Professional Documents

Culture Documents

BPCL-KOCHI REFINERY IDE-120 ISOLATION & STEAMOUT PROCEDURE

Uploaded by

Fayaz Mohammed0 ratings0% found this document useful (0 votes)

7 views1 pageThe document provides a procedure for isolating and steaming out DCU IDE-120 at the BPCL Kochi Refinery. It involves:

1) Isolating the individual exchangers and lines connected to IDE-120 by closing valves.

2) Deblinding and draining lines connected to IDE-120.

3) Conducting an initial 4 hour steamout by connecting steam hoses.

4) Conducting a final 4 hour steamout after blinding is completed.

5) Checking for hydrocarbons after steamout and handing over IDE-120 to maintenance if none are found.

Original Description:

Original Title

Copy of E-120AB isolation steamout procedure July 2020

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides a procedure for isolating and steaming out DCU IDE-120 at the BPCL Kochi Refinery. It involves:

1) Isolating the individual exchangers and lines connected to IDE-120 by closing valves.

2) Deblinding and draining lines connected to IDE-120.

3) Conducting an initial 4 hour steamout by connecting steam hoses.

4) Conducting a final 4 hour steamout after blinding is completed.

5) Checking for hydrocarbons after steamout and handing over IDE-120 to maintenance if none are found.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views1 pageBPCL-KOCHI REFINERY IDE-120 ISOLATION & STEAMOUT PROCEDURE

Uploaded by

Fayaz MohammedThe document provides a procedure for isolating and steaming out DCU IDE-120 at the BPCL Kochi Refinery. It involves:

1) Isolating the individual exchangers and lines connected to IDE-120 by closing valves.

2) Deblinding and draining lines connected to IDE-120.

3) Conducting an initial 4 hour steamout by connecting steam hoses.

4) Conducting a final 4 hour steamout after blinding is completed.

5) Checking for hydrocarbons after steamout and handing over IDE-120 to maintenance if none are found.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

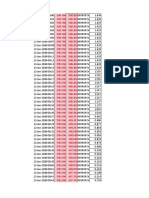

You are on page 1of 1

BPCL - KOCHI REFINERY

MANUFACTURING-REFINERY II: DCU

IDE-120 ISOLATION & STEAMOUT PROCEDURE- July 2020

Sr. No Activity description Date Actual Time Signature Remarks

1 Ensure that DCU is under shutdown

2 Ensure that IDC-101 (WGC) is in stopped condition.

3 Isolation:

Close IDE-119 A-F individual exchanger i/l B/V.

Close IDE-119 B-F individual exchanger o/l B/V. (IDE-119A o/l B/V should be in open condition)

Isolate TV-3601B. (Except u/s B/V)

Ensure TV-3601B bypass is closed.

Isolate FV-3602. (Except u/s B/V)

Ensure FV-3602 bypass is closed.

Close B/V in LCGO makeup to V-136 line (4"-P-ID-3630). Close 2nd B/V near flare KOD also.

Close B/V in LCGO makeup to IDLZ-117 (Demulsifier injection package) line (2"-P-ID-3656).

Close B/V in LCGO makeup to IDLZ-114 (Antifoam injection package) line (2"-P-ID-3611).

Ensure that IDE-120 A/B o/l CBD & OWS connections line's common B/V is in closed condition. Deblind CBD

& OWS lines.

Isolate FV-3603. (Except u/s B/V)

Ensure FV-3603 bypass is closed.

Isolate PSV-3601 A/B.

Line up IDE-120 A/B O/L to CBD and drain line quantity.

4 Deblind PSV-3601 A/B bypass line and line it up.

5 Intial steamout

Connect steam hoses at IDE-119A I/L B/V d/s 1.5" vent & TV-3601B u/s bleeder and open MP steam.

Connect FV-3602 u/s bleeder & FV-3603 u/s bleeder to CBD.

Once PSV-3601 A/B bypass line becomes hot, Close bleeder d/s B/V of the same line. And connect steam

hose to the bleeder.

Once IDE-120 A/B CBD line becomes hot, close CBD B/V of same line.

Carry out intial steam out for 4 hrs.

AFTER INITIAL STEAM OUT, Blinding to be done as per blindlist prepared.

6 Carryout final steam out for 4 hrs.

7 Check for any HC presence in the circuit. If no HC, IDE-120 can be handed over to maintenance.

Prepared by Dhanush P/Fayazuddin M

Reviewed by RAMESAN P R

Approved by SURESH KS

You might also like

- RMH-LC-ACV-DOC-006 RC Equipment Selection Seawater Cooled Package Air ConditionerDocument21 pagesRMH-LC-ACV-DOC-006 RC Equipment Selection Seawater Cooled Package Air Conditionercmc261185No ratings yet

- RGT16 02Document10 pagesRGT16 02prakash reddyNo ratings yet

- J910-XA00-P0ZEN-140073 - ELECTRICAL ROOM LAYOUT DRAWING - CHS C&E - Rev0 (AFC)Document6 pagesJ910-XA00-P0ZEN-140073 - ELECTRICAL ROOM LAYOUT DRAWING - CHS C&E - Rev0 (AFC)Devy MangimbaNo ratings yet

- Service Manual SKS14SBA - VKS14SBADocument21 pagesService Manual SKS14SBA - VKS14SBALindomar ChavesNo ratings yet

- Cdu Furnace Mock Drill DraftDocument8 pagesCdu Furnace Mock Drill Draft00083583rfNo ratings yet

- Inventario Auditoria Externa Al 06-01-2023Document19 pagesInventario Auditoria Externa Al 06-01-2023franklin carvallo castilloNo ratings yet

- EGF Electrical Load ListDocument3 pagesEGF Electrical Load ListHanugroho AjiNo ratings yet

- Skill Development On Power FailureDocument2 pagesSkill Development On Power Failure00083583rfNo ratings yet

- 611/621-Series: Typical ApplicationsDocument3 pages611/621-Series: Typical ApplicationsSetyawan Dwi CahyoNo ratings yet

- Service Manual Us21' Vfs21sba & Sfs21sdaDocument20 pagesService Manual Us21' Vfs21sba & Sfs21sdaLindomar ChavesNo ratings yet

- Dv185whm-Nm0 Accessory Gh523a (A12) Nov2013Document15 pagesDv185whm-Nm0 Accessory Gh523a (A12) Nov2013Khoa DangNo ratings yet

- Subba Central Data Sheet For T/R Units: Additional Development OF Luhais & Subba Oil Field ProjectsDocument7 pagesSubba Central Data Sheet For T/R Units: Additional Development OF Luhais & Subba Oil Field ProjectsMohamedHussein MohamedHusseinNo ratings yet

- GF-4172-QC-EI-FM-0006, Rev. 1 CHECKLIST FOR ABOVEGROUND CABLE LAYING WORKSDocument56 pagesGF-4172-QC-EI-FM-0006, Rev. 1 CHECKLIST FOR ABOVEGROUND CABLE LAYING WORKSsureshNo ratings yet

- Hydro Test Valves S.N Valve Valve Name BMD/TMD Emd C and I OPN Remark SDocument4 pagesHydro Test Valves S.N Valve Valve Name BMD/TMD Emd C and I OPN Remark Sritesh agarwalNo ratings yet

- Presentation - Ruby II - Fso Bd01 - Fpso Lam SonDocument127 pagesPresentation - Ruby II - Fso Bd01 - Fpso Lam SonRubyNo ratings yet

- Sansui Sps21sma-Cus Chassis Cy-ph2529top-Sw SMDocument24 pagesSansui Sps21sma-Cus Chassis Cy-ph2529top-Sw SMAlonso LamusNo ratings yet

- Motorized Valves and Dampers Equipment ListDocument9 pagesMotorized Valves and Dampers Equipment ListAshok RajNo ratings yet

- Tested by M/S Siemens Organized by M/S Emc Witnessed by M/S Pgcil Name G Ramesh Designation SignatureDocument2 pagesTested by M/S Siemens Organized by M/S Emc Witnessed by M/S Pgcil Name G Ramesh Designation SignatureRK KNo ratings yet

- r2b p3 206 02 P HD 00200 - Datasheets For Control Valve, Globe, U 21000 - Rev.1Document377 pagesr2b p3 206 02 P HD 00200 - Datasheets For Control Valve, Globe, U 21000 - Rev.1Diana Paula Echartea MolinaNo ratings yet

- 10) Site Inspection and Test Procedure - A-SignDocument19 pages10) Site Inspection and Test Procedure - A-SignHerman SyahNo ratings yet

- Air CompressorDocument139 pagesAir CompressorPraveen KumarNo ratings yet

- ADUM5402Document29 pagesADUM5402mar_barudjNo ratings yet

- (DT-0581) 21010-BAE-70000-IN-RL-0002 - Revb2Document8 pages(DT-0581) 21010-BAE-70000-IN-RL-0002 - Revb2karthikesan6No ratings yet

- Tcpl-1X63.75 MW Power Plant, Gummidipoondi - 1Document5 pagesTcpl-1X63.75 MW Power Plant, Gummidipoondi - 1SelvaNo ratings yet

- S DDRDocument3 pagesS DDREdciel Ebuen100% (1)

- ADUM5401Document28 pagesADUM5401Muhammad Fakhrur RijalNo ratings yet

- PAC Items U-8 W Remarks (4OCT2022)Document3 pagesPAC Items U-8 W Remarks (4OCT2022)Rene HebaNo ratings yet

- 3890137e Tech Spec Data Sheets 1556604052Document14 pages3890137e Tech Spec Data Sheets 1556604052Prakash AnnamalaiNo ratings yet

- Hydraulic Systems No. 1 or No. 2 - Fill With Hydraulic FluidDocument12 pagesHydraulic Systems No. 1 or No. 2 - Fill With Hydraulic FluidaliNo ratings yet

- Features Applications: D D D D D D DDocument10 pagesFeatures Applications: D D D D D D DHairfhwNo ratings yet

- ca-is3092_3098_datasheet_version1.07_en_20230320Document26 pagesca-is3092_3098_datasheet_version1.07_en_20230320khaled_emamNo ratings yet

- Haier AU422XIEAA User ManualDocument89 pagesHaier AU422XIEAA User Manualmavaka aiameNo ratings yet

- 33 KV Outdoor VCB Pv1750bDocument4 pages33 KV Outdoor VCB Pv1750bAnoop Kumar PandayNo ratings yet

- Ruwais Refinery Expansion Feed Project Feed: PhaseDocument9 pagesRuwais Refinery Expansion Feed Project Feed: PhaseAjit ParanjpeNo ratings yet

- Directional Valves WebinarDocument18 pagesDirectional Valves WebinarhaggNo ratings yet

- Vmy UkDocument8 pagesVmy UkEdwinNo ratings yet

- K.2 Series: User ManualDocument23 pagesK.2 Series: User ManualRafael Angel Vidurrízaga MazuelosNo ratings yet

- WR22 10 - 400 P 131110 e 00Document4 pagesWR22 10 - 400 P 131110 e 00Eng-Mohammed SalemNo ratings yet

- List TB HongDocument2 pagesList TB HongCIVH TB2PPNo ratings yet

- Installation SOP V4Document81 pagesInstallation SOP V4ethosgrNo ratings yet

- Qaswa - 100 ABFV 17.06.21Document1 pageQaswa - 100 ABFV 17.06.21FLOW VALVE AUTOMATIONNo ratings yet

- TM Ceiling Cassette E McQuayDocument120 pagesTM Ceiling Cassette E McQuaySalamet TeguhNo ratings yet

- 5000 horas de vida garantía tecnología alemana LED BoliviaDocument14 pages5000 horas de vida garantía tecnología alemana LED Boliviajose SaavedraNo ratings yet

- Led TV: AA AAADocument44 pagesLed TV: AA AAAJeevan NJNo ratings yet

- Mock Drill Report On IA Failure Dated 09.04.2023Document6 pagesMock Drill Report On IA Failure Dated 09.04.202300083583rfNo ratings yet

- SI0425Document2 pagesSI0425xihua liuNo ratings yet

- 3.EBS1-EPFA76-EBPI-DSEQ-1001-D02 Datasheet For Piping ValvesDocument5 pages3.EBS1-EPFA76-EBPI-DSEQ-1001-D02 Datasheet For Piping ValvesRedhaa .kNo ratings yet

- Flygt FLEXIBLE CABLES EnglishDocument15 pagesFlygt FLEXIBLE CABLES EnglishjuanetnaNo ratings yet

- Api 16A 3 Edition: Api 16A Chairman: John Busby Co-Chair: Jim MccabeDocument11 pagesApi 16A 3 Edition: Api 16A Chairman: John Busby Co-Chair: Jim Mccabesaeed65No ratings yet

- A Shift-12.02.2024 Report1Document1 pageA Shift-12.02.2024 Report1Shiavm PatelNo ratings yet

- 02.03.2021 Ref 1MOMDocument41 pages02.03.2021 Ref 1MOMravitejatalatamNo ratings yet

- Hazop Hazid Action SheetDocument4 pagesHazop Hazid Action Sheetwibowo wibowoNo ratings yet

- ULN2065Document12 pagesULN2065Ishaq BhattiNo ratings yet

- Sas Io ListDocument6 pagesSas Io ListUdaya KakaraNo ratings yet

- 79.01-A-Aux. Boiler Techincal Instructions For Wet PreservationDocument7 pages79.01-A-Aux. Boiler Techincal Instructions For Wet PreservationaironyxNo ratings yet

- Water system datasheets for scrubber & hydratorDocument1 pageWater system datasheets for scrubber & hydratorHEMANTNo ratings yet

- Fire N GasDocument20 pagesFire N GasRachid MenserNo ratings yet

- Ilive Service. Ilive PARTS IDENTIFICATION Issue 5 CONTENTSDocument22 pagesIlive Service. Ilive PARTS IDENTIFICATION Issue 5 CONTENTSpalprodNo ratings yet

- The Latest Advancements in Delayed Coke Drums Inspection Reliability Techniques Harold CIA Mumbai 2016 PDFDocument23 pagesThe Latest Advancements in Delayed Coke Drums Inspection Reliability Techniques Harold CIA Mumbai 2016 PDFFayaz MohammedNo ratings yet

- Bio Data FarhaDocument1 pageBio Data FarhaFayaz MohammedNo ratings yet

- Using Simulation As A Tool For Coker Troubleshooting The KBC Approach Bhise KBC DCU Mumbai 2016 PDFDocument17 pagesUsing Simulation As A Tool For Coker Troubleshooting The KBC Approach Bhise KBC DCU Mumbai 2016 PDFFayaz MohammedNo ratings yet

- Delayed Coking Unit ImprovementDocument43 pagesDelayed Coking Unit ImprovementtogentongNo ratings yet

- Troubleshooting and Inspection Experience in Delayed Coker UnitDocument21 pagesTroubleshooting and Inspection Experience in Delayed Coker UnitFayaz MohammedNo ratings yet

- Coker Vessel Life Extension Repair Implementation Amador AZZ DCU Mumbai 2016Document39 pagesCoker Vessel Life Extension Repair Implementation Amador AZZ DCU Mumbai 2016Fayaz MohammedNo ratings yet

- Handling Power and Steam Outage in DCU Vinothkanna Pai MRPL DCU Mumbai 2016 PDFDocument22 pagesHandling Power and Steam Outage in DCU Vinothkanna Pai MRPL DCU Mumbai 2016 PDFFayaz MohammedNo ratings yet

- Support Network Critical To Coker Crane Success Laughlin Sutar Konecranes DCU Mumbai 2016 PDFDocument25 pagesSupport Network Critical To Coker Crane Success Laughlin Sutar Konecranes DCU Mumbai 2016 PDFFayaz MohammedNo ratings yet

- Dcu Revamp For Capacity and Efficiency IncreaseDocument25 pagesDcu Revamp For Capacity and Efficiency IncreaseFayaz MohammedNo ratings yet

- Delayed Coker Heater Best Practices Bernhagen Amec Foster Wheeler DCU Mumbai 2016 PDFDocument46 pagesDelayed Coker Heater Best Practices Bernhagen Amec Foster Wheeler DCU Mumbai 2016 PDFFayaz MohammedNo ratings yet

- Mechanical Coker Buckets Inspection Repair Rebuilding Craft Sutar Anvil Attachments Konecranes DCU Mumbai 2016 PDFDocument19 pagesMechanical Coker Buckets Inspection Repair Rebuilding Craft Sutar Anvil Attachments Konecranes DCU Mumbai 2016 PDFFayaz MohammedNo ratings yet

- ROS-018 Edition 2015 Rev 00-2015 - Confined Space PDFDocument25 pagesROS-018 Edition 2015 Rev 00-2015 - Confined Space PDFFayaz MohammedNo ratings yet

- Bechtel Hydrocarbon Technology Solutions (BHTS) Thruplus® Delayed Coking TechnologyDocument19 pagesBechtel Hydrocarbon Technology Solutions (BHTS) Thruplus® Delayed Coking TechnologyFayaz MohammedNo ratings yet

- Cost Conscious Coker Unheading Valve Hydraulic System Design Cammy Blac DCU Mumbai 2016 PDFDocument24 pagesCost Conscious Coker Unheading Valve Hydraulic System Design Cammy Blac DCU Mumbai 2016 PDFFayaz MohammedNo ratings yet

- Heurtey Petrochem: Coker Furnace Run LengthDocument24 pagesHeurtey Petrochem: Coker Furnace Run LengthFayaz MohammedNo ratings yet

- Coke Cutting Systems For Cokers in India Paul Ruhrpumpen DCU Mumbai 2016Document30 pagesCoke Cutting Systems For Cokers in India Paul Ruhrpumpen DCU Mumbai 2016Fayaz MohammedNo ratings yet

- Coke Drum Flow DistributionsDocument25 pagesCoke Drum Flow DistributionsFayaz MohammedNo ratings yet

- ROS-028 A9.2-Formats For HAZOP PDFDocument1 pageROS-028 A9.2-Formats For HAZOP PDFFayaz MohammedNo ratings yet

- ROS-019 Edition 2015 Rev 00-2015 - Excavation PDFDocument20 pagesROS-019 Edition 2015 Rev 00-2015 - Excavation PDFFayaz MohammedNo ratings yet

- ROS-024 Edition 2015 Rev 00-2015 - Nucleonic Gauge PDFDocument21 pagesROS-024 Edition 2015 Rev 00-2015 - Nucleonic Gauge PDFFayaz MohammedNo ratings yet

- ROS-024 Edition 2015 Rev 00-2015 - Nucleonic Gauge PDFDocument21 pagesROS-024 Edition 2015 Rev 00-2015 - Nucleonic Gauge PDFFayaz MohammedNo ratings yet

- ROS-020 Edition 2015 Rev 00-2015 - Scaffold PDFDocument24 pagesROS-020 Edition 2015 Rev 00-2015 - Scaffold PDFFayaz MohammedNo ratings yet

- ROS-028 A9.2-Formats For HAZOP PDFDocument1 pageROS-028 A9.2-Formats For HAZOP PDFFayaz MohammedNo ratings yet

- Closed Coke Slurry System: An Advanced Coke Handling ProcessDocument33 pagesClosed Coke Slurry System: An Advanced Coke Handling ProcessFayaz MohammedNo ratings yet

- ROS-020 Edition 2015 Rev 00-2015 - Scaffold PDFDocument24 pagesROS-020 Edition 2015 Rev 00-2015 - Scaffold PDFFayaz MohammedNo ratings yet

- ROS-019 Edition 2015 Rev 00-2015 - Excavation PDFDocument20 pagesROS-019 Edition 2015 Rev 00-2015 - Excavation PDFFayaz MohammedNo ratings yet

- DCU DGM SHA REPORT 7 Sept 2020 D ShiftDocument3 pagesDCU DGM SHA REPORT 7 Sept 2020 D ShiftFayaz MohammedNo ratings yet

- 21 Jan Ticket Kochi To HydDocument2 pages21 Jan Ticket Kochi To HydFayaz MohammedNo ratings yet

- ROS-018 Edition 2015 Rev 00-2015 - Confined Space PDFDocument25 pagesROS-018 Edition 2015 Rev 00-2015 - Confined Space PDFFayaz MohammedNo ratings yet

- June Heater-B Spalling ReportDocument226 pagesJune Heater-B Spalling ReportFayaz MohammedNo ratings yet