Professional Documents

Culture Documents

FD & DFD 150X Models: Installation, Operation and Maintenance Instructions

Uploaded by

karyati haslinda KamaruddinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FD & DFD 150X Models: Installation, Operation and Maintenance Instructions

Uploaded by

karyati haslinda KamaruddinCopyright:

Available Formats

Part #453946

Installation, Operation and

Maintenance Instructions

FD and DFD 150X Series models are intended for

installation in accordance with fire damper requirements for FD & DFD 150X

established by:

National Fire Protection Association

MODELS

NFPA Standard 90A 1 1⁄2 Hour

BOCA National Building Codes Curtain Fire Dampers

ICBO Uniform Building Codes Vertical or Horizontal Mount

IBC International Building Codes

STI NG

SBCCI Standard Building Codes LI

OF

CALIFOR

NIA

STAT

CSFM California State Fire Marshal

STAT

L

FI

AL

Fire Damper Listing (#3225-0981:102) SE

RE

MARSH

RVI C E

1/4 in.

minimum total

clearance

New York City (BSA/MEA listing #260-91-M)

“UL CLASSIFIED (see complete marking on product)”

“UL CLASSIFIED to Canadian safety standards (see Wall or Floor

complete marking on product)”

UL Standard 555 (Listing #R13317) Maximum

6 in.

Maximum

6 in.

RECEIVING AND HANDLING

Upon receiving dampers, check for both obvious and hidden damage. If

damage is found, record all necessary information on the bill of lading and

file a claim with the final carrier. Check to be sure that all parts of the

shipment, including accessories, are accounted for. Duct

Damper

Dampers must be kept dry and clean. Indoor storage and protection from Retaining Angles

(See Section 3)

dirt, dust and the weather is highly recommended. Do not store at Type A

Wall or Floor

temperatures in excess of 100°F.

Damper

SAFETY WARNING:

Improper installation, adjustment, alteration, service or maintenance

can cause property damage, injury or death. Read the installation,

operating, and maintenance instructions thoroughly before installing

or servicing this equipment.

Duct

This manual is the property of the owner, and is required for future

maintenance. Please leave it with the owner when the job is complete.

Type B

Wall or Floor

WARRANTY On types R & CR factory

furnished duct collar

Greenheck warrants this equipment to be free from defects in material and qualifies as breakaway

connection.

workmanship for a period of one year from the purchase date. Any units or

parts which prove to be defective during the warranty period will be

repaired or replaced at our option. Greenheck shall not be liable for

damages resulting from misapplication or misuse of its products.

Greenheck will not be responsible for any installation or removal costs.

Greenheck will not be responsible for any service work or backcharges

without prior written authorization. Duct Damper

INSTALLATION SUPPLEMENTS Type C, CO, CR & R

Refer to the appropriate Greenheck installation supplements Figure 1: Type A, Type B, and Type C,

for special requirements: CO, CR, R damper installation

• Support Mullions diagrams.

• Shaftwall Supplement

• Drywall Supplement

• Grille Installation Supplement

Note: Refer to Greenheck IOM, Part #461335, for CFSD

models to be installed in corridor ceiling applications.

Downloaded from www.Manualslib.com manuals search engine

Table of Contents

Pre-Installation Guidelines........................................................................................................... .2

Installation......................................................................................................................................3-4

Breakaway Connections................................................................................................................5

Damper Maintenance.....................................................................................................................6

Damper Troubleshooting................................................................................................................6

Installation for Steel Stud Connection Option..............................................................................6-7

Pre-Installation Guidelines

The basic intent of a proper installation is to secure the fire damper in, not to, the opening in such a manner as

to prevent distortion and disruption of damper operation. This is accomplished by allowing the fire damper in

rated separation openings to expand and for the connecting duct to separate in the event of the collapse of the

hanging system. The following items will aid in completing the damper installation in a timely and effective

manner.

1. Check the schedules for proper damper locations within the building. Visually inspect the damper for damage

and verify that the fusible link is in place or has not separated. If fusible link is not present or has separated,

replace link. Never install a fire damper without the proper UL approved fusible link in place. (Fusible link is

standard control option. An electric link may have been provided.)

2. Lift or handle damper using sleeve or frame.

3. Install damper accordingly to comply with manufacturer’s appropriate UL procedure file number.

4. Damper must be installed into duct or opening square and free of twist or other misalignment. Damper must

not be squeezed or stretched into duct or opening.

5. Damper must be kept clean and protected from dirt, dust and other foreign materials prior to and after

installation. Examples of such foreign materials include, but are not limited to:

a. Mortar dust

b. Drywall dust

c. Firesafing materials

d. Wall texture

e. Paint overspray

6. Damper should be sufficiently covered as to prevent overspray of spray-on insulating, wall texturing, or spray

painting when performed within 5 feet of the damper. Excessive dirt or foreign material deposits can cause

damper to bind and not operate properly.

7. Caulking is not necessary, nor is it allowed, between the damper sleeve and the wall or floor opening (annular

space). However, caulking may be applied to the retaining angles.

8. ACCESS: Suitable access (such that fusible links can be changed) must be provided for damper inspection

and servicing. Where it is not possible to achieve sufficient size access, it will be necessary to install a

removable section of duct. (Refer to NFPA 90A).

9. The Code Authority Having Jurisdiction (AHJ) must evaluate and provide approval of final installation where

variations to these instructions are necessary.

Downloaded from www.Manualslib.com manuals search engine

Installation - Failure to follow these instructions will void all warranties.

These instructions apply to 1 1⁄2 hour rated fire dampers mounted in masonry, block or stud walls and concrete floors.

Specific requirements in these instructions are mandatory. These instructions meet the requirements of UL 555.

Installation shall comply with the requirements of NFPA 90A Standard for the Installation of Air Conditioning and

Ventilating Systems. U.L. listing R13317, California State Fire Marshal listings 3225-981:102, and New York City

BSA/MEA listing 260-91-M as they apply to these dampers.

1. NO ADDITIONAL SLEEVES ARE REQUIRED

The fire damper extended frame is an approved sleeve and can be properly installed without the need for a

supplemental field installed sleeve. Damper frame shall extend a maximum of 6 in. beyond the wall or floor

opening on each side.

2. CLEARANCES REQUIRED BETWEEN FIRE DAMPER SLEEVES AND WALL/FLOOR OPENINGS

Fire damper assemblies expand during periods of intense heat. Therefore, it is essential that openings in walls

or floors be larger than the fire damper assembly to allow for this expansion. Minimum clearances required

between the outside of fire damper sleeve assemblies and wall/floor openings are:

• Galvanized steel fire dampers and sleeves: 1/8 in. per linear foot of damper width and height with a minimum

clearance of 1/4 in. Recommended clearances, for width and/or height dimensions of:

1) 48 in. or less: 1/2 in. clearance

2) More than 48 in. and 96 in. or less: 1 in. clearance

3) More than 96 in.: 11/2 in. clearance

These are total clearances (ignoring fastener heads) and do not need to be equally spaced around the

damper. Refer to Section 3 and Figure 2 for additional installation considerations.

Example: A 12 in. x 12 in. damper would require a minimum clearance of 1/4 in.

A 48 in. x 12 in. damper would require a minimum clearance of 1/2 in. on width and 1/4 in. on height.

3. SECURING THE FIRE DAMPER TO WALL AND

FLOOR OPENINGS

Fire damper assemblies must be installed in wall and

floor openings using retaining angles on each side of the

wall or floor as described below:

• Retaining angles must be a minimum of 16 gauge

steel and have a minimum of 1 1⁄2 in. x 1 1⁄2 in. legs.

• Retaining angles must be attached to the damper

using one or more of the following methods of

Wall or

attachment: Floor

• tack or spot welds Min. 1 in.

Overlap*

Retaining

• #10 sheetmetal screws Angle Retaining

Angle

• 1/4 in. bolts and nuts Sleeve

• 3/16 in. steel pop rivets

Attachments must be spaced a maximum of 6 in. on

center and a maximum of 2 in. from corners. The angles 2 in

Duct

. Ma

must be attached to all 4 sides of the sleeve with butt x.

joints at each corner. A minimum of two attachments 6 in

. Ma Damper

x.

are required on each side, top and bottom. The angles

need not be attached to each other at the corners.

6 in

. Ma

x.

• Retaining angles must completely cover the

2 in

clearance space between the damper and the . Ma

x.

wall/floor opening, plus overlap the wall/floor a

minimum of 1 in. This coverage includes all corners

(see Figure 2). *only applicable for damper sizes above 36 in. x 36 in.

• Retaining angles should not be fastened to the

wall/floor material. The angles should only sandwich Figure 2: Retaining angle installation.

the wall/floor and allow for damper expansion during

periods of intense heat.

Downloaded from www.Manualslib.com manuals search engine

4. CONNECTING DUCTS TO THE FIRE DAMPER

All duct connections to FD & DFD 150X series

extended frame dampers must be “breakaway”

type connections. All connections shown on page 24 in. o.c. 24 in. o.c. Ceiling Runner

Maximum Maximum

6 are considered breakaway. Factory furnished (metal studs) (metal studs)

duct collars on types R & CR fire dampers are also

12 in.

considered breakaway (see Figure 1).

5. MULTIPLE SECTION FIRE DAMPERS

When multiple sections are shipped unassembled,

installer shall fasten dampers together as 24 in. o.c.

Maximum

described in Section 3. Table 1 shows maximum

sizes for multiple section damper.

2 in.

2 Panhead

Screws

2 in.

16 in. o.c. 16 in. o.c.

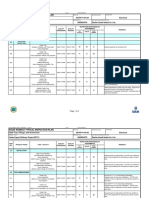

Damper Maximum Sizes Max Overall Size Maximum Maximum

for Single-Section for Multi-Section (wood studs) (wood studs)

Model Dampers Dampers

96 x 48

or Floor Runner

FD-150X (H or V) 48 x 48

120 x 40

72 x 48 Figure 3: Preparation detail for opening in stud wall.

DFD-150X (V) 36 x 36 or

60 x 60 Metal Stud Construction

DFD-150X (H) 30 x 30 48 x 36 Gypsum Wallboard

Note: V=Vertical Mount & H= Horizontal Mount

Table 1: Maximum sizes for single and multi-section

dampers.

Stud or Runner

Retaining

Angle

1 in. Min.

Damper

In metal stud construction,

Sleeve exposed steel surfaces need

not be covered with gypsum

Recommended Preparation of wallboard.

Openings in Wood and Metal Stud Figure 4: Detail of retaining angles and gypsum board

Walls application for metal and wooden stud construction.

Wooden Stud Construction

• Frame wall openings as shown in Figure 3.

• Double vertical studs are not required for openings 36 Gypsum Wallboard

in. x 36 in. or smaller.

• Gypsum wall board must be fastened 12 in. on center to

all stud and runner flanges surrounding opening (see Stud or Runner

Figure 4).

• All construction and fasteners must meet the

requirements of the appropriate wall design. (See UL Fire Retaining

Angle

Resistance Directory)

1 in. Min.

Damper In wood stud construction,

Sleeve gypsum wallboard must cover

all wood stud surfaces.

4

Downloaded from www.Manualslib.com manuals search engine

Breakaway Connections

Traditional Breakaway Style Transverse Joints

Transverse joints illustrated in Figure 5 have always

been approved as breakaway connections. SMACNA Plain “S” Slip Hemmed “S” Slip Double “S” Slip

testing has also approved the following variations as

breakaway connections.

• Standing “S” joints can be applied with #10

sheet metal screws (through joint and duct) subject

to the following limitations: Maximum 2 screws in

Inside Slip Joint Standing “S” Standing “S” (Alt.)

each side and in bottom joint.

• Transverse joints illustrated

can be applied as top and

bottom joints with Drive Slip - Drive Slip Joint

side joints in duct heights up to 20 in.

Round and Oval Duct Breakaway Connections Standing “S” (Alt.) Standing “S” Standing “S”

(Bar Reinforced) (Angle Reinforced)

Round or flat oval ducts connected to factory supplied Type

R, CR, or CO damper collars may use #10 sheet metal

Figure 5: Traditional breakaway style transverse joints.

screws as follows:

• Ducts 22 in. wide (or dia.) and smaller may use 3 NOTE: All breakaway connections described may have duct sealant, PA2084T

screws. duct sealant adhesive manufactured by Precision, applied in

• Ducts larger than 22 in. wide (or dia.) may use 5 screws. accordance with SMACNA recommendations.

Fire Damper Sleeve

Proprietary Flange System Breakaway Connections

6 in. long1/16in. max.

(Ductmate, Ward, Nexus) thickness plastic cleats;

12 in. c-c (min. 1 per side)

Flanged connection systems manufactured by Ductmate, Flanged system angles

Ward, and Nexus are approved as breakaway

connections when installed as illustrated in Figure 6.

(Attach per

manufacturer's

instructions)

Corners may be bolted

with 3/8 in. nuts and bolts

Neoprene gasket

between all angles

Duct

Figure 6: Detail of manufactured flanged system

breakaway connections.

(TDC by Lockformer, TDF by Engle)

TDC and TDF systems are approved as breakaway connections when installed as described in the SMACNA Duct

Construction Standards. Standard 6 in. metal clips may be used with spacing (see Figure 7). Three-eighth in. metal bolts and

nuts may be used to fasten together corner pieces (see Figure 8).

Clip Spacing Std. Clip Duct End

Length Flange

9 in.

6 in. 6 in. 6 in.

60 in. Duct Corner Piece

4 Req’d.

7 in. 7 in.

48 in. Duct

3 Req’d.

5 in. 5 in.

Sleeve Duct 36 in. Duct 3/8 in. bolt

3 Req’d. (optional)

5 in. 5 in.

24 in. Duct

2 Req’d.

Typical TDC/TDF joint

18 in. Duct &

Smaller

1 Req’d. CL

Duct

Figure 7: Detail of proprietary flanged system breakaway Figure 8: Detail of bolted corner.

connections.

5

Downloaded from www.Manualslib.com manuals search engine

Damper Maintenance

Dampers shall be maintained, cycled, and tested in intervals as stated in the latest editions of NFPA 90A, 92A,

and UL 864 unless local codes require more frequent inspections.

Dampers do not typically require maintenance as long as they are kept dry and clean. If cleaning is necessary,

use mild detergents or solvents. If lubrication is desired, do not use oil-based lubricants or any other lubricants

that attract contaminant’s such as dust.

Damper Trouble Shooting

The following is a cause and correction list for common concerns with the dampers.

Symptom Possible Cause Corrective Action

Frame is ‘racked’ causing blades to Adjust frame such that it is square

bind on jamb and plumb

Damper does not

fully open and/or Screws in damper linkage Locate screws and remove

fully close

Contaminant’s on damper Clean with a non-oil-based solvent

(see Damper Maintenance)

Link separated Heat Replace link

Installation for Steel Stud Connection (SSC) Option

These instructions apply to 1 1/2 hour rated fire dampers mounted in steel stud walls. Specific requirements in these

instructions are mandatory. These instructions meet the requirements of UL 555. Installation shall comply with the

requirements of NFPA 90A Standard for the Installation of Air Conditioning and Ventilating Systems. U.L. listings

R13317 and R13743, California State Fire Marshal listings 3225-981:102 and 3225-1241:101, and New York City

BSA/MEA listing 260-91-M as they apply to these dampers.

1. NO ADDITIONAL SLEEVES OR ANGLES ARE REQUIRED

The fire damper extended frame is an approved sleeve and the Steel Stud Connection (SSC) Option allows

fastening of the fire damper sleeve directly to the wall's steel stud framing. Damper frame shall extend a

maximum of 6 in. beyond the wall opening on either side. Maximum size fire damper that may be installed

using this SSC option is 36 in. W x 36 in. H.

2. INSTALLATION

Fire damper with SSC option must be in place before the wall is constructed or it can be installed as the wall

is being constructed. Wall opening is framed around the fire damper before sheet rock or other wall board

material is applied to the steel studs. This installation provides appropriate protection for duct penetrations

in fire resistant wall construction using steel studs with a fire resistance rating less than 3 hours. The

following wall design numbers (as detailed in the UL Fire Resistance Directory) are appropriate for fire

damper installations using this SSC option:

1 Hour Design: U405, U406, U422, U434, U448, U451, U456, U457, U465, U468, U469,

U485, U494

11⁄2 Hour Design: U449, U452, U470, U471

2 Hour Design: U403, U411, U412, U421, U425, U428, U429, U443, U453, U474, U475,

U477, U484, U491, U495

Downloaded from www.Manualslib.com manuals search engine

3. FRAMING OF WALL OPENING Item Description

Form a wall opening 1/8 in. to 1/4 in. larger than 1 FD150X Fire Damper with SSC Option

the OD of the fire damper's extended frame Steel Stud Wall (See UL Fire Resistance

2

(sleeve) using the same metal studs and Directory for specific details)

techniques required by the wall design per the UL 3 Steel Stud Frame around opening in wall

Fire Resistance Directory. Open side of the steel 4 Duct Connection (See Section 6)

stud channels shall face the fire damper and Wallboard (See UL Fire Resistance Directory

5

encompass the damper's retaining bar. for specific details)

Fasteners (See UL Fire Resistance Directory

6

4. APPLY WALLBOARD AFTER DAMPER and Section 5)

INSTALLATION

After damper is installed, wallboard shall be

applied to steel stud framework in the manner

required by the wall design per the UL Fire

Resistance Directory listing. Around the damper

perimeter use a minimum of 2 connections per

side, spaced 12 in. (max.) and located a maximum 3

of 2 in. from each corner. No additional retaining

angles are required to complete the installation.

5. CONNECTING DUCTS TO THE FIRE DAMPER

All duct connections to FD & DFD 150X series

extended frame dampers must be “breakaway”

type connections. All connections shown on page 2

6 are considered breakaway. Factory furnished

duct collars on types R, CR, & CO fire dampers are

also considered breakaway.

3

6

5 1

3

Retaining 1 4

Bar

4 2

Top Cross-Section View Side Cross-Section View of

Damper in Wall

Due to continuing research, Greenheck reserves the right to change specifications without notice.

GREENHECK

P.O. BOX 410 SCHOFIELD, WISCONSIN 54476-0410 IOM-FD/DFD-150X Series

PH. 715-359-6171 Rev. 9 April 2004

www.greenheck.com Copyright © 2004 Greenheck Fan Corp.

Downloaded from www.Manualslib.com manuals search engine

You might also like

- Provideo Converter Video Scan Converter Ii: February 1995 Ac095A Ac096ADocument26 pagesProvideo Converter Video Scan Converter Ii: February 1995 Ac095A Ac096AYour Brand New LookNo ratings yet

- RT 200 Manual de Operación y MantenimientoDocument342 pagesRT 200 Manual de Operación y MantenimientoLuis Enrique Peña100% (1)

- CHL-0714 60181509Document1 pageCHL-0714 60181509Femi AgbanaNo ratings yet

- Fire Dampers Installation 15858Document7 pagesFire Dampers Installation 15858Aiman AliNo ratings yet

- Inspection and Test Plan: ITP NO: 7979-ITP-ME-031-1 Title: Bolt Tightening WorksDocument9 pagesInspection and Test Plan: ITP NO: 7979-ITP-ME-031-1 Title: Bolt Tightening WorksDelta akathehuskyNo ratings yet

- Cargo Fire Detection / Extinguishing: P7 PanelDocument1 pageCargo Fire Detection / Extinguishing: P7 PanelMuhammed MudassirNo ratings yet

- Westfalia Control Unit C7-623 PDFDocument148 pagesWestfalia Control Unit C7-623 PDFAamir100% (2)

- RT 600Document258 pagesRT 600RuddyNo ratings yet

- Itp Tank-29jan 07Document3 pagesItp Tank-29jan 07Anonymous lv8SNRyNo ratings yet

- 5051 - Copilot ClockDocument4 pages5051 - Copilot ClockMarty SmallwoodNo ratings yet

- Castillo Ingenieros (Ci) : Inspection and Test Plan (Itp)Document1 pageCastillo Ingenieros (Ci) : Inspection and Test Plan (Itp)Luis Eduardo Hernández SalgadoNo ratings yet

- RFII-MRI - 5.6 K-Factor - Non Magnetic SprinklerDocument4 pagesRFII-MRI - 5.6 K-Factor - Non Magnetic SprinklerValentin A.No ratings yet

- VSX-D812 D912 RRV2732Document93 pagesVSX-D812 D912 RRV2732Reynaldo AlvaradoNo ratings yet

- Routine Work Card: ITEM NO: 11659-0016 Project: 9M-Pos-1 Task CodeDocument3 pagesRoutine Work Card: ITEM NO: 11659-0016 Project: 9M-Pos-1 Task CodeFL Technics DFPNo ratings yet

- SATIP-P-104-03 Rev 3 Cable Tray Fittings and AccessoriesDocument3 pagesSATIP-P-104-03 Rev 3 Cable Tray Fittings and AccessoriesIrfan AliNo ratings yet

- Vsx515k SMDocument79 pagesVsx515k SMRey ZahnNo ratings yet

- Model WS Specific Application Window Sprinklers Horizontal and Pendent Vertical Sidewall 5.6 K-Factor General DescriptionDocument8 pagesModel WS Specific Application Window Sprinklers Horizontal and Pendent Vertical Sidewall 5.6 K-Factor General DescriptionLe DucNo ratings yet

- 7villa-Om-Me-02 DX Hi Wall Split Ac UnitsDocument60 pages7villa-Om-Me-02 DX Hi Wall Split Ac UnitsAravindhan ANo ratings yet

- VSX D912 SDocument92 pagesVSX D912 SafraniobatistaNo ratings yet

- 1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureDocument6 pages1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureprasongNo ratings yet

- Saudi Arabian Oil Company: 5.5 TANK H45-D-8B Fire Detection & Foam Skid H45-U-0104 ActivationDocument2 pagesSaudi Arabian Oil Company: 5.5 TANK H45-D-8B Fire Detection & Foam Skid H45-U-0104 Activationsalman1111aNo ratings yet

- TUV Rheinland Certificate No 968-V1215.00-21 (Neles - Jamesbury Series Actuator)Document2 pagesTUV Rheinland Certificate No 968-V1215.00-21 (Neles - Jamesbury Series Actuator)Anonymous cKdbnUHNo ratings yet

- 5n-Lee - Serviceable TagDocument1 page5n-Lee - Serviceable TagFemi AgbanaNo ratings yet

- SATIP-K-001-01 Rev 6 Centrifugal FanDocument3 pagesSATIP-K-001-01 Rev 6 Centrifugal Fanimrankhan22No ratings yet

- Om-03 Hose Handling Crane PDFDocument126 pagesOm-03 Hose Handling Crane PDFcpîndaruNo ratings yet

- dAMPER IomDocument14 pagesdAMPER IomRahul PillaiNo ratings yet

- Pioneer VSX d712 K VSX d712 S Rrv2744Document91 pagesPioneer VSX d712 K VSX d712 S Rrv2744serv42311No ratings yet

- RT440B ENG Rev.01 - 2007 (1) (001-099)Document99 pagesRT440B ENG Rev.01 - 2007 (1) (001-099)Valmaq Prestação Serviço Lda100% (1)

- vsxd912s (Pioneer VSX D912 D812 Series Service Manual Repair Guide)Document92 pagesvsxd912s (Pioneer VSX D912 D812 Series Service Manual Repair Guide)Jirakorn NubnuengNo ratings yet

- Saudi Aramco Requirements Technical Links, Comments & ExceptionsDocument2 pagesSaudi Aramco Requirements Technical Links, Comments & ExceptionsJohn BuntalesNo ratings yet

- Stereo CD Receiver: This Manual Is Applicable To The Following Model (S) and Type (S)Document57 pagesStereo CD Receiver: This Manual Is Applicable To The Following Model (S) and Type (S)Liviu LvuNo ratings yet

- Product Catalogue 2008 EN-GB PDFDocument101 pagesProduct Catalogue 2008 EN-GB PDFazhan114No ratings yet

- 5051 - TR & Tool Kit CAMP CardsDocument2 pages5051 - TR & Tool Kit CAMP CardsMarty SmallwoodNo ratings yet

- SATIP-K-001-01 Rev 7 Centrifugal FanDocument3 pagesSATIP-K-001-01 Rev 7 Centrifugal FanRAMAKRISHNANo ratings yet

- Tyco TY5522 TFP250 - 08 - 2022Document5 pagesTyco TY5522 TFP250 - 08 - 2022First LAstNo ratings yet

- 1240-ARC-ITP-EL-008 Rev.a4Document5 pages1240-ARC-ITP-EL-008 Rev.a4Jovit BeaNo ratings yet

- Temp Brochure2018Document26 pagesTemp Brochure2018golivares17No ratings yet

- NPCL-YBP-RFI-TEL-000x Conduit Installation & Initial Mandrel Test SAIC-T-5709Document3 pagesNPCL-YBP-RFI-TEL-000x Conduit Installation & Initial Mandrel Test SAIC-T-5709afareenkhanNo ratings yet

- R-0 Boq HvacDocument11 pagesR-0 Boq HvacDivyansh GuptaNo ratings yet

- United Gas Engine OilDocument2 pagesUnited Gas Engine OilWira Nur IndrawanNo ratings yet

- Pioneer 1722Document61 pagesPioneer 1722telkonNo ratings yet

- 6-44-0016mmmmmmrev 4Document1 page6-44-0016mmmmmmrev 4Sumantrra ChattopadhyayNo ratings yet

- Initial SparesDocument1 pageInitial SparesPrabuNo ratings yet

- Unserviceable: ComponentDocument1 pageUnserviceable: ComponentFemi AgbanaNo ratings yet

- Forma 8070-1Document2 pagesForma 8070-1api-520977931No ratings yet

- Ayc Ic & Itp Roll Up DoorDocument10 pagesAyc Ic & Itp Roll Up Doormoytabura96No ratings yet

- Sims Report Hydrostatic Main Control ValveDocument1 pageSims Report Hydrostatic Main Control ValveEdo FedricoNo ratings yet

- C-Ingta-041-Francisco Javier Aguilar PadillaDocument2 pagesC-Ingta-041-Francisco Javier Aguilar Padillarobertorf04No ratings yet

- Pioneer VSX-D712-K (RRV2731)Document91 pagesPioneer VSX-D712-K (RRV2731)angel quinteroNo ratings yet

- Firelite Plus Ws Fact SheetDocument2 pagesFirelite Plus Ws Fact SheetYonish SisoNo ratings yet

- Hydraulic Accumulators - Rules and Regulations: PV 200 Mpa LDocument1 pageHydraulic Accumulators - Rules and Regulations: PV 200 Mpa LShoppingpak comNo ratings yet

- ARV-HII-ELECT-038 - XA - 28VDC Aux PWRDocument2 pagesARV-HII-ELECT-038 - XA - 28VDC Aux PWRArmando CastellanosNo ratings yet

- Instrument Air - Gate Valve Data SheetDocument2 pagesInstrument Air - Gate Valve Data SheetHabib ur rahmanNo ratings yet

- TerrainDocument1 pageTerrainMarty SmallwoodNo ratings yet

- Tection Global 15W - 40Document2 pagesTection Global 15W - 40carmaNo ratings yet

- TH460 Service Report 023832Document1 pageTH460 Service Report 023832eskully92No ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Installation Instructions: S S S SDocument24 pagesInstallation Instructions: S S S SJuan PonceNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- BS 1722-2-2000-Fences-Specification For Strained Wire and WiDocument32 pagesBS 1722-2-2000-Fences-Specification For Strained Wire and Wisujeesh_sankar5707100% (1)

- Colorado Order GuideDocument49 pagesColorado Order GuidejalopnikchrisNo ratings yet

- Quad-Band Panel Dual Polarization Half-Power Beam Width Adjust. Electr. DowntiltDocument2 pagesQuad-Band Panel Dual Polarization Half-Power Beam Width Adjust. Electr. DowntiltAnnBliss50% (2)

- Bs en 480-4 1997 Determination of Concrete BleedingDocument8 pagesBs en 480-4 1997 Determination of Concrete BleedingWASIMUDDIN SHEIKHNo ratings yet

- Kamatsu PC220 - 220LC-8Document7 pagesKamatsu PC220 - 220LC-8Piotr Gabryś Hi-this100% (1)

- Project Report On Proxy Server - PDF - Proxy Server - Web ServerDocument163 pagesProject Report On Proxy Server - PDF - Proxy Server - Web ServernaveeenilangoNo ratings yet

- Change The Username Password Prompt With AAADocument9 pagesChange The Username Password Prompt With AAAmaracyberstationNo ratings yet

- Wistron Petra UMA, 11324-1Document60 pagesWistron Petra UMA, 11324-1marusvNo ratings yet

- Configuracion Manuel Porcess MakerDocument242 pagesConfiguracion Manuel Porcess MakerAngela Pèrez SNo ratings yet

- FireEye Web Malware Protection System Stops Web-Based AttacksDocument2 pagesFireEye Web Malware Protection System Stops Web-Based AttacksFireEyeNo ratings yet

- Baugh Wooley Multiplier VHDL CODEDocument3 pagesBaugh Wooley Multiplier VHDL CODEAditya Kini0% (1)

- Guidelines For Selection of Strainers August 2006 EditionDocument10 pagesGuidelines For Selection of Strainers August 2006 EditionEver Briceño100% (1)

- HA464518Document146 pagesHA464518Hayden Lovett100% (3)

- Apache Solr Search Patterns - Sample ChapterDocument33 pagesApache Solr Search Patterns - Sample ChapterPackt PublishingNo ratings yet

- Pan Os 6.1Document680 pagesPan Os 6.1HenryNo ratings yet

- Press Tool Components Die MakingDocument29 pagesPress Tool Components Die Makingmayank123100% (1)

- ContentDocument0 pagesContentFernando Antonio Castro RojasNo ratings yet

- GMP For HvacDocument21 pagesGMP For HvacOmar BaroudiNo ratings yet

- Font Folio 11 DatasheetDocument2 pagesFont Folio 11 DatasheetkerintNo ratings yet

- aNALOG MODULEDocument26 pagesaNALOG MODULEManurung Edward Jr.0% (1)

- Indian Journal of Poultry ScienceDocument7 pagesIndian Journal of Poultry ScienceDrKiran KumarNo ratings yet

- RFP Eval InstructionsDocument3 pagesRFP Eval InstructionsKUTV 2NewsNo ratings yet

- Spek AluminiumWindows PDFDocument13 pagesSpek AluminiumWindows PDFSantoso Simanjuntak100% (1)

- 7266 401 A Can V2.1Document8 pages7266 401 A Can V2.1NightWay Alvin HowNo ratings yet

- Safe Driving Checklist: Is Your Driving Road-Worthy?Document4 pagesSafe Driving Checklist: Is Your Driving Road-Worthy?Sreekumar100% (1)

- FSMS Downloadable PDFDocument8 pagesFSMS Downloadable PDFadhavanannathuraiNo ratings yet

- Batidora Amasadora. Sp20 PDFDocument2 pagesBatidora Amasadora. Sp20 PDFranulfoNo ratings yet

- Costruction of 400feet Amochu Bailey Suspension Bridge Over Amochu On Dorokha-Denchukha Farm Road Under Samtse DzongkhagDocument39 pagesCostruction of 400feet Amochu Bailey Suspension Bridge Over Amochu On Dorokha-Denchukha Farm Road Under Samtse DzongkhagQuang NgocNo ratings yet

- A64 Cable Stringer S DatasheetDocument9 pagesA64 Cable Stringer S DatasheetCruzado Vilca AmesquitaNo ratings yet

- الرقمنة وآثارها التنظيمية في الجامعة الجزائريةDocument17 pagesالرقمنة وآثارها التنظيمية في الجامعة الجزائريةomar lakhdariNo ratings yet