distributor Designtaenker123No ratings yet

- Volum Water HydrotestDocument2 pagesVolum Water HydrotestFerinoviardi100% (1)

- Design of Spherical Pressure Vessel Agai PDFDocument5 pagesDesign of Spherical Pressure Vessel Agai PDFSumit PrasadNo ratings yet

- Hydrocyclone Request DatasheetDocument11 pagesHydrocyclone Request DatasheetMile ZoricNo ratings yet

- Kalkulasi Steam Trap MFO Rev 00Document20 pagesKalkulasi Steam Trap MFO Rev 00Rifka AisyahNo ratings yet

- Activated Carbon For Biogas TreatmentDocument8 pagesActivated Carbon For Biogas TreatmentVipul JainNo ratings yet

- SA-980-P-11449 - API 685 Submerged Pump PZ - Vert02Document5 pagesSA-980-P-11449 - API 685 Submerged Pump PZ - Vert02altipatlarNo ratings yet

- Strainer DatasheetDocument1 pageStrainer DatasheetdgmprabhakarNo ratings yet

- Stress RelievingDocument1 pageStress RelievingCruz Gabriel Rosetti100% (1)

- Quick Opening ClosuresDocument4 pagesQuick Opening ClosuresJuan CarvajalNo ratings yet

- Valve Sizing Calculation Sheet: Version: V3.1.0 Date: 20/01/2016Document4 pagesValve Sizing Calculation Sheet: Version: V3.1.0 Date: 20/01/2016JOSE MARTIN MORA RIVEROSNo ratings yet

- Sagging of The Pipe (F) Between 2 Pipe Clamps (1/"?") X LDocument7 pagesSagging of The Pipe (F) Between 2 Pipe Clamps (1/"?") X LEdwardhutaurukNo ratings yet

- C:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchDocument1 pageC:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchFadhila Ahmad AnindriaNo ratings yet

- Process Calculation: Flare Diameter (D)Document2 pagesProcess Calculation: Flare Diameter (D)kristian08No ratings yet

- Skid Weight Calculation HHI-RAR-SD-SCAL-004. REV.BDocument8 pagesSkid Weight Calculation HHI-RAR-SD-SCAL-004. REV.BAgus MarpaungNo ratings yet

- Special Process Items - Excerpt From Mihir's HandbookDocument17 pagesSpecial Process Items - Excerpt From Mihir's HandbookPedrito CalapuchaNo ratings yet

- A 1 KDocument5 pagesA 1 KSumantrra ChattopadhyayNo ratings yet

- Thickness Calculation of Pressure Vessel ShellDocument16 pagesThickness Calculation of Pressure Vessel ShellClaudia BonocoreNo ratings yet

- Condensate Tank - For 250Document3 pagesCondensate Tank - For 250Sakthi VelNo ratings yet

- S-Stamp Calculation Nozzle ShellDocument4 pagesS-Stamp Calculation Nozzle ShellmukeshNo ratings yet

- Data Sheet Centrifugal Pump: Client: Location: Service: Plant: Supplier MFR.: Equipment No.Document4 pagesData Sheet Centrifugal Pump: Client: Location: Service: Plant: Supplier MFR.: Equipment No.zvlcar nainNo ratings yet

- 4823-DS-2287-0 (P-5007A&B Separated Water Submersible Pumps)Document1 page4823-DS-2287-0 (P-5007A&B Separated Water Submersible Pumps)Sara KhanNo ratings yet

- Design Example 1: Example 1 - Elastomeric Leveling Pad Method A 1Document3 pagesDesign Example 1: Example 1 - Elastomeric Leveling Pad Method A 1koreshNo ratings yet

- Shed Work Details: S.No Building Fabrication Bom Material Description QTYDocument7 pagesShed Work Details: S.No Building Fabrication Bom Material Description QTYBala SundharamNo ratings yet

- Boiler Lab ReportDocument6 pagesBoiler Lab ReportYomal Wijesinghe0% (2)

- SFD Aisc 360 05Document197 pagesSFD Aisc 360 05mikollimNo ratings yet

- EagleBurgmann - AX Type Expansion Joints - ENDocument5 pagesEagleBurgmann - AX Type Expansion Joints - ENEl riza annamlNo ratings yet

- Construction and Building Materials: Idoia Arribas, Amaia Santamaría, Estela Ruiz, Vanesa Ortega-López, Juan M. MansoDocument12 pagesConstruction and Building Materials: Idoia Arribas, Amaia Santamaría, Estela Ruiz, Vanesa Ortega-López, Juan M. MansoLaura Michelle Rodriguez AriasNo ratings yet

- Automatic Tank Temperature SystemDocument6 pagesAutomatic Tank Temperature SystemShariq ZeibNo ratings yet

- Ansys Project WorkDocument24 pagesAnsys Project Workvicky120950% (2)

- Qcs 2010 Section 5 Part 05 AdmixturesDocument7 pagesQcs 2010 Section 5 Part 05 AdmixturesRotsapNayrbNo ratings yet

- Steam Source Book PDFDocument108 pagesSteam Source Book PDFJose Levican A100% (1)

- S-43, Phase-1, Badli Industrial Area Delhi-110042 (INDIA)Document9 pagesS-43, Phase-1, Badli Industrial Area Delhi-110042 (INDIA)Rakesh SharmaNo ratings yet

- 20-100/200/300 Series: Submittal Sheet Bronze Water GaugeDocument2 pages20-100/200/300 Series: Submittal Sheet Bronze Water GaugeDaniel SanNo ratings yet

- Catalogo Comercial Línea Blindada AkkapDocument6 pagesCatalogo Comercial Línea Blindada AkkapToni RenedoNo ratings yet

- Belleville SpringsDocument26 pagesBelleville SpringsMuthu Kumar RNo ratings yet

- Analysis and Comparison of Connections in Steel Structures PDFDocument55 pagesAnalysis and Comparison of Connections in Steel Structures PDFĐình Tuấn NguyễnNo ratings yet

- Brushbond Ultraflex BFLDocument2 pagesBrushbond Ultraflex BFLpeashNo ratings yet

- BS 81110 ReviewDocument52 pagesBS 81110 ReviewIbrahim MeharoofNo ratings yet

- Unequal Angles-ASIAN-STANDARD SIZEDocument6 pagesUnequal Angles-ASIAN-STANDARD SIZEBunheng LonNo ratings yet

- 2018 IebcDocument31 pages2018 IebcmuhannedNo ratings yet

- 230kv Cable Sizing 1Document6 pages230kv Cable Sizing 1Thirunavukkarasu VaratharajanNo ratings yet

- Water-Tite 103: Premium Flexible Cementitious WaterproofingDocument2 pagesWater-Tite 103: Premium Flexible Cementitious WaterproofingGerald Ordoñez Delos ReyesNo ratings yet

- BPD 3Document10 pagesBPD 3hemant sakhareNo ratings yet

- Jacketing Techniques For Retrofitting of RC Column and BeamDocument28 pagesJacketing Techniques For Retrofitting of RC Column and BeamJai Keerthi100% (4)

- Mehran University of Engineering and Technology SZAB Campus Khairpur Mir'sDocument64 pagesMehran University of Engineering and Technology SZAB Campus Khairpur Mir'sMarcusHuynh88No ratings yet

- Experiment 1 - Friction Losses in Pipes-ReportDocument41 pagesExperiment 1 - Friction Losses in Pipes-ReportKhairil Ikram67% (3)

- Physics ProjectDocument14 pagesPhysics Projectrgmaran06No ratings yet

- Natural Convection Heat Transfer Coe Cients in Phase Change Material (PCM) Modules With External Vertical FinsDocument11 pagesNatural Convection Heat Transfer Coe Cients in Phase Change Material (PCM) Modules With External Vertical FinsResearcherzNo ratings yet