Professional Documents

Culture Documents

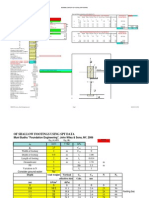

4 Design of Left Abutment Return Wall: Earth Pressure Diagram

Uploaded by

Palak ShivhareOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4 Design of Left Abutment Return Wall: Earth Pressure Diagram

Uploaded by

Palak ShivhareCopyright:

Available Formats

PAKAL DUL HYDRO ELECTRIC PROJECT – HRT PACKAGE

4 Design of Left Abutment Return Wall

Thickness of return wall at the top = 0.500 m

Average Thickness for Horizontal Design = 0.650 m

Thickness of return wall at junction = 0.800 m

Height of return wall, h = 6.000 m

3

Unit weight of soil fill gfill = 21.0 kN/m

Co-efficient of active earth prerssure ka = 0.200

Clear Cover = 50 mm

Grade of concrete = M30 Mpa

Tensile strength of concrete fctm = 2.50 MPa

Grade of steel = Fe500 Mpa

Characteristic yield strength of stirrups fyw = Fe500 N/mm2

Design compressive strength of concrete fcd = 13.40 Mpa

Design tensile strength of reinforcement fyd = 434.78 MPa

Secant modulus elasticity of Concrete Ecm = 31000 MPa

Elastic modulus of Steel Es = 200000 MPa

λ = 0.8

η = 1.0

limiting neutral axis to depth ratio Xu,max / d = 0.617

Return Wall

Abutment Stem

6.960

Return Wall

6.00

Footing

1 2

Earth Pressure diagram

Substructure Design for Proposed Steel Brigde

over Nagrah Nallah

O20315-S-HD-INF-BR-1008 Rev 1

# Sensitivity: LNT Construction Internal Use

PAKAL DUL HYDRO ELECTRIC PROJECT – HRT PACKAGE

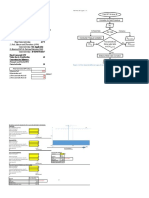

Here, β1 is vertical bending coefficient, β2 is horizontal bending coefficient,

ϒ1 is vertical shear coefficient & ϒ2 is horizontal shear coefficient

So vertical bending is given by Mv = -b x β1 x (b2 /6) FROM ROARKs Formulae by WARREN C. YOUNG

2

& horizontal bending is given by Mh = -b x β2 x (b /6) Table 11.4

2

For Live load surcharge, Q = =0.200×21.0 ×1.2 5.04 kN/m

Height of Length of Vertical BM Hori. BM

a/b ratio β1 β2 ϒ1 ϒ2

wall (b) m wall (a) m (kNm/m) (kNm/m)

6.00 6.960 1.160 2.104 2.1421 1.218 1.410 63.6 64.73

For active earth pressure, Q = =0.200×21.0 ×6.00 25.18 kN/m^2

Height of Length of Vertical BM Long. BM

a/b ratio β1 β2 ϒ1 ϒ2

wall (b) m wall (a) m (kNm/m) (kNm/m)

6.00 6.960 1.160 0.796 0.474 0.564 0.168 120.3 71.7

Net Vertical Moment (Factored) = 256.70 kNm/m

Net Horizontal Moment (Factored) = 185.20 kNm/m

4.1 Check for Flexure (Vertical Bending)

Moment at the base of the Return wall ML = 256.7 kN m

Assume reinforcement Diameter = 20 mm

Spacing = 140 mm

Clear cover to reinforcement = 50 mm

b = 1000 mm

deff prov = 740 mm

2

Astprovd = 2244 mm per metre

Depth required dreqd = 227.00 Hence depth is adequate

Neutral Axis Depth x = 33 mm

xumax = 457 mm

Under reinforced section

Area of reinforcement required Ast = 812 mm2

Hence OK

Minimum Area of reinforcement Required = 888 mm2

Check for Flexure (Horizontal Bending)

Moment at the base of the Return wall ML = 185.2 kN m

Assume reinforcement Diameter = 16 mm

Spacing = 140 mm

Clear cover to reinforcement = 75 mm

b = 1000 mm

deff prov = 567 mm

2

Astprovd = 1436 mm per metre

Substructure Design for Proposed Steel Brigde

over Nagrah Nallah

O20315-S-HD-INF-BR-1008 Rev 1

# Sensitivity: LNT Construction Internal Use

PAKAL DUL HYDRO ELECTRIC PROJECT – HRT PACKAGE

Depth required dreqd = 192.81 Hence depth is adequate

Neutral Axis Depth x = 31 mm

xumax = 350 mm

Under reinforced section

Area of reinforcement required Ast = 768 mm2 Hence OK

4.2 Check for Shear (Vertical)

Shear Fore Due to Live Load Surcharge = 32.254 kN/m

Shear Fore Due to Earth Pressure = 74.72 kN/m

Factored Shear Force = 150.78 kN/m

Depth of Stem at Deff = 0.76 m

Effective Depth = 695.00 mm

Design shear force, VEd = 151 kN/m

For Uniform cross section Vccd = 0 kN

For Uniform cross section Vtd = 0 kN

VRd s = VNS = 151 kN

Maximum Allowabe Shear Force ( for maximum shear force take Ɵ = 45 0 )

VRd.max = αcw x bw x z x v1 x (fcd/(cotƟ+tanƟ)) ( IRC:112-2011, cl. no. 10.3.3.2, Eq10.8)

where, αcw = 1

z = lever arm = 0.9d (For RCC)

v1 is the strength reduction factor for concrete cracked in shear

v1 = 0.54

Ɵ= 45 (CotƟ = 1)

fcd is the design value of concrete compression strength =αcc x fck /ɣm ( IRC: 112-2011, cl. no. 10.3.1 )

αcc = 0.67 (Refer IRC:112-2011, Pg.87)

ɣm = 1.50 (Partial factors for concrete for ULS)

VRd.max = 2271 kN Section is Safe

Allowable Shear Force without Reduction factor

VEd <= 0.5 * bw * d * v * fcd ( IRC:112-2011, cl. no. 10.3.2 Eq. 10.5 )

where, v= Strength reduction factor = 0.6 * [ 1 - ( fck / 310 )]

2

ν = 0.54 N/mm

VEd = 2524 kN Section is Safe

Force reduction factor

β= av / 2d but, 0.5 d <= av <= 2 d ( IRC:112-2011, cl.no.10.3.3.3 )

av = 1390.00 mm

Substructure Design for Proposed Steel Brigde β = 1

over Nagrah Nallah

O20315-S-HD-INF-BR-1008 Rev 1

# Sensitivity: LNT Construction Internal Use

PAKAL DUL HYDRO ELECTRIC PROJECT – HRT PACKAGE

Allowable Shear Force without Shear Reinforcement

VRd c = ( 0.12 x K (80 x ρ1 x fck )0.33 + 0.15 x σcp) bw x d ( IRC:112-2011, cl.no.10.3.2(2))

But, VRd.c min = (vmin + 0.15 x σcp) bw x d

where, K= 1+sqrt(200/d) <=2, where d is the depth in mm.

VRd c = The design shear resistance of the member without shear reinforcement.

vmin = 0.031 x K^3/2 x fck^1/2

σcp = Concrete compressive stress at the centroidal axis due to axial loading or prestressing.

ρ1 = Reinforcement ratio for longitudinal reinforcement , = Ast / (bw x d) <=0.02

K = 1.5

ρ1 = 0.0032

σcp = 0 For RCC

VRd c min = 225 kN

VRd c = 252 kN

Shear Reinforcement is not required

Check for Shear (Horizontal)

Shear Fore Due to Live Load Surcharge = 42.593 kN/m

Shear Fore Due to Earth Pressure = 25.33 kN/m

Factored Shear Force = 89.11 kN/m

Depth of Stem at Deff = 567.00 mm

Effective Depth = 567.00 mm

Design shear force, VEd = 89 kN/m

For Uniform cross section Vccd = 0 kN

For Uniform cross section Vtd = 0 kN

VRd s = VNS = 89 kN

Maximum Allowabe Shear Force ( for maximum shear force take Ɵ = 45 0 )

VRd.max = αcw x bw x z x v1 x (fcd/(cotƟ+tanƟ)) ( IRC:112-2011, cl. no. 10.3.3.2, Eq10.8)

where, αcw = 1

z = lever arm = 0.9d (For RCC)

v1 is the strength reduction factor for concrete cracked in shear

v1 = 0.54

Ɵ= 45 (CotƟ = 1)

fcd is the design value of concrete compression strength =αcc x fck /ɣm ( IRC: 112-2011, cl. no. 10.3.1 )

αcc = 0.67 (Refer IRC:112-2011, Pg.87)

ɣm = 1.50 (Partial factors for concrete for ULS)

VRd.max = 1853 kN Section is Safe

Substructure Design for Proposed Steel Brigde

over Nagrah Nallah

O20315-S-HD-INF-BR-1008 Rev 1

# Sensitivity: LNT Construction Internal Use

PAKAL DUL HYDRO ELECTRIC PROJECT – HRT PACKAGE

Allowable Shear Force without Reduction factor

VEd <= 0.5 * bw * d * v * fcd ( IRC:112-2011, cl. no. 10.3.2 Eq. 10.5 )

where, v= Strength reduction factor = 0.6 * [ 1 - ( fck / 310 )]

2

ν = 0.54 N/mm

VEd = 2059 kN Section is Safe

Force reduction factor

β= av / 2d but, 0.5 d <= av <= 2 d ( IRC:112-2011, cl.no.10.3.3.3 )

av = 1134.00 mm

β = 1

Allowable Shear Force without Shear Reinforcement

VRd c = ( 0.12 x K (80 x ρ1 x fck )0.33 + 0.15 x σcp) bw x d ( IRC:112-2011, cl.no.10.3.2(2))

But, VRd.c min = (vmin + 0.15 x σcp) bw x d

where, K= 1+sqrt(200/d) <=2, where d is the depth in mm.

VRd c = The design shear resistance of the member without shear reinforcement.

vmin = 0.031 x K^3/2 x fck^1/2

σcp = Concrete compressive stress at the centroidal axis due to axial loading or prestressing.

ρ1 = Reinforcement ratio for longitudinal reinforcement , = Ast / (bw x d) <=0.02

K = 1.6

ρ1 = 0.0025

σcp = 0 For RCC

VRd c min = 194 kN

VRd c = 197 kN

Shear Reinforcement is not required

4.3 Check for Serviceability limit state (SLS)

Check for Stress limitation - SLS

Stress limitation shall be checked for Rare combination as per Cl 12.2 of IRC 112-2011.

Allowable compressive stress in concrete under Rare combination = 0.48fck

σcc = 14.40 MPa

Allowable compressive stress in concrete under quasi permanent loads = 0.36fck

σcc = 10.80 MPa

Allowable tensile stress in reinforcement σst = 0.8fyk

σst = 400.0 MPa

Calculation of stress in concrete and reinforcement

Stress in concrete and reinforcement are calculated with this assumptions

1) Part of concrete area which is in tension completely neglected.

2) Reinforcement provided in compression area is not considered.

Substructure Design for Proposed Steel Brigde

over Nagrah Nallah

O20315-S-HD-INF-BR-1008 Rev 1

# Sensitivity: LNT Construction Internal Use

PAKAL DUL HYDRO ELECTRIC PROJECT – HRT PACKAGE

To find stress

Neutral axis depth calculated by equating first moment of compression area to first moment of

tension area

Cracked second moment of area of cross section shall be calculated as given below

Stress in concrete and reinforcement calculated using bending equation

Maximum compressive stress in concrete

Maximum tensile stress in reinforcement

Check for Stress in Vertical Direction

Notional size ho = 425 mm

Creep coefficient at 28 days RH = 80% = 1.53

Long term modulus of elasticity of concrete Ec,eff = 12253 MPa

Long term modular ratio m Es/Ec,eff = 16.32

Short term modular ratio m Ecm/Es = 6.45

Maximum Longitudinal moment under Rare combination M = 171.1 kNm

Maximum Longitudinal moment under Quasi permanent comb M = 120.3 kNm

Stress calculation for Long term effect

Neutral axis depth x = 199.06 mm

Cracked second moment of area of cross section Ic = 1.3.E+10 mm4

Maximum compressive stress in concrete under Rare comb σcc = 2.55 MPa

Maximum tensile stress in reinforcement under Rare comb σst = 113.21 MPa

Maximum compressive stress in concrete under Quasi comb σcc = 1.79 MPa

Maximum tensile stress in reinforcement under Quasi comb σst = 79.57 MPa

Stresses are within permissible limlt

Stress calculation for Short term effect

Neutral axis depth x = 132.61 mm

Cracked second moment of area of cross section Ic = 6.1.E+09 mm4

Maximum compressive stress in concrete under Rare comb σcc = 3.71 MPa

Maximum tensile stress in reinforcement under Rare comb σst = 109.61 MPa

Substructure Design for Proposed Steel Brigde

over Nagrah Nallah

O20315-S-HD-INF-BR-1008 Rev 1

# Sensitivity: LNT Construction Internal Use

PAKAL DUL HYDRO ELECTRIC PROJECT – HRT PACKAGE

Maximum compressive stress in concrete under Quasi comb σcc = 2.61 MPa

Maximum tensile stress in reinforcement under Quasi comb σst = 77.04 MPa

Stresses are within permissible limlt

Check for Stress in Horizontal Direction

Notional size ho = 362 mm

Creep coefficient at 28 days RH = 80% = 1.57

Long term modulus of elasticity of concrete Ec,eff = 12062 MPa

Long term modular ratio m Es/Ec,eff = 16.58

Short term modular ratio m Ecm/Es = 6.45

Maximum Longitudinal moment under Rare combination M = 123.5 kNm

Maximum Longitudinal moment under Quasi permanent comb M = 71.7 kNm

Stress calculation for Long term effect

Neutral axis depth x = 142.23 mm

Cracked second moment of area of cross section Ic = 5.3.E+09 mm4

Maximum compressive stress in concrete under Rare comb σcc = 3.34 MPa

Maximum tensile stress in reinforcement under Rare comb σst = 165.45 MPa

Maximum compressive stress in concrete under Quasi comb σcc = 1.94 MPa

Maximum tensile stress in reinforcement under Quasi comb σst = 96.06 MPa

Stresses are within permissible limlt

Stress calculation for Short term effect

Neutral axis depth x = 93.66 mm

Cracked second moment of area of cross section Ic = 2.3.E+09 mm4

Maximum compressive stress in concrete under Rare comb σcc = 4.92 MPa

Maximum tensile stress in reinforcement under Rare comb σst = 160.45 MPa

Maximum compressive stress in concrete under Quasi comb σcc = 2.86 MPa

Maximum tensile stress in reinforcement under Quasi comb σst = 93.16 MPa

Stresses are within permissible limlt

4.4 Calculation of Crack Width

Crack width shall be checked for quasi permanet combination as per cl 12.3.4 of IRC 112-2011

Maximum permissible value of crack width for moderate exposure = 0.30 mm

Substructure Design for Proposed Steel Brigde

over Nagrah Nallah

O20315-S-HD-INF-BR-1008 Rev 1

# Sensitivity: LNT Construction Internal Use

PAKAL DUL HYDRO ELECTRIC PROJECT – HRT PACKAGE

Check for crackwidth at Vertical Direction

Tensile strength of concrete fct,eff = 2.5 MPa

Depth of neutral axis x = 199.06 mm

Effective height of concrete in tension hceff = 150.00 mm

Area of concrete effective in tension Aceff = 150000 mm2

Modular ratio αe = 16.32

Factor dependent on duration of load kt = 0.5

Coefficient which takes account of bond properties of bonded reinforcement

k1 = 0.8

Coefficient which takes account of distribution of Strain k2 = 0.5

Diameter of reinforcement bar 1 Φ1 = 20 mm

Number of bar n1 = 7 nos

Diameter of reinforcement bar 2 Φ2 = 0 mm

Number of bar 2 n2 = 0 nos

Equivalent diameter of reinforcement Φ = 20 mm

Factor ρρ,eff = 0.0150

Maximum crack spacing

Maximum tensile stress in R/F under quasi load combination σst = 79.57 MPa

(Note : R/F means- Reinforcement)

Maximum crack spacing Sr,max = 397 mm

Difference in mean strain

Difference in mean strain εsm-εcm = 0.0002

Crack width Wk = 0.095 mm

Crack width 0.095 < 0.30 mm

Crack width is within permissible limit

Check for crackwidth at Horizontal Direction

Tensile strength of concrete fct,eff = 2.5 MPa

Depth of neutral axis x = 142.23 mm

Effective height of concrete in tension hceff = 194.26 mm

Area of concrete effective in tension Aceff = 110143 mm2

Modular ratio αe = 16.58

Factor dependent on duration of load kt = 0.5

Substructure Design for Proposed Steel Brigde

over Nagrah Nallah

O20315-S-HD-INF-BR-1008 Rev 1

# Sensitivity: LNT Construction Internal Use

PAKAL DUL HYDRO ELECTRIC PROJECT – HRT PACKAGE

Coefficient which takes account of bond properties of bonded reinforcement

k1 = 0.8

Coefficient which takes account of distribution of Strain k2 = 0.5

Diameter of reinforcement bar 1 Φ1 = 16 mm

Number of bar n1 = 7 nos

Diameter of reinforcement bar 2 Φ2 = 0 mm

Number of bar 2 n2 = 0 nos

Equivalent diameter of reinforcement Φ = 16 mm

Factor ρρ,eff = 0.0130

Maximum crack spacing

Maximum tensile stress in R/F under quasi load combination σst = 93.16 MPa

(Note : R/F means- Reinforcement)

Maximum crack spacing Sr,max = 379 mm

Difference in mean strain

Difference in mean strain εsm-εcm = 0.0003

Crack width Wk = 0.106 mm

Crack width 0.106 < 0.30 mm

Crack width is within permissible limit

4.5 Check for Minimum Reinforcement

Minimum vertical steel reinforcement required (As per Cl. 16.3.1 of IRC: 112-2011)

Minimum vertical steel reinforcement shall be 0.12% of concrete c/s area on either face

2

= 0.0012 b D = 888 mm SAFE

Provide minimum reinforcement on the outer side

20 f

2

Provide @ 140 at the outer face = 2244 mm SAFE

Maximum Vertical Reinforcement

2

Maximum Area of Vertical Reinforcement = 32000 mm

2

Total Area of Vertical Reinforcement Provided = 4488 mm SAFE

0.05

Minimum transverse reinforcement required

Minimum transverse reinforcement shall be higher of 0.1% of concrete c/s area or 25% of vertical reinforcement

2

= 1122.0 mm

20 f

2

Provide @ 140 at both faces = 4488.0 mm SAFE

Substructure Design for Proposed Steel Brigde

over Nagrah Nallah

O20315-S-HD-INF-BR-1008 Rev 1

# Sensitivity: LNT Construction Internal Use

You might also like

- Segment Design FinalDocument54 pagesSegment Design FinalDEBASIS BARMAN100% (1)

- Calculation of Crack Width in Accordance With EN 1992-1-1:2004 (E)Document2 pagesCalculation of Crack Width in Accordance With EN 1992-1-1:2004 (E)Yaser ShabasyNo ratings yet

- GT Report Open Cutting at Ch. 34 KM MizoramDocument15 pagesGT Report Open Cutting at Ch. 34 KM MizoramAnil kumarNo ratings yet

- Tunnel Linning Design: Flood Design Height Lowest Credible Water LevelDocument44 pagesTunnel Linning Design: Flood Design Height Lowest Credible Water LevelDEBASIS BARMANNo ratings yet

- Apsara BorderDocument15 pagesApsara BorderskumarsrNo ratings yet

- Design-Retaining Wall2 9555Document27 pagesDesign-Retaining Wall2 9555SureshSawantNo ratings yet

- Lateral Capacities As Per Is 2911 Part 2 - Building AreaDocument1 pageLateral Capacities As Per Is 2911 Part 2 - Building AreaSripara KrishnaNo ratings yet

- 12.2 M PSC GirderDocument18 pages12.2 M PSC GirdermithunNo ratings yet

- 19th Southeast Asian Geotechnical Conference ProceedingsDocument6 pages19th Southeast Asian Geotechnical Conference ProceedingsSen HuNo ratings yet

- Wallap Input Data Bada Chauraha Station Top Down Grid 08-11-750mm CS at 8.15mDocument18 pagesWallap Input Data Bada Chauraha Station Top Down Grid 08-11-750mm CS at 8.15msumit rawatNo ratings yet

- Underground Singapore 2018: Ground Improvement for Bored TunnelDocument10 pagesUnderground Singapore 2018: Ground Improvement for Bored TunnelSeng SiongNo ratings yet

- Design Gravity Retaining WallDocument3 pagesDesign Gravity Retaining WallPinapaSrikanth100% (1)

- U-shaped retaining wall design parametersDocument4 pagesU-shaped retaining wall design parametersAshish G100% (1)

- Effects of Preloading of Struts On Retaining Structures in Deep ExcavationsDocument12 pagesEffects of Preloading of Struts On Retaining Structures in Deep ExcavationsPremnath YadavNo ratings yet

- RVNL Bhubaneswar Project Introduces Innovative Kicker Block Method for Tilt CorrectionDocument9 pagesRVNL Bhubaneswar Project Introduces Innovative Kicker Block Method for Tilt CorrectionVenkateswarlu DanduNo ratings yet

- Portal DesignDocument8 pagesPortal DesignshishirpatleNo ratings yet

- Load Calculation CS-5Document3 pagesLoad Calculation CS-5yadav04_abhishekNo ratings yet

- Pile Design - 15m Length: Calculation of Stiffness FactorsDocument3 pagesPile Design - 15m Length: Calculation of Stiffness Factorskrishna kumarNo ratings yet

- Design - Pipe Cause WayDocument1 pageDesign - Pipe Cause WaysudhirsoniNo ratings yet

- Blast DesignDocument1 pageBlast DesignIndah Putrika RezkyNo ratings yet

- Footing Preliminary DesignDocument12 pagesFooting Preliminary Designप्रविणअर्यालNo ratings yet

- 18.3 M PSC GirderDocument27 pages18.3 M PSC GirdermithunNo ratings yet

- Project - Park Hotel Location - PuneDocument7 pagesProject - Park Hotel Location - PunewaquarstrNo ratings yet

- MRT DRR-08 (8jun2021) (Replied by Neo)Document6 pagesMRT DRR-08 (8jun2021) (Replied by Neo)yin hoe ongNo ratings yet

- 2Document105 pages2Zankar R ParikhNo ratings yet

- Analysis of Basal Heave Stability For Excavations in Soft Clay Using The Finite PDFDocument8 pagesAnalysis of Basal Heave Stability For Excavations in Soft Clay Using The Finite PDFJuan Carlos Patiño BautistaNo ratings yet

- Geotechnical Investigations of Mumbai-Pune ExpresswayDocument17 pagesGeotechnical Investigations of Mumbai-Pune Expresswayblackberry7100gNo ratings yet

- Protection PileDocument10 pagesProtection PilePrakash GuragainNo ratings yet

- Soft Soils Improved by Prefabricated Vertical Drains: Performance and PredictionDocument25 pagesSoft Soils Improved by Prefabricated Vertical Drains: Performance and PredictionAlep AzizNo ratings yet

- Grouting Pattern For Ground Consolidation: Stage 1Document2 pagesGrouting Pattern For Ground Consolidation: Stage 1DEBASIS BARMANNo ratings yet

- Rock Support Example 2Document6 pagesRock Support Example 2Imran SaikatNo ratings yet

- Stability Analysis of Plum WallDocument2 pagesStability Analysis of Plum WallShivendra KumarNo ratings yet

- BUDHIL HEP- POWER HOUSE CAVERN ESTIMATION OF ROCK LOADING AND SUPPORT REQUIREMENTSDocument5 pagesBUDHIL HEP- POWER HOUSE CAVERN ESTIMATION OF ROCK LOADING AND SUPPORT REQUIREMENTSDEBASIS BARMANNo ratings yet

- NATM Tunnel and Cross Passage Reinforcement DetailsDocument1 pageNATM Tunnel and Cross Passage Reinforcement DetailsDEBASIS BARMANNo ratings yet

- RMT Periphery Works for 9.5m Excavation DepthDocument1 pageRMT Periphery Works for 9.5m Excavation DepthManan ParikhNo ratings yet

- Design of Haunches in Box CulvertDocument2 pagesDesign of Haunches in Box CulvertaswayNo ratings yet

- Column DesignDocument6 pagesColumn DesignDEBASIS BARMANNo ratings yet

- Name of Work:-: M /sec M /sec M /sec M /sec M /sec M /sec M /secDocument9 pagesName of Work:-: M /sec M /sec M /sec M /sec M /sec M /sec M /secChauhan UjjvalNo ratings yet

- SCH-B Pragatipath Navsari DTP80 CRDocument100 pagesSCH-B Pragatipath Navsari DTP80 CRKETANNo ratings yet

- Retaining Wal DESIGNDocument7 pagesRetaining Wal DESIGNpankajppatilNo ratings yet

- Head Reg (Final) UNGATEDDocument6 pagesHead Reg (Final) UNGATEDsushilkumarNo ratings yet

- Slope StabilityDocument25 pagesSlope StabilityFerdousul Haque ShikderNo ratings yet

- Ugc 01 Geo SCP 1101 005 ADocument1 pageUgc 01 Geo SCP 1101 005 AAlhad PanwalkarNo ratings yet

- CTC Design and Estimation 1 PDFDocument25 pagesCTC Design and Estimation 1 PDFEr Bharath Yadav MNo ratings yet

- Mathcad - 06-Loads On Tile RoofDocument2 pagesMathcad - 06-Loads On Tile RoofMakaraSoyNo ratings yet

- Material Properties:: Main Builtup Girder Flexural CheckDocument22 pagesMaterial Properties:: Main Builtup Girder Flexural CheckDipak BorsaikiaNo ratings yet

- Input DataDocument3 pagesInput DataVarun VermaNo ratings yet

- Road Estimate FormatDocument7 pagesRoad Estimate Formatalok jhaNo ratings yet

- Bearing CapacityDocument7 pagesBearing CapacityLaura HernandezNo ratings yet

- Correction For Overburden: Bearing Capacity Based On Standard Penetration TestDocument41 pagesCorrection For Overburden: Bearing Capacity Based On Standard Penetration TestHimal KafleNo ratings yet

- CM & CD Works and Design of LI Schemes PDFDocument46 pagesCM & CD Works and Design of LI Schemes PDFAswani ReddyNo ratings yet

- Bhimgoda BarrageDocument2 pagesBhimgoda BarrageLuojisi CilNo ratings yet

- Abutment Design For CausewayDocument7 pagesAbutment Design For CausewayVinay ChandwaniNo ratings yet

- Model Sluice EstimateDocument24 pagesModel Sluice EstimateRAMACHANDRA MOORTHY100% (1)

- Name of Work:-Construction of Major Bridge Across River Vattigedda at KM 492/2-4 of Raipur - Visakhapatnam Section of NH-43 in Andhra PradeshDocument4 pagesName of Work:-Construction of Major Bridge Across River Vattigedda at KM 492/2-4 of Raipur - Visakhapatnam Section of NH-43 in Andhra PradeshUpadhyayula Subba RaoNo ratings yet

- Design of Parapet Wall up to 3.45m CushionDocument5 pagesDesign of Parapet Wall up to 3.45m Cushionsrikanth2vangaraNo ratings yet

- Found DesignDocument3 pagesFound Designsaif.ce.16No ratings yet

- Drain Foundation Analysis and DesignDocument6 pagesDrain Foundation Analysis and DesignUmesgNo ratings yet

- CEP pit wall designDocument382 pagesCEP pit wall designsoumi bhattacharyaNo ratings yet

- Irc 83 Part III 2002 Standard Specifications Code of Practice For Road Bridges PDFDocument42 pagesIrc 83 Part III 2002 Standard Specifications Code of Practice For Road Bridges PDFHemanthNo ratings yet

- Geosythetic Reinforced Unpaved RoadDocument10 pagesGeosythetic Reinforced Unpaved RoadPalak ShivhareNo ratings yet

- Geobag River DibangDocument6 pagesGeobag River DibangPalak ShivhareNo ratings yet

- Geophysical Investigation Dam SiteDocument7 pagesGeophysical Investigation Dam SitePalak ShivhareNo ratings yet

- Improved Fundation Marine ClayDocument4 pagesImproved Fundation Marine ClayPalak ShivhareNo ratings yet

- Laterally Loaded Pile 2911Document7 pagesLaterally Loaded Pile 2911Palak Shivhare100% (1)

- Failure of Retaining Wall - Case StudyDocument4 pagesFailure of Retaining Wall - Case StudyPalak ShivhareNo ratings yet

- Lateral Load Pile Scour DepthDocument9 pagesLateral Load Pile Scour DepthPalak ShivhareNo ratings yet

- Potential Landslide Zones Along Pipalkoti-Joshimath Road, Alaknanda ValleyDocument5 pagesPotential Landslide Zones Along Pipalkoti-Joshimath Road, Alaknanda ValleyPalak ShivhareNo ratings yet

- Compressive and Brazilian Test Tunel RockDocument10 pagesCompressive and Brazilian Test Tunel RockPalak ShivhareNo ratings yet

- Insitu Shear Test Gneissic Rock MassDocument10 pagesInsitu Shear Test Gneissic Rock MassPalak ShivhareNo ratings yet

- Geotech Investigation BouldersDocument7 pagesGeotech Investigation BouldersPalak ShivhareNo ratings yet

- Kolkata Organic SoilDocument9 pagesKolkata Organic SoilPalak ShivhareNo ratings yet

- Coir Waste FlyashDocument5 pagesCoir Waste FlyashRaghavNo ratings yet

- Highway Construction Along CanalDocument5 pagesHighway Construction Along CanalPalak ShivhareNo ratings yet

- Flyash Gypsum SoilDocument4 pagesFlyash Gypsum SoilPalak ShivhareNo ratings yet

- GPR RQDDocument8 pagesGPR RQDPalak ShivhareNo ratings yet

- 1.pa STUDY ON HYGROSCOPIC WATER CONTENT AND RESIDUAL WATER CONTENT OF SOILdfDocument3 pages1.pa STUDY ON HYGROSCOPIC WATER CONTENT AND RESIDUAL WATER CONTENT OF SOILdfmchetiaNo ratings yet

- Tyre Wase Bearing CapacityDocument4 pagesTyre Wase Bearing CapacityPalak ShivhareNo ratings yet

- Hollow Steel Single PileDocument4 pagesHollow Steel Single PilePalak ShivhareNo ratings yet

- Subgrade Rutting Flexible PavementDocument5 pagesSubgrade Rutting Flexible PavementPalak ShivhareNo ratings yet

- Socket Friction Micro PileDocument8 pagesSocket Friction Micro PilePalak ShivhareNo ratings yet

- Rigid Foundation Inclined LoadDocument9 pagesRigid Foundation Inclined LoadPalak ShivhareNo ratings yet

- Soil Profile - UdaipurDocument1 pageSoil Profile - UdaipurPalak ShivhareNo ratings yet

- Uplift Capacity T-Z MethodDocument5 pagesUplift Capacity T-Z MethodPalak ShivhareNo ratings yet

- Is 13365 Part4 DraftDocument15 pagesIs 13365 Part4 DraftPalak Shivhare0% (1)

- Slopes With Without NailsDocument8 pagesSlopes With Without NailsPalak ShivhareNo ratings yet

- Irf WRM 2017 Detailed ProgrammeDocument13 pagesIrf WRM 2017 Detailed ProgrammePalak ShivhareNo ratings yet

- Culvert Design ManualDocument54 pagesCulvert Design ManualMahmoud Al NoussNo ratings yet

- Finite Element Analysis of RC Beams With Externally Bonded Sifcon and Simcon Laminates Using Ansys IJERTV8IS010115Document4 pagesFinite Element Analysis of RC Beams With Externally Bonded Sifcon and Simcon Laminates Using Ansys IJERTV8IS010115SAFNANo ratings yet

- Stuctural Analysis Using AnsysDocument39 pagesStuctural Analysis Using AnsysVishnuPrasadNo ratings yet

- Flanged Bolt Couplings Torque CapacityDocument9 pagesFlanged Bolt Couplings Torque Capacitypoliman2017100% (1)

- IFR CalculationDocument15 pagesIFR CalculationSachin5586No ratings yet

- Stairs and Access Ramps Between Floors in Multi-Storey Buildings-BullDocument8 pagesStairs and Access Ramps Between Floors in Multi-Storey Buildings-Bulljunhe898No ratings yet

- Reinforced Timber BeamsDocument5 pagesReinforced Timber BeamsbertinNo ratings yet

- Strength of MaterialsDocument470 pagesStrength of MaterialsReDo DistiraNo ratings yet

- Assignment On Geo Technical Engg-IIDocument2 pagesAssignment On Geo Technical Engg-IIAshok Kumar RajanavarNo ratings yet

- Biomechanics Fracture FixationDocument70 pagesBiomechanics Fracture Fixationhugo alexis moreno asenciosNo ratings yet

- CV2013 - Compressibility SettlementDocument45 pagesCV2013 - Compressibility SettlementshivaNo ratings yet

- 3 2 CreepDocument7 pages3 2 CreepB Bala Venkata GaneshNo ratings yet

- CE 5340 Teach - 2016Document2 pagesCE 5340 Teach - 2016Anonymous Wm8Xh9No ratings yet

- Numerically Based Analysis of Buried GRPDocument8 pagesNumerically Based Analysis of Buried GRPjeovanNo ratings yet

- LN12 PDFDocument31 pagesLN12 PDFelty TanNo ratings yet

- W18 TOS Official Paper and Model Answer Paper 22402Document18 pagesW18 TOS Official Paper and Model Answer Paper 22402irshadmirza753No ratings yet

- Koo 2014Document7 pagesKoo 2014ching2001.21No ratings yet

- Built Up ColumnsDocument22 pagesBuilt Up Columnsfinn.crown100% (1)

- SFD and BMD (Questions)Document22 pagesSFD and BMD (Questions)Mayank ShelarNo ratings yet

- DESIGN OF INTERMEDIATE SPAN SIDE GIRTDocument2 pagesDESIGN OF INTERMEDIATE SPAN SIDE GIRTSantosh BapuNo ratings yet

- SDCDSCDocument9 pagesSDCDSCAnish NeupaneNo ratings yet

- Procedure Manual: FOR Underground FRP Storage TankDocument6 pagesProcedure Manual: FOR Underground FRP Storage Tankravi yemmadiNo ratings yet

- Mechanics of Materials: Fig. 4.2. Beam Subjected To Pure Bending (A) Before, and (B) After, The Moment Been AppliedDocument1 pageMechanics of Materials: Fig. 4.2. Beam Subjected To Pure Bending (A) Before, and (B) After, The Moment Been Appliedvik03223No ratings yet

- HILTI ExBar Rebar Design Soft WareDocument30 pagesHILTI ExBar Rebar Design Soft WareAline Tabet Abi SaadNo ratings yet

- Seismic strengthening of bridge pier lap splices using UHPFRC coverDocument13 pagesSeismic strengthening of bridge pier lap splices using UHPFRC coverSebastian Contreras ContrerasNo ratings yet

- Chapter 2 Beams Curved in Plan FinalDocument12 pagesChapter 2 Beams Curved in Plan Finalyosef gemessa100% (1)

- Indian Standard: Code of Practice For General Construction, in SteelDocument144 pagesIndian Standard: Code of Practice For General Construction, in Steelrvmehta18No ratings yet

- Zener Model 1Document11 pagesZener Model 1Vijay BahetiNo ratings yet

- Boundary Element Programming in Mechanics - 104207485Document6 pagesBoundary Element Programming in Mechanics - 104207485Anonymous 1rLNlqUNo ratings yet

- Advanced Modelling Techniques in Structural DesignFrom EverandAdvanced Modelling Techniques in Structural DesignRating: 5 out of 5 stars5/5 (3)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Marine Structural Design CalculationsFrom EverandMarine Structural Design CalculationsRating: 4.5 out of 5 stars4.5/5 (13)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsFrom EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNo ratings yet

- Design and Construction of Soil Anchor PlatesFrom EverandDesign and Construction of Soil Anchor PlatesRating: 5 out of 5 stars5/5 (1)

- Pile Design and Construction Rules of ThumbFrom EverandPile Design and Construction Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (15)

- Transmission Pipeline Calculations and Simulations ManualFrom EverandTransmission Pipeline Calculations and Simulations ManualRating: 4.5 out of 5 stars4.5/5 (10)

- Advanced Design Examples of Seismic Retrofit of StructuresFrom EverandAdvanced Design Examples of Seismic Retrofit of StructuresRating: 1 out of 5 stars1/5 (1)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingFrom EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNo ratings yet

- Matrix Methods for Advanced Structural AnalysisFrom EverandMatrix Methods for Advanced Structural AnalysisRating: 5 out of 5 stars5/5 (1)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Piezocone and Cone Penetration Test (CPTu and CPT) Applications in Foundation EngineeringFrom EverandPiezocone and Cone Penetration Test (CPTu and CPT) Applications in Foundation EngineeringNo ratings yet

- Pipeline Planning and Construction Field ManualFrom EverandPipeline Planning and Construction Field ManualRating: 5 out of 5 stars5/5 (3)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsFrom EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsRating: 4 out of 5 stars4/5 (16)

- Building Support Structures, 2nd Ed., Analysis and Design with SAP2000 SoftwareFrom EverandBuilding Support Structures, 2nd Ed., Analysis and Design with SAP2000 SoftwareRating: 4.5 out of 5 stars4.5/5 (15)

- Concrete Structures: Repair, Rehabilitation and StrengtheningFrom EverandConcrete Structures: Repair, Rehabilitation and StrengtheningNo ratings yet

- Offshore Pipelines: Design, Installation, and MaintenanceFrom EverandOffshore Pipelines: Design, Installation, and MaintenanceRating: 4.5 out of 5 stars4.5/5 (2)

- Engineering for Kids: Building and Construction Fun | Children's Engineering BooksFrom EverandEngineering for Kids: Building and Construction Fun | Children's Engineering BooksRating: 3 out of 5 stars3/5 (2)

- Built: The Hidden Stories Behind Our StructuresFrom EverandBuilt: The Hidden Stories Behind Our StructuresRating: 4 out of 5 stars4/5 (27)