Professional Documents

Culture Documents

Design of Junction Bay Covering Structure For Rayadurg S/S:: Top B W

Uploaded by

Anindit MajumderOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Junction Bay Covering Structure For Rayadurg S/S:: Top B W

Uploaded by

Anindit MajumderCopyright:

Available Formats

DESIGN OF JUNCTION BAY COVERING STRUCTURE FOR RAYADURG S/S:

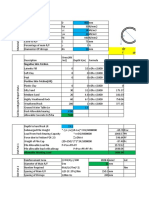

Design data :

Grade of concrete = M 25

fy = 500 N/sqmm

Thickness of cover slab (ttop) = 0.325 m

Thickness of base slab (tb) = 0.3 m

Thickness of wall (tw ) = 0.25 m

Height of wall (H) = 1.25 m

Height of wall from bottom of base slab 1.55 m

Maximum internal clearance of wall (le) = 1.635 m

Angle of internal friction (ϕ ) = 30 °

Active earth pressure coefficient (ka) = 0.333

Surcharge load (q) (From Eqpt. etc.) = 2 t/sqm

Unit weight of soil (γt) = 1.8 t/m

3

Unit wt of concrete (γc) = 2.5 t/m3

Load consideration :

Lateral pressure due to soil : kagh = 0.92907 t/sqm

Lateral pressure due to surcharge ka q = 0.666 t/sqm

Considering IRC class-A load for vehicle movement:( As per IRC -6)

Considering Critical condition of wheel load:

Influence Area of load after 45 o dispertion of wheel load

1100 mm

500mm

11.4 t 200mm 11.4 t 800 mm

wheel

After dispertion of 11.4 t/wheel load at 300 mm depth from road level to cover slab

Total load coming on cover slab =11.4 / (1.1 x 0.8) = 12.955 t/sqm

S/w of cover slab = 0.8125 t/sqm

soil wt. = 0.54 t/sqm

Total load on cover slab = 14.307 t/sqm

Design of cover slab: ( Slab - 1)

Thickness of cover slab = 0.325 m

clear cover = 0.025 m

Effective length of slab = 1.875 m

Using dia of bar = 0.025 m

D effective = 0.288 m

Moment = 6.287 t-m

Mu = 9.431 t-m

Mu/bd2 = 1.141 N/sqmm

corresponding % of steel = 0.278 %

Provided steel = 1.350 %

Required steel Ast = 3881.25 sqmm

Using dia of bar = 25 mm

Specing required = 126 mm

Provide 25 # bar @ 125 mm c/c

Distribution steel = 0.12% of bd = 345 sqmm

Using dia of bar = 10 mm

Specing required = 227.53623 mm

Provide 10 # bar @ 150 mm c/c

Shear check:

load = 14.307 t/m

Shear force v = 13.4128 t

Factored vu = 20.119219 t

Shear stress tv = vu/bd = 0.700 N/sqmm

Provided pt = 1.350 %

As per cls. 4.1 ,SP-16

b = 2.15

tc Allowable shear stress = 0.715 N/sqmm

Hence Ok

Deflection check:

Overall thickness of slab = 0.325 m

Effective thickness of slab = 0.288 m

% of steel provided (pt ) = 1.35 %

From Chart-22 of SP :16

Span/eff.depth = = 17.0

Effective span = 1.875 m

Effective depth required = 0.110 m

< 0.288 m

Hence Ok

Design of cover slab:(Slab-2)

Thickness of cover slab = 0.325 m

clear cover = 0.025 m

Effective length of slab = 1.16 m

Using dia of bar = 0.016 m

D effective = 0.292 m

Moment = 2.406 t-m

Mu = 3.610 t-m

Mu/bd2 = 0.423 N/sqmm

corresponding % of steel = 0.099 %

Provided steel = 0.500 %

Required steel Ast = 1460.00 sqmm

Using dia of bar = 16 mm

Specing required = 138 mm

Provide 16 # bar @ 125 mm c/c

Distribution steel = 0.12% of bd = 350.4 sqmm

Using dia of bar = 10 mm

Specing required = 224.02968 mm

Provide 10 # bar @ 200 mm c/c

Shear check:

load = 14.307 t/m

Shear force v = 8.2981 t

Factored vu = 12.44709 t

Shear stress tv = vu/bd = 0.426 N/sqmm

Provided pt = 0.500 %

As per cls. 4.1 ,SP-16

b = 2.19

tc Allowable shear stress = 0.437 N/sqmm

Hence Ok

Deflection check:

Overall thickness of slab = 0.325 m

Effective thickness of slab = 0.292 m

% of steel provided (pt ) = 0.50 %

From Chart-22 of SP :16

Span/eff.depth = = 23.0

This value is increased by 30% for continuity in slab /beam

Therefore Span/eff.depth = 29.9

Effective span = 1.160 m

Effective depth required = 0.050 m

< 0.292 m

Hence Ok

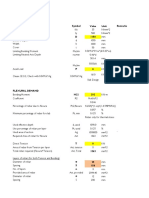

Design of vertical wall :

Height of Wall = 1.25 m

Thickness of wall = 0.25 m

Clear cover = 0.04 m

Using dia of bar = 0.012 m

Effective thickness = 0.204 m

computation of load in critical condition (when box is empty)

Load due to soil pressure = 0.581 t

Acting 0.417 m from base of wall

Moment (m1) = 0.242 t-m

Load due to surcharge = 0.833 t

Acting 0.625 m from base of wall

Moment (m2) = 0.520 t-m

Moment due to surcharge & soil pressure M =(m1+m2) = 0.762 t-m

Mu = 1.143 t-m

Mu/bd2 = 0.0003 N/sqmm

corresponding % of steel = 0.00006 %

Provided steel = 0.120 %

Required steel Ast = 244.80 sqmm

Using dia of bar = 12 mm

Specing required = 462 mm

Provide 12 # bar @ 150 mm c/c

Distribution steel = 0.12% of bd = 300 sqmm

Using dia of bar = 10 mm

Specing required = 261.66667 mm

Provide 10 # bar @ 200 mm c/c

Check the wall with axial load with uniaxial bending:

load coming on wall through cover slab (P)

14.307 x 0.9375x1 = 13.41 t

Pu = 20.119 t

Pu/fckbD = 0.0322 N/sqmm

Mu/fckbD2 = 0.0073 N/sqmm

Refering chart 35 ( Sp -16 ) p/fck = 0.01

Pt = 0.25

Ast required = 6.25 sqcm

Provide 4 Nos 12 Dia + 4 Nos 12 Dia bar

Ast provided = 9.0432 sqcm

Ok

Design of Base slab: critical condition ( Empty box)

Considering 1 m strip of base slab:

Effective span between two support = 1.875 m

Thickness of slab = 0.3 m

Clear cover = 0.05 m

Using dia of bar = 0.016 m

Effective thickness = 0.242 m

Load:

Wall load coming on slab = 26.83 t

Upword pressure = 14.307 t/m

Support moment wl2/10 = 5.030 t-m

Musupp = 7.545 t-m

Mu/bd2 = 1.288 N/sqmm

corresponding % of steel = 0.31632 %

Provided steel = 1.000 %

Required steel Ast = 2420.00 sqmm

Using dia of bar = 20 mm

Specing required = 130 mm

Provide 20 # bar @ 125 mm c/c

Span moment wl2/12 = 4.192 t-m

Muspan = 6.287 t-m

Mu/bd2 = 1.074

corresponding % of steel = 0.26 %

Provided steel = 0.300 %

Required steel Ast = 726.00 sqmm

Using dia of bar = 16 mm

Specing required = 277 mm

Provide 16 # bar @ 200 mm c/c

Using distribution steel = 0.120 %

Required steel Ast = 360.00 sqmm

Using dia of bar = 10 mm

Specing required = 218 mm

Provide 10 # bar @ 200 mm c/c

Shear check:

shear stress = 14.31 t/sqm

(critical shear distance d from face of wall)

Shear force v = 9.95 t

Factored vu = 14.93 t

Shear stress tv = vu/bd = 0.62 N/sqmm

Provided pt = 1.00 %

As per cls. 4.1 ,SP-16

b = 2.90

tc Allowable shear stress = 0.641 N/sqmm

Hence Ok

You might also like

- SPT-BH 17Document1 pageSPT-BH 17Umesh MishraNo ratings yet

- Concrete Compressive Strength Test ResultsDocument6 pagesConcrete Compressive Strength Test ResultsSurajit SahaNo ratings yet

- Settlememt Analysis For Shallow Foundations Based On N - ValuesDocument5 pagesSettlememt Analysis For Shallow Foundations Based On N - Valueskushaljp8989No ratings yet

- Pile Calculation 1BH1&BH2Document6 pagesPile Calculation 1BH1&BH2S SathiyarubanNo ratings yet

- 4 Design of Left Abutment Return Wall: Earth Pressure DiagramDocument9 pages4 Design of Left Abutment Return Wall: Earth Pressure DiagramPalak ShivhareNo ratings yet

- Cement Testing Week No 37Document1 pageCement Testing Week No 37DNYANESHWAR PATILNo ratings yet

- 41kW solar roof design documentDocument8 pages41kW solar roof design documentAmol GoleNo ratings yet

- Book hotel room invoiceDocument1 pageBook hotel room invoiceAnkit SinghNo ratings yet

- Project - Park Hotel Location - PuneDocument7 pagesProject - Park Hotel Location - PunewaquarstrNo ratings yet

- Wind Pressure Calculation For 3 Sec Gust Extreme StormDocument5 pagesWind Pressure Calculation For 3 Sec Gust Extreme StormChinnaraja GandhiNo ratings yet

- Segment Design FinalDocument54 pagesSegment Design FinalDEBASIS BARMAN100% (1)

- 1.0 Design of Bracket: Load On Bracket Type LevelDocument4 pages1.0 Design of Bracket: Load On Bracket Type LeveldsureshcivilNo ratings yet

- Construction of Hydraulic Tunnel Load CalculationDocument6 pagesConstruction of Hydraulic Tunnel Load CalculationAnil kumar100% (1)

- Soil Pressure CoeficientsDocument2 pagesSoil Pressure CoeficientsAddrien DanielNo ratings yet

- Bolt Design & Development LengthDocument3 pagesBolt Design & Development LengthShamik ChowdhuryNo ratings yet

- Resi. complex pile capacityDocument4 pagesResi. complex pile capacityEr Navneet JassiNo ratings yet

- Building ID-NCRTC-RRTS-BCS PKG-8MB - 563Document17 pagesBuilding ID-NCRTC-RRTS-BCS PKG-8MB - 563mayank dixitNo ratings yet

- IS 800:2007 Section 8 Design of Members Subjected To BendingDocument33 pagesIS 800:2007 Section 8 Design of Members Subjected To BendingJSP Sudipta SekhNo ratings yet

- Radial Check EtcDocument38 pagesRadial Check EtcDEBASIS BARMANNo ratings yet

- Description Symbol Value Unit RemarksDocument1 pageDescription Symbol Value Unit RemarksRakesh SapkotaNo ratings yet

- Water Tank Platform Foundation and Beam DesignDocument21 pagesWater Tank Platform Foundation and Beam Design4geniecivilNo ratings yet

- Haryana TestDocument1 pageHaryana TestPankaj SherwalNo ratings yet

- Blast DesignDocument1 pageBlast DesignIndah Putrika RezkyNo ratings yet

- Footing J1922018 v1Document15 pagesFooting J1922018 v1eco protectionNo ratings yet

- Input Data Soil ProfileDocument35 pagesInput Data Soil ProfileAnonymous USbc7XzsA6No ratings yet

- Stability Analysis of Plum WallDocument2 pagesStability Analysis of Plum WallShivendra KumarNo ratings yet

- L Pile KNS - 02 06 2016Document1 pageL Pile KNS - 02 06 2016Kanaiyalal N. ShethNo ratings yet

- Analysis of Basal Heave Stability For Excavations in Soft Clay Using The Finite PDFDocument8 pagesAnalysis of Basal Heave Stability For Excavations in Soft Clay Using The Finite PDFJuan Carlos Patiño BautistaNo ratings yet

- Final Report-Volume-III For Bina-Guna Pkg-1 (Structures From CH 977 (1) .3 Km. To CH 1095.0 KM.)Document117 pagesFinal Report-Volume-III For Bina-Guna Pkg-1 (Structures From CH 977 (1) .3 Km. To CH 1095.0 KM.)Prasanta Kumar ParidaNo ratings yet

- Catchment Area Ab Road1Document66 pagesCatchment Area Ab Road1skumarsrNo ratings yet

- GT Report Open Cutting at Ch. 34 KM MizoramDocument15 pagesGT Report Open Cutting at Ch. 34 KM MizoramAnil kumarNo ratings yet

- Name of Work:-: M /sec M /sec M /sec M /sec M /sec M /sec M /secDocument9 pagesName of Work:-: M /sec M /sec M /sec M /sec M /sec M /sec M /secChauhan UjjvalNo ratings yet

- L&T Construction: Power Transmission & DistributionDocument6 pagesL&T Construction: Power Transmission & DistributionharishduttNo ratings yet

- Geotechnical Investigations of Mumbai-Pune ExpresswayDocument17 pagesGeotechnical Investigations of Mumbai-Pune Expresswayblackberry7100gNo ratings yet

- Correction For Overburden: Bearing Capacity Based On Standard Penetration TestDocument41 pagesCorrection For Overburden: Bearing Capacity Based On Standard Penetration TestHimal KafleNo ratings yet

- 1 Dimensions of Tank Proper:: Design of 50 KL OhsrDocument30 pages1 Dimensions of Tank Proper:: Design of 50 KL OhsrMegatech Engineering ConsultantsNo ratings yet

- Beam Design With Deflection CheckDocument2 pagesBeam Design With Deflection Checkbhavin_civilNo ratings yet

- CC PDFDocument4 pagesCC PDFRanjan Kumar SahooNo ratings yet

- CW ChannelDocument40 pagesCW ChannelNitesh SinghNo ratings yet

- Liquefaction AnalysisDocument16 pagesLiquefaction AnalysisKristi Engineering Services Pvt. Ltd.No ratings yet

- 1674 - KMRC - Well Sinking Options Generated SINCE DEC-2014Document8 pages1674 - KMRC - Well Sinking Options Generated SINCE DEC-2014Raja RajanNo ratings yet

- MJB 16+785 DC 301 PierDocument79 pagesMJB 16+785 DC 301 PierChandra BabuNo ratings yet

- Stabilization of Black Cotton Soil Using PDFDocument6 pagesStabilization of Black Cotton Soil Using PDFSushmit KatkaleNo ratings yet

- Beam Section Property ChangesDocument33 pagesBeam Section Property Changespratap jadhavNo ratings yet

- Agi TP RT 03Document53 pagesAgi TP RT 03Sumanth GundetiNo ratings yet

- Conc M25 Rate Analysis 2021Document24 pagesConc M25 Rate Analysis 2021Gautam DuttaNo ratings yet

- 1.2 B-001 - Master Template Without MedianDocument7 pages1.2 B-001 - Master Template Without MediankanagarajodishaNo ratings yet

- Material Properties:: Main Builtup Girder Flexural CheckDocument22 pagesMaterial Properties:: Main Builtup Girder Flexural CheckDipak BorsaikiaNo ratings yet

- Foundation Design f1Document2 pagesFoundation Design f1Sampath Kumar KandasamyNo ratings yet

- RetainingWall SBC 150Document35 pagesRetainingWall SBC 150Elvis GrayNo ratings yet

- Box Structure PDFDocument177 pagesBox Structure PDFAtanu AdhiakryNo ratings yet

- Settlement of piles founded in rock calculation as per IS 8009 (Part IIDocument2 pagesSettlement of piles founded in rock calculation as per IS 8009 (Part IIpravinNo ratings yet

- GEOTECHNICAL INVESTIGATION REPORT FOR 24MLD STPDocument5 pagesGEOTECHNICAL INVESTIGATION REPORT FOR 24MLD STPsagar kolheNo ratings yet

- Dynamics of Machinery Exam QuestionsDocument1,095 pagesDynamics of Machinery Exam QuestionsSunnyNo ratings yet

- Calculations of Pile Capacity of Pile: K EI TDocument5 pagesCalculations of Pile Capacity of Pile: K EI Tgaurav sharmaNo ratings yet

- Padghe - Cable Trench With Bells FormulaDocument50 pagesPadghe - Cable Trench With Bells FormulaAnindit MajumderNo ratings yet

- CABLE TRENCH PadgheDocument25 pagesCABLE TRENCH PadgheAnindit MajumderNo ratings yet

- Design of Drain Box FoundationDocument16 pagesDesign of Drain Box FoundationGOMASH RCPNo ratings yet

- Design of Cable Trench - R0Document17 pagesDesign of Cable Trench - R0RahulNo ratings yet

- Isolated Footing Design As Per Is 456Document2 pagesIsolated Footing Design As Per Is 456Sanjay Rokka50% (2)

- Design of Pile (Assuming Fixed Head) : (According To Load Case - 206) Considering Minimum Load and Maximum MomentDocument22 pagesDesign of Pile (Assuming Fixed Head) : (According To Load Case - 206) Considering Minimum Load and Maximum MomentAnindit MajumderNo ratings yet

- Septic Tank 16.08.19-ModelDocument1 pageSeptic Tank 16.08.19-ModelAnindit MajumderNo ratings yet

- Design Dharmanagar 14.03.18Document38 pagesDesign Dharmanagar 14.03.18Anindit MajumderNo ratings yet

- Check Detailing For 160 Mva Fire WallDocument12 pagesCheck Detailing For 160 Mva Fire WallAnindit MajumderNo ratings yet

- Design Dharmanagar 14.03.18Document38 pagesDesign Dharmanagar 14.03.18Anindit MajumderNo ratings yet

- CABLE TRENCH PadgheDocument25 pagesCABLE TRENCH PadgheAnindit MajumderNo ratings yet

- Padghe - Cable Trench With Bells FormulaDocument50 pagesPadghe - Cable Trench With Bells FormulaAnindit MajumderNo ratings yet

- Compound WallDocument1 pageCompound WallAnindit MajumderNo ratings yet

- CABLE TRENCH PadgheDocument25 pagesCABLE TRENCH PadgheAnindit MajumderNo ratings yet

- Rail Wagon Loading Gantry: Design of Piles & Pile CapsDocument30 pagesRail Wagon Loading Gantry: Design of Piles & Pile CapsAnindit MajumderNo ratings yet

- Block Foundation PDFDocument13 pagesBlock Foundation PDFAnindit MajumderNo ratings yet

- Design - R R WALLDocument10 pagesDesign - R R WALLAnindit MajumderNo ratings yet

- Clause Item Description Qty UnitDocument28 pagesClause Item Description Qty UnitAnindit MajumderNo ratings yet

- Rail Wagon Loading Gantry: Design of Piles & Pile CapsDocument30 pagesRail Wagon Loading Gantry: Design of Piles & Pile CapsAnindit MajumderNo ratings yet

- Rail Wagon Loading Gantry: Design of Piles & Pile CapsDocument30 pagesRail Wagon Loading Gantry: Design of Piles & Pile CapsAnindit MajumderNo ratings yet

- Rail Wagon Loading Gantry: Design of Piles & Pile CapsDocument30 pagesRail Wagon Loading Gantry: Design of Piles & Pile CapsAnindit MajumderNo ratings yet

- Design of Pile (Assuming Fixed Head) : (According To Load Case - 206) Considering Minimum Load and Maximum MomentDocument22 pagesDesign of Pile (Assuming Fixed Head) : (According To Load Case - 206) Considering Minimum Load and Maximum MomentAnindit MajumderNo ratings yet

- Design Doc. - Rt. WallDocument16 pagesDesign Doc. - Rt. WallAnindit MajumderNo ratings yet

- Design of Junction Bay Covering Structure For Rayadurg S/S:: Top B WDocument5 pagesDesign of Junction Bay Covering Structure For Rayadurg S/S:: Top B WAnindit MajumderNo ratings yet

- Design Retaining WallDocument15 pagesDesign Retaining WallAnindit MajumderNo ratings yet

- C42135AA Beckman Coulter ClearLLab 10C Casebook PDFDocument586 pagesC42135AA Beckman Coulter ClearLLab 10C Casebook PDFHam Bone100% (1)

- Arpèges de Trois Notes: Arpeggios in TripletsDocument3 pagesArpèges de Trois Notes: Arpeggios in TripletspanapapakNo ratings yet

- Structurix MEcoDocument12 pagesStructurix MEcoPierpaolo AparoNo ratings yet

- Sample Resume For HRDocument2 pagesSample Resume For HRnapinnvoNo ratings yet

- 3ms Squence 3 (Summary)Document3 pages3ms Squence 3 (Summary)toumi khadidjaNo ratings yet

- Strategic Management and Municipal Financial ReportingDocument38 pagesStrategic Management and Municipal Financial ReportingMarius BuysNo ratings yet

- RSG 303Document196 pagesRSG 303Makinde TimiNo ratings yet

- Certified Islamic Professional Accountant (Cipa) ProgramDocument13 pagesCertified Islamic Professional Accountant (Cipa) ProgramTijjani Ridwanulah AdewaleNo ratings yet

- San Lam Stratus FundsDocument2 pagesSan Lam Stratus FundsTiso Blackstar GroupNo ratings yet

- Studentwise Final Placement DetailsLast 3 YearsDocument18 pagesStudentwise Final Placement DetailsLast 3 YearsAmitNo ratings yet

- SampleContract ShuttleDocument10 pagesSampleContract ShuttleLJ BNo ratings yet

- Photon BrochureDocument1 pagePhoton Brochureshwetha281889242No ratings yet

- Not So Itty Bitty Book of The Cif 2Document85 pagesNot So Itty Bitty Book of The Cif 2api-307100415No ratings yet

- WEEK 7 ICPS - and - ICSSDocument31 pagesWEEK 7 ICPS - and - ICSScikguhafidzuddinNo ratings yet

- Remove Fuel Sub TankDocument9 pagesRemove Fuel Sub Tankthierry.fifieldoutlook.comNo ratings yet

- Jun 2005 - AnsDocument13 pagesJun 2005 - AnsHubbak Khan100% (1)

- Calculating Maintenance and ReliabilityDocument7 pagesCalculating Maintenance and ReliabilityArdian P Noviatmoko100% (1)

- Vernacular Terms in Philippine ConstructionDocument3 pagesVernacular Terms in Philippine ConstructionFelix Albit Ogabang IiiNo ratings yet

- The Behaviour ContinuumDocument2 pagesThe Behaviour Continuumapi-459326447No ratings yet

- From Birth Till Palatoplasty Prosthetic.20Document5 pagesFrom Birth Till Palatoplasty Prosthetic.20Maria FernandaNo ratings yet

- Vaping in Preganacy A Systematic ReviewDocument8 pagesVaping in Preganacy A Systematic ReviewMia LouwNo ratings yet

- Chapter 6 Physics LabDocument3 pagesChapter 6 Physics Labraquelloveswow0% (1)

- Frogkisser! by Garth Nix (Excerpt)Document17 pagesFrogkisser! by Garth Nix (Excerpt)I Read YA0% (1)

- Labcir - Marwa - FinalDocument119 pagesLabcir - Marwa - FinalMashavia AhmadNo ratings yet

- Company Electronics Appliances Semiconductors South Korea's: SamsungDocument61 pagesCompany Electronics Appliances Semiconductors South Korea's: Samsunghaseeb ahmedNo ratings yet

- Taxation Management AssignmentDocument11 pagesTaxation Management AssignmentniraliNo ratings yet

- Unit IV - CPU Scheduling and Algorithm Section 4.1 Scheduling Types Scheduling ObjectivesDocument18 pagesUnit IV - CPU Scheduling and Algorithm Section 4.1 Scheduling Types Scheduling ObjectivessmsaranyaNo ratings yet

- 02+sebring+2.7+timing+chainDocument10 pages02+sebring+2.7+timing+chainMaushil Salman MarkNo ratings yet

- Chapter 2Document5 pagesChapter 2Ayush Hooda class 12 ANo ratings yet

- VariablesDocument11 pagesVariablesKzy ayanNo ratings yet