Professional Documents

Culture Documents

Unit 4

Uploaded by

sreenivasMtechdisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Unit 4

Uploaded by

sreenivasMtechdisCopyright:

Available Formats

UNIT IV

DRYING

1. What is meant by equilibrium moisture?

This is the moisture content of a substance when at equilibrium with a given partial pressure

of the vapor.

2. What is bound water?

This refers to the moisture contained by a substance which exerts an equilibrium vapor

pressure less than that of the pure liquid at the same temperature.

3. What is drying?

Drying refers to the removal of moisture from a substance.

4. What are the types of moisture?

Equilibrium moisture, Bound moisture, unbound moisture and free moisture

5. What is meant by moisture content?

The moisture content of a solid or solution is described in terms of weight % moisture

and unless otherwise qualified this is ordinarily understood to be expressed on wet basis

6. What are hygroscopic substances?

Substances containing bound water are called hygroscopic substance

7. What is fiber saturation point?

The condition at which wood textiles and other cellular materials is in equilibrium

with saturated air is called fiber saturation point.

8. What are the types of drying?

Batch drying, Continuous drying, freeze drying, Cross circulation drying, through

circulation drying.

9. What is free moisture?

It is the moisture contained by a substance in excess of the equilibrium moisture only

free moisture can be evaporated. Free moisture content of the solid depends upon the vapor

concentration in the gas.

10. What are special drying methods?

IR radiation, Dielectric heating and vaporization from ice.

11. What are the disadvantages of batch drying?

High labour cost

Expensive operation and temperature of the interior falls at the time of loading and unloading.

12. What are the advantages of batch drying?

Low maintenance cost

13. What are the advantages of tunnel driers?

Convenience of continuous operation

It is used on brick, ceramic, and other materials must be dried.

14. What are the advantages of Rotoloure?

It does not lift the material and drop it down through the shell but merely allows it to

roll along the bottom. There is less tendency for size degradation and fragile materials.

Hot air passes through the material the air comes more nearly in equilibrium with the material.

15. What is funicular state?

It is that condition in drying a porous body when capillary suction results in air being sucked

in to the pores.

16. What is pendular state?

It is that state of a liquid in a porous solid when a continuous film of liquid no longer exists

around and between discrete particles so that flow by capillary cannot occurs

This state succeeds the funicular state.

17. What is shrinkage?

An important factor in controlling the drying rate is the shrinkage of the solid as the

moisture content is lowered, rigid, porous or non-porous solids do not shrink appreciably

during drying. But colloidal and fibrous materials undergo severe shrinkage as the moisture is

removed from them.

18. What are the effects of shrinkage?

It alters the surface of the material per unit weight.

This is true for vegetables and food stuffs.

19. What is meant by case hardening?

There may be developed hardened layer on the surface. It occurs in clay and soap

Change in gross structure. This slows down the drying.

20. What are freeze drying?

Substance which cannot be heated even to moderate temperature such as food stuffs

and pharmaceuticals can be dried by this method.

PART B

1. a) Explain the mechanism of dying during constant rate and falling rate period. (MAY14)

b) A porous solid is to be batch dried under constant drying conditions. A trial shows that it

requires 6 hours to reduce the moisture content from 30 to 10%. The critical moisture content

is 16% and the equilibrium moisture content is 2.5%. Assuming that the rate of drying during

the falling rate period is proportional to the free moisture content. How long will it take to dry

a sample of the same solid from 35% to 6% under the same drying conditions? All moisture

contents are on a wet basis.

2. With neat diagrams, explain the working of:

a) Spray dryer

b) Rotary dryer

c) Mechanically agitated dryers

3. (i) Write short notes on: Critical Moisture content, Bound and unbound moisture.

(ii) Describe any one industrial dryer for continuous operation. Give a neat sketch.

4. Explain how time of drying can be calculated.

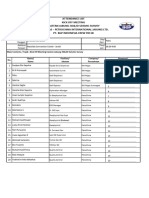

5. 1400 kg. of bone dry granular solid is to be dried under constant drying conditions. From a

moisture content of 0.2 kg water/kg. dry solid to a final value of 0.02 kg. Water/kg. Dry solid.

The material has an effective area of 0.0616, m2/kg. dry solid. Calculate the time of drying

Flux (kg/hr.m2) 1.71 1.71 1.71 1.46 1.29 0.88 0.54 0.376

Moisture content 0.3 0.2 0.14 0.096 0.056 0.046 0.026 0.016

(dry basis)

6. Find an expression for the determination of total time of drying of a wet solid material

under constant drying conditions to a final moisture content well below the critical moisture

content.

7. In a textile mill, wet cloth passes through a hot air drier. The cloth enters with 90%

moisture regain and leaves at 6% moisture regain at a speed of 1.15 m/sec. The width of the

cloth is 120 cm and its density on bone-dry basis is 0.095 kg/m2. The temperature of the cloth

leaving the drier is 368 K. The ambient air enters the dryer at 303 K DB and 298 K WB while

the hot air leaves the dryer at 393 K DB and 328 K WB. Calculate:

(i) the bone-dry production of the dryer

(ii) the evaporation taking place in the dryer and

(iii) the air circulation rate.

8. A time of 5 hrs. Was taken to dry a material from an initial moisture of 30% to a final

moisture of 7%. Critical and equilibrium moisture are found to be 15% and 2% respectively.

How much further time would be required to dry the material to a final moisture of 4%. All

moisture contents are on wet basis.

9. Explain about tray dryer and fluidized bed dryer with neat sketches.

10. Describe the temp. Patterns in batch and continuous countercurrent adiabatic dryers.

You might also like

- Dryers Problem and SolutionDocument4 pagesDryers Problem and SolutionAngielou Sialana100% (2)

- DryingDocument3 pagesDryingAlvin Salmingo100% (1)

- Easily control your TV with one remoteDocument4 pagesEasily control your TV with one remoteJeradin_01No ratings yet

- Tutorial 2 - Drying PDFDocument3 pagesTutorial 2 - Drying PDFSalihah AbdullahNo ratings yet

- Drying2 and TutorialDocument9 pagesDrying2 and TutorialDr-Khalid Al-Shemmari100% (1)

- Principle and Mechanism of DryingDocument59 pagesPrinciple and Mechanism of DryingNayem Hossain86% (7)

- Tutorial DryingDocument5 pagesTutorial DryingIqmal HakeemNo ratings yet

- Solid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityFrom EverandSolid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityRating: 5 out of 5 stars5/5 (2)

- Introduction To Continuum Bio Mechanics (Synthesis Lectures On Bio Medical Engineering)Document221 pagesIntroduction To Continuum Bio Mechanics (Synthesis Lectures On Bio Medical Engineering)Carko100% (1)

- Six Behavioral ObjectivesDocument4 pagesSix Behavioral Objectivesapi-349767644No ratings yet

- Drying Notes FinalDocument34 pagesDrying Notes FinalKeith OmwoyoNo ratings yet

- Drying-4-Document48 pagesDrying-4-『ABN』NARUTO أبن ناروتو (Gamer)No ratings yet

- Drying PDFDocument48 pagesDrying PDFuzzal ahmedNo ratings yet

- Drying of Solids: 18.0 Instructional ObjectivesDocument48 pagesDrying of Solids: 18.0 Instructional ObjectivesIvan MarmilichNo ratings yet

- Lab 2 Full Report PDFDocument20 pagesLab 2 Full Report PDFmuhammad ilyas100% (1)

- Rying of Solids: Mohammad Hadi Usama Zulfiqar Abdullah IqbalDocument30 pagesRying of Solids: Mohammad Hadi Usama Zulfiqar Abdullah IqbalHadi SiddiqiNo ratings yet

- Ministry of Higher Education and Scientific Research Al Muthanna University Collage of Engineering / Chemical Engineering DepartmentDocument5 pagesMinistry of Higher Education and Scientific Research Al Muthanna University Collage of Engineering / Chemical Engineering Departmentعبد اللهNo ratings yet

- Dryer DesignDocument39 pagesDryer DesignPrashanth Chidambaram75% (4)

- Diseño de SecadoresDocument39 pagesDiseño de SecadoresJosé Helí Vallejos CoronadoNo ratings yet

- Tray DryerDocument16 pagesTray DryerZalina Samsuddin100% (1)

- DryingDocument39 pagesDryingochotpremNo ratings yet

- Drying of Solids: Classification & Mechanisms of Common DryersDocument53 pagesDrying of Solids: Classification & Mechanisms of Common DryersIqra Mubeen100% (1)

- Design of DryersDocument39 pagesDesign of DryersAnara Alam100% (1)

- Drying ExperimentDocument10 pagesDrying ExperimentKris Dominic RubillosNo ratings yet

- Terminologies in DryersDocument4 pagesTerminologies in DryersKristine Ann ReclosadoNo ratings yet

- 1-Drying 082633Document16 pages1-Drying 082633Mikhoy RiveralNo ratings yet

- Drying LectureDocument85 pagesDrying LectureHaroon RahimNo ratings yet

- Dryers and Drying ProcessesDocument24 pagesDryers and Drying ProcessesKristine Joy MataroNo ratings yet

- Problems On DryingDocument1 pageProblems On DryingmelanieNo ratings yet

- Problems On DryingDocument1 pageProblems On Dryingmelanie100% (1)

- Heat and Mass TransferDocument90 pagesHeat and Mass TransferAnonymous 0zrCNQNo ratings yet

- Drying, and Drying Equipments 2Document37 pagesDrying, and Drying Equipments 2Adheep DasNo ratings yet

- DryingDocument18 pagesDryinganthony ijigaNo ratings yet

- CH 4Document20 pagesCH 4ARBAZ KHOKHARNo ratings yet

- Force Draft Tray Dryer Experimental ManualDocument21 pagesForce Draft Tray Dryer Experimental ManualShoaib Pathan100% (2)

- Drying: Review QuestionsDocument2 pagesDrying: Review Questionsshankar sutarNo ratings yet

- Drying Competency 20112Document1 pageDrying Competency 20112Albert Junior EvangelistaNo ratings yet

- Prepared By: Ankita Yagnik Assistant Professor Akshar-Preet Institute of PharmacyDocument65 pagesPrepared By: Ankita Yagnik Assistant Professor Akshar-Preet Institute of PharmacyKamran Jalil100% (1)

- Types of Industrial Dryers and Their Selection PDF (1) (1)Document20 pagesTypes of Industrial Dryers and Their Selection PDF (1) (1)Hari KishoreNo ratings yet

- Ejercicios InglesDocument2 pagesEjercicios InglesJhoisy AguilarCaseuxNo ratings yet

- DRYING CURVES EXPERIMENTDocument13 pagesDRYING CURVES EXPERIMENTNeil BrionesNo ratings yet

- CHE 321 Unit Operation 1 (3 Units) : 1: Drying, Conveying 2: Sedimentation, ClarificationDocument28 pagesCHE 321 Unit Operation 1 (3 Units) : 1: Drying, Conveying 2: Sedimentation, ClarificationGlory UsoroNo ratings yet

- Drying of Wet Solids: An IntroductionDocument17 pagesDrying of Wet Solids: An IntroductionANURAG BANERJEENo ratings yet

- Scribed 2Document51 pagesScribed 2Hafiz Muhammad AzamNo ratings yet

- 2-Forced Tray DryerDocument15 pages2-Forced Tray DryerChintan ModiNo ratings yet

- Cooling Towers & Dryers ExplainedDocument18 pagesCooling Towers & Dryers ExplaineddaanNo ratings yet

- Department of Chemical Engg. ASSIGNMENT-3, Mass Transfer IDocument3 pagesDepartment of Chemical Engg. ASSIGNMENT-3, Mass Transfer IKimberly BautistaNo ratings yet

- Pre Lab Forced Draft DrierDocument8 pagesPre Lab Forced Draft DrierAmoluck BhatiaNo ratings yet

- Experiment No: 09 Objective:: Fluidized Bed DryersDocument4 pagesExperiment No: 09 Objective:: Fluidized Bed DryersAnonymous oKRAtONo ratings yet

- Drying Fundamentals ExplainedDocument62 pagesDrying Fundamentals ExplainedmohammmadNo ratings yet

- Drying ReviewerDocument45 pagesDrying ReviewerConrad MonterolaNo ratings yet

- Richard P Feynman-Surely Youre Joking MR Feynman v5Document3 pagesRichard P Feynman-Surely Youre Joking MR Feynman v5Anonymous Nayak0% (1)

- A Presentaion On DryingDocument40 pagesA Presentaion On DryingMd. Abu Bakar Siddique TayefNo ratings yet

- Drying Time Calculations for Food ProductsDocument3 pagesDrying Time Calculations for Food ProductsJaynie Lee VillaranNo ratings yet

- DryingDocument43 pagesDryingMary Grace Narvaez GarciaNo ratings yet

- Faculty of Engineering and The Built Environment (Febe) Department of Chemical Engineering Unochb2: Unit Operations 2B TUTORIAL 5-DryingDocument2 pagesFaculty of Engineering and The Built Environment (Febe) Department of Chemical Engineering Unochb2: Unit Operations 2B TUTORIAL 5-DryingThabo ThaboNo ratings yet

- Tutorial 2 - DryingDocument3 pagesTutorial 2 - DryingDinesh Kumar VijeyanNo ratings yet

- Tray DryerDocument22 pagesTray DryerjuaxxoNo ratings yet

- Industrial Dryer PresentationDocument20 pagesIndustrial Dryer PresentationTeox100% (1)

- Factors Affecting Drying Rates and MechanismsDocument4 pagesFactors Affecting Drying Rates and MechanismsMahesh VoraNo ratings yet

- 90pharmaceutical Unit Operations - PDF DryingDocument18 pages90pharmaceutical Unit Operations - PDF DryingGS SandhuNo ratings yet

- The Dyeing of Cotton Fabrics: A Practical Handbook for the Dyer and StudentFrom EverandThe Dyeing of Cotton Fabrics: A Practical Handbook for the Dyer and StudentNo ratings yet

- Paavai Engineering College - Namakkal: B.Tech. - Chemical Engineering CM16701 - Transport PhenomenaDocument1 pagePaavai Engineering College - Namakkal: B.Tech. - Chemical Engineering CM16701 - Transport PhenomenasreenivasMtechdisNo ratings yet

- Design IIDocument1 pageDesign IIsreenivasMtechdisNo ratings yet

- ProblemDocument2 pagesProblemsreenivasMtechdisNo ratings yet

- CM16706-PROCESS Equipment Design IiDocument4 pagesCM16706-PROCESS Equipment Design IisreenivasMtechdisNo ratings yet

- TheoriesDocument3 pagesTheoriessreenivasMtechdisNo ratings yet

- Unit 4Document4 pagesUnit 4sreenivasMtechdisNo ratings yet

- Unit-2 Q&BDocument4 pagesUnit-2 Q&BsreenivasMtechdisNo ratings yet

- UNIT-3 QuestionsDocument4 pagesUNIT-3 QuestionssreenivasMtechdis100% (1)

- Fick's law of diffusion explainedDocument3 pagesFick's law of diffusion explainedsreenivasMtechdisNo ratings yet

- R 2008 Chemical SyllabusDocument62 pagesR 2008 Chemical SyllabussreenivasMtechdisNo ratings yet

- Synthesis and Characterization of Composite Molecular Sieves Comprising Zeolite Beta With MCM-41 StructuresDocument5 pagesSynthesis and Characterization of Composite Molecular Sieves Comprising Zeolite Beta With MCM-41 StructuressreenivasMtechdisNo ratings yet

- TUCSS Annual Lecture 2023 Shirlaw SlidesDocument51 pagesTUCSS Annual Lecture 2023 Shirlaw SlidesKo Pyi SoeNo ratings yet

- Air PermeabilityDocument3 pagesAir PermeabilityChuxuan SunNo ratings yet

- Experiment 8: Determination of The Ratio of The Specific Heats of AIRDocument9 pagesExperiment 8: Determination of The Ratio of The Specific Heats of AIRwallace kitoNo ratings yet

- A Physically Based Variable Contributing Area Model of Basin Hydrology Un Mod Le Base Physique de Zone D Appel Variable de L Hydrologie Du BassinDocument28 pagesA Physically Based Variable Contributing Area Model of Basin Hydrology Un Mod Le Base Physique de Zone D Appel Variable de L Hydrologie Du BassinJorge Vasconcelos NettoNo ratings yet

- Me8491 em Unit - IIDocument119 pagesMe8491 em Unit - IIParameswara Raja100% (1)

- Pole FDNDocument24 pagesPole FDNyoussefNo ratings yet

- An Investigation On The Performance Characteristics of A Centrifugal CompressorDocument7 pagesAn Investigation On The Performance Characteristics of A Centrifugal CompressorIJERDNo ratings yet

- Activated Sludge Rheology A Critical Review On Data Collection and ModellingDocument20 pagesActivated Sludge Rheology A Critical Review On Data Collection and ModellingZohaib Ur RehmanNo ratings yet

- Dictionary of Physical GeographyDocument626 pagesDictionary of Physical GeographyDiana Olarasu100% (3)

- 2BE4 MiniDocument1 page2BE4 MiniRiandrika Iman SetyonoNo ratings yet

- Detailed Bridge Design 25mDocument2 pagesDetailed Bridge Design 25mAnu PathakNo ratings yet

- Revised 2023-24 - Sr.2Hrs Programme - Teaching & Test Schedule@17!10!2023Document67 pagesRevised 2023-24 - Sr.2Hrs Programme - Teaching & Test Schedule@17!10!2023suhasiyer02No ratings yet

- Algebra ExerciseDocument31 pagesAlgebra ExerciseJose Barrera GaleraNo ratings yet

- Periodic Classification of ElementsDocument2 pagesPeriodic Classification of ElementsADWAITH LALUNo ratings yet

- 2.2 and 2.3 TestDocument8 pages2.2 and 2.3 TestLeo DennisNo ratings yet

- A Novel One-Step Chemical Method For Preparation of Copper NanofluidsDocument4 pagesA Novel One-Step Chemical Method For Preparation of Copper NanofluidsbacNo ratings yet

- Mathematics - IIIA: (Numerical Analysis, Complex Analysis and Probability and Statistics)Document51 pagesMathematics - IIIA: (Numerical Analysis, Complex Analysis and Probability and Statistics)sarojpapuNo ratings yet

- Crystallography 333Document613 pagesCrystallography 333Biciin MarianNo ratings yet

- Ionic Equilibria Questions Set 2 2 PDFDocument4 pagesIonic Equilibria Questions Set 2 2 PDFdanielmahsaNo ratings yet

- What Is DC Component?Document2 pagesWhat Is DC Component?rzorNo ratings yet

- JCAMECH Volume 52 Issue 1 Pages 102-125Document24 pagesJCAMECH Volume 52 Issue 1 Pages 102-125Subodh KumarNo ratings yet

- Study of Bauschinger Effect in SpringDocument95 pagesStudy of Bauschinger Effect in Springmail_sambhuNo ratings yet

- Draft - Daftar Hadir KoM - Update 19.00Document3 pagesDraft - Daftar Hadir KoM - Update 19.00sowongNo ratings yet

- Regression analysis for transport planningDocument15 pagesRegression analysis for transport planningHussein OmranNo ratings yet

- Albert Einstein - Wikipedia, The Free EncyclopediaDocument34 pagesAlbert Einstein - Wikipedia, The Free EncyclopediaalhanunNo ratings yet

- Photography by DayaganDocument243 pagesPhotography by DayaganClaudine Gubia-on PuyaoNo ratings yet

- 389-Article Text-1590-1-10-20230129Document6 pages389-Article Text-1590-1-10-20230129wahyu satriaNo ratings yet