Professional Documents

Culture Documents

ITW Product Catalog23 PDF

ITW Product Catalog23 PDF

Uploaded by

johnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ITW Product Catalog23 PDF

ITW Product Catalog23 PDF

Uploaded by

johnCopyright:

Available Formats

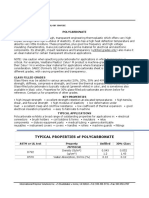

WEARING COMPOUNDS/EPOXIES/URETHANES

Wearing Compounds

Devcon® Devcon® Devcon®

Devcon® Devcon® Plexus®

Physical Properties Wear Guard™ Wear Guard™ Wear Guard™

Tile Adhesive HV Tile Adhesive MMA Tile Adhesive

Fine Load High Load High Temp

Color Grey Grey Grey White Grey White

Mix ratio by weight/volume

2:1 / 2:1 2:1 / 2:1 13.7:1 / 6:1 1.1:1 / 1:1 1.1:1 / 1:1 1.1:1 / 1:1

(resin:hardener)

Mixed viscosity (cP) Putty Putty Putty Putty Putty Putty

Functional cure (hours) 6-8 6-8 Heat Cured 12 8 1.5

Pot life (minutes @ 75˚F) 30 30 120 240 35 14

Specific volume (inches1/pound) 12.4 12.9 14.3 19.2 19 27.7

Coverage per pound

50 50 60 76.8 76 118

(inches2 @ 1⁄4" thickness)

Cured hardness

87 87 87 81 81 60

(ASTM D2240) (Shore D)

Cured shrinkage

0.0006 0.0006 0.0010 0.0010 0.0010 0.005

(ASTM D2566) (inch/inch)

Adhesive tensile shear

1,375 1,474 2,300 2,890 1,825 2,458

(ASTM D1002) (psi)

Compressive strength

11,000 11,000 13,200 9,620 11,800 3,254

(ASTM D695) (psi)

Flexural strength

7,190 7,140 8,220 5,480 5,400 4,719

(ASTM D790) (psi)

Coefficient of thermal expansion

34 32 27 14 14 18

(ASTM D696)[(in)/(in x ˚F)] x 10-6

Dielectric constant

46.0 41.0 38.0 46.0 45.0 43.0

(ASTM D150) (1 kHz)

Maximum continuous dry

300 300 450 200 200 180

service temperature (˚F)

Maximum continuous wet

140 140 150 150 N/A 150

service temperature (˚F)

NOTES: 2 Three-part system, beads separate

Devcon® Devcon® Devcon®

Devcon® Devcon® Plexus®

Chemical Resistance Wear Guard™ Wear Guard™ Wear Guard™

Tile Adhesive HV Tile Adhesive MMA Tile Adhesive

Fine Load High Load High Temp

ACIDS

Acetic 10%

Hydrochloric 10%

Sulfuric 10%

ALCOHOLS

Methanol

Isopropanol

KETONES

Acetone

Methyl ethyl ketone

ALKALIS

Ammonium hydroxide 20%

Sodium hydroxide 10%

HYDROCARBONS

Gasoline (unleaded)

Mineral spirits

CHLORINATED

HYDROCARBONS

1-1-1 Trichloroethane

SALTS

Sodium chloride

Trisodium phosphate

Key: Excellent Very Good Fair Poor

855 -489 -7262 23

You might also like

- Epoxy Curing With INVISTA DiaminesDocument5 pagesEpoxy Curing With INVISTA DiaminesUnknownNo ratings yet

- CorrosionDocument16 pagesCorrosionsiswout100% (2)

- Life ProcessesDocument53 pagesLife Processessagar100% (1)

- Extractive Metallurgy of CopperDocument12 pagesExtractive Metallurgy of CopperBORUTO ANIMEZONE100% (1)

- Strobe StarsDocument3 pagesStrobe StarsMuthu KumarNo ratings yet

- Devcon Catalog PDFDocument24 pagesDevcon Catalog PDFSergio MarchettiNo ratings yet

- 1 Wa-Catalog7Document1 page1 Wa-Catalog7johnNo ratings yet

- ITW Product Catalog21 PDFDocument1 pageITW Product Catalog21 PDFjohnNo ratings yet

- 1 Wa-Catalog13Document1 page1 Wa-Catalog13johnNo ratings yet

- Technical Information: (BR) (WR-2) (Special F)Document1 pageTechnical Information: (BR) (WR-2) (Special F)johnNo ratings yet

- 1 Wa-Catalog5Document1 page1 Wa-Catalog5johnNo ratings yet

- 1 Wa-Catalog9Document1 page1 Wa-Catalog9johnNo ratings yet

- ITW Product Catalog30 PDFDocument1 pageITW Product Catalog30 PDFjohnNo ratings yet

- Technical Information: (A) (SF) (ST) (F)Document1 pageTechnical Information: (A) (SF) (ST) (F)johnNo ratings yet

- Technical Data Sheet PVC: (Polyvinyl Chloride)Document1 pageTechnical Data Sheet PVC: (Polyvinyl Chloride)Adnan KhanNo ratings yet

- Technical Data Sheet CPVC: (Chlorinated Polyvinyl Chloride)Document1 pageTechnical Data Sheet CPVC: (Chlorinated Polyvinyl Chloride)Nam NguyenNo ratings yet

- ITW Adhesive Plexus-MA3940-Data-SheetDocument2 pagesITW Adhesive Plexus-MA3940-Data-SheetMilind singhNo ratings yet

- UHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteelDocument4 pagesUHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteeldangdinhthyNo ratings yet

- Epoxy Adhesives: Devcon 10 Minute Epoxy Devcon HP 250Document1 pageEpoxy Adhesives: Devcon 10 Minute Epoxy Devcon HP 250johnNo ratings yet

- Hex Bonde A 9394 Structi L PDFDocument2 pagesHex Bonde A 9394 Structi L PDFFlorian Le MaoNo ratings yet

- LdpeDocument1 pageLdpeArdy WiyogoNo ratings yet

- Typical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesDocument2 pagesTypical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesAdnan KhanNo ratings yet

- 3X-TDS-R4D-ECHT-technical Note PDFDocument2 pages3X-TDS-R4D-ECHT-technical Note PDF今夕何夕No ratings yet

- Plexus Ma 300 TdsDocument2 pagesPlexus Ma 300 Tdsfernando machadoNo ratings yet

- Araldite 2011-A/B: Advanced MaterialsDocument6 pagesAraldite 2011-A/B: Advanced Materialsmehmet kığılıNo ratings yet

- Technical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)Document1 pageTechnical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)HARSHA PNo ratings yet

- PolystyreneDocument1 pagePolystyrenejoshkajasmineNo ratings yet

- Techtron PPS HPV & Ketron PEEK HPV SpecificationsDocument3 pagesTechtron PPS HPV & Ketron PEEK HPV SpecificationsPeterWayNo ratings yet

- Tairilac ABS Resin: Properties (1/3)Document3 pagesTairilac ABS Resin: Properties (1/3)DiegoTierradentroNo ratings yet

- Resin - ABS Tairalac PDFDocument3 pagesResin - ABS Tairalac PDFDiegoTierradentroNo ratings yet

- Bergquist Gap Pad Comparison TableDocument1 pageBergquist Gap Pad Comparison TableMaike SongNo ratings yet

- Scotchweld EC 2216BADocument8 pagesScotchweld EC 2216BAbenNo ratings yet

- Devcon Plastic Steel Putty ADocument3 pagesDevcon Plastic Steel Putty AAZLAN ABDULLAINo ratings yet

- Molins: Technical Data SheetDocument2 pagesMolins: Technical Data SheetsasidharkanthetiNo ratings yet

- Technical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneDocument1 pageTechnical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneQuality teamNo ratings yet

- Dokumen - Tips - Waterborne CNSL Curing Agent For Grout and Adhesive Curing Agent Dry ConcreteDocument16 pagesDokumen - Tips - Waterborne CNSL Curing Agent For Grout and Adhesive Curing Agent Dry Concretem_shahbaghiNo ratings yet

- Datasheet SD Ferralium 255 SD50 BarDocument4 pagesDatasheet SD Ferralium 255 SD50 Barpranav kariaNo ratings yet

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02No ratings yet

- PSG Epoxy Glass PhenolicsDocument1 pagePSG Epoxy Glass PhenolicsmadhunnadigNo ratings yet

- Araldite Av138 hv998Document7 pagesAraldite Av138 hv998Nautique SolutionsNo ratings yet

- Exact 8201Document2 pagesExact 8201Kashif MuhammadNo ratings yet

- Ensinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Document2 pagesEnsinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Arthur EmidioNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- TDS-ENGAGE-8100Document3 pagesTDS-ENGAGE-8100afernandezNo ratings yet

- Corys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsDocument1 pageCorys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsVenkadesh PeriathambiNo ratings yet

- Technical Data Sheet Ultem (Pei) : (Polyetherimide)Document3 pagesTechnical Data Sheet Ultem (Pei) : (Polyetherimide)Dynamic SaravananNo ratings yet

- UCAR™ Latex DL 450 - MielcoDocument5 pagesUCAR™ Latex DL 450 - MielcoLong An DoNo ratings yet

- Technical Data Sheet Peek: Typical Properties of Virgin (Unfilled) PeekDocument2 pagesTechnical Data Sheet Peek: Typical Properties of Virgin (Unfilled) PeekSyed MoinNo ratings yet

- TDS 3M Scotch-Weld Epoxy Adhesive DP100 GENERALDocument8 pagesTDS 3M Scotch-Weld Epoxy Adhesive DP100 GENERALAkbar Perwira UtamaNo ratings yet

- Serge Ferrari Membrane Roofing MaterialDocument2 pagesSerge Ferrari Membrane Roofing MaterialSt. Laila QadriantiNo ratings yet

- Sikadur 42 Gorut Palk LE - CaDocument2 pagesSikadur 42 Gorut Palk LE - Carobert benavidesNo ratings yet

- Technical Data Sheet G-10: General DescriptionDocument1 pageTechnical Data Sheet G-10: General Descriptionbahtiar affandyNo ratings yet

- Dupont Kalrez Perfluoroelastomer Parts: Chemical Process Industry (Cpi) Product Selector GuideDocument5 pagesDupont Kalrez Perfluoroelastomer Parts: Chemical Process Industry (Cpi) Product Selector GuideskullbasherNo ratings yet

- Dfense Blok™: Technical Data SheetDocument1 pageDfense Blok™: Technical Data SheetjohnNo ratings yet

- AralditeDocument7 pagesAralditeRohit RanaNo ratings yet

- 02Document3 pages02awesomesiddharth2001No ratings yet

- Covia SLC TdsDocument1 pageCovia SLC TdsEzequiel MarroquinNo ratings yet

- Technical Data: Plastic Steel 5-Minute Putty (SF)Document4 pagesTechnical Data: Plastic Steel 5-Minute Putty (SF)Hoàng DũngNo ratings yet

- Teflon (PTFE) Data SheetDocument1 pageTeflon (PTFE) Data SheetMarisa Yuni Nur AzizaNo ratings yet

- Technical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Document1 pageTechnical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Dharmendra DubeyNo ratings yet

- Polikim EFALON® T-100 Virgin PTFEDocument2 pagesPolikim EFALON® T-100 Virgin PTFEPriyadarshini KrishnaswamyNo ratings yet

- ITW Product Catalog40 PDFDocument1 pageITW Product Catalog40 PDFjohnNo ratings yet

- ITW Product Catalog29 PDFDocument1 pageITW Product Catalog29 PDFjohnNo ratings yet

- ITW Product Catalog39 PDFDocument1 pageITW Product Catalog39 PDFjohnNo ratings yet

- ITW Product Catalog29 PDFDocument1 pageITW Product Catalog29 PDFjohnNo ratings yet

- ITW Product Catalog33 PDFDocument1 pageITW Product Catalog33 PDFjohnNo ratings yet

- ITW Product Catalog30 PDFDocument1 pageITW Product Catalog30 PDFjohnNo ratings yet

- ITW Product Catalog17Document1 pageITW Product Catalog17johnNo ratings yet

- ITW Product Catalog16 PDFDocument1 pageITW Product Catalog16 PDFjohnNo ratings yet

- ITW Product Catalog12Document1 pageITW Product Catalog12johnNo ratings yet

- Epoxy Adhesives: Devcon 10 Minute Epoxy Devcon HP 250Document1 pageEpoxy Adhesives: Devcon 10 Minute Epoxy Devcon HP 250johnNo ratings yet

- ITW Product Catalog13Document1 pageITW Product Catalog13johnNo ratings yet

- Sprayable Syntactic Materials: Radius Compound Coring/Bulk Print BlockerDocument1 pageSprayable Syntactic Materials: Radius Compound Coring/Bulk Print BlockerjohnNo ratings yet

- Methacrylate Structural Adhesives: Dispensing Equipment (10:1)Document1 pageMethacrylate Structural Adhesives: Dispensing Equipment (10:1)johnNo ratings yet

- Tadeo, José L - Analysis of Pesticides in Food and Environmental Samples-CRC Press (2019)Document30 pagesTadeo, José L - Analysis of Pesticides in Food and Environmental Samples-CRC Press (2019)HevertonJonnysNo ratings yet

- Preservation of Waterborne Oil Samples: Standard Practice ForDocument3 pagesPreservation of Waterborne Oil Samples: Standard Practice ForOh No PotatoNo ratings yet

- UPS1 Chapter1 SK016Document5 pagesUPS1 Chapter1 SK016Avinash Bala50% (2)

- MigDocument6 pagesMigPensel KoNtotNo ratings yet

- Schreier Et Al 2023 Trends in Electrocatalysis The Microenvironment Moves To Center StageDocument6 pagesSchreier Et Al 2023 Trends in Electrocatalysis The Microenvironment Moves To Center Stagepandiaraj1988No ratings yet

- The Mineral TopazDocument6 pagesThe Mineral Topazapi-281334959No ratings yet

- Biodegradable Wastes: Hospital WasteDocument4 pagesBiodegradable Wastes: Hospital WasteFAIZA A PASCUALNo ratings yet

- Training On Raw Material TestingDocument4 pagesTraining On Raw Material TestingElizabeth MaryNo ratings yet

- 0620 w17 Ms 41 PDFDocument8 pages0620 w17 Ms 41 PDFyuke kristinaNo ratings yet

- Program 200522Document10 pagesProgram 200522melosNo ratings yet

- Worksheet - I: Biology XDocument7 pagesWorksheet - I: Biology XDharmendra SinghNo ratings yet

- Electrophilic AdditionDocument15 pagesElectrophilic AdditionShiyi YauNo ratings yet

- CBSE Class 12 Chemistry Important Questions& Answers @5marksDocument10 pagesCBSE Class 12 Chemistry Important Questions& Answers @5marksPramit RanjanNo ratings yet

- CLASS X (2020-21) Science (Code 086) Sample Paper-1: Time: 3 Hours Maximum Marks: 80 General InstructionsDocument8 pagesCLASS X (2020-21) Science (Code 086) Sample Paper-1: Time: 3 Hours Maximum Marks: 80 General InstructionsHemant HomkarNo ratings yet

- Lugol's - Solution (Diluted) 0.33 % Iodine: DescriptionDocument1 pageLugol's - Solution (Diluted) 0.33 % Iodine: DescriptionSiddharta GauthamaNo ratings yet

- Iodometric Determination of Copper and Iron in One SolutionDocument3 pagesIodometric Determination of Copper and Iron in One SolutionSianiiChavezMoránNo ratings yet

- HAZMAT Storage Incompatible Materials Chart - US ArmyDocument1 pageHAZMAT Storage Incompatible Materials Chart - US Armymaxcas999114No ratings yet

- Liquid Liquid ExtractionDocument73 pagesLiquid Liquid ExtractionUbaid RaanNo ratings yet

- A Textbook of HydrometallurgyDocument17 pagesA Textbook of HydrometallurgyPanashe Raphael NyamakaNo ratings yet

- Cambridge IGCSE: Combined Science 0653/42Document24 pagesCambridge IGCSE: Combined Science 0653/42body fayezNo ratings yet

- Old Questions AAS NMR and MSDocument7 pagesOld Questions AAS NMR and MSramesh pokhrelNo ratings yet

- MSDS Ec-Ro-16Document3 pagesMSDS Ec-Ro-16Souljah Khiffer60% (5)

- Determination of Ammonia in The Atmosphere (Indophenol Method)Document4 pagesDetermination of Ammonia in The Atmosphere (Indophenol Method)ECRD83% (6)

- Data Sheet Roto ZDocument8 pagesData Sheet Roto ZGabo RamirezNo ratings yet

- Chapter 4 SUBSTITUTION REACTIONDocument35 pagesChapter 4 SUBSTITUTION REACTIONHalimatun MustafaNo ratings yet

- Design of Packed Tower PDFDocument4 pagesDesign of Packed Tower PDFAnonymous FWlt8Y100% (1)