Professional Documents

Culture Documents

Comparison of Permeability Characteristics of Granular Sub Base Layer in A Model Pavement For Different Grades As Per Mo

Uploaded by

Sandeep BoraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comparison of Permeability Characteristics of Granular Sub Base Layer in A Model Pavement For Different Grades As Per Mo

Uploaded by

Sandeep BoraCopyright:

Available Formats

Available online at www.scholarsresearchlibrary.

com

Scholars Research Library

European Journal of Applied Engineering and

Scientific Research, 2017, 6(1):1-10

ISSN: 2278-0041

Comparison of Permeability Characteristics of Granular Sub Base Layer in a

Model Pavement for Different Grades as per MORT&H 5th Revision

Shivaraj Halyal1, Prof.G. Kavitha2, Avinash Balegar3

1

Department of Civil Engineering, K.L.E. Technological University, Hubli, Karnataka, India

2

Department of Civil Engineering, RASTA-Centre for Road Technology VTU-Extension Centre,

Bangalore, Karnataka, India

3

Balegar Associates, Haveri, Karnataka, India

ABSTRACT

Sub Surface drainage is a key element in the design of pavement system, because it is often lead directly to the

pavement failure if laid with lack of preliminary studies need to be conducted for getting good performance of

pavement structure throughout its design life . The sub surface drainage problems encountered on each section of

highways may be different and will require specific consideration and treatment depending upon site condition. Proper

construction and QC/QA testing operations can help to ensure good performance of the sub-base layer. Excessive

compaction can alter the gradation and create additional fines that may result in lower permeability than determined

in laboratory tests and used in the pavement system design. However, the optimization of structural contributions

from high stability, versus the need to provide adequate drainage for pavement materials is still a point of debate.

Hence it is very essential to study and compare Drainage characteristics of Granular Subbase in terms of Coefficient

of Permeability so that along with stability it’s possible to have a clear idea on effect of its material characterization

on their effective drainage property as wells before actual execution on site. From this study an attempt has been

made to determine and compare drainage characteristics of GSB layer on field using semi model pavement. Such

that Permeability characteristics are examined for all six GSB gradations specified in the MoRT&H 5th revision and

AASHTO-57 GSB Grade as shown in Table 1 and 2 by varying hydraulic gradient with constant head permeability

concept in metal chamber which simulates semi model pavement, so that optimum hydraulic gradient (camber to GSB

Layer) is determined for each grades at which maximum hydraulic conductivity is expected. Amongst all six GSB

grades specified in MoRT&H (5th revision) Grade III gives maximum permeability of 3675.66 m/day at optimum

gradient 2.5% & which is most suitable for all locations where drainage is an at most important consideration. Test

conducted on Grade II & Grade I at all gradients, showed no flow through them, because thick particle interlocking.

Therefore it is suggested to use in less rainfall areas or areas where there is need of structural support to pavement

rather than drainage requirement.

Keywords: Coefficient of Permeability, Hydraulic Gradient, Hydraulic Conductivity, Granular Subbase or GSB

INTRODUCTION

One of the most important factors in building a road is drainage. If every other aspect of highway Design and

construction is done perfectly but the drainage does not work well, the road will fail quickly. Highway drainage and

sub drainage systems are complex and location specific. Because, sub surface drainage problems encountered on each

section of highways may be different and will require specific consideration and treatment. There are many factors to

consider when designing drainage systems. Most of the design guides and equations available come from empirical

studies applicable only to limited geographic regions. Yet processes derived from empirical studies are often used

indiscriminately. It is important to be aware of the situations for which a particular design process is applicable.

Subsurface drainage problem has several adverse effects especially on pavement performance as manifested in

premature rutting, cracking. They may also lead to slope failures, particularly when fills are constructed on existing

Scholars Research Library 1

Halyal, et al., Euro. J. Appl. Eng. Sci. Res., 2017, 6(1): 1-10

slopes or when roads are constructed through steep cuts. Subsurface drainage that removes excess water from the

pavement structure increases the performance and life of a pavement section.

The current practices of pavement construction in India consider the Granular Sub-Base (GSB) as a drainage layer.

Good drainage characteristics are generally achieved by providing suitable grade of material having adequate

permeability characteristics along with structural adequacy which depending upon site condition with respect to

rainfall intensity in that area, also it is important to analyze various factors which affects performance of drainage

layer before actually providing it on site, so that designed drainage system will keep pavement structure well drained,

well in condition and well performed throughout its design life.

Granular Subbase

According to MoRTH 5th revision, material to be used for the work shall be natural sand, crushed gravel, crushed

stone, crushed slag, or combination there of depending upon the grading required. Use of materials like brick metal,

kankar and crushed concrete shall be permitted in the lower sub-base. The materials shall be free from organic or

other deleterious constituents and shall conform to the gradings and physical requirements given in Table 4. Gradings

III and IV shall preferably be used in lower sub-base. Gradings V and VI shall be used as a sub-base cum drainage

layer. Where the sub-base is laid in two layers as upper sub-base and lower sub-base the thickness of each layer shall

not be less than 150 mm.

In present study Drainage characteristics are to be determined interms of Permeability characteristics of GSB mix by

preparing specimens fulfilling the required gradation of Granular Sub-base layer specified by different agencies such

as MORT&H(5th revision), AASHTO-57 as per Job mix formula by using Constant Head Permeability concept with

the help of permeability chamber such as Model Pavement of size 2 m x 1.5 m x 1.0 m, pavement of area 1.5 m x 1.5

m with varying the Hydraulic gradient (i) that is slope to permeability chamber of 2.5%, 3.5% and 4% , to simulate

the field condition and permeability values are calculated and compared for different gradations.

Coefficient of Permeability

The coefficient of permeability, k, also called the hydraulic conductivity. This is a unit of velocity, is a measure of the

ease with which fluids can travel through a porous medium.

Darcy’s Law

Darcy’s law implies a linear relationship between the rate of flow q;or flow velocity, V; and the hydraulic gradient, i.

For valid laminar flow condition, which is the flow of water through void spaces between soil particles, Darcy’s law

is generally expressed as:

v=k x i

Or q=k x i x A

Where: v=flow discharge velocity in cm/sec, i=hydraulic gradient; q=volume of flow per unit of time in cc/sec; A=

cross-sectional area to the direction of flow in cm2, and k=coefficient of permeability in cm/sec

Optimum Hydraulic Gradient

Excessive gradients lead to turbulent flow, a condition that should be avoided for several reasons. First, Darcy’s

law no longer applies under turbulent conditions. Second, high seepage Pressures could lead to consolidation of

the specimen and, turbulent flow may induce fines movement. Hence it is important to check the hydraulic gradient

at which maximum flow or hydraulic conductivity is occured. In current study optimum hydraulic gradients can

be detected by plotting hydraulic conductivity vs. gradient. Darcy’s law says that these two variables are directly

proportional. If at some point the slope begins to decrease with increasing gradient, something is inhibiting flow. This

could be the onset of the turbulent flow. Alternately, discharge could be plotted against gradient. A drop in hydraulic

conductivity would indicate a problem.

LITERATURE REVIEW

To properly protect highway pavement structural sections, subsurface drains must be capable of removing the water

as fast as it enters.

Scholars Research Library 2

Halyal, et al., Euro. J. Appl. Eng. Sci. Res., 2017, 6(1): 1-10

Surface water can enter into highway pavement structural sections through cracks or joints in rigid pavements; or

through cracks, joints or the pavement surface in flexible pavements. Temperature changes, weathering, pavement

deflection under traffic, and other actions can produce openings or highly permeable areas in road surfaces to permit

water to enter pavement structural sections. Since all of the specific locations where water can enter structural sections

cannot be predicted in advance, so for this purpose subsurface drainage systems are needed for the full width of

pavements that may be subjected to significant numbers of heavy wheel impacts while the sections contain excess

water.

Chapuis developed a horizontal permeameter to measure the permeability of granular and sandy soils. Dimensions

of the permeameter were 0.15 m x 0.15 m x 0.30 m. The design details were compatible with those of the vertical

permeameter recommended by ASTM D2434, except a flexible rubber membrane was used on the top of compaction

mold, to provide a good seal against leakage. After the sample is saturated using de-aired water, tests are conducted

at various hydraulic gradients.

Veeraragavan have reported comparable values of laboratory measured permeability of all six GSB gradations given

in the MORT&H (4th revision) speculations. The permeability values obtained in terms of coefficient of permeability

of GSB mixes are less than 3.17 m/d indicating that these mixes cannot be used for subsurface drainage purpose. On

the contrary, the use of such layer may serve as a structural layer that is a lower sub base but without desired drainage

property.

Randolph also developed a horizontal permeameter to measure the permeability of granular materials. A sample

is compacted vertically and the measurement of permeability is done horizontally, representing field conditions of

vertical compaction and horizontal movement of water in bases. The cross sectional dimensions of the permeameter

mould are 0.3 m X 0.3 m. X 0.45 m. Long. This permeameter cell has a perforated plate with 9 mm diameter holes

both at the inlet and outlet end of the flow. Flexible closed-cell polypropylene foam sheets are glued to all sides of the

sample cell to ensure no leakage in the system. Water chambers are attached with piezometer at the outflow and inflow

end to measure the head loss during flow. Using the measured head loss and the quantity of water flowing through

sample, horizontal permeability of the material is determined using Darcy’s equation.

Present Study

The metal chamber was fabricated to the dimension of 200*150*100 cm and the porous plates are provided at 25 cm

from either side as shown in Figure 1. Subgrade was first laid in the mould and compacted in three layers to get the

required compaction i.e. 97% of obtained lab density as per MoRT&H specification. Above the compacted subgrade

a plastic sheet was placed as a separation layer in between sub grade and GSB to arrest the water entering into sub

grade while studying the permeability of the GSB mix. The drainage characteristics were evaluated for different GSB

gradations for material layer thickness of 300 mm. A camber of 2.5%, 3.5% and 4.0% were provided to Permeability

chamber itself with the help of Hydraulic Jack arrangement so as to replicate the actual field condition.

Table 1: Grading for Granular Sub-base Materials as per latest MoRT&H 5th

Revision

IS sieve Percent by weight passing the IS sieve

designation Grading I Grading II Grading III Grading IV Grading V Grading VI

75.0mm 100 - - - 100 -

53.0mm 80-100 100 100 100 80-100 100

26.5mm 55-90 70-100 55-75 50-80 55-90 75-100

9.50mm 35-65 50-80 - - 35-65 55-75

4.75mm 25-55 40-65 10-30 15-35 25-50 30-55

2.36mm 20-40 30-50 - - 10-25 10-25

0.85mm - - - - 2-10 -

0.425mm 10-15 10-15 - - 0-5 0-8

0.075mm <5 <5 <5 <5 - 0-3

Scholars Research Library 3

Halyal, et al., Euro. J. Appl. Eng. Sci. Res., 2017, 6(1): 1-10

Table 2: Grading for Granular Sub-base Materials Proposed by AASHTO- 57

Sieve size in mm Percent by Weight Passing Sieve

37.5mm 100

25mm 95-100

19mm -

12.5mm 25-60

9.5mm -

4.75mm 0-10

2.36mm 0-5

1.18mm -

0.3mm -

0.075mm -

Experimental setup for Horizontal Permeability

Water

Rectangular notch

300 mm GSB

700 mm subgrade

Drain Valve

2000mm

SIDE VIEW

Figure 1: Side view of permeability chamber

Figure 2: Flow chart of Experimental Work conducted

The materials used in the present study are Crushed stones from Tippagondanahalli quarry area near Magadi in

Ramanagar district. Different sizes of aggregates used for present study are 40 mm down, 20 mm down, 12 mm down,

6 mm down, 4.75 mm down and quarry dust as shown in Figure 2. The physical properties of the these aggregate

Scholars Research Library 4

Halyal, et al., Euro. J. Appl. Eng. Sci. Res., 2017, 6(1): 1-10

materials were determined in the VOLVO RASTA laboratory and values got were under the limit and satisfying

requirements of study as per MoRT&H 5th revision 2013. Weight of the total quantity of dry aggregate required to

fit volume of semi model pavement area is calculated as per volume of an area for each grade material separately

and then according to Rothfutch’s method, proportioning of GSB gradation is carried out to determine percentage of

different sizes aggregate required to prepare sample according to each grade specified in MoRT&H 5th revision as

shown in Table 1 and 2.

Table 3: Optimum Moisture Content and Maximum Dry Density for GSB Grades obtained from laboratory compaction test

Mix Grades Max Dry Density (gm/cc) Optimum Moisture Content (%)

GRADE-III 2.14 3.18

GRADE-IV 2.16 3.50

GRADE-V 2.20 3.53

GRADE-VI 2.29 3.87

As per Job Mix Formula

GRADE-I 2.42 4.15

GRADE-II 2.39 4.00

AASHTO-57 2.03 1.73

Hydraulic Jack Arrangement is provided as shown in the Figure 4 & 6 at one side of Permeability Chamber to

provide hydraulic gradient or camber to simulate field condition by lifting chamber itself and analyze permeability

characteristics of GSB gradations at different Hydraulic gradients. In present study it has been considered 2.5%, 3.5%

and 4.0% camber to check variability of permeability value of GSB grades.

Water is taken from an Over Head tank which is at top of the building; a separate connection is made from the tank

to the field area which is the gravity flow. Capacity of over head tank is 10000 liters.

A geo filter textile was placed between the sub base specimen and the porous plate and for preventing the fines from

clogging the porous Plates and affecting actual permeability values. In this study Geotextile of 200 GSM is provided,

as higher the GSM (Grams per square meter) was restricting the flow.

Material were staked as per the sizes nearby experimental setup according to size of aggregates and calculated quantity

of different size aggregate material for each grade are taken and mixed thoroughly in mechanical mixer by adding

OMC (Optimum Moisture Content) which is previously determined by Modified Compaction test in laboratory for

all six grades values are shown in Table 3, during process of mixing and laying of GSB material it was confirmed

that there is no segregation occurred. The prepared sample is laid in two layers and compaction is carried till it

achieves required density by aid of metal plate hammer. In case of combination grades like Grade-III + Grade-V,

sample is prepared as per the required quantity and laid in two layers each of 150 mm respectively as per MoRT&H

specification.

After laying and compaction of GSB layer, water supply was provided from the overhead tank, 2 inlet and outlet

valves of 2 inch and 1.5 inch respectively were provided for the entry of water into the specimen and also Rectangular

notch of 15 cm width, 26 cm length & 2.5 cm depth is provide for collection of discharge.. Initially the sample was

kept for saturation for about 24 hours so as make sure that all the air voids were removed, saturation hours may

extend depending upon the gradations because dense gradations may require saturation up to 8 days. After attaining

the saturated condition the water was discharged through the Rectangular notch with clear discharge of water and

expulsion of air from the sample.

Once completing the all prerequisites, Gradient is provided to Permeability chamber itself at one end of the chamber

by lifting chamber itself by hydraulic jack arrangement (rear end), by varying hydraulic gradient discharge is

collected through Notch till constant set of readings are obtained. The discharge time recorded to collect 10000

ml water; usually readings are collected every hour by noting temperature, water viscosity changes primarily with

temperature because unit weight and other properties remain constant. Since permeability is inversely proportional

to viscosity, permeability increases when the temperature is higher. During whole process of permeability test for

each grade of GSB, Constant Head of water is maintained at entry of metal chamber itself even though head is

maintained at Overhead tank. Finally Coefficient of Permeability is calculated for each grade using Darcy’s constant

Head Permeability formula in m/day or cm/sec as shown in Table 4.

Scholars Research Library 5

Halyal, et al., Euro. J. Appl. Eng. Sci. Res., 2017, 6(1): 1-10

Multiple linear regression equation is developed by correlating statically, observed coefficient of permeability of

different grades with those properties which known to exert influence on Permeability. The result shows that most

significant properties were effective grain size D10, Porosity n, Voids ration e, achieved compacted density, material

passing 75 micron sieve as shown in Table 5.

Figure 3 : Field Setup of Horizontal Permeability Chamber

Figure 4: Rear Elevation of Fabricated Chamber showing Hydraulic Jack arrangement

Figure 5: Front Elevation of Fabricated Chamber

Figure 6: Gradient provision by Hydraulic Jack Arrangement to semi model pavement

Scholars Research Library 6

Halyal, et al., Euro. J. Appl. Eng. Sci. Res., 2017, 6(1): 1-10

Data collection and analysis

Horizontal permeability characteristics determined for granular sub-base Grade III, Grade III+V, Grade III+VI, Grade

IV, Grade V, Grade VI, Grade IV+V, Grade IV+VI, Grade II (MORT&H 5th revision) and AASHTO-57 gradations

by varying Hydraulic gradient 2.5%, 3.5% and 4.0%. Combination Grades such as Grade III+V, Grade III+VI, Grade

IV+V, Grade IV+VI are laid in two layers of 150 mm+150 mm,(viz bottom layer will be Grade III and top layer will

be Grade V as per MORT&H 5th revision).

ABSTRACT OF PERMEABILITY READINGS

(HORIZONTAL PERMEABILITY CHAMBER)

Table 4: Abstract of k values at different gradient

PERMEABILITY at PERMEABILITY at PERMEABILITY at

GRADE OF GSB

2.5% slope, m/day 3.5% slope, m/day 4% slope, m/day

GRADE III 3675.66 3056.23 2831.52

GRADE III+V 3049.40 2493.53 2263.51

GRADE III+VI 2432.37 2212.83 1913.35

GRADE IV 2418.28 1698.74 1601.42

GRADE IV+V 2366.20 2040.49 1943.52

GRADE IV+VI 1605.64 1489.04 1489.12

AASHTO57 3186.70 2319.21 2132.59

GRADE V 2423.14 1930.83 1695.51

GRADE VI 1293.62 1297.34 1476.96

GRADE I & II NO FLOW WAS OBSERVED FOR ALL HEADS

Figure 7: Comparison of Coefficient Permeability for all Grades of GSB

Multiple Linear Regression equation

Table 5: Parameters for developing Multiple Linear Regression equation

Observed Permeability 75micron Effective grain Predicted permeability,

Grade Voids ratio, e

highest, K m/day passing,% size D10 K m/day

GRADE I&II 0 0.16 2.050 0.15 28.32

GRADE III 3675.66 0.36 0.660 0.86 2907.75

GRADE IV 2418.28 0.28 0.780 0.5 2343.65

GRADE V 2423.14 0.24 0.000 1.3 2140.57

GRADE VI 1476.96 0.19 0.780 0.55 1443.55

AASHTO-57 3186.70 0.43 0.000 1.63 3633.52

Equation generated by statistical correlation is as follows,

Y = 1.250598 + 10.97405X1 -1.37138X2-1.08219X3

Scholars Research Library 7

Halyal, et al., Euro. J. Appl. Eng. Sci. Res., 2017, 6(1): 1-10

Where,

Y= Permeability of different grades in m/day X1= Voids ratio, n

X2= 75micron passing material, % X3= Effective grain size, D10

RESULTS AND DISCUSSION

Permeability results for different gradations as specified in the MoRT&H 5th revision and AASHTHO-57 are tabulated

in the Table 1 and discussion about all grades are quoted as follows.

In present study multiple regression equation was developed by comparing maximum hydraulic conductivity with

parameter affecting K values such as Voids ratio e, 75micron passing material and effective grain size material D10.

By regression equation predicted permeability values are obtained for all grades. Out of six GSB grades Grade III,

Grade IV, Grade V and Grade VI obtained permeability values are more than predicted values. AASHTO-57 Grade

obtained permeability is around 17%less than predicted value, for Grade I & Grade II no flow of water is observed so

values are less than predicted value. So it requires ascertaining these parameters before conducting test to know trend

of ‘k’ values with these parameters as shown in Figure 3.

Grade III

According to Indian standards i.e. MoRT&H 5th revision Grade III is open grade to be provided for GSB. As

per compaction test conducted and obtained MDD of 2.14gm/cc & OMC of 3.18 % to be achieved in the field.

Permeability test conducted in the field for Grade III at 2.5%, 3.5% & 4.0% hydraulic gradients. At 2.5% hydraulic

gradient maximum hydraulic conductivity of 3675.66 m/day is observed and which is more than predicted values

obtained by multiple linear regression analysis by comparing various factors.

Grade IV

Grade IV is also having open gradation but having approximately 5% more finer material compare to Grade III.

MDD & OMC obtained from compaction test conducted at lab level are 2.16 gm/cc and 3.5%. Same as Grade

III permeability test conducted on Grade IV also at all three hydraulic gradients and obtained maximum hydraulic

conductivity of 2418.28 m/day at optimum gradient of 2.5% which is less than predicted value from multiple linear

regressions model developed.

Grade V

Grade V is having approximately 50% finer material i.e.4.75 mm sieve passing, so this grade is considered as close

graded. MDD & OMC obtained are 2.2 gm/cc & 3.53% respectively. Test results for this grade shows that optimum

hydraulic gradient is 2.5% for maximum hydraulic conductivity of 2423.14 m/day.

Grade VI

Grade VI is having 5% more 4.75 mm passing material, 3% more 425 micron passing material and also 3% 75micron

material than Grade V so it is little denser than compared to Grade V. MDD and OMC are 2.19 gm/cc & 3.87%

respectively. Permeability result shows that 4.0% is optimum gradient at maximum hydraulic conductivity of 1476.96

m/day.

Combination grades of GSB

In present study it has been worked on combination grade to know their drainage performance on site, Permeability

test result for combination grade of Grade III+V is gave maximum hydraulic conductivity of 3049.4 m/day at optimum

gradient of 2.5%.

For Combination Grade III+VI, maximum hydraulic conductivity is 2432.37 m/day at optimum gradient of 2.5%.

Like Grade III combination, it has been worked on Grade VI combinations also. Permeability test conducted on

Grade IV+V and got maximum hydraulic conductivity of 2366.20 m/day at optimum hydraulic gradient 2.5%. For

combination of Grade IV+VI maximum hydraulic conductivity of 1605.6 m/day at optimum hydraulic gradient of

2.5% is observed.

Scholars Research Library 8

Halyal, et al., Euro. J. Appl. Eng. Sci. Res., 2017, 6(1): 1-10

Grade I & II

Grade II is the densest grade next to the Grade I amongst all Indian grades specified in the MoRT&H 5th revision.

This grade is having around 65% of 4.75 mm passing material and around 30-50% of 2.36 mm passing material so

it is Grade II is the close graded. MDD & OMC from lab compaction test on this grade gives result of 2.29 gm/cc &

4.15% respectively. Permeability test also for this grade is conducted at 2.5%, 3.5% & 4.0% gradients but no flow

was observed for any of gradients. In case of Grade I also flow of water is observed because it is denser than Grade

II in particle distribution.

AASHTO-57

AASHTO-57 is open grade amongst all foreign grades of Granular Subbase gradations available; this grade is

selected in this study and tested for Coefficient of Permeability at different hydraulic gradients of 2.5%, 3.5% &

4.0% as conducted for Indian grades to compare with them. MDD & OMC for this grade are 2.03 gm/cc & 1.73%

respectively. Obtained maximum hydraulic conductivity is 3186.70 mm/day at optimum gradient of 2.5% which is

less than predicted from regression model.

Optimum Gradient

By test results on all grades it is observed that all most all grades having optimum gradient of 2.5% at which maximum

permeability can be expected and for many grades higher hydraulic gradient was causing turbulence in flow of water

due to this obtained coefficient of permeability was less at that respective gradient as shown in Figure 7.

CONCLUSION

Grade III gives highest coefficient of permeability amongst all gradations specified in the MoRT&H for GSB at

optimum gradient of 2.5% because of it has most open material gradation. So Grade III can be effectively used

for heavy monsoon regions for best performance of GSB layer as a Drainage layer. Along with effective drainage

property, Structural stability of this grade can be improved by working on combination grade III+V because it is

showing good performance as compared to other combination grade.

Test conducted on Grade I & Grade II at all gradients, showed no flow, it is because of dense material gradation,

there is thick particle interlocking. These grades showed good structural stability than drainage property. Therefore

for better performance of these grades it is suggested to use them in areas where there is need of structural support to

pavement rather than drainage requirement.

For Grade V and Grade VI even though there is specification to use them as structural layer in combination grade,

both fulfils the drainage requirement with providing full thickness of 300 mm also, by viewing all data obtained from

study conducted it can be inferred that they can also be used as drainage come structural layer in medium rainfall

areas. But while proving these grades for full thickness gradient or camber provision must be over looked.

Combination grades as specified in the MoRT&H 5th revision gives satisfactory permeability results.

AASHTO-57 is the most open grade in foreign specification for GSB layer, by test result for this grade shows that it

is satisfy drainage requirement so can be used in heavy rainfall regions. But comparing to Indian grades, Grade III is

giving much more better result at same optimum gradient than AASHTO-57 so is it suggested to go with Indian grade

only rather than foreign.

It was observed that at higher side of hydraulic gradients flow of water was becoming turbulent so by this it is

conclude that gradient is the one of the effective parameter affecting permeability of GSB, as higher the gradient

provision there may be decrease in the ‘K’ value.

ACKNOWLEDGMENT

One of the authors Prof. Shivaraj S.Halyal gratefully acknowledges G. Kavitha and Dr. Krishnamurthy and

Mr.Avinash Balegar for the kind sustainable support and fruitful discussions, during the project.

REFERENCE

[1]. Veeraragavan, A. and Grover, S., Natl Acad Sci Eng Med, 2010.

Scholars Research Library 9

Halyal, et al., Euro. J. Appl. Eng. Sci. Res., 2017, 6(1): 1-10

[2]. Ministry of Road Transport and Highways (MORT&H). Government of India, Fifth Revision, 2012.

[3]. Richardson, D.N., J Transp Eng, 1997.

[4]. Cedergren, H.R., O’Brien, K.H. and Ajrman, J.A., Federal Highway Administration. Office of Research, United

States,1972. 72(30).

[5]. American Association of State Highway and Transportation Officials. AASHTO guide for design of pavement

structures, Washington, D.C., 4th Edn, 1998.

[6]. US Department of transportation., FWHA report no. SA-92-008, 1992.

[7]. Khanna, S.K. and Justo, C.E.G., Nemchand and Brothers Publications, Roorkee, 2001.

[8]. Khanna, S.K., Justo C.E.G. and Veerraghavan, A., Nemchand and Brothers Publications, Roorkee, 2009.

[9]. Kumar, S., Thesis Report (Unpublished), RASTA-Center for Road Technology.

Scholars Research Library 10

You might also like

- Cohesive Sediments in Open Channels: Erosion, Transport and DepositionFrom EverandCohesive Sediments in Open Channels: Erosion, Transport and DepositionNo ratings yet

- Improvement of Road Drainage System For Indian Roads: Team Leader Resident Engineer Lnmippl ITLDocument3 pagesImprovement of Road Drainage System For Indian Roads: Team Leader Resident Engineer Lnmippl ITLGaurav RajNo ratings yet

- Numerical Modelling and Analysis of Fluid Flow and Deformation of Fractured Rock MassesFrom EverandNumerical Modelling and Analysis of Fluid Flow and Deformation of Fractured Rock MassesXing ZhangNo ratings yet

- Estimating The Benefits of Improved Drainage On Pavement PerformanceDocument15 pagesEstimating The Benefits of Improved Drainage On Pavement PerformancesidxxxnitcNo ratings yet

- Drainage For DamsDocument10 pagesDrainage For Damschutton681No ratings yet

- 13Document5 pages13yash_monu05No ratings yet

- Preene - Design and Interpretation of Packer TestingDocument43 pagesPreene - Design and Interpretation of Packer TestingTechan EshetuNo ratings yet

- Weber Zornberg 2005a PDFDocument7 pagesWeber Zornberg 2005a PDFHồ ThắngNo ratings yet

- Ijciet 06 09 012Document11 pagesIjciet 06 09 012IAEME PublicationNo ratings yet

- Structural and Hydrological Design of Permeable PavementsDocument20 pagesStructural and Hydrological Design of Permeable Pavementssach1116No ratings yet

- Using Simulated Annealing and Evolutionary Algorithm to Optimize Clay Core Dimensions in Earth DamsDocument16 pagesUsing Simulated Annealing and Evolutionary Algorithm to Optimize Clay Core Dimensions in Earth Damsyaseen90azizNo ratings yet

- TOCIEJ-9-388 Permeability of Subballast PDFDocument6 pagesTOCIEJ-9-388 Permeability of Subballast PDFPetruMarcuNo ratings yet

- Finite Element Simulation of Construction Site Dewatering: Carlos Alonso, Alejandro Ferrer, Vicente SoriaDocument8 pagesFinite Element Simulation of Construction Site Dewatering: Carlos Alonso, Alejandro Ferrer, Vicente SoriajulianaNo ratings yet

- Water 11 00444Document21 pagesWater 11 00444AFIYA NARZISNo ratings yet

- Sustainability 12 06667 v2Document30 pagesSustainability 12 06667 v2yehunzer yeneshNo ratings yet

- Permeable Concrete Eco-Paving As Best Management Practice in Australian Urban Road EngineeringDocument11 pagesPermeable Concrete Eco-Paving As Best Management Practice in Australian Urban Road Engineeringhasan syukurNo ratings yet

- Water Testing For Grouting LUGEONDocument12 pagesWater Testing For Grouting LUGEONElba BrizuelaNo ratings yet

- Numerical Analysis of Buried Pipes Under Field Geo-Environmental ConditionsDocument23 pagesNumerical Analysis of Buried Pipes Under Field Geo-Environmental ConditionsAmanda SafiraNo ratings yet

- Development of Permeability Test Method For Porous Concrete Block Pavement Materials Considering CloggingDocument7 pagesDevelopment of Permeability Test Method For Porous Concrete Block Pavement Materials Considering CloggingRizal RifdoNo ratings yet

- Geocellular Railway Drainage Systems Physical andDocument12 pagesGeocellular Railway Drainage Systems Physical andlindaNo ratings yet

- Deoetal 2019Document6 pagesDeoetal 2019Asad ImranNo ratings yet

- Monterrosa 2019Document18 pagesMonterrosa 2019GERARDO TORRES RUIZNo ratings yet

- Al-Rubaei Long-Term Hydraulic PerformanceDocument13 pagesAl-Rubaei Long-Term Hydraulic PerformanceJosef HosorioNo ratings yet

- Kia 2021Document22 pagesKia 2021Chamux skalNo ratings yet

- 5 - Une Étude Approfondie Des Différents Types de Contrôle Des InfiltrationsDocument15 pages5 - Une Étude Approfondie Des Différents Types de Contrôle Des InfiltrationsabdelhamidNo ratings yet

- Effects of Concrete Block Pavement On Flow Retardation FactorDocument9 pagesEffects of Concrete Block Pavement On Flow Retardation FactorSnehal AbhyankarNo ratings yet

- Study On Drainage Related Performance of Flexible Highway PavementsDocument12 pagesStudy On Drainage Related Performance of Flexible Highway PavementsGaurav RajNo ratings yet

- Predict undrained uplift capacity of buried offshore pipelinesDocument49 pagesPredict undrained uplift capacity of buried offshore pipelinesaaaNo ratings yet

- Design for efficient drainage of railway track foundationsDocument12 pagesDesign for efficient drainage of railway track foundationsAVSSSNo ratings yet

- Assessing Slope Stability of Egypt's Ismailia Canal After Geotextile LiningDocument13 pagesAssessing Slope Stability of Egypt's Ismailia Canal After Geotextile LiningEngr. Muhammad Jamil Alam SandhuNo ratings yet

- Methods of Interpretation of Borehole Falling-Head Tests Performed in Compacted Clay LinersDocument13 pagesMethods of Interpretation of Borehole Falling-Head Tests Performed in Compacted Clay LinersMohamed MamdohNo ratings yet

- Modelling and Analysing Failure Modes of Buried Pipelines Perpendicularly Crossing Landslide BoundariesDocument12 pagesModelling and Analysing Failure Modes of Buried Pipelines Perpendicularly Crossing Landslide BoundariesJaime SeguraNo ratings yet

- Omar Y. Mohammed and Ammar A. Shiekha: Dewatering System Control by MATLAB SoftwareDocument9 pagesOmar Y. Mohammed and Ammar A. Shiekha: Dewatering System Control by MATLAB SoftwareLucas sckuvieNo ratings yet

- Paper - Numerical Analysis of Buried PipesDocument22 pagesPaper - Numerical Analysis of Buried Pipeswebs.usuarioNo ratings yet

- Evaluation of Three Analysis Methods of Dewatering SystemsDocument17 pagesEvaluation of Three Analysis Methods of Dewatering Systems_seeNo ratings yet

- Applsci 11 08118 v2Document17 pagesApplsci 11 08118 v2JHEIMY EDWIN CARIHUASAIRO NAZARIONo ratings yet

- wst086071681 (1)Document12 pageswst086071681 (1)Jeffrey ilevbagieNo ratings yet

- J.jenvman.2019.109510 - Paving SystemDocument13 pagesJ.jenvman.2019.109510 - Paving SystemAndry BereNo ratings yet

- Groundwater Seepage Rate (GSR) A New Method For Prediction of Groundwater Inflow Into Jointed Rock Tunnels 1-s2.0-S0886779816308902-MainDocument13 pagesGroundwater Seepage Rate (GSR) A New Method For Prediction of Groundwater Inflow Into Jointed Rock Tunnels 1-s2.0-S0886779816308902-MainqgliangNo ratings yet

- Publication DR Je It 15009210Document10 pagesPublication DR Je It 15009210brogini.dNo ratings yet

- Estimation of The Grout Take Using Empirical Relationships (Case Study: Bakhtiari Dam Site)Document15 pagesEstimation of The Grout Take Using Empirical Relationships (Case Study: Bakhtiari Dam Site)garusingheNo ratings yet

- The Impacts of Poor Drainage On Road Performance in KhartoumDocument8 pagesThe Impacts of Poor Drainage On Road Performance in KhartoumVgkBharadwajNo ratings yet

- The Impacts of Poor Drainage On Road Performance in KhartoumDocument8 pagesThe Impacts of Poor Drainage On Road Performance in Khartoummuhd amirulNo ratings yet

- Liu 2020Document23 pagesLiu 2020Girard Immanuel SorianoNo ratings yet

- Lab Report 4 CEG453Document6 pagesLab Report 4 CEG453azrainNo ratings yet

- Dominic Et Al. (2019) Computational Investigation of Hydraulic PerformanceDocument11 pagesDominic Et Al. (2019) Computational Investigation of Hydraulic PerformanceCarlos Arturo Gomez JimenezNo ratings yet

- Iowa Storm Water Management Manual: Design Standards Chapter 10-Pavement SystemsDocument52 pagesIowa Storm Water Management Manual: Design Standards Chapter 10-Pavement SystemsriteshNo ratings yet

- Effect of Factors Influencing Bridge Scour: AbstractDocument10 pagesEffect of Factors Influencing Bridge Scour: AbstractLydiaNo ratings yet

- Travasarou Et Al 2012 PDFDocument12 pagesTravasarou Et Al 2012 PDFZine L DelNo ratings yet

- A Comprehensive Study of Different Types of Seepage Control Measures For Earth Dam Using FEMDocument15 pagesA Comprehensive Study of Different Types of Seepage Control Measures For Earth Dam Using FEMMeku TNo ratings yet

- Weiss 2017Document21 pagesWeiss 2017Girard Immanuel SorianoNo ratings yet

- SPE/IADC 140144 Dynamic Aspects Governing Cement Plug Placement in Deepwater WellsDocument14 pagesSPE/IADC 140144 Dynamic Aspects Governing Cement Plug Placement in Deepwater WellsCoolProphetNo ratings yet

- Pore-scale investigation reveals factors controlling hydraulic conductivityDocument13 pagesPore-scale investigation reveals factors controlling hydraulic conductivityAli AhmadNo ratings yet

- Chemical Engineering Science: Abdalellah O. Mohmmed, Hussain H. Al-Kayiem, A.B. OsmanDocument19 pagesChemical Engineering Science: Abdalellah O. Mohmmed, Hussain H. Al-Kayiem, A.B. OsmanDiego Sanmiguel VillacresesNo ratings yet

- Avalia Modelos de ErosaoDocument17 pagesAvalia Modelos de ErosaoJoão Guilherme CyrilloNo ratings yet

- Froude Number Data Analysis and Its Implications On Local ScourDocument6 pagesFroude Number Data Analysis and Its Implications On Local ScourMNo ratings yet

- Structural Behavior of Weirs With One Bottom Circular OpeningDocument13 pagesStructural Behavior of Weirs With One Bottom Circular Openingayman_awadallahNo ratings yet

- Finite Element Modelling For PDocument14 pagesFinite Element Modelling For PjackqNo ratings yet

- Case Studies in Construction Materials: Rishi GuptaDocument9 pagesCase Studies in Construction Materials: Rishi GuptaRajaSekhararayudu SanaNo ratings yet

- Study On Porous PavementsDocument22 pagesStudy On Porous PavementsPavan KumarNo ratings yet

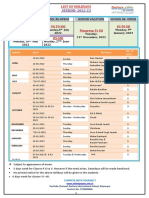

- List of Holidays 2022-23Document1 pageList of Holidays 2022-23Sandeep BoraNo ratings yet

- Microprocessor Digital Hot Air Oven QuoteDocument1 pageMicroprocessor Digital Hot Air Oven QuoteSandeep BoraNo ratings yet

- Shri Mata Vaishno Devi Shrine Board Poojan Parchi Services - Aky - 9Document2 pagesShri Mata Vaishno Devi Shrine Board Poojan Parchi Services - Aky - 9Sandeep BoraNo ratings yet

- INsitu DimensionDocument1 pageINsitu DimensionSandeep BoraNo ratings yet

- Loan EMI Table: Loan Number Loan Booked Date Loan Type Principal Amount Interest Rate Tenure O/S PrincipalDocument1 pageLoan EMI Table: Loan Number Loan Booked Date Loan Type Principal Amount Interest Rate Tenure O/S PrincipalAmaanNo ratings yet

- MTS - Quote - 2022-191304 (IIT Kanpur - MTS 244.11 Actuator (15kN) With HPU, HSM & Controller)Document17 pagesMTS - Quote - 2022-191304 (IIT Kanpur - MTS 244.11 Actuator (15kN) With HPU, HSM & Controller)Sandeep BoraNo ratings yet

- CONSTRUCTIONS OF ANGLESDocument6 pagesCONSTRUCTIONS OF ANGLESyugiNo ratings yet

- Acknowledgement SlipDocument1 pageAcknowledgement SlipGurbir SinghNo ratings yet

- Uttar Pradesh Power Corporation Ltd. - PAYMENTDocument1 pageUttar Pradesh Power Corporation Ltd. - PAYMENTSandeep BoraNo ratings yet

- Graphs of Vill-Itora Ch-26.200 KM, B.H.-1Document8 pagesGraphs of Vill-Itora Ch-26.200 KM, B.H.-1Sandeep BoraNo ratings yet

- P 04 Asset Form Assemble - 1Document1 pageP 04 Asset Form Assemble - 1Sandeep BoraNo ratings yet

- Consolidated Drained Triaxial Compression Test For SoilsDocument12 pagesConsolidated Drained Triaxial Compression Test For SoilsRaul Vilcherrez Mendieta100% (1)

- Sandeep Bora: Know Your Client (KYC) Application Form (For Individuals Only)Document5 pagesSandeep Bora: Know Your Client (KYC) Application Form (For Individuals Only)Sandeep BoraNo ratings yet

- Brajesh Kumar TA - 05 - 08 - 22Document3 pagesBrajesh Kumar TA - 05 - 08 - 22Sandeep BoraNo ratings yet

- Log of Borehole, Bh-1: Kahta (Jalaun)Document1 pageLog of Borehole, Bh-1: Kahta (Jalaun)Sandeep BoraNo ratings yet

- Something ConfidentialDocument107 pagesSomething ConfidentialBhagyesh DokeNo ratings yet

- Je 2903221110057Document5 pagesJe 2903221110057Sandeep BoraNo ratings yet

- Semi-Automatic Air Water Pressure Triaxial Testing System DatasheetDocument1 pageSemi-Automatic Air Water Pressure Triaxial Testing System DatasheetSandeep BoraNo ratings yet

- Aashto Laboratory: ReferenceDocument18 pagesAashto Laboratory: ReferenceSandeep BoraNo ratings yet

- Oo 84 28 05 21Document9 pagesOo 84 28 05 21Sandeep BoraNo ratings yet

- HM 33 Table of ContentsDocument59 pagesHM 33 Table of Contentsoscort027No ratings yet

- Semi-Automatic Air Water Pressure Triaxial Testing System DatasheetDocument1 pageSemi-Automatic Air Water Pressure Triaxial Testing System DatasheetSandeep BoraNo ratings yet

- Wifi With Single Signon PDFDocument2 pagesWifi With Single Signon PDFgarima sighNo ratings yet

- Manual Earth Tomo 2 USGovDocument1,278 pagesManual Earth Tomo 2 USGovosp_tigre100% (3)

- NHPC Recruitment for Engineers, Accountants and Medical OfficerDocument7 pagesNHPC Recruitment for Engineers, Accountants and Medical OfficerLily Aditya ChoudharyNo ratings yet

- Geotechnical Engineering Office Publications - Catalogue: Manuals, Guides and Specifications Title No. PriceDocument35 pagesGeotechnical Engineering Office Publications - Catalogue: Manuals, Guides and Specifications Title No. PriceSandeep BoraNo ratings yet

- Test Procedures Manual 2017Document594 pagesTest Procedures Manual 2017Sajjad HussainNo ratings yet

- Soil Calculation Parameter Shear Shear Strength CuDocument77 pagesSoil Calculation Parameter Shear Shear Strength Cucharleshutabara951100% (1)

- Geospec 3 - Model Specification For Soil Testing First EditionDocument2 pagesGeospec 3 - Model Specification For Soil Testing First EditionSandeep BoraNo ratings yet

- Chemical Unit-20 Colorado Procedures - Laboratory:: Aashto AstmDocument2 pagesChemical Unit-20 Colorado Procedures - Laboratory:: Aashto AstmSandeep BoraNo ratings yet

- Flow Through PipesDocument8 pagesFlow Through PipesVijaykumar SurlaNo ratings yet

- Unit 1. Fluid and Fluid PropertiesDocument9 pagesUnit 1. Fluid and Fluid PropertiesNirmal PatelNo ratings yet

- Chapter 4 - PermeabilityDocument44 pagesChapter 4 - PermeabilityAfnan HamimiNo ratings yet

- Open Channels Design GuideDocument31 pagesOpen Channels Design GuideVOJNo ratings yet

- NDHMS v4.3 Tech Note User Guide v1.0Document88 pagesNDHMS v4.3 Tech Note User Guide v1.0krankxxNo ratings yet

- Sheet 2-Pressure DropDocument2 pagesSheet 2-Pressure Dropmohelg83No ratings yet

- Pipes in Series and ParallelDocument12 pagesPipes in Series and ParallelAngelica LosaresNo ratings yet

- Pres. 14 (1hr) Blighs TheoryDocument10 pagesPres. 14 (1hr) Blighs TheoryJahanzeb AliNo ratings yet

- Water Distribution Exam Book PDFDocument136 pagesWater Distribution Exam Book PDFMukomaNo ratings yet

- AttachmentDocument31 pagesAttachmenttedy yidegNo ratings yet

- Topic - 7 - Permeability & SeepageDocument32 pagesTopic - 7 - Permeability & Seepagejimmys45No ratings yet

- Main Principles of Pumps SelectionDocument14 pagesMain Principles of Pumps SelectionMMM000No ratings yet

- CH 7Document127 pagesCH 7qusayNo ratings yet

- Problems Worked in Class - All PDFDocument245 pagesProblems Worked in Class - All PDFGeva GarradoNo ratings yet

- M3c Hazen WilliamsDocument8 pagesM3c Hazen WilliamsTariq AfridiNo ratings yet

- Hydraulic Calculation of Box Culvert: Wlu HC Hu C HLB Blu BLC WLCDocument1 pageHydraulic Calculation of Box Culvert: Wlu HC Hu C HLB Blu BLC WLCIwanTiaraMotorNo ratings yet

- Is Iec 60534 2 1 1998 PDFDocument48 pagesIs Iec 60534 2 1 1998 PDFJorge DuranNo ratings yet

- (CGPR - 82) Nathaniel Bradley and Daniel R. VandenBerge-Beginners Guide For Geotechnical Finite Element Analyses-Center For Geotechnical Practice and Research (2015)Document102 pages(CGPR - 82) Nathaniel Bradley and Daniel R. VandenBerge-Beginners Guide For Geotechnical Finite Element Analyses-Center For Geotechnical Practice and Research (2015)hapsinte100% (1)

- Hydraulics 2 Plate No. 1Document1 pageHydraulics 2 Plate No. 1Charm GarciaNo ratings yet

- Colebrook EquationDocument3 pagesColebrook EquationMuhammad Ghufran KhanNo ratings yet

- Water Supply Design CED 2Document12 pagesWater Supply Design CED 2Mohd Fadhil Musbah100% (1)

- Boiler Feed PumpDocument46 pagesBoiler Feed Pumppratapsingh12100% (1)

- All Chilll Water Products Manual 2008Document38 pagesAll Chilll Water Products Manual 2008Patricia D GarciaNo ratings yet

- Fluid Mechanics PDFDocument59 pagesFluid Mechanics PDFsunny chaurasiaNo ratings yet

- H4 Pipe Friction GroupDocument31 pagesH4 Pipe Friction GroupYash PersÌeNo ratings yet

- Astm d856Document8 pagesAstm d856ADS ADSNo ratings yet

- Waterhammer Analysis John Parmakain Charts PDFDocument13 pagesWaterhammer Analysis John Parmakain Charts PDFdaskirNo ratings yet

- T8 Seepage FlownetDocument11 pagesT8 Seepage FlownetVidyaSagarSinghNo ratings yet

- Fluid Mechanics Question BankDocument11 pagesFluid Mechanics Question BankBharath Waj100% (1)

- AWWA M22 Water MetersDocument126 pagesAWWA M22 Water MetersObeth MichelNo ratings yet